Press release

Soft Bottom Thermoformable Films Market to Reach USD 684 Million by 2031 Top 15 Company Globally

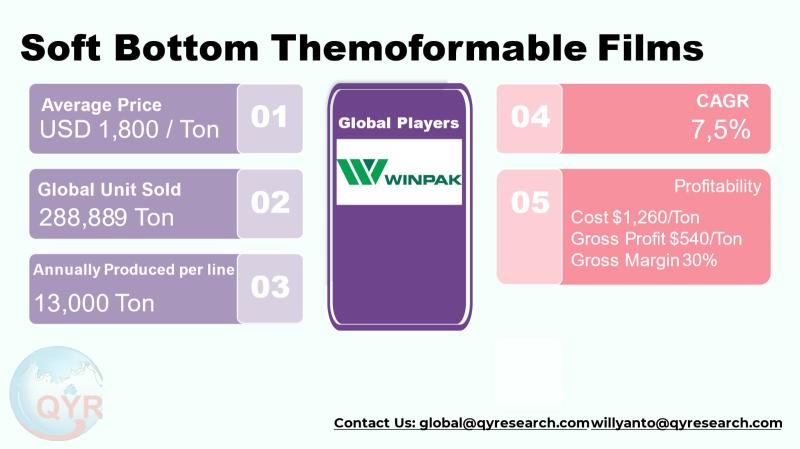

Soft bottom thermoformable films are specialty flexible films engineered to form the base or flexible tray/pack component in thermoformed packaging systems. They are formulated for deep drawability, controlled shrink and recovery, barrier balance, and printability, and are widely used where a soft, conformable bottom is required for items such as fresh meat trays, ready-meals, deli goods, and some medical/consumer goods trays. The segment sits at the intersection of flexible and thermoformed packaging: it borrows ease-of-formation from thermoforming grade films while meeting the mechanical and barrier demands of flexible packaging.The global soft bottom thermoformable films market size in 2024 is USD 412 million, growing at a compound annual growth rate of 7.5% through 2031, reaching market size USD 684 million by 2031. With an average selling price at USD 1,800 per ton, implies total global sales volume of approximately 228,889 tons in 2024. A factory gross margin is 30%, implies a COGS is at USD 1,260 per ton and a factory gross profit is at USD 540 per ton. A COGS breakdown is raw polymer & resin feedstock, energy & utilities, labor, packaging & logistics, inks/coatings/additives, maintenance/overhead and quality control & waste. A single line full machine capacity production is around 13,000 ton per line per year. Downstream demand is dominated by flexible packaging with vacuum packaging and modified atmosphere packaging (MAP).

Latest Trends and Technological Developments

The industry is being shaped by recyclability/mono-material moves, barrier innovation, and bioplastics scale-up. A recent case reported (Oct 2025) showed Specialty Polyfilms presenting thermoforming-protective film innovations at K 2025 focused on surface protection and non-PVC food wrapping, reinforcing the market push for alternatives to PVC and improved surface protection. Another development (Sept 2025) from Fraunhofer researchers announced new PBS bioplastic grades with thermoforming suitability an example of materials R&D that could enable more compostable/biobased thermoformable films. In March 2025 Innovia Films opened a new high-capacity specialty film line (announced Mar 2025) that highlights the ongoing capital investment trend to support higher-volume, thinner, and more consistent specialty films this kind of capacity change affects supply dynamics and pricing power for specialty thermoformable grades. These examples illustrate the twin industry forces of sustainability-driven material innovation and capital-led capacity expansion.

A major player in the fresh poultry packaging sector, Butterball, LLC, consistently purchases large volumes of high-barrier, soft-bottom thermoformable films from Sealed Air Corporation for its line of modified atmosphere packaging (MAP) trays. This specialized film, which features a peelable lidding layer and is engineered for high-speed form-fill-seal machinery.

The product is applied on the packaging lines at Ready Pac Foods, Inc., a leading producer of fresh-cut salads and fruits. There, the soft-bottom thermoformable film is used to create the base of the clamshell containers for their salad kits. The film's ability to be deeply drawn into a rigid cavity while maintaining excellent oxygen and moisture barriers is critical for preserving product freshness and extending shelf life. The application of this film, including the lidding process, adds a material cost depending on the size and complexity of the tray.

