Press release

Multi Layer Thermoforming Films Market to Reach CAGR 7,8% by 2031 Top 20 Company Globally

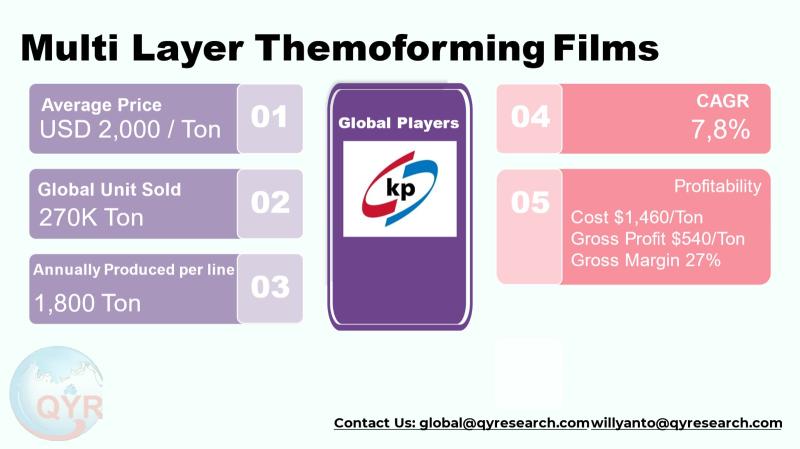

Multi-layer thermoforming films are engineered, co-extruded film structures designed to be thermoformed into trays, blisters, lids and other rigid or semi-rigid packaging shapes while delivering targeted barrier, mechanical and sealing properties. These films serve food (fresh meat, cheese, ready meals), medical and pharmaceutical trays, and a growing number of consumer-goods and industrial packaging applications where clarity, shelf life and processability are critical. Demand drivers include continued growth in convenience foods, retailer focus on shelf presentation and reduced food waste, and regulatory and brand pressure toward recyclable or lower-carbon film systems.The global multi layer thermoforming films market size is at USD 540 million in 2024 with a compound annual growth rate of 7.8% through 2031, raching market size USD 914 million by 2031. With an average selling price of USD 2,000 per ton implies to a total of 270K ton sold globally in 2024. A factory gross margin is 27% equals to factory gross profit at USD 540 per ton and cost of goods sold at USD 1,460 per ton. A COGS breakdown is raw materials (polymers, adhesives, barrier resins) followed by energy/utility and converting/line labor. A single line full machine capacity production is around 1,800 ton. Downstream demand is concentrated in food & beverage pacakaging followed by electronic products packaging and medical device packaging and other uses.

Latest Trends and Technological Developments

The industry continues to shift toward recycle-ready and circular thermoforming solutions: major suppliers are releasing recycle-ready thermoforming films and collaborating with resin players to improve PET-based thermoform circularity (example announcements and partnerships in 2023 to 2025). Recent equipment and process innovation for compact multi-layer blown and co-extrusion lines has been reported (e.g., product/line innovations announced January 2025). Market research and press in midlate 2025 also highlights growth in multilayer co-extruded film segments with renewed analyst coverage reporting expanding addressable markets (news item published very recently). These developments reflect two linked pressures: brand & regulatory demand for recyclability and converters need for more compact, flexible production equipment that supports smaller regional batches and recycled content.

A major food packaging distributor like Pratt Industries purchases multi-layer high-barrier thermoforming films from a leading producer such as Sealed Air Corporation. This specific film, often a co-extrusion of PA/EVOH/PE, is sought for its excellent oxygen barrier and deep-draw capabilities, which are critical for preserving the shelf life and quality of premium food products for their clients in the retail supply chain.

The product is used by a fresh meal manufacturer like Fresh Realm for packaging their gourmet prepared salads and protein bowls. The multi-layer film is thermoformed into precise cavities on a Multivac packaging line, where the base tray is filled with food, sealed with a lidding film, and modified atmosphere gas is flushed. This application consumes the film a crucial investment that ensures product freshness, prevents spoilage, and meets the demanding quality standards of retailers like Kroger and Albertsons.

