Press release

Aluminum Market to Reach USD 462 Billion by 2034 Driven by EV Adoption and Sustainable Packaging Demand | TMR

Aluminum is one of the most widely used and economically significant metals in the world. Known for its lightweight nature, corrosion resistance, ductility, and excellent conductivity, aluminum plays a central role across multiple industries such as automotive, aerospace, construction, packaging, electrical and electronics, and renewable energy. It accounts for nearly 8% of the Earth's crust, making it one of the most abundant metals available for industrial use. The global push toward sustainability, energy efficiency, and reduced carbon emissions has contributed significantly to the rising demand for aluminum and its alloys in both mature and emerging markets.Access key findings and insights from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=23807

The metal's production involves mining bauxite, refining alumina, and smelting aluminum - a process that is energy-intensive but increasingly optimized through low-carbon technologies. The shift toward greener production methods such as inert anode smelting (ELYSISTM technology), increased recycling rates, and technological advancements in alloy development are reshaping the aluminum industry landscape. As industries adopt lightweight and sustainable materials, aluminum has emerged as the material of choice due to its recyclability, high performance-to-weight ratio, and adaptability for various industrial processes including casting, forging, rolling, extrusion, and stamping.

The Aluminum Market is expected to witness strong growth through 2034, driven by rising demand in automotive manufacturing, aerospace applications, green building materials, renewable energy systems, and sustainable packaging solutions.

Market Definition & Scope

The Aluminum Market includes the production, processing, and commercialization of primary and secondary aluminum products across various grades and processes. It encompasses:

Grades

Aluminum (pure grades): 1050, 1100, etc.

Alloy Grades: 2024, 2014, 2219, 3003, 5086, 5005, 6061, 6063, 7075, and others.

Processes Covered

Forging

Casting

Foundry

Wrought

Stamping

Rolling

Extrusion

Other forming and finishing processes

Applications Covered

Automotive (powertrain, chassis, suspension, body components)

Aerospace & Defense

Renewable Energy

Building & Construction

Electrical & Electronics

Foils & Packaging

Industrial Machinery

Others

Geographic Scope

North America, Latin America, Europe, Asia Pacific, Middle East & Africa

With detailed analysis of major countries including the U.S., China, India, Germany, Japan, Brazil, GCC, among others.

Explore our report to uncover in-depth insights -

https://www.transparencymarketresearch.com/aluminum-market.html

Analyst's Viewpoint on Aluminum Market Scenario

Analysts anticipate steady demand growth in the aluminum market, driven by its expanding use across varied sectors. The market, valued at US$ 255.2 Bn in 2023, is projected to reach US$ 462.0 Bn by 2034, expanding at a CAGR of 5.6%. The strongest growth driver remains the automotive industry, where global manufacturers are aggressively shifting toward lightweight materials to meet stringent emission targets and improve fuel efficiency. The rising adoption of aluminum-intensive electric vehicles (EVs), which require lighter body structures to offset heavy battery packs, will further accelerate demand.

Asia Pacific continues to dominate the global landscape with nearly 59.8% share, supported by rapid industrialization, increasing urbanization, and the concentration of automotive production hubs. Meanwhile, Europe's stringent sustainability regulations and North America's robust aerospace industry bolster regional growth.

Analysts also highlight a significant rise in R&D investments focused on next-generation aluminum alloys with enhanced strength, corrosion resistance, and machinability. Furthermore, the adoption of low-carbon smelting technologies is expected to alter the competitive landscape by enabling eco-efficient aluminum production, thereby appealing to industries prioritizing decarbonization.

Market Dynamics

Drivers

a. Rising Use of Aluminum in Automotive and Aerospace Industries

The automotive and aerospace sectors are undergoing a major transformation with strong emphasis on energy efficiency and reduced CO2 emissions. Aluminum's high strength-to-weight ratio, corrosion resistance, durability, and recyclability make it essential for structural and functional components.

The average aluminum content per vehicle is expected to rise from 170 kg in 2020 to nearly 190 kg by 2025.

