Press release

Precision Machines for Polymers Market Outlook 2025-2035: Key Developments and Future Scope

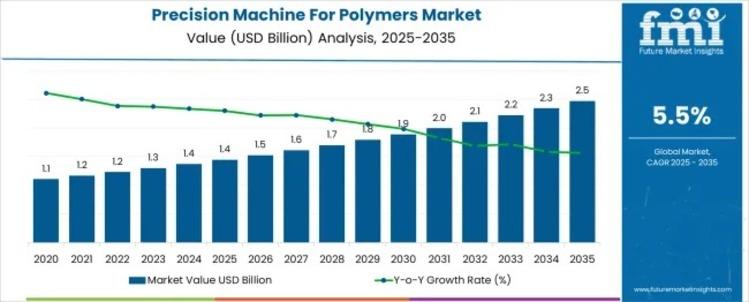

The global precision machines for polymers market is gearing up for robust expansion through 2035, propelled by the surging demand for lightweight, high-performance plastics in aerospace, medical devices, and automotive sectors, alongside breakthroughs in automation and CNC integration.According to Future Market Insights (FMI), the market stands at USD 1.4 billion in 2025 and is forecasted to climb to USD 2.5 billion by 2035, achieving a compound annual growth rate (CAGR) of 5.5%.

The FMI report, "Precision Machines for Polymers Market Size, Share, and Forecast 2025-2035," projects a total revenue surge of USD 1.1 billion over the decade, fueled by the shift from metals to polymers for corrosion-resistant, biocompatible components that demand micro-level tolerances and high-speed production.

A Decade of Growth Anchored by Automation and Polymer Innovation:

The market's evolution is marked by the rise of smart, automated machining systems that minimize variability and boost throughput. From 2025 to 2030, the sector is expected to add approximately USD 0.6 billion in value, driven by early adoption in medical and electronics prototyping.

By 2030-2035, FMI anticipates an additional USD 0.5 billion uplift, as Industry 4.0 technologies like predictive maintenance and multi-axis CNC become mainstream, enhancing efficiency in large-scale manufacturing.

"Precision polymer machining is no longer a niche-it's the backbone of next-gen lightweighting and sustainability in high-stakes industries," said an FMI research analyst. "Advancements in sensor integration and adaptive controls are slashing downtime while unlocking unprecedented customization."

Precision Machines for Polymers Key Market Insights at a Glance:

Global Estimate

* Market Value (2025): USD 1.4 billion

* Forecast Value (2035): USD 2.5 billion

* CAGR: 5.5%

* Top Polymer Type: PTFE (31% share)

* Dominant Machine Type: Milling (28% share)

* Fastest-Growing Operation: Automatic (41% share, with 6.2% CAGR)

The Fastest-Growing Precision Machines for Polymers Market:

FMI's in-depth analysis spotlights Asia-Pacific as the global powerhouse, with China leading at a blistering 7.4% CAGR. Valued at USD 0.45 billion in 2025, the regional market is set to hit USD 0.85 billion by 2035, propelled by a 12% year-over-year jump in automotive production and 14% growth in CNC equipment sales. India's market, growing at 6.9% CAGR, benefits from 15% export rises and 11% increases in medical device output, where 40% of new installations feature CNC capabilities for polymer processing.

This boom underscores Asia's pivot to high-precision exports, with e-commerce and direct B2B channels accelerating access to advanced milling and turning tools.

Precision Machines for Polymers Five Forces Driving Market Expansion:

Polymer Advancements: PTFE's thermal stability and low friction dominate, enabling seamless CNC compatibility in semiconductors and aerospace.

Automation Surge: Smart sensors and Industry 4.0 integration cut cycle times by up to 30%, fostering lean production.

Sector Demand Boom: Aerospace lightweighting and medical biocompatible devices drive 42% of growth, with automotive parts up 9% annually.

Sustainability Push: Recyclable polymers and energy-efficient machines align with global net-zero goals, reducing waste by 25%.

Regional Manufacturing Shift: Asia-Pacific's infrastructure investments, including China's export hubs, amplify demand for high-throughput grinding and laser cutting.

Precision Machines for Polymers Market Segment Overview:

By Polymer Type: PTFE commands 31% of 2025 revenues, prized for chemical inertness in pharmaceuticals and electronics; FEP and PVDF follow, with ETFE fastest-growing at 6.1% CAGR for flexible applications.

By Machine Type: Milling leads with 28% share, excelling in complex shaping and surface finishes; turning and drilling trail, while laser cutting surges at 6.8% CAGR for non-contact precision.