Asia remains a global center of production for multi-layer thermoforming films because of proximity to large food-packaging converters, availability of extrusion & converting machinery, and a dense supplier base for polymer resins. In East Asia (China, Japan, Korea) the emphasis is on high-barrier and high-quality PET/PA/PE stacks for premium food and medical applications and rapid technology adoption (recycle-ready PET solutions, barrier improvements). In South Asia the market is expanding largely for cost-competitive PA/PE and PP-based stacks for chilled and frozen foods. Key Asian suppliers and technology leaders operate regional lines to serve domestic demand and export to neighboring Southeast Asian markets. Several global players maintain dedicated product portfolios optimized for Asian thermoforming converters.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5486330

Multi Layer Thermoforming Films by Type:

Flexible Film

Semi-Rigid Film

Rigid Film

Multi Layer Thermoforming Films by Product Category:

PS

PE

PP

PVC

Others

Multi Layer Thermoforming Films by Size:

Thin Gauge (150 microns)

Others

Multi Layer Thermoforming Films by Shape:

Skin Pack films

Embossed Films

Smooth Surface Films

Coextruded Structures

Others

Multi Layer Thermoforming Films by Features:

High Barrier

Ultra High Clarity

Anti Scratch Coated Films

Losk Seal Type

Others

Multi Layer Thermoforming Films by Application:

Medical Device Packaging

Electronic Product Packaging

Food Packaging

Others

Global Top 20 Key Companies in the Multi Layer Thermoforming Films Market

Klöckner Pentaplast

Napco National

Duropac

ITP

Sumibe

Bagla Group

DIC Corporation

Wipak

Evertis

Living Fresh Packaging

Jayshri Propack

CORDIS

Sidorenko Foodtech

Vishakha Polyfab

Mitsubishi Chemical

Vecom

Soretrac

Hypac Packaging

Clifton Packaging Group

Oliver Healthcare Packaging

Regional Insights

Southeast Asia shows accelerating demand driven by modern retail growth, rising consumption of chilled/ready meals and a transition from flexible pouching to tray formats for improved shelf presentation. Indonesia in particular is an important and growing market for thermoforming films because of its large population, expanding cold-chain and increasing manufacturing of processed foods. Local and regional film producers and converters in ASEAN often source co-extruded multi-layer films from domestic manufacturers or regional suppliers and are also investing in in-country converting capacity to shorten lead times. Price sensitivity remains important in ASEAN; therefore competitive PA/PE and PET/PE stacks and more compact extrusion capacity are common solutions for converters in the region.

Principal challenges include rising and volatile polymer resin costs (affecting COGS), regulatory and customer pressure for recyclability or reduced packaging complexity, and the technical complexity of producing multi-layer stacks that balance barrier, sealability and recyclability. Converters and brand owners also face supply chain constraints for specialty barrier resins and inconsistent regional recycling streams, which complicate measurement of true circularity. Capital intensity for high-quality co-extrusion lines and the need to qualify new recycle-ready materials across numerous SKUs present adoption friction.

Suppliers should prioritize modular line architectures and formulations that enable higher recycled content without sacrificing thermoforming memory and seal performance. Converters should evaluate flexible procurement strategies near-sourcing lower-value stacks while securing supply contracts for premium barrier resins to manage margin compression during resin cost cycles. Brands should emphasize design for recycling and work with film suppliers to qualify PET or mono-polymer stacks where local recycling infrastructure enables closed-loop collection. Finally, investment in regional converting capacity in ASEAN (including Indonesia) will reduce logistics lead times and help manufacturers capture growth in chilled and prepared food segments.

Product Models

ulti-layer thermoforming films are engineered sheet materials made from two or more polymer layers bonded together to deliver combinations of barrier protection, formability, sealability, and appearance for thermoformed packaging.

lexible Film is a thin, highly formable multi-layer films designed for deep draw and high-conformality thermoforming where elasticity and tight product contact matter; typically used for flexible trays, lidding, and soft-pack applications. Notable products include:

FlexSeal Ultra - Klöckner Pentaplast: a deep-draw, multi-layer flexible film engineered for high clarity and reliable peelable seals for fresh-food lidding.

NeoForm L-Soft - Napco National: a soft, highly stretchable thermoformable film that conforms tightly to irregular-shaped products for vacuum-packed produce.

