Press release

Aerospace Composites Market Key Players - Share Consolidation Trends & Capital Growth Signals

The aerospace composites market is emerging as a cornerstone of next-generation aircraft engineering, driven by the demand for lighter, stronger, and more fuel-efficient airframes. As the aviation industry transitions toward sustainability, electrification, and advanced manufacturing, aerospace composites - primarily carbon fiber-reinforced polymers (CFRP), aramid fibers, and thermoplastic composites - are redefining material science in aerospace production.From commercial aircraft OEMs and defense contractors to space exploration firms, the industry is witnessing a paradigm shift toward composite-driven innovation. With government-backed research initiatives, rising aircraft fleet modernization, and demand for high-performance lightweight materials, the aerospace composites ecosystem is expanding its technological and investment frontiers.

This article explores the competitive hierarchy, capability strengths, and investment signals defining the aerospace composites landscape through 2035.

➤ Request Free Sample PDF Report @ https://www.researchnester.com/sample-request-3822

Top Companies & Their Strategies

1. Hexcel Corporation - Hexcel is one of the foremost leaders in advanced composites, specializing in carbon fiber, resin systems, and honeycomb materials. The company's strategy focuses on deep integration across aerospace OEM supply chains, supported by robust partnerships with Airbus, Boeing, and defense manufacturers. Its recent innovation in thermoplastic composites enhances manufacturability and recyclability, aligning with aerospace sustainability trends. Hexcel's extensive R&D investments and global production footprint across North America and Europe strengthen its position as a critical materials provider for commercial and military aircraft programs.

2. Toray Industries, Inc. - Toray Industries commands a leading share of the global carbon fiber market, offering a broad portfolio of thermoset and thermoplastic composites tailored for aerospace use. The company's strategy centers on continuous capacity expansion, vertical integration, and partnerships with aircraft OEMs for next-generation aircraft programs. Its development of the TORAYCA® T1100 carbon fiber offers superior tensile strength and stiffness, setting benchmarks in lightweight structural applications. Toray's presence across Asia, the U.S., and Europe provides supply chain resilience and scalability for major aircraft manufacturers.

3. Solvay S.A. - Solvay plays a pivotal role in high-performance polymers and structural composites for aerospace applications. The company's strategy emphasizes sustainable innovation through its Thermoplastic Composites (TPC) and prepreg solutions, which deliver superior strength-to-weight ratios and lower energy use in manufacturing. Solvay's "One Planet" sustainability initiative integrates circular chemistry into its aerospace material portfolio, addressing the environmental imperatives of modern aviation. Its collaboration with OEMs and Tier-1 suppliers positions Solvay as a technology-driven sustainability partner in the aerospace composites domain.

4. SGL Carbon SE - SGL Carbon specializes in carbon and graphite-based materials, supporting structural applications across aerospace and space systems. Its strategic focus lies in precision carbon composites for fuselage, interior, and propulsion components. The company is expanding its thermoplastic composite capacity to serve the emerging urban air mobility (UAM) and unmanned aerial vehicle (UAV) sectors. SGL's engineering expertise, combined with a strong European manufacturing base, provides a strategic advantage in meeting evolving lightweighting and performance needs.

➤ Get deeper insights into competitive positioning and strategic benchmarking: Download our sample Aerospace Composites Market report here → https://www.researchnester.com/sample-request-3822

5. Teijin Limited - Teijin's aerospace strategy revolves around material innovation, including advanced carbon fiber and thermoplastic resins used in high-stress aircraft components. The company's Tenax® carbon fiber and thermoplastic unidirectional tapes are widely adopted by leading aerospace OEMs. Teijin's acquisition of Continental Structural Plastics strengthened its downstream capabilities in composite component manufacturing. Its R&D-driven approach and sustainability-focused operations position Teijin as a global innovation leader in lightweight composite structures.

6. Owens Corning - Owens Corning leverages its expertise in glass fiber and structural reinforcement to cater to aerospace and defense applications. The company's composite materials enhance durability and impact resistance while minimizing overall aircraft weight. Owens Corning's strategy focuses on high-performance hybrid composites that blend glass and carbon fibers, optimizing strength and cost efficiency. Its global production and materials science excellence allow it to serve a broad customer base across commercial, defense, and space segments.

