Press release

High Heat Resistance Phenolic Molding Compounds Market Future Trends and Innovation Opportunities 2025-2031

Los Angeles, United States - QY Research has unveiled its latest study titled "Global High Heat Resistance Phenolic Molding Compounds Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031." This newly released report delivers a comprehensive overview of the global High Heat Resistance Phenolic Molding Compounds market, analyzing the forces shaping its growth trajectory and providing valuable insights for stakeholders, investors, and industry professionals. the research covers key areas including market dynamics, segmentation, regional performance, competitive landscape, and emerging technology trends that are redefining industry standards. Backed by reliable data and expert analysis, the report serves as a trusted guide to understanding both microeconomic and macroeconomic factors driving market evolution.The global market for High Heat Resistance Phenolic Molding Compounds was estimated to be worth US$ 436 million in 2024 and is forecast to a readjusted size of US$ 612 million by 2031 with a CAGR of 4.8% during the forecast period 2025-2031.

Download Free Sample PDF Report (with full TOC, tables, and charts) To Explore Detailed Insights and Forecasts @ https://qyresearch.in/request-sample/chemical-material-high-heat-resistance-phenolic-molding-compounds-global-market-share-and-ranking-overall-sales-and-demand-forecast-2025-2031

Phenolic molding compound is based on phenolic resin as the matrix resin, hexamethyltetramine as the curing agent, plus various additives such as inorganic ore fillers, glass fibers, etc. The thermosetting plastics after high temperature mixing, its intentional heat resistance, The mechanical properties, acid resistance, alkali resistance and electrical insulation properties make the application of phenolic molding compounds more and more widely.

High heat resistance phenolic molding compound is a type of phenolic molding compound, it is widely used in electrical industry equipment, automobile parts, high temperature resistant cookware and other fields due to its ultra-high heat resistance.

Geographically, Japan's high heat-resistant phenolic molding compound has an international leading level and has a long history. Some Japanese manufacturers such as Sumitomo Bakelite and Panasonic, which are market leaders, have production sites in China. In recent years, China's production has been at the forefront of the world.

The global key High Heat Resistance Phenolic Molding Compounds manufacturers include Sumitomo Bakelite, Panasonic, Chang Chun Group, Plenco, Fudow Company Limited, Hexion, Jiangsu Zhongpeng New Material, Wuxi Chuangda Advanced Materials, etc. From the perspective of manufacturers, High Heat Resistance Phenolic Molding Compounds are relatively concentrated, and the top three manufacturers accounted for more than 54% of revenue in 2024. The competitive advantages of high heat-resistant phenolic molding compound manufacturers are mainly reflected in their entry barriers and technical barriers.

Looking to the future, new energy electric vehicles are expected to come into more common use around the world, and this will drive continuous growth in demand for high heat resistance phenolic molding compounds. The market for advanced equipment is set to expand, spurred by the development of newer products and broader areas of application. Accordingly, the demand for automotive components will likely grow, a prospect for which ensuring a stable supply of high heat resistance phenolic molding compounds is expected to become increasingly important.

Competitive Landscape: -

Sumitomo Bakelite

Panasonic

Chang Chun Group

Plenco

Hexion

Fudow Company

Jiangsu Zhongpeng New Material

Wuxi Chuangda Advanced Materials

Raschig GmbH

Beijing Sino-tech Electronic Material

Taizhou Changxiong Plastic

Shanghai European-Asian Synthetic Material

Changshu Southeast Plastic

Sprea Misr

Amity Thermosets (P) Ltd

Market Drivers and Restraints -

This section of the High Heat Resistance Phenolic Molding Compounds report discusses various drivers and restrains that have shaped the global market. The detailed study of numerous drivers of the market enable readers to get a clear perspective of the market, which includes market environment, government policies, product innovations, breakthroughs, and market risks.

The research report also points out the myriad opportunities, challenges, and market barriers present in the global High Heat Resistance Phenolic Molding Compounds market. The comprehensive nature of the information will help the reader determine and plan strategies to benefit from. Restrains, challenges, and market barriers also help the reader to understand how the company can prevent itself from facing downfall.