Asia Pacific leads global demand for packaging films and is the most dynamic region for soft bottom thermoformable films due to booming food processing, meat and seafood export supply chains, and growing retail ready-meal consumption. Large Asian players and contract packers are investing in mono-material thermoformable solutions (e.g., PP-based mono-PP structures) to improve recyclability and meet retailer demands. Local resin supply and feedstock pricing in Asia (naphtha/monomers) heavily influence margins; producers in South Korea, Japan, Thailand, India, and China are expanding coextrusion and multilayer capabilities to satisfy both domestic demand and export customers. Investment in wide-web, high-speed lines (10,000+ tpa per line for medium-large plants) has been reported in the region as manufacturers target scale advantages and thinner-gauge specialty films

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5486338

Soft Bottom Thermoformable Films by Type:

Coextruded Films

Laminated Films

Soft Bottom Thermoformable Films by Product Category:

PA

PE

PP

Others

Soft Bottom Thermoformable Films by Size:

Flexible thin films (50120 microns)

Medium thickness (120200 microns)

High-draw films (>200 microns)

Others

Soft Bottom Thermoformable Films by Usage:

Fresh Meat, Poultry and Seafood Packaging

Cheese, Deli Products, Sausages

Ready Meals and Convenience Food

Frozen Food Packaging

Others

Soft Bottom Thermoformable Films by Shape:

Flexible Soft Bottom Forming Webs

Skin Compatible Soft Forming Layers

Deep Draw Thermoforming Structures

Others

Soft Bottom Thermoformable Films by Application:

Flexible Vacuum Packs

Soft Modified Atmosphere Packaging (MAP)

Global Top 15 Key Companies in the Soft Bottom Thermoformable Films Market

ExxonMobil Chemical

MULTIVAC Group

Ampac Packaging

Korozo Group

Winpak

Bagla Group

Aksedef Plastik

Napco National

JM Packaging

Duropac

ITP

Servo Artpack

Euralpack

EK-Pack Folien

Nemco

Regional Insights

Within ASEAN, demand is concentrated in Thailand, Malaysia, Vietnam, Indonesia, and the Philippines where food processing, cold chain, and e-commerce packaging are expanding. Thailand remains a regional film-manufacturing hub (multi-line capacity, export orientation), while Indonesia shows a mix of local converters and integrated film makers investing in extrusion lines and converting capacity several Indonesian producers publicly list extrusion capacity in the single- to double-digit-thousand tonnes per annum range across multiple machines, reflecting a growing local supply base for thermoformable film demand. ASEAN customers are increasingly specifying mono-PP and recyclable film constructions for thermoformed trays and soft bottoms to simplify downstream recycling and lower post-consumer contamination risk.

The segment faces margin pressure from raw-material price volatility (polyolefin feedstocks), regulatory and retailer demands for recyclability that often require reformulation or new capital investments, and the technical challenge of balancing deep-drawability with barrier properties in mono-material constructions. Another practical challenge is supply-chain complexity for multilayer coextrusion films (adhesives, EVOH layers) when customers push for mono-material or lower-layer-count constructions. Finally, scale is a constraint for specialty soft bottom grades: small-batch bespoke formulations are costlier per ton than commodity films, making price competition with larger commodity film lines an ongoing concern.

Manufacturers should prioritize scalable, mono-material PP/PE solutions for thermoforming applications where feasible, invest in thin-gauge coextrusion capability to reduce material input per pack, and partner with major retailers/brand owners on recyclability trials. Converters should evaluate line upgrades that improve gauge control and optical consistency (lower waste yields). From a sourcing standpoint, securing feedstock through long-term agreements or regional integration reduces exposure to volatile spot resin markets. Finally, offering value-added services (custom printing, EVOH barrier laminates for high-barrier needs, and circularity take-back programs) can protect margin as the market commoditizes.

Product Models

Soft bottom thermoformable films refer to flexible multilayer films designed to deform under heat and pressure, forming customized trays or cavities for food, pharmaceutical, and industrial products.

Coextruded films which are produced in a single continuous multilayer extrusion step for high strength and barrier consistency. Notable products include:

ThermoFlex CX-70 Amcor: A high-barrier coextruded film designed for deep-draw food applications with excellent puncture resistance.

FormShrink CX-R Sealed Air: A shrinkable coextruded bottom film suitable for irregular-shaped protein products.

FlexForm E-Series Winpak: A multilayer coextrusion optimized for MAP packaging with strong sealing performance.