7. Spirit AeroSystems Holdings, Inc. - As one of the world's largest independent aerospace component manufacturers, Spirit AeroSystems integrates composite fabrication into critical fuselage, nacelle, and wing structures. The company's strategy emphasizes automation in composite layup and assembly, improving production throughput and precision. Spirit's partnerships with Boeing and Airbus, along with investments in advanced resin transfer molding (RTM) and thermoplastic integration, reinforce its leadership in high-volume aerospace composites manufacturing.

8. Mitsubishi Chemical Group - Mitsubishi Chemical continues to strengthen its position through composite innovations designed for next-generation mobility platforms. Its strategy focuses on developing high-performance prepregs and carbon fiber materials optimized for aircraft weight reduction and structural endurance. The company's acquisition-driven growth and partnerships with aerospace suppliers enhance its vertical integration and global market presence.

➤ View our Aerospace Composites Market Report Overview here: https://www.researchnester.com/reports/aerospace-composites-market/3822

SWOT Analysis

Strengths - Leading players in the aerospace composites market possess deep expertise in advanced materials engineering, vertically integrated production systems, and long-term partnerships with OEMs like Boeing, Airbus, and Lockheed Martin. Their R&D capabilities drive continuous innovation in carbon fiber performance, thermoplastic composites, and sustainable resins. Global manufacturing presence and collaborative research programs strengthen resilience and supply chain reliability.

Weaknesses - The sector remains capital-intensive, with high R&D costs and complex manufacturing processes limiting scalability for smaller entrants. Supply chain constraints for carbon fiber precursors and dependence on specialized equipment hinder cost optimization. Moreover, the recyclability of thermoset composites remains a challenge, creating end-of-life management issues that could slow the transition to circular aerospace manufacturing.

Opportunities - Rising demand for fuel-efficient, low-emission aircraft and electric air mobility platforms presents vast growth opportunities for composite integration. The expansion of space exploration, drone manufacturing, and defense modernization programs is further accelerating composite adoption. Investment in automation, additive manufacturing, and AI-driven materials modeling is opening new avenues for cost reduction and design optimization. Government-backed initiatives promoting sustainable aviation fuel (SAF) and green aircraft materials are catalyzing long-term industry transformation.

Threats - Volatility in raw material prices, particularly acrylonitrile and carbon fiber precursors, poses risks to profitability. Strict certification standards and long validation cycles delay the commercialization of new composite materials. Competitive pressures from metallic alternatives and emerging nanomaterials could challenge traditional composite applications. Additionally, geopolitical tensions and trade restrictions may disrupt global aerospace supply chains and impact investment flows.

➤ Interested in a customized SWOT for your target competitor? Request your tailored assessment → https://www.researchnester.com/sample-request-3822

Investment Opportunities & Trends

1. Advanced Composite Manufacturing & Automation: Investors are increasingly funding automation in composite fabrication, including robotic layup systems, resin infusion technologies, and digital twins for quality assurance. Companies focusing on automated thermoplastic processing and out-of-autoclave (OOA) manufacturing are gaining traction, particularly for cost-efficient high-volume aerospace production.

2. Sustainable Materials & Recycling Technologies: The push toward circular aviation is driving investments in recyclable thermoplastic composites and eco-friendly resin systems. Startups developing carbon fiber recycling and closed-loop composite recovery systems are attracting venture funding. Europe and North America remain at the forefront of policy-backed initiatives for sustainable aerospace materials.

3. Defense & Space Sector Integration: Defense modernization programs are creating demand for high-temperature-resistant composites for military jets, helicopters, and space vehicles. Space exploration firms and satellite manufacturers are investing in ultra-light composites to improve payload efficiency and reduce launch costs. Strategic partnerships between aerospace OEMs and materials innovators are accelerating technology adoption in these domains.

4. M&A and Strategic Collaborations: The aerospace composites sector is witnessing increased merger and acquisition activity as major chemical and materials firms consolidate capabilities. Notable examples include cross-industry partnerships between composite manufacturers and aerospace engineering companies for integrated design-to-production models. Vertical integration continues to be a key strategy for securing long-term OEM contracts and ensuring supply chain stability.