Regional Insights -

The report takes readers on a journey through four key regions: United States, Asia-Pacific, and EMEA. Key nations like the United States, Germany, the United Kingdom, China, Japan, South Korea, and more are thoroughly examined. The data is presented in a timeline from 2024 as the base year, with projections extending to 2031.

North America: United States, Canada, Mexico

Latin America: Brazil and other key markets

Asia Pacific: China, Japan, South Korea, India, ASEAN countries

Europe, Middle East & Africa (EMEA): Major European economies, GCC countries, and African nations

The report provides a region-wise breakdown of market share, consumption trends, and future prospects.

Detailed of High Heat Resistance Phenolic Molding Compounds Market Segmentation -

The report offers great insights into important segments of the global High Heat Resistance Phenolic Molding Compounds market while concentrating on their CAGR, market size, market share, and future growth potential. The global High Heat Resistance Phenolic Molding Compounds market is mainly segmented according to type of product, application, and region. Each segment in these categories is extensively researched to become familiar with their growth prospects and key trends. Segmental analysis is highly important to identify key growth pockets of a global market. The report provides specific information on the market growth and demand of different products and applications to help players to focus on profitable areas of the global High Heat Resistance Phenolic Molding Compounds market.

Segmentation By Type :-

Compression Molding Compound

Injection Molding Compound

Segmentation By Application -

Automotive Components

Electrical and Eelectronic Equipment

Others

This segmentation helps identify high-growth opportunities and niche segments for investors and businesses.

Request for Pre-Order Enquiry On This Exclusive Report @ https://qyresearch.in/pre-order-inquiry/chemical-material-high-heat-resistance-phenolic-molding-compounds-global-market-share-and-ranking-overall-sales-and-demand-forecast-2025-2031

Why This Report is a Must-Have -

ᗒ Historical Analysis (2020-2024) & Forecasts (2025-2031): Gain a clear understanding of market trends and future growth potential.

ᗒ Comprehensive Market Segmentation: Detailed breakdown by Type, Application, and Region to identify lucrative opportunities.

ᗒ Competitive Landscape: Insights into key players, their market share, and strategic developments like mergers, acquisitions, and expansion plans.

ᗒ Drivers & Restraints: Understand the factors shaping the market's growth and the challenges that could impact your strategy.

ᗒ Expert Opinions & Market Dynamics: Benefit from expert analysis to navigate market risks and capitalize on emerging trends.

High Heat Resistance Phenolic Molding Compounds Market Report Objectives -

(1) Analyzing the size of the global High Heat Resistance Phenolic Molding Compounds market on the basis of value and volume

(2) Accurately calculating the market shares, consumption, and other vital factors of different segments of the global High Heat Resistance Phenolic Molding Compounds market

(3) Exploring key dynamics of the global High Heat Resistance Phenolic Molding Compounds market

(4) Highlighting important trends of the global High Heat Resistance Phenolic Molding Compounds market in terms of production, revenue, and sales

(5) Deeply profiling top players of the global High Heat Resistance Phenolic Molding Compounds market and showing how they compete in the industry

(6) Studying manufacturing processes and costs, product pricing, and various trends related to them

(7) Showing the performance of different regions and countries in the global High Heat Resistance Phenolic Molding Compounds market

(8) Forecasting the market size and share of all segments, regions, and the global market.

Important Questions Answered included in the Report:-

(A) What is the market size and growth rate of the global and regional market by various segments?

(B) What is the market size and growth rate of the market for selective Countries?

(C) Which region or sub-segment is expected to drive the market in the forecast period?

(D) What factors are estimated to drive and restrain the market growth?

(E) What are the key technology and market trends shaping the market?

(F) what are the key opportunity in the market?

(G) Who are the leading manufacturers operating in the global High Heat Resistance Phenolic Molding Compounds market?

(H) Which key player accounted for the highest market share?

(I) What are the growth opportunities for the new entrants in the global High Heat Resistance Phenolic Molding Compounds market?