Automotive manufacturers are increasingly using aluminum for body panels, chassis, suspension systems, and powertrain components.

In aerospace applications, aluminum alloys such as 2024, 6061, 7075, and 2219 are extensively used due to their high structural integrity and fatigue resistance.

The shift toward electric vehicles further amplifies demand, as lightweight materials help optimize battery performance and energy consumption.

b. Demand for Environmentally Friendly Packaging Material

Consumers and governments globally prefer sustainable packaging. Aluminum packaging - including cans, foils, aerosol containers, and food-grade wraps - is highly recyclable and reduces transportation emissions due to its lightweight nature.

Aluminum cans are 100% recyclable, and nearly 75% of all aluminum ever produced remains in use.

Many brands are switching from plastic to aluminum packaging in response to strict regulations on single-use plastics.

c. Expanding Construction and Infrastructure Activities

Aluminum is widely used in modern architectural structures for windows, doors, facades, curtain walls, framing, and structural applications due to its corrosion resistance and design flexibility. Rapid urbanization in Asia and Africa significantly stimulates demand.

Restraints

a. High Energy Consumption in Smelting Processes

Aluminum production requires substantial electricity, leading to high operational costs and emissions, making producers vulnerable to energy price volatility.

b. Volatility in Raw Material Prices

Prices of bauxite and alumina fluctuate due to geopolitical tensions, supply chain disruptions, and trade tariffs, impacting profitability.

c. Environmental Concerns Related to Mining

Bauxite mining generates red mud waste and environmental degradation, prompting stricter regulations that raise compliance costs.

Opportunities

a. Growth in Renewable Energy Applications

Aluminum is increasingly used in solar frames, wind turbine components, and energy storage systems due to its durability and lightweight.

b. Development of High-Performance Aluminum Alloys

Innovative alloys enable new applications in defense, aerospace, 3D printing, and high-strength construction.

c. Rise in Demand for Green Aluminum

Technologies such as ELYSISTM (Alcoa-Rio Tinto) produce aluminum with zero direct carbon emissions, creating lucrative opportunities driven by ESG mandates.

Global Aluminum Market Overview

Aluminum is among the most versatile industrial metals due to its property enhancements through alloying. When alloyed with copper, zinc, magnesium, manganese, and silicon, aluminum becomes stronger, more durable, and more suitable for advanced engineering applications.

Key Market Highlights

Market Size (2023): US$ 255.2 Bn

Market Forecast (2034): US$ 462.02 Bn

CAGR (2024-2034): 5.6%

Dominant Segment: Alloy aluminum (84% market share)

Leading Region: Asia Pacific (59.8% share)

These figures reflect the increasing focus on lightweight products, sustainability, and technological advancements that continue to broaden the industrial use cases of aluminum.

Segmentation Analysis

By Grade

a. Aluminum (Pure Grades)

Includes series 1000 grades such as 1050 and 1100, often used for electrical applications due to high conductivity and corrosion resistance.

b. Alloy Aluminum - Dominant Segment (84% Share)

Alloy grades such as 2024, 6061, 6063, 7075, and others offer improved strength, fatigue resistance, and manufacturability, making them essential to:

Automotive manufacturing

Aerospace components

Structural framing

Packaging materials

Industrial machinery

The dominance of alloys underscores their crucial role in advanced engineering applications.

By Process

a. Casting

Allows complex shapes at lower cost; widely used in automotive and industrial machinery.

b. Extrusion

Key for construction, automotive profiles, and electric vehicle battery enclosures.

c. Rolling

Used in foils, packaging, automotive body sheets, and beverage can stock.

d. Forging & Stamping

Suitable for high-strength components in aerospace and automotive powertrains.

e. Wrought & Foundry

Critical for aerospace structures, high-load components, and precision parts.

The availability of these processes enables the industry to meet diverse structural and functional requirements.

By Application

Automotive - Fastest Growing Segment

Includes powertrain, chassis, body components, and EV battery frames.

Building & Construction

Includes windows, curtain walls, panels, structural frames, roofing, and interior components.