FormPack 900 Coveris: A deep-draw coextruded film offering reliable machinability on high-speed lines.

CoexForm Ultra Plastopil: A durable bottom film with enhanced resistance for dairy and semi-hard cheese.

Laminated films which combine two or more separately produced layers using adhesives to achieve specialized performance such as enhanced sealing, printability, or abrasion resistance. Examples include:

PET-PE ThermoLam Clear Polyplex: A clear laminated film providing strong forming depth and transparency.

LamForm MedicalPlus Amcor Healthcare: A laminate developed for medical trays requiring sterilization compatibility.

LamiDeep 800 Sealed Air: A PET/PE laminated thermoform film engineered for deep-draw meat and poultry packs.

ThermoLam Elite Südpack: A high-performance laminate with EVOH barrier and excellent formability for premium food applications.

LamiForm OptiSeal Glenroy: A laminated structure offering enhanced sealing for moist or oily food products.

Soft bottom thermoformable films are an important niche bridging flexible and thermoformed packaging: they serve high-volume food applications while facing evolving sustainability and recyclability requirements. The 2024 market base of USD 412 million and projected CAGR of 7.5% to 2031 imply robust growth driven by foodservice, retail-ready meals, and regional expansion in Asia and Southeast Asia. Manufacturers that combine technical product development (mono-material thermoformable solutions), prudent capacity investments, and supply-chain stabilization will stand to gain in a market where product performance and circularity increasingly determine commercial success.

Investor Analysis

Investors should focus on three value levers: technology differentiation, capacity & scale, and downstream customer traction. Technology differentiation (mono-material PP thermoformable films, high-barrier thin-gauge coextrusion) reduces regulatory/compliance risk and can command premium customer contracts. Capacity & scale determine cost competitiveness: nominal capability can deliver lower unit costs and absorb spot resin volatility better. Downstream traction (contracts with meat processors, major retailers, and co-packers) signals sustainable demand volumes and easier commercialization of new film grades. Understanding regional dynamics in Asia/ASEAN helps investors allocate capital to assets where feedstock access, labor cost, and export orientation favor margin expansion. In short, the reports market-size, margin, and capacity indicators help investors assess whether a target company is product-differentiated, has scalable assets, and enjoys sticky downstream demand the three pillars that tend to drive valuation multiple expansion in packaging materials.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5486338

5 Reasons to Buy This Report

To get a focused market sizing and CAGR trajectory to 2031 specific to soft bottom thermoformable films.

To access a regional breakdown and actionable insights for Asia and ASEAN markets.

To understand manufacturing economics: price-per-ton, estimated COGS and gross-profit per ton, and typical per-line capacity metrics.

To review the latest industry developments, material innovations, and capital-investment news.

To obtain a short list of leading producers and competitive context useful for M&A, supplier selection, or partnership strategies.

5 Key Questions Answered

What was the 2024 market size and how many tonnes did that represent?

What are the typical factory margins, COGS per ton, and cost breakdown for film manufacturers?

Which companies are the leading global and regional players in soft bottom thermoformable films?

What recent technology or material developments are shaping the market?

How do Asia and ASEAN differ in capacity, demand drivers, and investment priorities for this film segment?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Related Report Recommendation

Global Soft Bottom Thermoformable Films Market Research Report 2025

https://www.qyresearch.com/reports/5486338/soft-bottom-thermoformable-films

Global Soft Bottom Thermoformable Films Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

https://www.qyresearch.com/reports/5486336/soft-bottom-thermoformable-films

Global Soft Bottom Thermoformable Films Market Outlook, InDepth Analysis & Forecast to 2031

https://www.qyresearch.com/reports/5486337/soft-bottom-thermoformable-films

Soft Bottom Thermoformable Films - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

https://www.qyresearch.com/reports/5486339/soft-bottom-thermoformable-films

Global Thermoformable PET Film Market Research Report 2025

https://www.qyresearch.com/reports/3456635/thermoformable-pet-film

Global Thermoformable Barrier Film Market Research Report 2025

https://www.qyresearch.com/reports/4432293/thermoformable-barrier-film

Global High Barrier Thermoformable Films Market Research Report 2025

https://www.qyresearch.com/reports/4203007/high-barrier-thermoformable-films

Global Thermoformable Films for Food Packaging Market Research Report 2025

https://www.qyresearch.com/reports/5431758/thermoformable-films-for-food-packaging

