Press release

Polymers for 3D Printing Market Accelerates with 19.6% CAGR as PEEK & PEKK Transform Industrial Manufacturing

The global Polymers for 3D Printing Market was valued at US$ 1.17 billion in 2024 and is projected to reach US$ 4.09 billion by 2031, expanding at a strong CAGR of 19.6% during the forecast period. High-performance polymer materials such as PEEK and PEKK also show rapid acceleration, with their segment expected to climb from US$ 1.43 billion in 2024 to US$ 7.14 billion by 2033, reflecting the rising demand for durable, lightweight, and high-temperature-resistant materials used in industrial 3D printing.The global market maintains a competitive and fast-growing position, supported by surging adoption of additive manufacturing across aerospace, automotive, healthcare, and industrial production. Increasing use of FDM, SLA, SLS, and resin-based technologies, along with advancements in engineering thermoplastics, photopolymers, and elastomers, continues to drive strong market expansion. As manufacturers push for faster prototyping, mass customization, and enhanced material performance, the polymers for 3D printing market is set for sustained global growth.

Get a Free Sample PDF Of This Report (Get Higher Priority for Corporate Email ID): https://www.datamintelligence.com/download-sample/polymers-for-3d-printing-market?sai-v

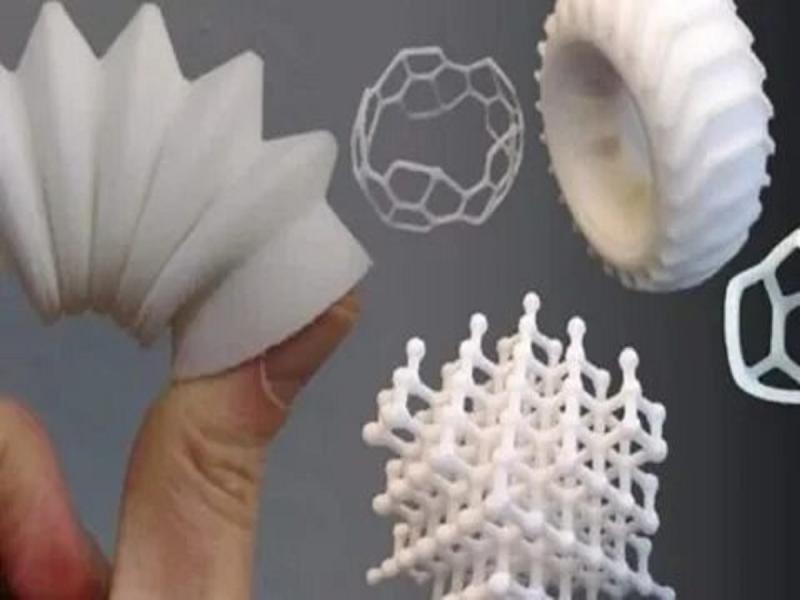

Polymers for 3D Printing Market refers to the industry centered on polymer-based materials engineered for additive manufacturing to produce lightweight, durable, and complex 3D-printed components across various sectors.

Key Developments

United States

✅ April 2025: 3D Systems expanded its U.S. R&D facilities to accelerate development of high-performance polymer materials for industrial and medical 3D printing applications.

✅ June 2025: Nano Dimension shared updates on its integration of Markforged, emphasizing stronger capabilities in composite and polymer 3D-printing materials.

✅ May 2025: U.S. material innovators increased production of advanced polymers such as PEEK, PEKK, and carbon-fiber-reinforced blends, driven by rising demand for functional end-use 3D-printed components.

✅ July 2025: U.S. manufacturers advanced work on sustainable polymer materials, with new formulations based on biodegradable and recycled plastics entering pilot production.

Japan

✅ May 2025: Japan's photopolymer segment recorded stronger domestic demand, supported by higher adoption of resin-based 3D printing in automotive, electronics, and dental manufacturing.

✅ June 2025: Japanese material suppliers accelerated R&D on bio-based polymers, especially recycled nylon and cellulose-reinforced filaments, to support sustainability-focused 3D-printing applications.

Mergers and Acquisitions

United States

✅ April 2025: Nano Dimension completed the acquisition of Markforged, strengthening its position in composite and polymer 3D-printing materials and systems.

✅ May 2025: Stratasys finalized the integration of Forward AM into its materials division, expanding its portfolio of polymers for industrial additive manufacturing.