Table of Contents - Major Key Points:

1 Market Overview

1.1 High Heat Resistance Phenolic Molding Compounds Product Introduction

1.2 Global High Heat Resistance Phenolic Molding Compounds Market Size Forecast

1.2.1 Global High Heat Resistance Phenolic Molding Compounds Sales Value (2020-2031)

1.2.2 Global High Heat Resistance Phenolic Molding Compounds Sales Volume (2020-2031)

1.2.3 Global High Heat Resistance Phenolic Molding Compounds Sales Price (2020-2031)

1.3 High Heat Resistance Phenolic Molding Compounds Market Trends & Drivers

1.3.1 High Heat Resistance Phenolic Molding Compounds Industry Trends

1.3.2 High Heat Resistance Phenolic Molding Compounds Market Drivers & Opportunity

1.3.3 High Heat Resistance Phenolic Molding Compounds Market Challenges

1.3.4 High Heat Resistance Phenolic Molding Compounds Market Restraints

1.4 Assumptions and Limitations

1.5 Study Objectives

1.6 Years Considered

2 Competitive Analysis by Company

2.1 Global High Heat Resistance Phenolic Molding Compounds Players Revenue Ranking (2024)

2.2 Global High Heat Resistance Phenolic Molding Compounds Revenue by Company (2020-2025)

2.3 Global High Heat Resistance Phenolic Molding Compounds Players Sales Volume Ranking (2024)

2.4 Global High Heat Resistance Phenolic Molding Compounds Sales Volume by Company Players (2020-2025)

2.5 Global High Heat Resistance Phenolic Molding Compounds Average Price by Company (2020-2025)

2.6 Key Manufacturers High Heat Resistance Phenolic Molding Compounds Manufacturing Base and Headquarters

2.7 Key Manufacturers High Heat Resistance Phenolic Molding Compounds Product Offered

2.8 Key Manufacturers Time to Begin Mass Production of High Heat Resistance Phenolic Molding Compounds

2.9 High Heat Resistance Phenolic Molding Compounds Market Competitive Analysis

2.9.1 High Heat Resistance Phenolic Molding Compounds Market Concentration Rate (2020-2025)

2.9.2 Global 5 and 10 Largest Manufacturers by High Heat Resistance Phenolic Molding Compounds Revenue in 2024

2.9.3 Global Top Manufacturers by Company Type (Tier 1, Tier 2, and Tier 3) & (based on the Revenue in High Heat Resistance Phenolic Molding Compounds as of 2024)