Electrical & Electronics

Used in cables, heat sinks, conductors, and electronic housings.

Foils & Packaging

Covers beverage cans, household wraps, medical packaging, aerosol cans, and food packaging.

Renewable Energy

Used in solar panel frames, wind turbine parts, and energy storage.

Industrial Machinery

Includes robotics, automation systems, conveyor structures, and manufacturing equipment.

Buy this Premium Research Report for exclusive, in-depth insights -

https://www.transparencymarketresearch.com/checkout.php?rep_id=23807

Regional Insights

Asia Pacific - Dominant Region

The region leads due to:

Massive manufacturing bases in China and India

Strong growth in automotive, construction, electronics, and renewable energy

Government investments in industrialization and smart cities

China remains the world's largest producer and consumer of aluminum, with extensive smelting capacity and integrated supply chains.

Europe (20.2% Share)

Growth in Europe is driven by:

Strong focus on sustainability and circular economy

High aluminum recycling rates

Demand from automotive and aerospace sectors

Regulatory pressure for low-emission materials

Germany, France, Italy, and the U.K. remain key markets.

North America

Key factors include:

Advanced aerospace and defense production

Rising construction activity

Strong presence of global producers like Alcoa, Kaiser Aluminum, and Rio Tinto

The U.S. remains a technological innovation hub for green aluminum production.

Latin America

Brazil and Mexico lead the region due to industrial growth and increasing EV adoption.

Middle East & Africa

The region benefits from:

Large-scale smelting operations in UAE and GCC

Low energy costs enabling competitive production

Growing construction and infrastructure spending

Competitive Landscape

The aluminum industry is highly consolidated and dominated by integrated producers involved in mining, refining, smelting, and global distribution.

Key Players Profiled

Alcoa Corporation

Aluminum Corporation of China Limited (CHALCO)

Norsk Hydro ASA

United Company RUSAL

Emirates Global Aluminium PJSC

Rio Tinto

China Hongqiao Group Co., Ltd.

State Power Investment Corporation (SPIC)

East Hope Group

Xinfa Group Co. Ltd.

Kaiser Aluminum

Competitive Strategies

Expansion of smelting capacity

Investment in low-carbon aluminum production

Backward integration into bauxite and alumina assets

Development of high-performance alloys

Mergers, acquisitions, and strategic partnerships

Chinese companies continue to strengthen their positions with cost-efficient production and large-scale capacity expansions.

Key Market Developments

January 02, 2024 - Alcoa & Nexans Collaboration

Alcoa announced plans to supply Nexans with aluminum produced using the ELYSISTM process, a breakthrough technology that eliminates direct greenhouse gas emissions during smelting. Nexans will use this aluminum to produce next-generation, sustainable cabling solutions.

July 25, 2022 - CHALCO Acquires Stake in Yunnan Aluminum

CHALCO announced its decision to acquire a 19% stake in Yunnan Aluminum, becoming its largest shareholder. The transaction was valued at 6.662 billion yuan, enhancing CHALCO's supply chain integration and market position.

These developments reflect growing industry focus on sustainability, innovation in smelting technologies, and strategic consolidation.

Future Outlook & Conclusion

The Aluminum Market is poised for robust growth through 2034, supported by transformative shifts in technology, sustainability, and industrial development. Aluminum's expanding role in automotive lightweighting, electric vehicle manufacturing, energy-efficient aerospace structures, and green building materials firmly positions it as a critical material for global decarbonization efforts.

The rise of green aluminum, driven by next-generation smelting technologies and stringent emission regulations, is likely to redefine competitive dynamics and create new market segments. The metal's recyclability will be a cornerstone of sustainability-focused industries, particularly packaging and construction.

Asia Pacific will continue to dominate, but mature markets in Europe and North America will see accelerated demand due to electric vehicle growth, renewable energy installations, and sophisticated manufacturing ecosystems. Companies that invest in high-performance alloys, advanced manufacturing processes, and low-carbon technologies will gain a significant competitive edge.