By Operations: Automatic systems hold 41% dominance, optimizing labor and consistency; semi-automatic grows at 5.2% CAGR amid digital upgrades.

By Application: Equipment and components capture 35% share, fueled by aerospace and automotive; electrical insulation and coatings follow, with medical devices accelerating at 7.1% CAGR.

By Distribution Channel: Direct sales lead at 55% share for customized B2B deals; indirect channels, including online platforms, expand at 6.3% CAGR.

Precision Machines for Polymers Market Regional Overview:

Asia-Pacific: Global leader with 7.4% CAGR in China and 6.9% in India, driven by manufacturing exports and tech hubs.

Europe: Steady 6.3% CAGR, spearheaded by Germany (USD 0.3 billion to USD 0.5 billion), where 60% of aerospace parts require polymer precision.

North America: 4.7% CAGR, with the U.S. at USD 0.35 billion in 2025, bolstered by 48% automation-ready systems and 9% defense procurement growth.

Latin America: Brazil at 4.1% CAGR, emerging via industrial upgrades; Middle East & Africa trail but gain from UAE's 5.5% infrastructure spend.

Subscribe for Year-Round Insights → Stay ahead with quarterly and annual data updates: https://www.futuremarketinsights.com/reports/sample/rep-gb-23577

Get data that aligns with your strategic priorities - ask for report customization today: https://www.futuremarketinsights.com/customization-available/rep-gb-23577

Precision Machines for Polymers Market Competitive Landscape:

* Entegris Inc.

* Swisstec AG

* APTCO Technologies

* Mitsubishi Chemical Advanced Materials

* Saint-Gobain Performance Plastics

Entegris, Swisstec, and Mitsubishi collectively hold over 35% market share, prioritizing contamination-free processing, multi-axis versatility, and sustainable material synergies to capture innovation-led gains.

Precision Machines for Polymers Market Outlook: Machining the Future of Lightweight Innovation:

As the decade unfolds, precision polymer machines will pivot from mechanical prowess to AI-driven ecosystems, with torque sensors and real-time analytics redefining tolerances below 10 microns. Emerging trends like fiber-reinforced composites and zero-waste extruders, such as STEER World's iSeries (launched June 2025), signal a greener horizon.

"These machines are evolving into intelligent partners for manufacturers, blending polymer science with digital precision to meet the demands of a lighter, smarter world," the FMI analyst concluded. "Leaders investing in adaptive tech will not just grow-they'll reshape industries."

Related Reports

Conveyor Dryer Market- https://www.futuremarketinsights.com/reports/conveyor-dryer-market

USA Power Tool Market- https://www.futuremarketinsights.com/reports/united-states-power-tool-market

Emulsion Explosive Market- https://www.futuremarketinsights.com/reports/emulsion-explosive-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Precision Machines for Polymers Market Outlook 2025-2035: Key Developments and Future Scope here

News-ID: 4279984 • Views: …

More Releases from Future Market Insights

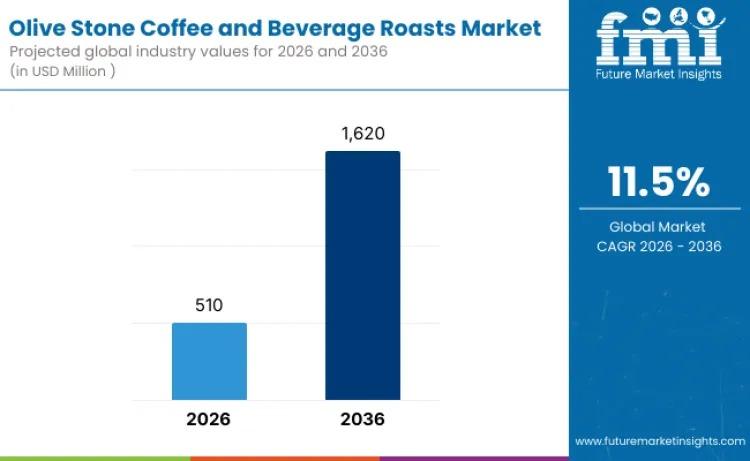

Global Olive Stone Coffee and Beverage Roasts Market to Reach USD 1,620 Million …

The global olive stone coffee and beverage roasts market is entering a high-growth decade, fueled by sustainability innovation and evolving specialty coffee culture. Valued at USD 510 million in 2026, the market is projected to reach USD 1,620 million by 2036, expanding at a compelling CAGR of 11.5%.