FormEase Stretch - ITP: a thin, high-elongation film optimized for automated rotary thermoforming lines and tight product definition.

Bagla FlexWrap Pro - Bagla Group: a low-temperature sealing flexible film that reduces cycle time and improves cosmetic finish for deli packaging.

Wipak SoftForm - Wipak: a hygiene-grade flexible film for fresh-produce and meat trays, balancing barrier and peelability.

Semi-Rigid Film Mid-thickness multi-layer films that thermoform into stable trays or blisters with moderate stiffness suitable when some structural support is required but a fully rigid part isnt necessary. Examples include:

SemiTray Plus - Jayshri Propack: a semi-rigid sheet for deli and bakery trays offering structural integrity while remaining recyclable in some blends.

FreshHold SR-400 - Sidorenko Foodtech: a semi-rigid multi-layer film for portion trays that resists warping during filling and sealing.

TriLayer SemiForm - Mitsubishi Chemical: a precision-calibrated semi-rigid film for thermoformed blisters with strong seal and barrier properties.

Soretrac SR-Edge - Soretrac: a semi-rigid sheet optimized for thermoforming shallow trays and clamshells with crisp edges.

Hypac PackForm SR - Hypac Packaging: a cost-effective semi-rigid film for electronics and hardware blister packaging.

Rigid Film is Thicker, stiffer multi-layer films engineered to thermoform into robust parts with high dimensional stability and load-carrying capacity used for medical trays, heavy-duty clamshells, and reusable containers. Notable products include:

Pentaplast RigidPlus - Klöckner Pentaplast: a high-crystalline, rigid multi-layer film for demanding thermoformed medical and appliance components.

Napco RigidGuard - Napco National: a rigid film with excellent dimensional stability for blister cards and tamper-evident shells.

Duropac ToughForm - Duropac: a heavy-gauge rigid film that forms into load-bearing trays and protective packaging for electronics.

Bagla RigidCast - Bagla Group: a rigid, glossy film targeted at retail trays and point-of-sale packaging requiring premium finish.

Tangke RigidPro - Shanghai Tangke New Materials Technology: a rigid thermoforming film engineered for thick, structural trays used in medical and industrial packaging.

Multi-layer thermoforming films occupy an essential niche between flexible films and rigid plastic packaging: they offer the visual appeal and barrier performance that modern retail and food safety expectations require while also being the subject of intense innovation to meet recyclability targets. With the market sized at USD 540 million in 2024 and growth at an assumed CAGR of 7.8% through 2031, growth is concentrated in food packaging and fast-expanding medical/pharma applications; Asia and ASEAN are strategically important both for production capacity and end-market demand. Success in the coming five to eight years will depend on managing raw material cost volatility, progressing recycle-ready formulations, and agile regional capacity investments.

Investor Analysis

What to watch: product portfolios that are recycle-ready, partnerships between film makers and resin recyclers, and modular investments in regional extrusion/converting capacity. How to act: prioritize investments in companies with proven commercial recycle-ready thermoforming grades or long-term supply deals with converters in high-growth ASEAN markets; consider backing equipment or service providers enabling flexible, smaller-batch multi-layer film production. Why it matters: the convergence of consumer sustainability demand, regulation, and persistent growth in convenience/ready-to-eat food creates a structural demand tailwind that rewards players who can deliver high-performance, cost-competitive and circular thermoforming solutions. Investors should therefore favor firms with technology differentiation, regional footprint in Asia/ASEAN, and strong commercial relationships with major food and medical brand owners.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5486330

5 Reasons to Buy This Report

Consolidated market sizing and growth outlook focused on multi-layer thermoforming films with Asia/ASEAN emphasis.

Actionable regional insights for Indonesia and Southeast Asia supply/demand dynamics.

Technology & sustainability trend coverage including recent product/equipment news.

Competitive landscape and supplier profiling for sourcing and partnership decisions.

Investor guidance that links technical, commercial and regulatory trends to investment opportunities.

5 Key Questions Answered

What is the 2024 market size and projected CAGR for multi-layer thermoforming films through 2031?

How are price and cost structures affecting supplier margins and conversion economics?

