Press release

Cashew Powder Manufacturing Plant: Complete Cost & ROI Analysis (2025)

Cashew powder is a fine, creamy-textured product made by grinding high-quality, shelled cashew nuts into a smooth powder. It is widely used in bakery products, confectionery, beverages, ice creams, sauces, curries, and nutritional supplements due to its rich flavor and high content of healthy fats, proteins, vitamins, and minerals. Cashew powder also serves as a popular ingredient in plant-based and vegan recipes as a dairy alternative. Its long shelf life and versatility make it highly valuable in both the food processing and hospitality industries.Setting up a cashew powder manufacturing plant involves sourcing premium cashew kernels, installing cleaning, drying, roasting, and grinding machinery, and establishing proper packaging facilities. The process includes sorting, gentle roasting, fine grinding, sieving, and hygienic packing. Key requirements include food-grade processing areas, quality control labs, cold storage, and efficient dust-control systems. Compliance with food safety standards, proper waste management, and skilled labor are essential. A strategic location near cashew-growing regions and transport hubs helps reduce raw material and logistics costs.

Request for a Sample Report: https://www.imarcgroup.com/cashew-powder-manufacturing-plant-project-report/requestsample

IMARC Group's report, titled "Cashew Powder Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a calcium phosphinate manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

This comprehensive business plan outlines every critical step involved in setting up a calcium phosphinate manufacturing plant successful unit - from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as calcium phosphinate manufacturing plant setup, cost breakdown, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Cashew Powder Industry Outlook 2025:

The cashew powder industry is expected to witness steady growth by 2025, driven by rising demand for healthy, plant-based, and gluten-free ingredients in food and beverage applications. Increasing popularity of vegan diets, nutritionally enriched foods, and ready-to-eat products is boosting market demand. The bakery, dairy-alternative, and dessert sectors will remain major consumers. Asia-Pacific is projected to lead production, while North America and Europe will see strong demand for premium and organic variants. Innovation in packaging and value-added products will further expand market opportunities.

Key Insights for Cashew Powder Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=22969&flag=C

Key Cost Components of Setting Up a Cashew Powder Plant:

• Land & Site Development: Purchase/lease of land, site clearing, leveling, and basic infrastructure

• Plant Construction: Processing facility, warehouses, offices, cold storage, and utility blocks

• Machinery & Equipment: Cleaning machines, dryers, roasters, grinders, sieving units, and packaging machines

• Raw Materials: Procurement of cashew kernels and food-grade additives (if required)

• Utilities & Power Systems: Electricity, water supply, boilers, compressors, and power backup systems

• Quality Control & Laboratory Setup: Testing instruments for moisture, microbiological safety, and product consistency

• Food Safety & Compliance: Licensing, certifications (FSSAI/ISO/HACCP), and inspection fees

• Packaging & Storage: Pouches, jars, labeling machines, sealing units, pallets, and storage racks

• Labor & Workforce: Operators, quality control staff, supervisors, and administrative personnel

• Transportation & Logistics: Raw material procurement and finished goods distribution

• Maintenance & Spares: Routine equipment servicing and spare parts

• Marketing & Branding: Product design, branding, promotions, and distribution setup

• Working Capital & Contingency: Funds for day-to-day operations, unexpected costs, and inventory management

Economic Trends Influencing Cashew Powder Plant Setup Costs 2025:

• Rising Cashew Nut Prices: Fluctuations in raw cashew kernel supply and pricing increase procurement and inventory costs

• Higher Energy & Utility Costs: Increased electricity and fuel prices raise expenses for roasting, drying, grinding, and cold storage operations

• Inflation in Machinery & Construction: Higher costs for food-processing equipment, packaging machines, steel, and building materials

• Currency & Import Dependency Risks: Dependence on imported cashew nuts and machinery exposes investors to exchange-rate fluctuations

• Growing Labor Expenses: Rising wages and demand for skilled workers increase production and operational costs

• Stricter Food Safety Regulations: Additional investment required for certifications, testing labs, hygiene systems, and compliance infrastructure

• Increased Packaging Costs: Higher prices for eco-friendly, airtight, and food-grade packaging materials

• Transportation & Logistics Challenges: Higher fuel and freight rates impact raw material sourcing and product distribution

• Rising Demand for Automation: Investment in advanced machinery to improve efficiency and reduce manual labor increases initial setup cost

• Location-Based Cost Differences: Plants located near ports or cultivation zones have lower logistics costs compared to remote areas