Overall, the Aluminum Market's transition toward modern alloys, sustainable production, and circular economy principles ensures strong growth prospects, with the global market set to reach US$ 462.0 Bn by 2034, reflecting the enduring importance of aluminum in shaping the future of industries worldwide.

Explore Latest Research Reports by Transparency Market Research:

Shotcrete (Sprayed Concrete) Market - https://www.transparencymarketresearch.com/shotcrete-sprayed-concrete-market.html

Wood Pellet Market - https://www.transparencymarketresearch.com/wood-pellet-market.html

Barite Market - https://www.transparencymarketresearch.com/barite-market.html

Precipitated Silica Market - https://www.transparencymarketresearch.com/precipitated-silica-market.html

Industrial Silica Sands Market - https://www.transparencymarketresearch.com/industrial-silica-sands-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

Follow Us: LinkedIn| Twitter| Blog | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aluminum Market to Reach USD 462 Billion by 2034 Driven by EV Adoption and Sustainable Packaging Demand | TMR here

News-ID: 4287403 • Views: …

More Releases from Transparency Market Research

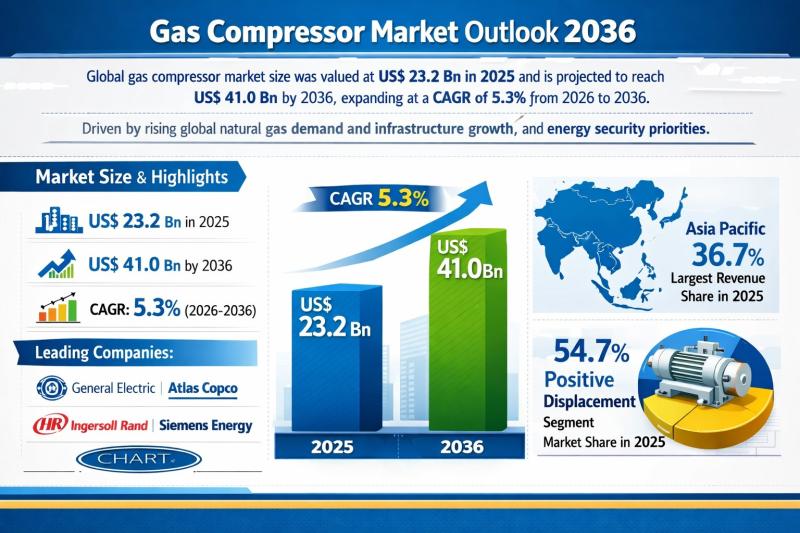

Gas Compressor Market Outlook 2036: Global Industry Expected to Reach US$ 41.0 B …

The global gas compressor market was valued at US$ 23.2 Bn in 2025 and is projected to reach US$ 41.0 Bn by 2036, expanding at a compound annual growth rate (CAGR) of 5.3% from 2026 to 2036. This steady growth trajectory reflects the structural importance of gas compression systems across upstream, midstream, and downstream gas value chains. Rising natural gas consumption, expansion of pipeline and LNG infrastructure, and national energy…

Anesthesia Drugs Market to be Worth USD 12.6 Bn by 2036 - By Drug / By Applicati …

The global anesthesia drugs market was valued at US$ 7.6 billion in 2025 and is projected to reach US$ 12.6 billion by 2036, expanding at a compound annual growth rate (CAGR) of 4.7% from 2026 to 2036. This steady growth trajectory reflects the essential and non-substitutable role of anesthesia drugs in modern healthcare systems. As surgical interventions continue to rise globally-across both elective and emergency procedures-the demand for safe, effective,…