What are the latest technological and equipment developments that impact regional production models?

Which companies lead the multi-layer thermoforming film space and what are their value propositions?

How should investors prioritize opportunities across Asia and ASEAN given growth and sustainability drivers?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Related Report Recommendation

Global Multi-layer Thermoforming Films Market Research Report 2025

https://www.qyresearch.com/reports/5486330/multi-layer-thermoforming-films

Global Multi-layer Thermoforming Films Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

https://www.qyresearch.com/reports/5486328/multi-layer-thermoforming-films

Global Multi-layer Thermoforming Films Market Outlook, InDepth Analysis & Forecast to 2031

https://www.qyresearch.com/reports/5486329/multi-layer-thermoforming-films

Multi-layer Thermoforming Films - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

https://www.qyresearch.com/reports/5486331/multi-layer-thermoforming-films

Global Multi-layer Thermoforming Films for Food Packaging Market Research Report 2025

https://www.qyresearch.com/reports/5486333/multi-layer-thermoforming-films-for-food-packaging

Global Thermoforming Films Market Research Report 2025

https://www.qyresearch.com/reports/4204091/thermoforming-films

Global Thermoforming Films for Retort Market Research Report 2025

https://www.qyresearch.com/reports/5431760/thermoforming-films-for-retort

Global High Barrier Thermoforming Film Market Research Report 2025

https://www.qyresearch.com/reports/3457135/high-barrier-thermoforming-film

Global Thermoforming Stretch Film Packing Machine Market Research Report 2025

https://www.qyresearch.com/reports/3612243/thermoforming-stretch-film-packing-machine

Global Lidding Films for Thermoforming Market Research Report 2025

https://www.qyresearch.com/reports/5431764/lidding-films-for-thermoforming

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Multi Layer Thermoforming Films Market to Reach CAGR 7,8% by 2031 Top 20 Company Globally here

News-ID: 4281083 • Views: …

More Releases from QY Research

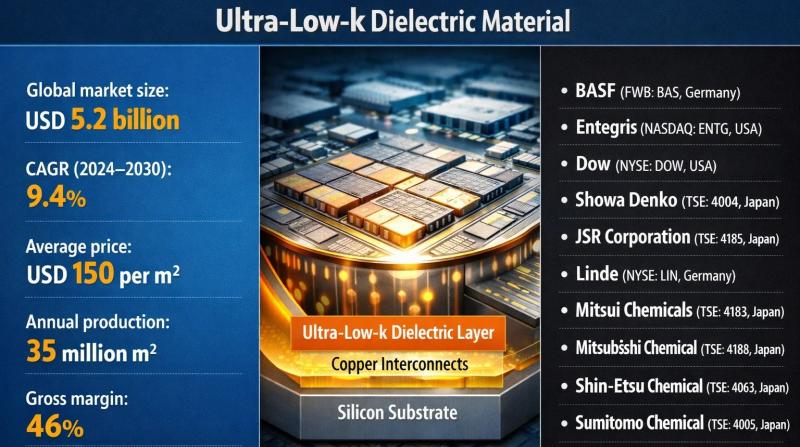

Market Overview - Ultra-low-k Dielectric Material

QY Research has recently published a comprehensive market study on Ultra-low-k Dielectric Material, a critical class of advanced insulating materials engineered to reduce parasitic capacitance and signal delay in advanced semiconductor interconnects. Ultra-low-k dielectrics are essential enablers for sub-7 nm logic nodes, advanced memory, high-performance computing, and AI accelerators, where interconnect RC delay increasingly limits device performance and power efficiency.

The market is transitioning from dense SiO2 and conventional low-k materials…

Global and U.S. Quadruped Mobile Robots Market Report, Published by QY Research.