As consumers increasingly seek beverages that combine sustainability, functionality, and distinctive taste, olive stone-based roasting solutions are transitioning from niche experimentation to structured…

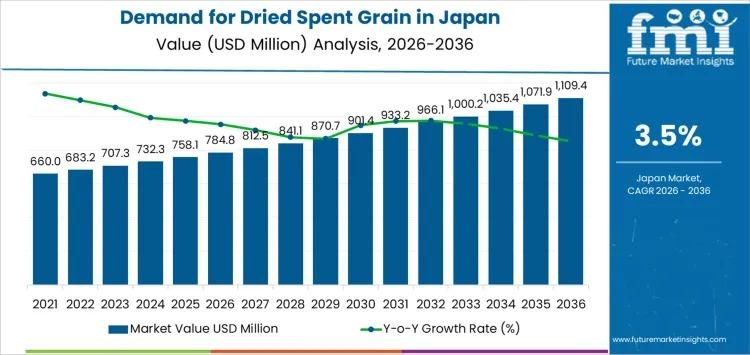

Japan Dried Spent Grain Market to Surpass USD 1.1 Billion by 2036 as Feed Optimi …

Japan's dried spent grain market is entering a decade of steady, value-driven expansion, supported by structured feed demand, brewery byproduct utilization, and rising integration of fiber-rich ingredients into food manufacturing. Industry estimates place the market at USD 784.8 million in 2026, with projections indicating growth to USD 1,109.4 million by 2036, reflecting a CAGR of 3.5%.

Between 2020 and 2026, demand increased from USD 637.5 million to USD 784.8 million, shaped…

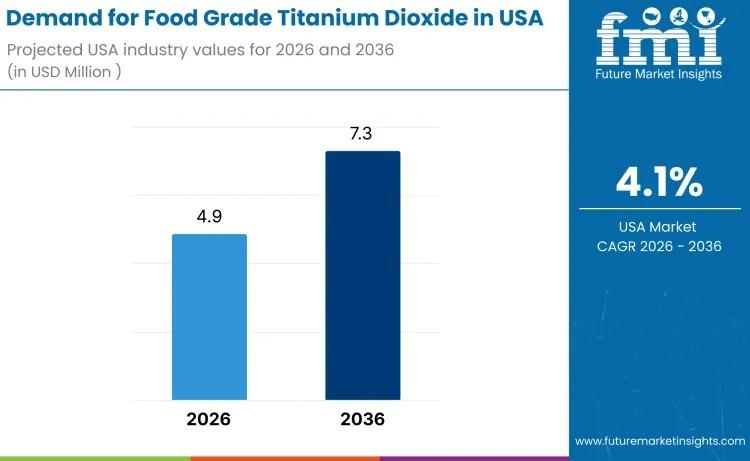

USA Food Grade Titanium Dioxide Market to Reach USD 7.3 Million by 2036 Amid Ste …

The demand for food grade titanium dioxide in the USA is valued at USD 4.9 million in 2026 and is projected to reach USD 7.3 million by 2036, expanding at a CAGR of 4.1%. Growth remains moderate yet stable, supported by continued use of titanium dioxide as a whitening and opacifying agent across confectionery coatings, bakery decorations, sauces, dairy analogues, and processed food matrices.

Despite heightened regulatory scrutiny and evolving clean-label…

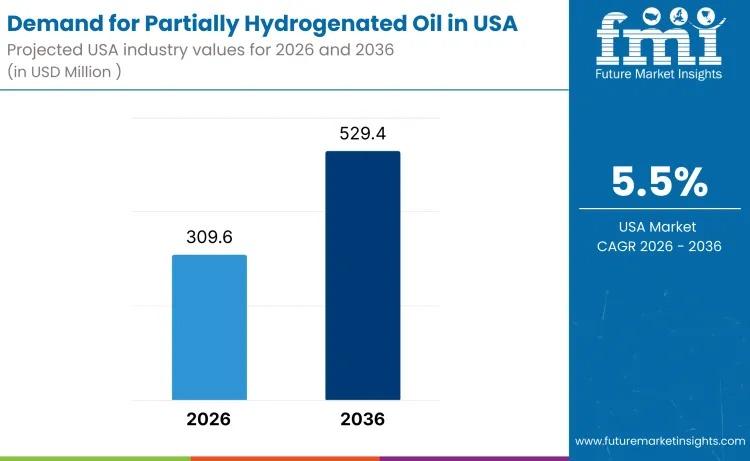

USA Partially Hydrogenated Oil Market to Reach USD 529.4 Million by 2036 Amid Me …

The demand for partially hydrogenated oil in the USA is projected to rise from USD 309.6 million in 2026 to USD 529.4 million by 2036, expanding at a steady CAGR of 5.5%. While edible applications remain tightly regulated, demand persists across specialty industrial and permitted food-related segments where oxidative stability, viscosity control, and texture performance remain critical.