5. Regional Expansion Hotspots: Asia-Pacific is emerging as a critical investment hub, with Japan, China, and India advancing domestic composite manufacturing capabilities. Europe remains a leader in sustainability-driven innovation, while North America's strong defense and space ecosystems ensure consistent capital inflows. Middle Eastern and African markets are beginning to adopt composite materials for regional aircraft and UAV development programs.

Notable Developments in the Last 12 Months

• Sustainability Integration: Several aerospace suppliers introduced bio-based resin systems and recyclable carbon fiber technologies aligned with sustainable aviation initiatives.

• Strategic Partnerships: Major collaborations were announced between composite producers and aircraft OEMs for developing lightweight next-gen airframes.

• Automation Adoption: Multiple aerospace manufacturers deployed automated fiber placement (AFP) and digital inspection systems to boost production efficiency.

• Material Breakthroughs: Introduction of ultra-high-modulus carbon fibers and thermoplastic prepregs optimized for hybrid-electric and hydrogen-powered aircraft.

• Defense & Space Expansion: Increased utilization of composites in hypersonic systems and reusable launch vehicles across the U.S. and Europe.

➤ Request Free Sample PDF Report @ https://www.researchnester.com/sample-request-3822

Contact Data

AJ Daniel

Corporate Sales, USA

Research Nester

77 Water Street 8th Floor, New York, 10005

Email: info@researchnester.com

USA Phone: +1 646 586 9123

Europe Phone: +44 203 608 5919

About Research Nester

Research Nester is a one-stop service provider with a client base in more than 50 countries, leading in strategic market research and consulting with an unbiased and unparalleled approach towards helping global industrial players, conglomerates and executives for their future investment while avoiding forthcoming uncertainties. With an out-of-the-box mindset to produce statistical and analytical market research reports, we provide strategic consulting so that our clients can make wise business decisions with clarity while strategizing and planning for their forthcoming needs and succeed in achieving their future endeavors. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aerospace Composites Market Key Players - Share Consolidation Trends & Capital Growth Signals here

News-ID: 4269431 • Views: …

More Releases from Research Nester Pvt Ltd

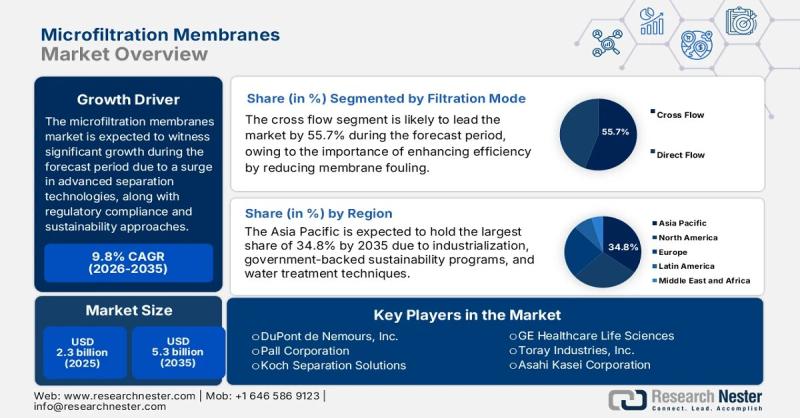

Microfiltration Membranes Market size to reach $5.3Billion by 2035 | Key players …

Market Outlook and Forecast

The microfiltration membranes market size reached USD 2.3 billion in 2025 and is projected to expand to USD 5.3 billion by 2035, reflecting strong industry fundamentals and sustained adoption across diverse end-use industries. The market is expected to grow at a compound annual growth rate (CAGR) of 9.8% between 2026 and 2035, driven by industrial modernization, environmental regulations, and technological innovation.

➤ Request Free Sample PDF Report @…

Top Companies in Food Grade Alcohol Market - Benchmarking Performance & Future V …

The food grade alcohol market is shaped by multinational ingredient producers, regional distillation leaders, and specialized ethanol processors. Competitive positioning is largely determined by feedstock access, regulatory compliance, supply chain resilience, and product customization for food and beverage applications.