Key Players:

ELIX Polymers | Carbon Inc. | Arkema Group | Evonik | Stratasys Ltd. | EnvisionTEC Inc. | 3D Systems Corporation

Key Highlights:

• Stratasys Ltd. - Generates around USD 0.45 billion from 3D-printing plastics with a 7.1% share of the global 3D-printing plastics market; strong in FDM and PolyJet systems driving material demand.

• 3D Systems Corporation - Reports close to USD 0.41 billion in 3D-printing plastics revenue, holding about 6.5% share; recognized for SLA and SLS-based industrial materials.

• Evonik Industries AG - Achieves roughly USD 0.25 billion revenue from high-performance 3D-printing polymers, securing around 3.8% of the market; strong in PA12, PEEK, and medical-grade powders.

• Arkema Group - Generates approximately USD 0.19 billion from advanced 3D-printing materials with a 2.9% share; key provider of PEKK and high-temperature polymers for aerospace and engineering.

• EnvisionTEC Inc. - Records about USD 0.12 billion in 3D-printing plastics revenue, representing 1.9% share; major contributor to dental, jewelry, and precision resin materials.

• ELIX Polymers - Supplies specialty ABS materials widely used in automotive and industrial 3D printing; contributes meaningfully to engineering-grade polymer consumption.

• Carbon Inc. - Strong in high-grade resin materials through its DLS technology platform, widely adopted in medical, footwear, and consumer-product manufacturing .

Buy Now & Unlock 360° Market Intelligence:https://www.datamintelligence.com/buy-now-page?report=polymers-for-3d-printing-market?sai-v

Market Drivers

• Rising use of additive manufacturing in automotive and aerospace for producing lightweight, durable, and heat-resistant components suitable for structural, functional, and high-performance applications. Companies are increasingly shifting from traditional metal parts to advanced polymer-based materials to reduce production time and cost.

• Increasing demand for biocompatible and medical-grade polymers used in implants, surgical tools, prosthetics, orthotics, and dental devices. These materials enable high precision, patient-specific customization, and compliance with stringent regulatory requirements.

• Growing application of polymer-based filaments and resins in mass customization across consumer goods, including wearables, household products, and lifestyle accessories. The ability to customize designs, textures, and mechanical properties is accelerating polymer adoption.

• Expansion of industrial automation driving greater reliance on rapid prototyping, production tooling, and functional testing components. Industries increasingly prefer polymer-based 3D printed parts due to faster printing cycles, cost efficiency, and suitability for complex geometries.

Industrial Developments

• Introduction of high-performance engineering polymers such as PEKK, PEEK, and reinforced composite materials for industrial-grade 3D printing. These advanced polymers offer exceptional strength, chemical resistance, and thermal stability for demanding industrial applications.

• Advancements in photopolymer resin technologies are enhancing accuracy, mechanical robustness, and surface finish, particularly benefiting dental, electronics, medical, and micro-manufacturing applications where precision is essential.

• Increasing deployment of industrial 3D printers across manufacturing facilities is boosting demand for specialized polymer formulations tailored for prototyping, tooling, and low-volume production.

• Strategic collaborations among material suppliers, 3D printer manufacturers, and OEMs aim to improve compatibility across multiple printing platforms and expand the range of materials available for end-use parts.

Regional Insights

- North America - US$ 480 million (33% share)

Growth is driven by strong adoption of additive manufacturing in aerospace, defense, and healthcare. The region leads in the use of engineering-grade polymers and high-performance resins due to stringent quality demands and advanced manufacturing infrastructure. Investments in industrial automation and R&D further support polymer material innovation and deployment.

- Europe - US$ 410 million (28% share)

Growth is supported by advanced automotive production, strong investment in industrial automation, and growing adoption of sustainable and recyclable polymer materials. European industries emphasize precision engineering, fuel-efficient designs, and environmental compliance, driving broader use of high-performance 3D printing polymers across automotive, healthcare, and machinery sectors.

- Asia-Pacific - US$ 510 million (35% share)

Asia-Pacific shows the fastest expansion due to large-scale manufacturing operations, rapid electronics production, and increasing use of polymer-based filaments across consumer goods, prototyping, and small-batch manufacturing. China, Japan, and South Korea lead adoption, supported by strong industrial ecosystems and significant investments in 3D printing technologies.