Global Coextruded Multilayer Films Market Research Report 2025

https://www.qyresearch.com/reports/3421956/coextruded-multilayer-films

Global Laminated Film Market Research Report 2025

https://www.qyresearch.com/reports/4202817/laminated-film

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Soft Bottom Thermoformable Films Market to Reach USD 684 Million by 2031 Top 15 Company Globally here

News-ID: 4281087 • Views: …

More Releases from QY Research

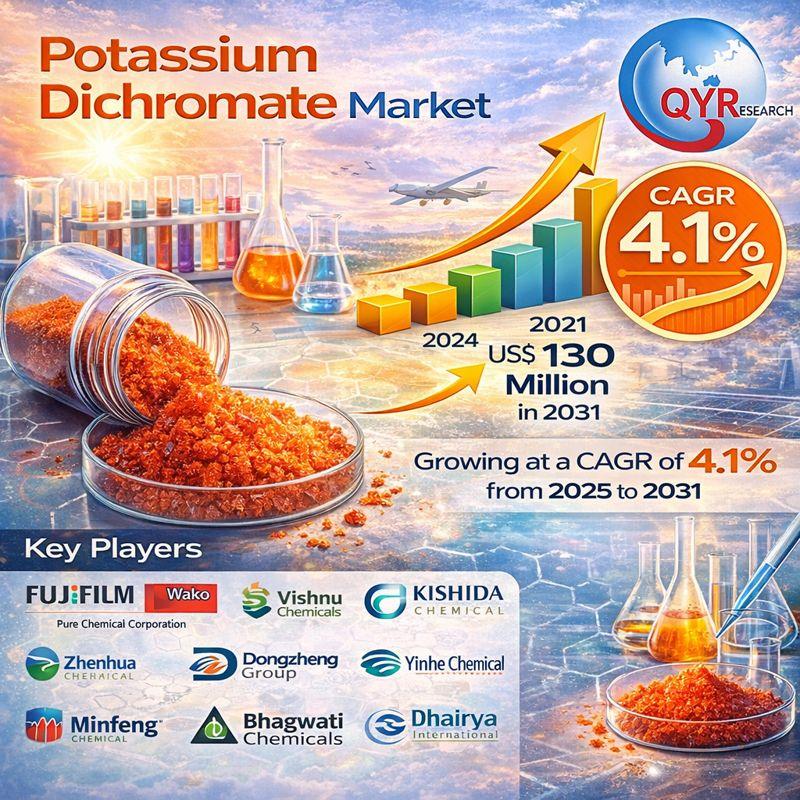

Potassium Dichromate Market to Reach US$ 130 Million by 2031, Driven by Electrop …

Market Summary -

The global Potassium Dichromate market was estimated to be worth US$ 97 million in 2024 and is forecast to reach a readjusted size of US$ 130 million by 2031, expanding at a CAGR of 4.1% during the forecast period 2025-2031.

According to QY Research, the newly released report titled "Potassium Dichromate Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031" provides a comprehensive, data-driven assessment of the global…

Top 30 Indonesian Garment Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

Indonesias garment and textile industry remains an important manufacturing backbone, supplying both domestic demand and global export markets. The sector encompasses textile/fiber producers, garment makers, and finished apparel exporters. Government support for export competitiveness and capital investment continued through 2025, while global pressures (e.g., competition, tariffs) persisted.

PT Polychem Indonesia Tbk (ADMG)

PT Argo Pantes Tbk (ARGO)

PT Trisula Textile Industries Tbk (BELL)

PT Century Textile Industry Tbk…

Plastic-Free Coated Paper Industry Forecast to 2031: Regions, Technologies, and …

The global plastic-free coated paper industry represents a rapidly evolving segment of sustainable materials that replaces traditional plastic and PFAS-based coatings with biodegradable, recyclable, and plant-based barrier solutions. These innovations respond to regulators, brands, and consumers demanding environmentally responsible packaging alternatives, especially in food, beverage, and consumer goods applications. Plastic-free coated paper not only delivers performance attributes such as grease, moisture, and oxygen resistance but also aligns with circular economy…

