Press release

Facing Die Build-Up, Rough Surfaces, and Low Output? Here's the PFAS-Free Way to Solve It

HDPE and MDPE pipes form the backbone of modern water infrastructure - delivering safe, durable, and high-pressure performance.Yet during extrusion, manufacturers often face recurring issues: die build-up, melt fracture, unstable back pressure, and inconsistent surface finish. These problems not only affect pipe appearance but also reduce line speed, increase maintenance downtime, and raise energy costs.

For decades, fluoropolymer-based processing aids such as 3M Trademark Dynamar Trademark PPA have been used to ease these challenges. However, with growing PFAS restrictions worldwide, the pipe industry urgently needs a non-fluorinated, sustainable alternative - one that maintains or exceeds existing performance standards.

Why the Pipes Industry Is Moving Beyond PFAS-Based PPAs

PFAS (Per- and Polyfluoroalkyl Substances) are under growing scrutiny due to their persistence in the environment and potential health risks.According to the EU REACH Regulation and US EPA 2024 Roadmap, PFAS-containing processing aids will face progressive bans or strict reporting requirements.For manufacturers exporting pipes to Europe or North America, compliance is no longer optional - it's a market necessity.

As a result, pipe producers are actively seeking PFAS-free polymer processing aids that can deliver the same extrusion smoothness and stability, without environmental or reputational risk.

Introducing the SILIKE SILIMER Series - A 100% Pure, PFAS-Free, Silicone-Based PPA

Developed by Chengdu SILIKE Technology, the SILIMER Series represents a major breakthrough in extrusion processing aids.

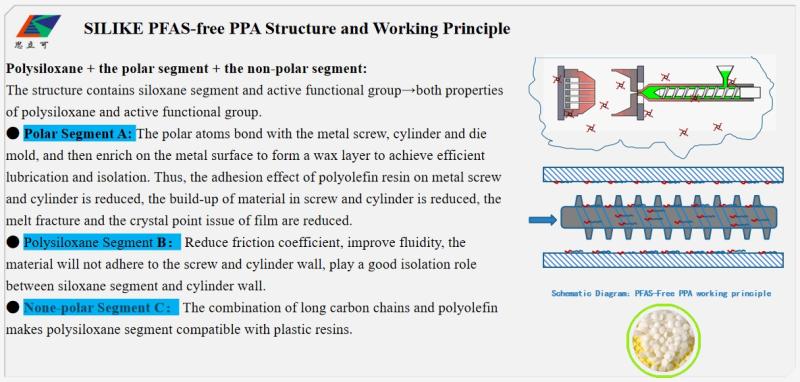

Unlike fluoropolymer PPAs, SILIMER silicon based plastics additives are based on a pure modified copolysiloxane molecular structure, combining the low surface energy of silicone with polar modified groups that actively migrate to metal surfaces.

Once at the die wall, these molecules form a stable lubricating layer, reducing melt friction, stabilizing shear stress, and minimizing die pressure - all without using any fluorine components.

How SILIMER series PFAS-free polymer processing aids (PPA) Works: The Science Behind PFAS-Free Performance

Image: https://www.siliketech.com/uploads/SILIKE-PFAS-FREE-polymer-processing-aids.jpg

Solve Pipe Extrusion Challenges with PFAS-Free PPA Solutions - SILIKE's Fluorine-Free Polymer Additives

Image: https://www.siliketech.com/uploads/Boost-Pipe-Extrusion-Efficiency-with-SILIKE-SILIMER-9400-PFAS-Free-PPA.jpg

SILIMER PFAS-Free PPAs are typically compounded into a masterbatch and added at low dosage levels (500-1000 ppm) to HDPE, MDPE, LLDPE, LDPE, PP, or PERT systems.

Even in small amounts, they provide major processing improvements:

Smoother polymer flow & melt uniformity

Reduced back pressure and torque

Elimination of shark-skin and die drool

Longer cleaning cycles and stable line speed

Higher output and lower energy consumption

Verified Results of Fluorine-Free Plastic Processing Additives [https://www.siliketech.com/pfas-free-solutions-for-eu-ppwr-compliance/] in Pipe Extrusion Trials

Image: https://www.siliketech.com/uploads/SILIKE-PFAS-Free-PPA-Reduced-Back-pressure.jpg

According to customer feedback, their internal test results show that after using SILIMER PFAS-Free PPA, die pressure decreases by 10-20%, extrusion surfaces become smoother and more uniform, line speed increases by 10-15%, energy consumption is reduced by 5-8%, and the equipment cleaning cycle is extended up to three times longer than before.

Non-PFAS additive SILIMER 9400 [https://www.siliketech.com/pfas-free-and-fluorine-free-polymer-processing-aidsppa-silimer-9400-for-polyolefins-film-extrusion-product/]- Tailored for HDPE & MDPE Pipe Extrusion

Within the SILIMER family, SILIMER 9400 stands out as a fluorine-free PPA additive specifically engineered for HDPE and MDPE pipe extrusion lines.

It delivers exceptional lubricity and processing stability under high shear conditions, ensuring cleaner dies, higher throughput, and a superior surface finish - all while being 100% fluorine-free and fully compliant with global PFAS restrictions.

Transitioning to PFAS-free extrusion no longer means compromising performance.

With SILIKE SILIMER Series pfas free ppa, the next-generation silicone-based alternatives to fluoropolymer PPAs/PTFE, manufacturers can now achieve faster throughput, cleaner dies, and full regulatory compliance - all within a sustainable, high-efficiency processing system.

SILIMER PFAS-Free PPA solutions transform HDPE and MDPE pipe production by addressing processing challenges and surface defects - including the elimination of melt fracture (sharkskin), enhanced melt flow, and improved surface smoothness for high-quality finished pipes.