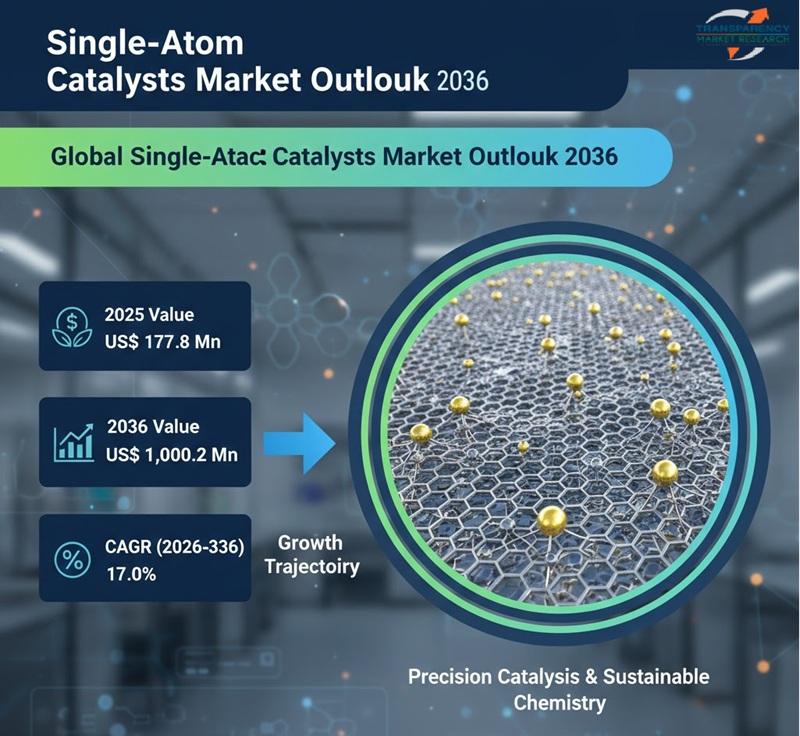

Single-Atom Catalysts Market Size is Expected to Expand from US$ 177.8 Million t …

The global single-atom catalysts (SACs) market is poised for remarkable growth as industries seek highly efficient, cost-effective, and sustainable catalytic solutions. Valued at US$ 177.8 million in 2025, the market is projected to reach US$ 1,000.2 million by 2036, expanding at a robust compound annual growth rate (CAGR) of 17.0% from 2026 to 2036. This rapid expansion reflects the growing importance of advanced catalysis in energy, chemicals, environmental protection, and…

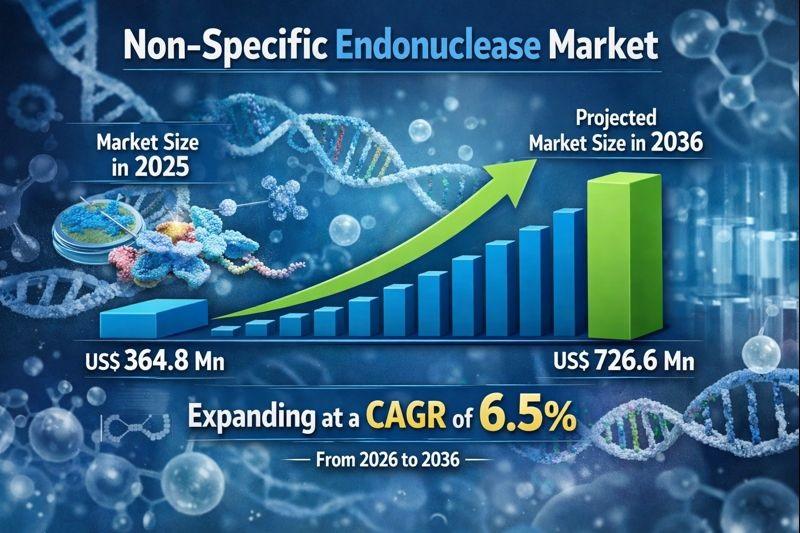

Non-specific Endonuclease Market to Reach USD 726.6 Million by 2036, Supported b …

The non-specific endonuclease market is witnessing steady growth, driven by the expanding use of molecular biology tools across biotechnology, pharmaceuticals, diagnostics, and academic research. Non-specific endonucleases are enzymes that cleave nucleic acids without requiring a specific recognition sequence, making them highly valuable for applications such as DNA/RNA degradation, sample preparation, viscosity reduction, and contamination control. Their broad activity profile differentiates them from restriction enzymes and enables versatile usage across multiple…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…