Despite regulatory constraints on trans fats in conventional food manufacturing, PHOs continue to serve…

More Releases for Polymer

MDR Certificate For Single Polymer Clip Applier And Multiple Polymer Clip Applie …

EU Quality Management System Certificate

Regulation (EU)2017/745, Annex Ix Chapter I and III

MDR 804963 R000

Manufacturer: Hangzhou Sunstone Technology Co., Ltd

Address:

2nd Floor of Building 1,

#460 Fucheng Rd, Qiantang Area

Hangzhou

Zhejiang

310018

China

Single Registration Number: CN-MF-000040501

EU Authorised Representative: MedPath GmbH

Address:

Mies-van-der-Rohe-Strasse 8

80807

Munich

Germany

Scope: See attached Device Schedule

On the basis of our examination of the quality system in accordance with Regulation (EU) 2017/745, Annex IX

Chapter I and lll, the quality system meets the requirements of the Regulation. For the…

Acrylic Polymer Market

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐩𝐨𝐥𝐲𝐦𝐞𝐫 𝐦𝐚𝐫𝐤𝐞𝐭 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝐔𝐒𝐃 𝟐𝟎 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐞𝐝 𝐭𝐨 𝐫𝐞𝐚𝐜𝐡 𝐔𝐒𝐃 𝟑𝟔.𝟗 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟐, 𝐠𝐫𝐨𝐰𝐢𝐧𝐠 𝐚𝐭 𝐚 𝐜𝐨𝐦𝐩𝐨𝐮𝐧𝐝 𝐚𝐧𝐧𝐮𝐚𝐥 𝐠𝐫𝐨𝐰𝐭𝐡 𝐫𝐚𝐭𝐞 (𝐂𝐀𝐆𝐑) 𝐨𝐟 𝟔.𝟒% 𝐟𝐫𝐨𝐦 𝟐𝟎𝟐𝟑 𝐭𝐨 𝟐𝟎𝟑𝟐.

𝐀𝐜𝐫𝐲𝐥𝐢𝐜 𝐏𝐨𝐥𝐲𝐦𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰

The acrylic polymer market has experienced significant growth due to its versatile applications across various industries, including paints and coatings, adhesives, textiles, and construction. Acrylic polymers are favored for…

Polymer Processing Aids: Enhancing Efficiency and Quality in Polymer Manufacturi …

Introduction

Polymer Processing Aids (PPAs) are indispensable additives used to improve the efficiency, quality, and cost-effectiveness of polymer manufacturing. These aids, often added in small quantities, significantly enhance polymer production by reducing surface defects, improving flow properties, and reducing wear on manufacturing equipment. Their role is critical in enabling smooth, uninterrupted processing, leading to higher-quality end products and improved manufacturing productivity. With the ever-growing demand for polymers across industries like automotive,…

What Are Lithium Polymer? Information About Lithium Polymer Batteries Guide

Did people know that Lithium Polymer power over 80% of the drones used in recreational and commercial applications today? Lithium Polymer (LiPo) batteries have become a staple in modern electronics. From powering smartphones and laptops to energizing drones and electric vehicles, these batteries offer a blend of high energy density and flexibility that makes them ideal for a wide range of applications. In this article, we'll dive deep into what…

Custom Polymer Synthesis Market 2023 Will Record Massive Growth, Trend Analysis …

The Custom Polymer Synthesis Market Trends Overview 2023-2030:

A new Report by Stratagem Market Insights, titled "Custom Polymer Synthesis Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," offers a comprehensive analysis of the industry, which comprises insights on the Custom Polymer Synthesis market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures, tables, and charts,…

Silyl Modified Polymer (MS Polymer) Market Forecast Research Reports Offers Key …

Silyl Modified Polymer (MS Polymer) Market: Introduction

MS polymers, also known as silyl modified polymers or silyl terminated polymers, are polymers with a silane group. A silyl modified polymer (MS polymer) usually refers to a hybrid polymer backbone, usually polyurethane or polyether and a silane end group. Formulators can change the backbone polymer in sealants and adhesives utilizing MS polymers to match the specified application, achieving silicone-like performance while avoiding the…