Contact SILIKE today to optimize your polymer processing and enhance the performance and aesthetics of your pipe extrusion systems.

Also, you can reach out directly at amy.wang@silike.cn or visit www.siliketech.com [https://www.siliketech.com/contact-us/]to explore our eco-friendly pipe additive solutions.

Media Contact

Company Name: Chengdu Silike Technology Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=facing-die-buildup-rough-surfaces-and-low-output-heres-the-pfasfree-way-to-solve-it]

Country: China

Website: https://www.siliketech.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Facing Die Build-Up, Rough Surfaces, and Low Output? Here's the PFAS-Free Way to Solve It here

News-ID: 4274368 • Views: …

More Releases from ABNewswire

Star Voyager Returns for the School Holidays from 22 May - 26 June 2026

Star Voyager returns to Southeast Asia with more sailings from Singapore & Kuala Lumpur (via Port Klang) with popular 2, 3 & 5 Night Cruises from 22 May - 26 June 2026.

Just in time for the school holidays, StarCruises is thrilled to welcome back the Star Voyager from 22 May until 26 June 2026, offering families, couples and friends an exciting, convenient and value-packed round-trip cruise holiday - all departing…

Motor Neuron Disease Treatment Pipeline Shows Strong Momentum as 180+ Pharma Com …

DelveInsight's, "Motor Neuron Disease Pipeline Insight 2025" report provides comprehensive insights about 180+ companies and 200+ pipeline drugs in Motor Neuron Disease pipeline landscape. It covers the Motor Neuron Disease pipeline drug profiles, including clinical and nonclinical stage products. It also covers the Motor Neuron Disease pipeline therapeutics assessment by product type, stage, route of administration, and molecule type. It further highlights the inactive pipeline products in this space.

Download DelveInsight's…

Metastatic Hormone Refractory Prostate Cancer Clinical Trial Pipeline Expands as …

DelveInsight's, "Metastatic Hormone Refractory Prostate Cancer Pipeline Insight 2025" report provides comprehensive insights about 180+ companies and 200+ pipeline drugs in Metastatic Hormone Refractory Prostate Cancer pipeline landscape. It covers the pipeline drug profiles, including clinical and nonclinical stage products. It also covers the therapeutics assessment by product type, stage, route of administration, and molecule type. It further highlights the inactive pipeline products in this space.

Explore our latest breakthroughs in…

Non-Hodgkin's Lymphoma Clinical Trial Pipeline Shows Potential with Active Contr …

DelveInsight's, "Non-Hodgkin Lymphoma Pipeline Insights 2025" report provides comprehensive insights about 180+ companies and 200+ pipeline drugs in Non-Hodgkin Lymphoma pipeline landscape. It covers the Non-Hodgkin's Lymphoma pipeline drug profiles, including clinical and nonclinical stage products. It also covers the Non-Hodgkin's Lymphoma pipeline therapeutics assessment by product type, stage, route of administration, and molecule type. It further highlights the inactive pipeline products in this space.

Dive into DelveInsight's comprehensive report today!…

More Releases for PFAS

PFAS Remediation Market Is Going to Boom |• AquaBlok • Arcadis

Worldwide Market Reports has released a new in-depth research study on the "PFAS Remediation Market," highlighting strong growth potential in the coming years. The report delivers a structured and data-driven analysis of the market landscape, combining robust research methodology, market sizing, validated data modeling, and insights sourced from reliable primary and secondary channels.

The study thoroughly examines key market aspects, including growth drivers, restraints, challenges, emerging opportunities, technological advancements, innovation trends,…

PFAS-Free Synthetic Turf Solutions | Eco-Friendly Artificial Grass and Non-PFAS …

This article delves into the key challenges and difficulties faced by the synthetic turf industry in achieving a "PFAS-free" transition, with a focus on innovative non-PFAS additive solutions designed to offer a sustainable path that balances high performance, safety, and environmental responsibility.

Challenges in Traditional Synthetic Turf Manufacturing | PFAS Risks Performance vs. Safety Dilemma

Traditional synthetic turf often relies on fluorinated polymers to achieve:

- Exceptional UV and weather durability

- Stain and…

Global PFAS-free Membranes Market Outlook Report 2025

Global Info Research's report is a detailed and comprehensive analysis for global PFAS-free Membranes market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the PFAS-free Membranes market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of…

PFAS-free Polymer Membranes Market Demand Analysis Report 2025

Global Info Research announces the release of the report "Global PFAS-free Polymer Membranes Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031". This report provides a detailed overview of the PFAS-free Polymer Membranes market scenario, including a thorough analysis of the PFAS-free Polymer Membranes market size, sales quantity, average price, revenue, gross margin and market share.The PFAS-free Polymer Membranes report provides an in-depth analysis of the competitive landscape,…

PFAS-free Polymer Processing Aids (PFAS-Free PPA Additives), a solution to the p …

In the plastic processing industry, die build-up is a common problem that can lead to surface defects in products, affecting product quality and production efficiency.

Die build-up refers to the accumulation of material at the outlet of the mold during plastic processing, forming deposits that are difficult to remove. This phenomenon usually occurs in injection molding, extrusion and other processes, especially in the processing of high viscosity and high melting point…

PFAS: What they are & how to avoid them

These "Forever Chemicals" have existed for what seems like forever, but they've just recently begun making headlines. Here's what you need to know about these troubling compounds.

In the world we live in today, the alphabet soup of acronyms for both good and bad substances can make your brain feel like mush. But there's one that you've probably seen popping up more and more. And it's one worth remembering.

PFAS, or "Forever…