- Rest of the World - US$ 50 million (4% share)

Demand is growing steadily across emerging industrial sectors and developing manufacturing hubs, particularly in the Middle East, Latin America, and parts of Africa. Growth is supported by increasing adoption of digital manufacturing, local production of consumer goods, and foundational investments in industrial 3D printing infrastructure.

Key Segments:

By Type

Polycarbonate leads due to its strength, durability, and suitability for high-performance industrial parts. Poly Ether is preferred for high-temperature and high-strength applications in aerospace and medical sectors. Photopolymers are widely used for detailed and precise printing in prototyping. Acrylonitrile Butadiene Styrene remains popular for general-purpose applications because of its affordability and ease of processing. Polyetherimide and Polyamide offer excellent mechanical and thermal stability for engineering-grade components. Nylon continues to gain traction in functional prototypes and end-use parts. Other materials support specialized applications across multiple industries.

By Form

Filament dominates the market due to its extensive use in desktop and industrial extrusion systems. Liquid forms are preferred in resin-based processes where high precision and fine details are required. Powder form is critical for advanced technologies such as selective laser sintering and powder bed fusion used in high-strength functional parts.

By Processes

Material extrusion is widely adopted due to its low cost, simplicity, and suitability for both hobby and industrial use. Vat polymerisation is used for high-detail components, especially in dental, jewelry, and design applications. Powder bed fusion supports complex geometries and high-performance materials used in aerospace and automotive industries. Material jetting offers excellent surface finish and multi-material capability, making it valuable for premium prototypes.

By Application

Prototyping remains the primary application as industries accelerate product development cycles and improve design validation capabilities. Manufacturing applications are growing quickly as companies adopt additive techniques for low-volume production, tooling, and customized parts.

By End User

Healthcare leads with rising demand for dental models, surgical guides, implants, and customized medical devices. Aerospace relies on high-performance printed components for lightweight structures and complex geometries. Defense uses additive manufacturing for mission-specific parts and rapid part replacement. Automotive benefits from prototyping, tooling, and low-volume production. Electrical and electronics industries use printed parts for enclosures, connectors, and functional components. Other industries apply additive manufacturing for customized and specialized products.

Speak to Our Analyst and Get Customization in the report as per your requirements: https://www.datamintelligence.com/customize/polymers-for-3d-printing-market?sai-v

Unlock 360° Market Intelligence with DataM Subscription Services: https://www.datamintelligence.com/reports-subscription

Power your decisions with real-time competitor tracking, strategic forecasts, and global investment insights all in one place.

✅ Competitive Landscape

✅ Sustainability Impact Analysis

✅ KOL / Stakeholder Insights

✅ Unmet Needs & Positioning, Pricing & Market Access Snapshots

✅ Market Volatility & Emerging Risks Analysis

✅ Quarterly Industry Report Updated

✅ Live Market & Pricing Trends

✅ Import-Export Data Monitoring

Have a look at our Subscription Dashboard: https://www.youtube.com/watch?v=x5oEiqEqTWg

Contact Us -

Company Name: DataM Intelligence

Contact Person: Sai Kiran

Email: Sai.k@datamintelligence.com

Phone: +1 877 441 4866

Website: https://www.datamintelligence.com

About Us -

DataM Intelligence is a Market Research and Consulting firm that provides end-to-end business solutions to organizations from Research to Consulting. We, at DataM Intelligence, leverage our top trademark trends, insights and developments to emancipate swift and astute solutions to clients like you. We encompass a multitude of syndicate reports and customized reports with a robust methodology.

Our research database features countless statistics and in-depth analyses across a wide range of 6300+ reports in 40+ domains creating business solutions for more than 200+ companies across 50+ countries; catering to the key business research needs that influence the growth trajectory of our vast clientele.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polymers for 3D Printing Market Accelerates with 19.6% CAGR as PEEK & PEKK Transform Industrial Manufacturing here

News-ID: 4282115 • Views: …

More Releases from DataM intelligence 4 Market Research LLP

Healthcare Cybersecurity Zero Trust Architecture Market (2033) - Opportunities & …

DataM Intelligence has published a new research report on "Healthcare Cybersecurity - Zero Trust Architecture Market Size 2025". The report explores comprehensive and insightful Information about various key factors like Regional Growth, Segmentation, CAGR, Business Revenue Status of Top Key Players and Drivers. The purpose of this report is to provide a telescopic view of the current market size by value and volume, opportunities, and development status.