2.10 Mergers & Acquisitions, Expansion

3 Segmentation by Type

3.1 Introduction by Type

3.1.1 Compression Molding Compound

3.1.2 Injection Molding Compound

3.2 Global High Heat Resistance Phenolic Molding Compounds Sales Value by Type

3.2.1 Global High Heat Resistance Phenolic Molding Compounds Sales Value by Type (2020 VS 2024 VS 2031)

3.2.2 Global High Heat Resistance Phenolic Molding Compounds Sales Value, by Type (2020-2031)

3.2.3 Global High Heat Resistance Phenolic Molding Compounds Sales Value, by Type (%) (2020-2031)

3.3 Global High Heat Resistance Phenolic Molding Compounds Sales Volume by Type

3.3.1 Global High Heat Resistance Phenolic Molding Compounds Sales Volume by Type (2020 VS 2024 VS 2031)

3.3.2 Global High Heat Resistance Phenolic Molding Compounds Sales Volume, by Type (2020-2031)

3.3.3 Global High Heat Resistance Phenolic Molding Compounds Sales Volume, by Type (%) (2020-2031)

3.4 Global High Heat Resistance Phenolic Molding Compounds Average Price by Type (2020-2031)

4 Segmentation by Application

4.1 Introduction by Application

4.1.1 Automotive Components

4.1.2 Electrical and Eelectronic Equipment

4.1.3 Others

4.2 Global High Heat Resistance Phenolic Molding Compounds Sales Value by Application

4.2.1 Global High Heat Resistance Phenolic Molding Compounds Sales Value by Application (2020 VS 2024 VS 2031)

4.2.2 Global High Heat Resistance Phenolic Molding Compounds Sales Value, by Application (2020-2031)

4.2.3 Global High Heat Resistance Phenolic Molding Compounds Sales Value, by Application (%) (2020-2031)

4.3 Global High Heat Resistance Phenolic Molding Compounds Sales Volume by Application

4.3.1 Global High Heat Resistance Phenolic Molding Compounds Sales Volume by Application (2020 VS 2024 VS 2031)

4.3.2 Global High Heat Resistance Phenolic Molding Compounds Sales Volume, by Application (2020-2031)

4.3.3 Global High Heat Resistance Phenolic Molding Compounds Sales Volume, by Application (%) (2020-2031)

4.4 Global High Heat Resistance Phenolic Molding Compounds Average Price by Application (2020-2031)

5 Segmentation by Region

5.1 Global High Heat Resistance Phenolic Molding Compounds Sales Value by Region

5.1.1 Global High Heat Resistance Phenolic Molding Compounds Sales Value by Region: 2020 VS 2024 VS 2031

5.1.2 Global High Heat Resistance Phenolic Molding Compounds Sales Value by Region (2020-2025)

5.1.3 Global High Heat Resistance Phenolic Molding Compounds Sales Value by Region (2026-2031)

5.1.4 Global High Heat Resistance Phenolic Molding Compounds Sales Value by Region (%), (2020-2031)

5.2 Global High Heat Resistance Phenolic Molding Compounds Sales Volume by Region

5.2.1 Global High Heat Resistance Phenolic Molding Compounds Sales Volume by Region: 2020 VS 2024 VS 2031

5.2.2 Global High Heat Resistance Phenolic Molding Compounds Sales Volume by Region (2020-2025)

5.2.3 Global High Heat Resistance Phenolic Molding Compounds Sales Volume by Region (2026-2031)

5.2.4 Global High Heat Resistance Phenolic Molding Compounds Sales Volume by Region (%), (2020-2031)

5.3 Global High Heat Resistance Phenolic Molding Compounds Average Price by Region (2020-2031)

5.4 North America

5.4.1 North America High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

5.4.2 North America High Heat Resistance Phenolic Molding Compounds Sales Value by Country (%), 2024 VS 2031

5.5 Europe

5.5.1 Europe High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

5.5.2 Europe High Heat Resistance Phenolic Molding Compounds Sales Value by Country (%), 2024 VS 2031

5.6 Asia Pacific

5.6.1 Asia Pacific High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

5.6.2 Asia Pacific High Heat Resistance Phenolic Molding Compounds Sales Value by Region (%), 2024 VS 2031

5.7 South America

5.7.1 South America High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

5.7.2 South America High Heat Resistance Phenolic Molding Compounds Sales Value by Country (%), 2024 VS 2031

5.8 Middle East & Africa

5.8.1 Middle East & Africa High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

5.8.2 Middle East & Africa High Heat Resistance Phenolic Molding Compounds Sales Value by Country (%), 2024 VS 2031

6 Segmentation by Key Countries/Regions

6.1 Key Countries/Regions High Heat Resistance Phenolic Molding Compounds Sales Value Growth Trends, 2020 VS 2024 VS 2031

