Press release

Planning a Cupronickel Foils Plant? Get the 2025 Cost Breakdown & Financial Feasibility Report

Cupronickel foils are thin sheets produced from an alloy of copper and nickel, known for excellent resistance to corrosion, especially in marine and high-humidity environments. These foils offer good thermal and electrical conductivity, strength, and durability. They are widely used in heat exchangers, batteries, electronic components, shipbuilding, coinage, and shielding applications. Their ability to withstand harsh conditions and maintain performance makes cupronickel foils valuable across multiple industrial and technological sectors.Setting up a cupronickel foil manufacturing plant involves sourcing high-purity copper and nickel, installing melting furnaces, alloying systems, casting equipment, rolling mills, annealing units, slitting machines, and surface finishing tools. The manufacturing process includes alloy preparation, casting, hot and cold rolling, heat treatment, and final finishing. The plant requires skilled metallurgists, efficient energy systems, quality control laboratories, and strict safety and environmental measures. Locating the facility near raw material sources, power supply, and transportation hubs improves efficiency and reduces logistics costs.

Request for a Sample Report: https://www.imarcgroup.com/cupronickel-foils-manufacturing-plant-project-report/requestsample

IMARC Group's report, titled "Cupronickel Foils Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a calcium phosphinate manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

This comprehensive business plan outlines every critical step involved in setting up a calcium phosphinate manufacturing plant successful unit - from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as calcium phosphinate manufacturing plant setup, cost breakdown, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Cupronickel Foils Industry Outlook 2025:

By 2025, the cupronickel foils industry is expected to grow steadily, supported by rising demand in marine, renewable energy, battery technology, and electronics sectors. Increased focus on corrosion-resistant materials and sustainable production methods will strengthen market adoption. Advancements in foil processing, recycling technologies, and lightweight durable alloys will expand application areas. Asia-Pacific is likely to dominate manufacturing, while North America and Europe will continue to drive innovation and high-end usage. Overall, the outlook remains positive, with strong opportunities for specialized and high-performance foil producers.

Key Insights for Cupronickel Foils Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=24160&flag=C

Key Cost Components of Setting Up a Cupronickel Foils Plant:

• Land & Site Development: Purchase/lease of land, site clearing, grading, and internal infrastructure

• Plant Construction: Production hall, warehouses, quality-control labs, offices, and utility areas

• Machinery & Equipment: Induction/melting furnaces, alloying units, casting machines, rolling mills, annealing furnaces, slitting and finishing machines

• Raw Materials: Copper, nickel, alloying elements, and protective gases

• Utilities & Power Systems: High-capacity electrical supply, cooling water systems, gas supply, and power backup

• Environmental & Safety Systems: Emission control units, dust collectors, ventilation systems, and waste management facilities

• Quality Control & Laboratory Setup: Testing instruments for composition analysis, thickness measurement, tensile strength, and surface quality

• Installation & Commissioning: Machinery installation, equipment calibration, trial runs, and process optimization

• Labor & Skilled Workforce: Metallurgists, engineers, machine operators, and quality inspectors

• Packaging & Storage: Coils, protective wrapping, pallets, and controlled-environment storage areas

• Transportation & Logistics: Raw material procurement and finished product distribution setup

• Licensing & Regulatory Compliance: Industrial permits, safety approvals, and environmental clearances

• Maintenance & Spares: Routine servicing, spare parts, and repair tools

• Working Capital & Contingency: Funds for daily operations, raw material inventory, and unexpected expenses

Economic Trends Influencing Cupronickel Foils Plant Setup Costs 2025:

• Raw Material Price Fluctuations: Copper and nickel prices are subject to global supply-chain disruptions and mining constraints, increasing input costs.

• Energy & Utility Cost Escalation: Melting, rolling, annealing and foil production consume high energy; rising electricity/gas tariffs raise operational budgets.

• Machinery & Construction Cost Inflation: Equipment for casting, rolling mills, finishing systems, and industrial buildings are becoming more expensive.

• Growth in High-Performance Demand: Demand from marine, aerospace, renewable energy, battery and electronics sectors pushes investment in higher quality alloys and tighter tolerances, raising production costs.

• Environmental & Compliance Costs: Stricter regulations on emissions, waste heat recovery, and resource efficiency raise capital outlay for pollution control and sustainability features.

• Logistics & Supply Chain Stress: Import duties, freight cost spikes, and delays in equipment/machinery increase setup time and capital tied up.

• Currency & Financing Risk: Volatile exchange rates increase imported equipment and raw material costs; higher interest rates raise cost of capital.

• Automation & Skill Premium: Trend toward digital manufacturing, automation and skilled metallurgical workforce increases initial investment.

• Sustainability & Recycling Pressure: Demand for recycled content and circular economy compliance may require investment in new processing and alloy recovery systems.

• Location & Infrastructure Variation: Countries with expensive utilities, land, or weak supply-chain infrastructure face higher CAPEX and OPEX compared to more industrialised regions.