United States: Recent Industry…

Healthcare LLM Platforms Market Forecast (2026) | Trends, Drivers & Leading Comp …

Market Size and Growth

Healthcare LLM Platform market is exploding in 2025-2026, fueled by the transformative power of large language models (LLMs) tailored for healthcare. These platforms specialized AI systems built on or fine-tuned with medical data help clinicians summarize patient records, assist in diagnostics, automate clinical documentation, generate reports, support drug discovery, and even enable personalized patient interactions.

Request Custom Research Report (Get Higher Priority for Corporate Email ID):- https://www.datamintelligence.com/custom-research?kbllm

United States:…

Flat Panel Antenna Market Forecast for Robust Growth to US$ XX Million by 2031 a …

The Flat Panel Antenna Market reached US$ XX million in 2021 and is expected to record significant growth by reaching up to US$ XX million by 2029, growing at a CAGR of 30.10% during the forecast period (2024-2031).

Market growth is driven by surging demand for high-speed satellite communications, expansion of low Earth orbit (LEO) constellations like Starlink, and rising adoption in 5G networks and aviation. Advancements in phased array technology,…

mRNA Therapeutics Manufacturing Platform Market Insights (2026) | Top Companies, …

mRNA Therapeutics Manufacturing Platform refers to the end‐to‐end infrastructure, technologies, processes, and quality systems that support the development and large‐scale production of messenger RNA (mRNA)‐based medicines, including vaccines and therapeutics. Unlike traditional biologics, mRNA products use a streamlined synthetic process that enables rapid design and scalability, making them ideal for vaccines, cancer therapies, rare diseases, and personalized medicine applications.

The platform integrates specialized capabilities such as in vitro transcription (IVT), purification,…

More Releases for Poly

Poly(vinyl Acetate) Market Size Report 2025

On Mar 8, 2025, Global Info Research released a research report titled "Global Poly(vinyl Acetate) Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031". This report provides detailed data analysis of the Poly(vinyl Acetate) market from 2020 to 2031. Including the market size and development trends of Poly(vinyl Acetate) Market, it analyzes market size indicators such as sales, sales volume, average price and CAGR, it also provides a…

Poly Aluminium Chloride Market Research Report 2023

Polyaluminium Chloride Market

Polyaluminium chloride (PAC) is manufactured in both liquid and powder form. The product is used in deodorants and antiperspirants, as a flocculant in water purification, in treatment of drinking / potable water, wastewater treatment and paper sizing.

In this report, poly alumnium chloride is classified into liquid and powder type. All the poly alumnium chloride products are converted into 30% Al2O3 content.

Due to the COVID-19 pandemic, the global…

Poly-Vents Market to Witness Remarkable Growth | Filtration Group Corporation; P …

Data Bridge Market Research has provides the Qualitative and informative knowledge by adding titled “Poly-Vents Market Analysis and Forecast, 2020 – 2027”. In this report, Researchers have analysed Strength, Weakness, opportunities and threats in the market and provides the unbiased picture of the market with the informative knowledge. The Poly-Vents Market report additionally states import/trade utilization, free market activity figures, cost, value, volume and gross edges.

The study bridges the historical…

Poly-Vents Market To Witness Astonishing Growth | Competitive Outlook By Filtrat …

The Latest survey report on Poly-Vents Market?research gives a holistic overview of the growth and other aspects of the industry in vital countries (regions). The regions provided in this market document show the geographical boundaries across the globe. This report is a wonderful guide to achieve an information or key data about market, emerging trends, product usage, customer inclinations, motivating factors for customers, competitor strategies, brand positioning, future trends, customer…

Poly Adenosine Diphosphate Ribose Polymerase Market Drivers

Poly adenosine diphosphate ribose polymerase (PARP) is a family of 17 enzymes that combine several (poly) units of ADP-ribose in a chain and transfer them to the target proteins. These proteins aid in restoring the damage in DNA caused due to various factors such as exposure to UV rays, radiation, some anti-cancer drugs or other substances in the environment. PARP inhibitors aid in blocking the enzyme important for the repair…

Poly Adenosine Diphosphate Ribose Polymerase Market Drivers

Poly adenosine diphosphate ribose polymerase (PARP) is a family of 17 enzymes that combine several (poly) units of ADP-ribose in a chain and transfer them to the target proteins. These proteins aid in restoring the damage in DNA caused due to various factors such as exposure to UV rays, radiation, some anti-cancer drugs or other substances in the environment. PARP inhibitors aid in blocking the enzyme important for the repair…