6.2 Key Countries/Regions High Heat Resistance Phenolic Molding Compounds Sales Value and Sales Volume

6.2.1 Key Countries/Regions High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

6.2.2 Key Countries/Regions High Heat Resistance Phenolic Molding Compounds Sales Volume, 2020-2031

6.3 United States

6.3.1 United States High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

6.3.2 United States High Heat Resistance Phenolic Molding Compounds Sales Value by Type (%), 2024 VS 2031

6.3.3 United States High Heat Resistance Phenolic Molding Compounds Sales Value by Application, 2024 VS 2031

6.4 Europe

6.4.1 Europe High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

6.4.2 Europe High Heat Resistance Phenolic Molding Compounds Sales Value by Type (%), 2024 VS 2031

6.4.3 Europe High Heat Resistance Phenolic Molding Compounds Sales Value by Application, 2024 VS 2031

6.5 China

6.5.1 China High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

6.5.2 China High Heat Resistance Phenolic Molding Compounds Sales Value by Type (%), 2024 VS 2031

6.5.3 China High Heat Resistance Phenolic Molding Compounds Sales Value by Application, 2024 VS 2031

6.6 Japan

6.6.1 Japan High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

6.6.2 Japan High Heat Resistance Phenolic Molding Compounds Sales Value by Type (%), 2024 VS 2031

6.6.3 Japan High Heat Resistance Phenolic Molding Compounds Sales Value by Application, 2024 VS 2031

6.7 South Korea

6.7.1 South Korea High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

6.7.2 South Korea High Heat Resistance Phenolic Molding Compounds Sales Value by Type (%), 2024 VS 2031

6.7.3 South Korea High Heat Resistance Phenolic Molding Compounds Sales Value by Application, 2024 VS 2031

6.8 Southeast Asia

6.8.1 Southeast Asia High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

6.8.2 Southeast Asia High Heat Resistance Phenolic Molding Compounds Sales Value by Type (%), 2024 VS 2031

6.8.3 Southeast Asia High Heat Resistance Phenolic Molding Compounds Sales Value by Application, 2024 VS 2031

6.9 India

6.9.1 India High Heat Resistance Phenolic Molding Compounds Sales Value, 2020-2031

6.9.2 India High Heat Resistance Phenolic Molding Compounds Sales Value by Type (%), 2024 VS 2031

6.9.3 India High Heat Resistance Phenolic Molding Compounds Sales Value by Application, 2024 VS 2031

7 Company Profiles

7.1 Sumitomo Bakelite

7.1.1 Sumitomo Bakelite Company Information

7.1.2 Sumitomo Bakelite Introduction and Business Overview

7.1.3 Sumitomo Bakelite High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.1.4 Sumitomo Bakelite High Heat Resistance Phenolic Molding Compounds Product Offerings

7.1.5 Sumitomo Bakelite Recent Development

7.2 Panasonic

7.2.1 Panasonic Company Information

7.2.2 Panasonic Introduction and Business Overview

7.2.3 Panasonic High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.2.4 Panasonic High Heat Resistance Phenolic Molding Compounds Product Offerings

7.2.5 Panasonic Recent Development

7.3 Chang Chun Group

7.3.1 Chang Chun Group Company Information

7.3.2 Chang Chun Group Introduction and Business Overview

7.3.3 Chang Chun Group High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.3.4 Chang Chun Group High Heat Resistance Phenolic Molding Compounds Product Offerings

7.3.5 Chang Chun Group Recent Development

7.4 Plenco

7.4.1 Plenco Company Information

7.4.2 Plenco Introduction and Business Overview

7.4.3 Plenco High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.4.4 Plenco High Heat Resistance Phenolic Molding Compounds Product Offerings

7.4.5 Plenco Recent Development

7.5 Hexion

7.5.1 Hexion Company Information

7.5.2 Hexion Introduction and Business Overview

7.5.3 Hexion High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.5.4 Hexion High Heat Resistance Phenolic Molding Compounds Product Offerings

7.5.5 Hexion Recent Development

7.6 Fudow Company

7.6.1 Fudow Company Company Information

7.6.2 Fudow Company Introduction and Business Overview

7.6.3 Fudow Company High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.6.4 Fudow Company High Heat Resistance Phenolic Molding Compounds Product Offerings

7.6.5 Fudow Company Recent Development

7.7 Jiangsu Zhongpeng New Material

7.7.1 Jiangsu Zhongpeng New Material Company Information

7.7.2 Jiangsu Zhongpeng New Material Introduction and Business Overview

7.7.3 Jiangsu Zhongpeng New Material High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.7.4 Jiangsu Zhongpeng New Material High Heat Resistance Phenolic Molding Compounds Product Offerings