➤ Request Free Sample PDF Report @ https://www.researchnester.com/sample-request-8307

Top Companies & Their Strategies

Archer Daniels Midland Company (ADM)

ADM remains one of the most influential players in the Food Grade Alcohol Market due to…

Energy Harvesting System Market Dominance: Top Companies Strengthening Share & I …

The energy harvesting system market is rapidly evolving as industries seek sustainable, maintenance-free power solutions for IoT devices, wireless sensor networks, industrial automation, healthcare wearables, and smart infrastructure. Energy harvesting systems convert ambient energy sources - including solar, thermal, vibration, and radio frequency (RF) - into usable electrical power.

As the global transition toward energy efficiency and decentralized power accelerates, the competitive landscape within the energy harvesting system market is intensifying.…

Luxury Hotel Market Players - Competitive Positioning, Strategic Strengths & Inv …

The Luxury Hotel Market is undergoing structural transformation as global travelers increasingly prioritize curated experiences, sustainability, and digital-first service models. No longer defined solely by opulence, the luxury hotel market now revolves around personalization, wellness integration, brand storytelling, and technological innovation. Leading hospitality companies are repositioning portfolios, expanding into high-growth destinations, and investing in asset-light models to strengthen competitive positioning.

This strategic analysis explores the top companies shaping the luxury hotel…

More Releases for OEM

OEM Partnership Guide: Working with a Touch-free Automatic Kitchen Garbage Can O …

With increasing global demand for smart home solutions, Sinoware International Ltd, a top provider in household products industry, is pleased to unveil expanded OEM partnership initiatives.

Sinoware has established itself in Jiangmen--China's premier stainless steel industry zone--as an indispensable touch-free automatic kitchen garbage can OEM manufacturer for global brands seeking to incorporate high-tech sanitation solutions into their portfolios.

By combining their decades-old tradition of metal craftsmanship with cutting-edge infrared and…

Revolutionizing OEM Coatings With Sustainable Solutions Trend: A Crucial Influen …

Which drivers are expected to have the greatest impact on the over the oem coatings market's growth?

The surge in requirements from final consumer industries is forecasted to boost the expansion of the OEM coatings market. These coatings, referred to as OEM, are utilized during the integration of other firms' products into the substrate process or application. They prove to be beneficial for a variety of end-user sectors, including automotive and…

OEM Technology Partnerships Launches Brokerage Specializing in 100+ OEM Technolo …

San Francisco, California, USA - February 13, 2025 - OEM Technology Partnerships is thrilled to announce the launch of its specialized brokerage focused on connecting businesses with a comprehensive portfolio of over 100 Original Equipment Manufacturer (OEM) technologies. This new venture is poised to revolutionize how companies access and implement cutting-edge solutions across diverse industries.

Leveraging deep industry expertise and a vast network of OEM partners, OEM Technology Partnerships offers a…

OEM or ODM Watches? What's the Difference?

When searching for a watch manufacturer for your store or watch brand, you may come across the terms OEM and ODM. But do you truly understand the difference between them? In this article, we will delve into the distinctions between OEM and ODM watches to help you better grasp and choose the manufacturing service that suits your needs.

Image: https://www.naviforce.com/uploads/15a6ba3911.png

What's OEM / ODM Watches [https://www.naviforce.com/products/]

OEM (Original Equipment Manufacturer) watches are produced…

OEM Partnership with Extreme Networks

ComputerVault announces an OEM partnership with Extreme Networks and has certified its switches for use with ComputerVault enterprise software to deliver virtual desktop infrastructure (VDI).

Extreme Networks industry leading switches deliver ComputerVault Virtual Desktops at faster than PC speeds in the LAN and WAN.

“ComputerVault is very excited to work with Extreme Networks. Not only are their switches very reliable, but their exceptional performance guarantees a great user experience”, said Marc…

Humidity Measurement Module for OEM Applications

The EE1900 humidity module from E+E Elektronik is optimised for the measurement of relative humidity (RH) or dew point temperature (Td) in climate and test chambers. With outstanding temperature compensation across the working range from -70 °C to 180 °C (-94 °F to 356 °F) and the choice of stainless steel and plastic probes, the module is suitable for a wide range of applications.

High Accuracy in Harsh Environment

The excellent…