Challenges and Considerations for Investors in Cupronickel Foils Plant Projects:

• Volatile Raw Material Prices: Fluctuations in copper and nickel prices can significantly impact production costs and margins

• High Capital Investment: Advanced melting, rolling, and finishing equipment require large upfront spending

• Energy-Intensive Operations: Significant power consumption increases operating expenses and sensitivity to energy price changes

• Technological Complexity: Precise alloy composition and thickness control require advanced metallurgical expertise

• Strict Environmental Compliance: Emission control, waste management, and recycling requirements add to setup and operating costs

• Skilled Workforce Dependency: Need for experienced metallurgists and trained machine operators

• Supply Chain Risks: Dependence on mining output, global trade conditions, and imports may cause delays or shortages

• Market Competition: Established global producers and alternative alloy materials create pricing and entry challenges

• Product Quality Consistency: High-performance applications demand tight tolerances and strict quality control

• Demand Cyclicality: Dependence on industries like shipbuilding, electronics, and EVs exposes revenues to market cycles

• Infrastructure & Location Constraints: Access to stable power, water, transport, and industrial facilities is critical

• Long Return-on-Investment Period: High initial investment leads to longer breakeven timelines

Buy Now:

https://www.imarcgroup.com/checkout?id=24160&method=1911

Conclusion:

A cupronickel foil manufacturing plant offers strong long-term potential due to growing demand from marine, electronics, renewable energy, and advanced industrial applications. However, investors must carefully consider high capital requirements, volatile raw material prices, strict environmental regulations, and the need for skilled technical expertise. Strategic location planning, reliable supplier partnerships, energy efficiency, and continuous technological upgrading are essential for achieving sustainable operations, competitive advantage, and long-term profitability in this specialized metals market.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Planning a Cupronickel Foils Plant? Get the 2025 Cost Breakdown & Financial Feasibility Report here

News-ID: 4280540 • Views: …

More Releases from IMARC Group

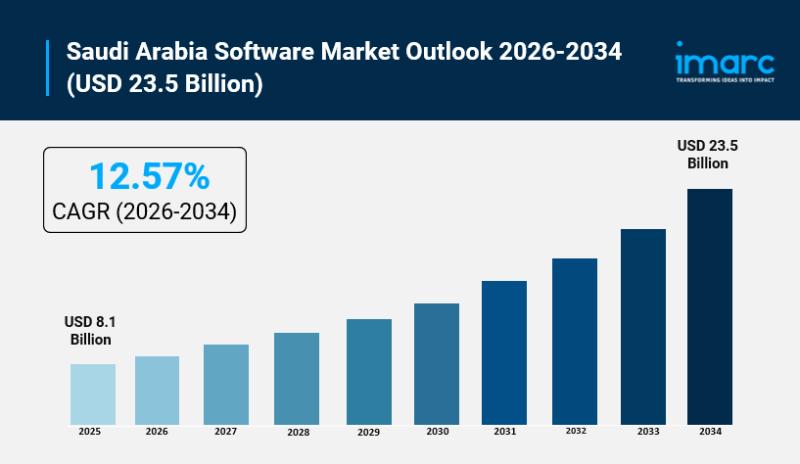

Saudi Arabia Software Market Size Set to Surge to USD 23.5 Billion by 2034 | CAG …

Saudi Arabia Software Market Overview

Market Size in 2025: USD 8.1 Billion

Market Forecast in 2034: USD 23.5 Billion

Market Growth Rate 2026-2034: 12.57%

According to IMARC Group's latest research publication, "Saudi Arabia Software Market Report by Type (Application Software, System Infrastructure Software, Development and Deployment Software, Productivity Software), Deployment Mode (On-premises, Cloud-based), Enterprise Size (Small and Medium-sized Enterprises, Large Enterprises), Industry Vertical (IT and Telecom, BFSI, Retail, Government/Public Sector, Energy and Utilities, Healthcare,…

Copper Busbars Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapE …

Setting up a copper busbars manufacturing plant positions investors in one of the most strategically critical segments of the global electrical infrastructure and power distribution value chain, driven by increasing demand for efficient power distribution systems, the accelerating expansion of renewable energy infrastructure, growing adoption of electric vehicles requiring robust high-current electrical connections, and rising investment in smart grids, data centers, and industrial automation worldwide.

Market Overview and Growth Potential:

The global…

Titanium Prices, Latest Trend, Demand, Index & Uses Feb 2026

North America - Titanium Prices February 2026

In North America, Titanium Prices reached USD 6.92 per kg in February 2026, marking a 2.4% decline compared to the previous month. The downward movement was primarily attributed to stable raw material availability and moderate demand from aerospace and industrial sectors. Despite the short-term correction, long-term demand fundamentals remain supported by infrastructure development and advanced manufacturing applications.

Regional Analysis: The price analysis can be extended…

Tin Prices Update: Northeast Asia Leads at USD 53.21/KG, Europe at USD 51.18/KG …

Northeast Asia - Tin Prices February 2026

In February 2026, Tin Prices in Northeast Asia reached USD 53.21 per kg, reflecting firm regional demand from electronics and solder manufacturing industries. Strong semiconductor production and steady industrial activity supported elevated pricing levels. Balanced supply conditions and active trade flows further reinforced the region's resilient tin market performance.

Get the Real-Time Prices Analysis: https://www.imarcgroup.com/tin-pricing-report/requestsample

Europe - Tin Prices February 2026

Tin prices in Europe stood at…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…