7.7.5 Jiangsu Zhongpeng New Material Recent Development

7.8 Wuxi Chuangda Advanced Materials

7.8.1 Wuxi Chuangda Advanced Materials Company Information

7.8.2 Wuxi Chuangda Advanced Materials Introduction and Business Overview

7.8.3 Wuxi Chuangda Advanced Materials High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.8.4 Wuxi Chuangda Advanced Materials High Heat Resistance Phenolic Molding Compounds Product Offerings

7.8.5 Wuxi Chuangda Advanced Materials Recent Development

7.9 Raschig GmbH

7.9.1 Raschig GmbH Company Information

7.9.2 Raschig GmbH Introduction and Business Overview

7.9.3 Raschig GmbH High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.9.4 Raschig GmbH High Heat Resistance Phenolic Molding Compounds Product Offerings

7.9.5 Raschig GmbH Recent Development

7.10 Beijing Sino-tech Electronic Material

7.10.1 Beijing Sino-tech Electronic Material Company Information

7.10.2 Beijing Sino-tech Electronic Material Introduction and Business Overview

7.10.3 Beijing Sino-tech Electronic Material High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.10.4 Beijing Sino-tech Electronic Material High Heat Resistance Phenolic Molding Compounds Product Offerings

7.10.5 Beijing Sino-tech Electronic Material Recent Development

7.11 Taizhou Changxiong Plastic

7.11.1 Taizhou Changxiong Plastic Company Information

7.11.2 Taizhou Changxiong Plastic Introduction and Business Overview

7.11.3 Taizhou Changxiong Plastic High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.11.4 Taizhou Changxiong Plastic High Heat Resistance Phenolic Molding Compounds Product Offerings

7.11.5 Taizhou Changxiong Plastic Recent Development

7.12 Shanghai European-Asian Synthetic Material

7.12.1 Shanghai European-Asian Synthetic Material Company Information

7.12.2 Shanghai European-Asian Synthetic Material Introduction and Business Overview

7.12.3 Shanghai European-Asian Synthetic Material High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.12.4 Shanghai European-Asian Synthetic Material High Heat Resistance Phenolic Molding Compounds Product Offerings

7.12.5 Shanghai European-Asian Synthetic Material Recent Development

7.13 Changshu Southeast Plastic

7.13.1 Changshu Southeast Plastic Company Information

7.13.2 Changshu Southeast Plastic Introduction and Business Overview

7.13.3 Changshu Southeast Plastic High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.13.4 Changshu Southeast Plastic High Heat Resistance Phenolic Molding Compounds Product Offerings

7.13.5 Changshu Southeast Plastic Recent Development

7.14 Sprea Misr

7.14.1 Sprea Misr Company Information

7.14.2 Sprea Misr Introduction and Business Overview

7.14.3 Sprea Misr High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.14.4 Sprea Misr High Heat Resistance Phenolic Molding Compounds Product Offerings

7.14.5 Sprea Misr Recent Development

7.15 Amity Thermosets (P) Ltd

7.15.1 Amity Thermosets (P) Ltd Company Information

7.15.2 Amity Thermosets (P) Ltd Introduction and Business Overview

7.15.3 Amity Thermosets (P) Ltd High Heat Resistance Phenolic Molding Compounds Sales, Revenue, Price and Gross Margin (2020-2025)

7.15.4 Amity Thermosets (P) Ltd High Heat Resistance Phenolic Molding Compounds Product Offerings

7.15.5 Amity Thermosets (P) Ltd Recent Development

8 Industry Chain Analysis

8.1 High Heat Resistance Phenolic Molding Compounds Industrial Chain

8.2 High Heat Resistance Phenolic Molding Compounds Upstream Analysis

8.2.1 Key Raw Materials

8.2.2 Raw Materials Key Suppliers

8.2.3 Manufacturing Cost Structure

8.3 Midstream Analysis

8.4 Downstream Analysis (Customers Analysis)

8.5 Sales Model and Sales Channels

8.5.1 High Heat Resistance Phenolic Molding Compounds Sales Model

8.5.2 Sales Channel

8.5.3 High Heat Resistance Phenolic Molding Compounds Distributors

9 Research Findings and Conclusion

10 Appendix

10.1 Research Methodology

10.1.1 Methodology/Research Approach

10.1.1.1 Research Programs/Design

10.1.1.2 Market Size Estimation

10.1.1.3 Market Breakdown and Data Triangulation

10.1.2 Data Source

10.1.2.1 Secondary Sources

10.1.2.2 Primary Sources

10.2 Author Details

10.3 Disclaimer

About Us:

QYResearch established as a research firm in 2007 and have since grown into a trusted brand amongst many industries. Over the years, we have consistently worked toward delivering high-quality customized solutions for wide range of clients ranging from ICT to healthcare industries. With over 50,000 satisfied clients, spread over 80 countries, we have sincerely strived to deliver the best analytics through exhaustive research methodologies.

Contact Us:

Arshad Shaha | Marketing Executive

QY Research, INC.

315 Work Avenue, Raheja Woods,

Survey No. 222/1, Plot No. 25, 6th Floor,

Kayani Nagar, Yervada, Pune 411006, Maharashtra

Tel: +91-8669986909

Emails - arshad@qyrindia.com

Web - https://www.qyresearch.in

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release High Heat Resistance Phenolic Molding Compounds Market Future Trends and Innovation Opportunities 2025-2031 here

News-ID: 4276168 • Views: …

More Releases from QYResearch.Inc

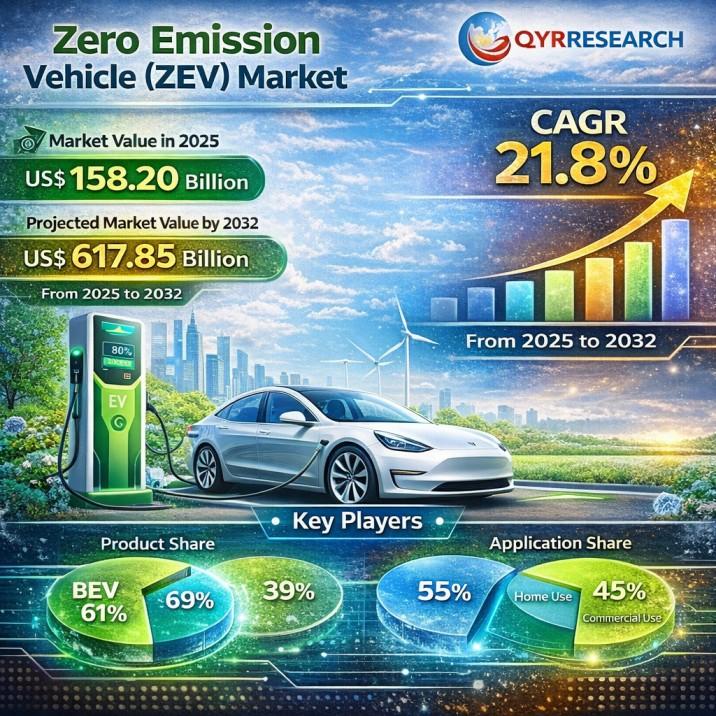

Zero Emission Vehicle (ZEV) Market Size Worth US$ 617.85 Billion by 2032, Growin …

Market Overview and Research Scope -

QY Research Inc., A global market research and consulting firm, has announced the release of its latest 2026 report titled "Zero Emission Vehicle (ZEV) - Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032." The report provides a data-driven analysis of the global Zero Emission Vehicle (ZEV) market, integrating historical insights from 2020-2025 with forward-looking forecasts through 2032. It covers market size, competitive…

Marine Electronics Market to Reach US$ 20.6 Billion by 2032 as Smart Shipping an …

Market Overview and Research Scope -

QY Research Inc., A global market research and consulting firm, has announced the release of its latest 2026 report titled "Marine Electronics - Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032." The report provides a data-driven analysis of the global Marine Electronics market, integrating historical insights from 2020-2025 with forward-looking forecasts through 2032. It covers market size, competitive landscape, demand trends, and…