QY Research has released a comprehensive new market report on Quadruped Mobile Robots, are four-legged robotic systems designed to move and operate in complex, unstructured environments by mimicking the locomotion of animals. They use a combination of advanced sensors, actuators, AI algorithms, and real-time control systems to maintain balance, navigate uneven terrain, climb obstacles, and adapt to dynamic conditions. Because of their high stability and mobility, quadruped robots are widely…

Global and U.S. Industrial Edge Cloud Devices Market Report, Published by QY Res …

QY Research has released a comprehensive new market report on Industrial Edge Cloud Devices, ruggedized computing platforms that bring cloud-native processing, storage, and AI analytics directly to the industrial edge-close to machines, sensors, and control systems. By executing latency-sensitive workloads locally while synchronizing with central or public clouds, these devices enable real-time decision-making, improved reliability, and secure data governance across factories, utilities, energy assets, and transportation infrastructure. As Industry 4.0,…

Top 30 Indonesian Ceramic Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Arwana Citramulia Tbk (ARNA)

PT Cahayaputra Asa Keramik Tbk (CAKK)

PT Intikeramik Alamasri Industri Tbk (IKAI)

PT Keramika Indonesia Assosiasi Tbk (KIAS)

PT Mulia Industrindo Tbk (MLIA)

PT Asahimas Flat Glass Tbk (AMFG) (glass & ceramic-adjacent)

PT Niro Ceramic Nasional Indonesia

PT Eleganza Tile Indonesia

PT Roman Ceramic International

PT Platinum Ceramics Industry

PT Granito (Citra Granito)

PT Diamond Keramik Indonesia

PT Indogress (Inti Keramik Sejahtera)

PT Indopenta Sakti Teguh

PT Sun Power Ceramics

PT Satyaraya Keramindo Indah…

More Releases for Film

Introducing heat sealable bopp film: Cloud Film Unveils Revolutionary Heat Seala …

Qingdao Cloud Film Packaging Materials Co., Ltd., a leading innovator in the packaging industry, is thrilled to announce the launch of heat sealable bopp film, a breakthrough heat sealable BOPP film set to revolutionize flexible packaging and labeling applications globally. This exciting development represents a significant advancement in packaging technology and underscores Qingdao Cloud Film's commitment to delivering cutting-edge solutions to its customers worldwide.

In a world where packaging integrity and…

Film Marketing & Film Financing

Film Sales Agency TheMovieAgency.com is now offering extra assistance to filmmakers. If you are looking for raising funds for your next feature film or simply looking for assistance in marketing your completed feature film on the road to distribution, The Movie Agency might be able to help you with no upfront fee and no hidden fee!!!

We offer:

Free consultation.

Sourcing investors and future distributors, film buyers.

North American Distribution for the feature…

Winter Film Awards International Film Festival Returns for 10th Annual Celebrati …

New York City's Winter Film Awards showcases films from emerging filmmakers from around the world in all genres, with a special emphasis on highlighting the work of women and under-represented filmmakers. The 10th annual Festival runs September 23-October 2 in New York City. The lineup includes 91 fantastic films from 28 countries, 7 free education sessions and amazing parties.

Winter Film Awards International Film Festival, which was one of NYC's last…

Global Film Capacitors Market 2021 Applications, Leading Manufacturers, Analysis …

Syndicate Market Research recently launched a study report on the global Film Capacitors market project light on the significant drifts and vigorous cannon into the evolution of the trade, which includes the restraints, market drivers, and opportunities. The report talks about the competitive environment prevailing in the Film Capacitors market worldwide. The report lists the key players in the market and also provides insightful information about them such as their…

Biaxially Oriented Polyester (BoPET) Market Share: Key players, Application, Foc …

Biaxially Oriented Polyester (BoPET) Market report provides Six-Year forecast 2019-2025 with Overview, Classification, Industry Value, Price, Cost and Gross Profit. The prime objective of this report is to help the user understand the market in terms of its definition, segmentation, market potential, influential trends, and the challenges that the market is facing. It also covers types, enterprises and applications. To start with, analytical view to complete information of Biaxially Oriented Polyester (BoPET) market. It offers market view…

Global Polyester Film (PET Film) Market Growth 2017-2022 Mitsubishi Polyester Fi …

PET or polyethylene terephthalate film is a thermoplastic polymer commonly referred to as polyester film. Like most thermoplastics, PET films can be biaxially oriented or bubble extruded. Polyester film is one of the most common substrates used in the converting industry because of its balance of properties in relation to other thermoplastic polymers.

Ask For Sample Copy of Report : http://bit.ly/2toHtBg

This report provides detailed analysis of worldwide markets for Polyester Film…