Challenges and Considerations for Investors in Cashew Powder Plant Projects:

• Raw Material Price Volatility: Fluctuating cashew kernel prices can directly impact production costs and profit margins

• Quality Dependency: Consistent access to high-grade cashews is essential for maintaining product taste and texture

• Strict Food Safety Standards: Compliance with FSSAI, HACCP, ISO, and hygiene regulations adds operational complexity

• Risk of Contamination & Spoilage: Requires controlled processing, storage, and packaging environments

• Energy-Intensive Operations: High power usage for roasting, drying, grinding, and storage increases expenses

• Skilled Labor Requirement: Trained workers are needed for quality processing and inspection

• Intense Market Competition: Established brands and private labels create pricing and market entry challenges

• Storage & Shelf-Life Management: Moisture-proof and temperature-controlled conditions are necessary

• Import & Supply Chain Dependence: Delays and price fluctuation in imported cashews can disrupt production

• High Initial Investment: Considerable capital required for machinery, infrastructure, and compliance systems

• Distribution & Marketing Needs: Strong distribution channels and branding efforts are required for market presence

• Location Sensitivity: Distance from ports or growing regions affects logistics and operating costs

Buy Now:

https://www.imarcgroup.com/checkout?id=22969&method=1911

Manufacturing Process

• Steaming: Raw cashew nuts are steamed in a boiler to soften and loosen the hard outer shells.

• Shelling: The softened shells are cracked and removed using a shelling machine to extract the raw kernels.

• Drying: The kernels are dried in controlled ovens to reduce moisture content and improve shelf life.

• Grinding: The dried kernels are ground in short, controlled cycles to produce a fine powder while preventing oil release and clumping.

• Packaging: The finished cashew powder is hygienically packed in PP bags or other suitable food-grade containers for storage and distribution.

Conclusion:

A cashew powder manufacturing plant presents attractive growth potential due to rising demand for plant-based, healthy, and premium food ingredients. However, investors must carefully manage raw material price fluctuations, strict food safety compliance, energy costs, and quality control challenges. Strategic location selection near cashew-sourcing hubs, investment in efficient processing technology, and a strong focus on hygiene, branding, and supply chain management are essential for achieving profitability and long-term sustainability in this competitive market.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cashew Powder Manufacturing Plant: Complete Cost & ROI Analysis (2025) here

News-ID: 4280433 • Views: …

More Releases from IMARC Group

India Bottled Water Market 2026: Explosive Growth, Key Players & Future Opportun …

Introduction:

According to the latest research report titled "India Bottled Water Market Size, Share, Trends and Forecast by Product Type, Distribution Channel, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Bottled Water Market Overview:

The India bottled water market size was valued at USD 10.71 Billion in 2025 and is projected to reach USD 29.70 Billion by 2034, growing at…

India E-Bike Market 2026: Explosive Growth, Top Brands & Investment Opportunitie …

Introduction:

According to the recent data, the report titled "India E-Bike Market Size, Share, Trends and Forecast by Propulsion Type, Battery Type, Power, Application, and Region, 2026-2034" offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India E-bike Market Overview:

The India E-bike market attained a valuation of USD 1,420.78 Million in 2025 and is forecasted to reach USD 3,007.19 Million by 2034, demonstrating a robust compound…

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

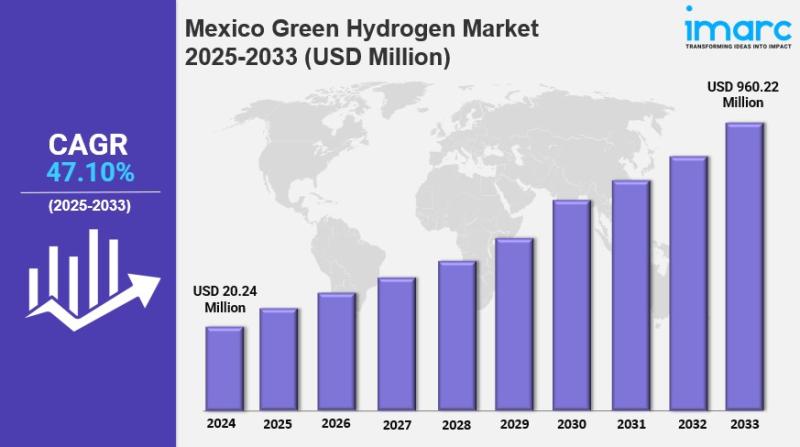

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…