Dry Etching Equipment Market Rising Demand, Trends, Growth, Competitive And Futu …

Market Overview and Research Scope -

QY Research Inc., A global market research and consulting firm, has announced the release of its latest 2026 report titled "Dry Etching Equipment - Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032." The report provides a data-driven analysis of the global Dry Etching Equipment market, integrating historical insights from 2020-2025 with forward-looking forecasts through 2032. It covers market size, competitive landscape, demand…

Non-Volatile Dual In-Line Memory Module (NVDIMM) Market 2026 : Report, Market Si …

Market Overview and Research Scope -

QY Research Inc., A global market research and consulting firm, has announced the release of its latest 2026 report titled "Non-Volatile Dual In-Line Memory Module (NVDIMM) - Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032." The report provides a data-driven analysis of the global Non-Volatile Dual In-Line Memory Module (NVDIMM) market, integrating historical insights from 2020-2025 with forward-looking forecasts through 2032. It…

More Releases for Molding

Differences Between Flaskless Molding Machines and Flask Molding Machines

Flaskless molding machines [https://www.junengmachinery.com/servo-molding-machine-products/] and flask molding machines are two primary types of equipment used in foundry production for making sand molds (castings molds). Their core distinction lies in whether they use a flask to contain and support the molding sand. This fundamental difference leads to significant variations in their processes, efficiency, cost, and applications.

Key Differences

Core Concept:

Flask Molding Machine: Requires the use of a flask during mold making. A flask…

LSR Molding: Understanding Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) molding is a specialized manufacturing process used to create flexible, durable, and heat-resistant silicone parts. This technique is widely used across industries such as automotive, medical, electronics, and consumer goods. Its ability to produce high-quality parts with precision and consistency makes it a top choice for many manufacturers.

• What Is LSR Molding?

LSR molding, or Liquid Silicone Rubber injection molding (https://www.newtopcustomsilicone.com/capabilities/liquid-silicone-injection-molding/), involves injecting two-component platinum-cured silicone into…

HDPE Blow Molding and Injection Molding Containers Market

Persistence Market Research (PMR) has published a new research report on HDPE blow molding and injection molding containers. The report has been titled "HDPE Blow Molding and Injection Molding Containers Market: Global Industry Analysis 2013-2017 and Forecast 2018-2026." The proliferating demand for HDPE blow molding and injection molding containers is largely from the beverage, chemical & petrochemicals, and pharmaceuticals industries, owing to the barrier properties of HDPE and convenience in…

Sheet Molding Compound and Bulk Molding Compound Market - Growth Prophesy 2025 | …

Global Sheet Molding Compound and Bulk Molding Compound Market: Snapshot

The global market for sheet molding compound and bulk molding compound is expected to advance with the launch of superior quality, lightweight, and more durable bulk molding and sheet molding compounds. By virtue of their higher line throughputs and lower production costs, these compounds are increasingly preferred by several leading manufacturers. As an augmenting number of advanced automobiles and luxury brands…

HDPE Blow Molding and Injection Molding Containers Market 2026

Due to its intrinsic physical and mechanical properties, high density polyethylene (HDPE) is highly used as packaging materials in different industries including food, beverages, pharmaceuticals, cosmetics, homecare, chemicals, and petrochemicals. Urbanization, changing consumer preferences, and expanding middle class have significantly contributed to the rising demand for consumer goods. Increased demand for consumer goods has, in turn, revolutionized the packaging industry, especially plastic packaging.

Polyethylene is most commonly used in the packaging…

Sheet Molding Compound and Bulk Molding Compound Market 2017-2025 : Polynt S.P.A …

Global Sheet Molding Compound and Bulk Molding Compound Market: Snapshot

The global market for sheet molding compound and bulk molding compound is expected to advance with the launch of superior quality, lightweight, and more durable bulk molding and sheet molding compounds. By virtue of their higher line throughputs and lower production costs, these compounds are increasingly preferred by several leading manufacturers. As an augmenting number of advanced automobiles and luxury brands…