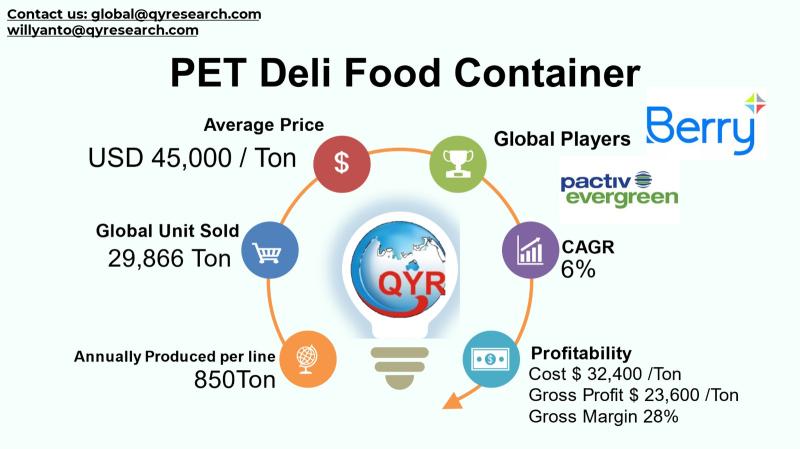

Global PET Food Container Industry 2026: Trends, Technologies, and Regional Insi …

The global PET deli food container industry occupies a vital niche within the broader polyethylene terephthalate (PET) packaging ecosystem, serving quick-service restaurants, supermarkets, food processors, and retail food service channels. PET containers are prized for their transparency, lightweight nature, recyclability, and food safety compliance, making them a preferred solution for deli meals, salads, ready-to-eat foods, and convenience meal kits. These containers also support consumer trends toward on-the-go consumption, hygienic packaging,…

More Releases for Film

Introducing heat sealable bopp film: Cloud Film Unveils Revolutionary Heat Seala …

Qingdao Cloud Film Packaging Materials Co., Ltd., a leading innovator in the packaging industry, is thrilled to announce the launch of heat sealable bopp film, a breakthrough heat sealable BOPP film set to revolutionize flexible packaging and labeling applications globally. This exciting development represents a significant advancement in packaging technology and underscores Qingdao Cloud Film's commitment to delivering cutting-edge solutions to its customers worldwide.

In a world where packaging integrity and…

Film Marketing & Film Financing

Film Sales Agency TheMovieAgency.com is now offering extra assistance to filmmakers. If you are looking for raising funds for your next feature film or simply looking for assistance in marketing your completed feature film on the road to distribution, The Movie Agency might be able to help you with no upfront fee and no hidden fee!!!

We offer:

Free consultation.

Sourcing investors and future distributors, film buyers.

North American Distribution for the feature…

Winter Film Awards International Film Festival Returns for 10th Annual Celebrati …

New York City's Winter Film Awards showcases films from emerging filmmakers from around the world in all genres, with a special emphasis on highlighting the work of women and under-represented filmmakers. The 10th annual Festival runs September 23-October 2 in New York City. The lineup includes 91 fantastic films from 28 countries, 7 free education sessions and amazing parties.

Winter Film Awards International Film Festival, which was one of NYC's last…

Global Film Capacitors Market 2021 Applications, Leading Manufacturers, Analysis …

Syndicate Market Research recently launched a study report on the global Film Capacitors market project light on the significant drifts and vigorous cannon into the evolution of the trade, which includes the restraints, market drivers, and opportunities. The report talks about the competitive environment prevailing in the Film Capacitors market worldwide. The report lists the key players in the market and also provides insightful information about them such as their…

Biaxially Oriented Polyester (BoPET) Market Share: Key players, Application, Foc …

Biaxially Oriented Polyester (BoPET) Market report provides Six-Year forecast 2019-2025 with Overview, Classification, Industry Value, Price, Cost and Gross Profit. The prime objective of this report is to help the user understand the market in terms of its definition, segmentation, market potential, influential trends, and the challenges that the market is facing. It also covers types, enterprises and applications. To start with, analytical view to complete information of Biaxially Oriented Polyester (BoPET) market. It offers market view…

Global Polyester Film (PET Film) Market Growth 2017-2022 Mitsubishi Polyester Fi …

PET or polyethylene terephthalate film is a thermoplastic polymer commonly referred to as polyester film. Like most thermoplastics, PET films can be biaxially oriented or bubble extruded. Polyester film is one of the most common substrates used in the converting industry because of its balance of properties in relation to other thermoplastic polymers.

Ask For Sample Copy of Report : http://bit.ly/2toHtBg

This report provides detailed analysis of worldwide markets for Polyester Film…