Press release

Liquid Silicone Rubber Market Analysis, Applications, and Competitive Landscape Forecast 2035

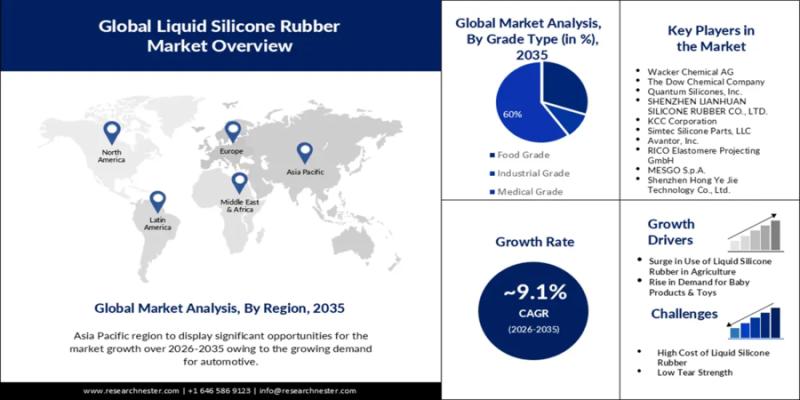

Market Outlook and ForecastThe liquid silicon rubber market is on a transformative path, gaining traction across a wide range of applications due to its superior material properties, versatility, and durability. Valued at USD 3.16 billion in 2025, the market is projected to reach USD 7.55 billion by 2035, expanding at a CAGR of 9.1% during the forecast period (2026-2035). The rising demand for lightweight, biocompatible, and heat-resistant materials in sectors such as medical devices, automotive components, electronics, and consumer goods is propelling market growth.

The medical industry continues to be one of the largest consumers of LSR, leveraging the material for catheters, seals, valves, and wearable medical devices due to its exceptional flexibility, chemical inertness, and sterilization compatibility. Similarly, in the automotive sector, liquid silicone rubber is becoming integral to sealing systems, sensor covers, and lighting components as electric vehicle production surges globally.

Growing emphasis on performance efficiency and design flexibility is driving the adoption of LSR-based components in industrial machinery and electrical applications. Moreover, ongoing research into hybrid silicone formulations and advanced injection molding processes is enabling manufacturers to expand LSR's use into emerging fields such as soft robotics, smart sensors, and next-generation medical wearables.

➤Request Free Sample PDF Report @ https://www.researchnester.com/sample-request-5168

Regional Performance Highlights

Asia Pacific is expected to account for the highest market share of about 30% during the forecast period, supported by robust manufacturing activity, expanding automotive production, and a thriving healthcare sector. China, Japan, and South Korea are among the most significant contributors, driven by investments in silicone production capacity and increasing adoption of automation technologies.

Europe also represents a strong growth hub, driven by stringent regulatory standards, a focus on sustainable materials, and the expansion of medical device manufacturing. Germany, the UK, and France are leading countries emphasizing high-performance silicone use in automotive and electronics industries. The region's well-established chemical manufacturing base and demand for energy-efficient solutions are further fueling LSR adoption.

➤Gain access to expanded insights on competitive strategies, market size, and regional analysis. View our Liquid Silicone Rubber Market Report Overview here: https://www.researchnester.com/reports/liquid-silicone-rubber-lsr-market/5168

Market Segmentation

The Grade Type segment of the Liquid Silicone Rubber Market is divided into industrial grade, medical grade, and food grade. Medical grade LSR continues to witness strong demand, primarily driven by the rising adoption of minimally invasive medical devices and wearables. Industrial-grade LSR is utilized in sectors like automotive and electronics due to its superior weather resistance and electrical insulation.

Under the Processing Techniques segment, liquid injection molding (LIM) dominates, owing to its precision, high production efficiency, and capability to produce complex geometries. Other methods such as extrusion and 3D printing are gaining momentum as industries adopt flexible and customized manufacturing techniques. The advancement of LIM systems integrated with automation and robotics has further optimized LSR production cycles, enhancing scalability and reducing waste.

➤Discover how the Liquid Silicone Rubber Market is evolving globally - access your free sample report → https://www.researchnester.com/sample-request-5168

Top Market Trends

1. Rising Adoption in the Medical and Healthcare Industry

The use of LSR in healthcare applications has surged due to its excellent biocompatibility and ability to withstand sterilization processes. From surgical implants to wearable health monitors, the demand for LSR is driven by innovations in medical device design. The pandemic accelerated the integration of silicone components in diagnostic and respiratory devices, highlighting LSR's importance in healthcare resilience.

2. Advancements in Injection Molding and Processing Technologies

Manufacturers are investing heavily in automated injection molding systems to enhance precision and scalability. Smart manufacturing technologies, including digital mold design and automated material handling, are enabling rapid customization and cost efficiency. Companies are increasingly focusing on closed-loop production systems that minimize material waste and energy consumption, supporting both profitability and sustainability.

3. Sustainability and Circular Economy Integration

Sustainability is emerging as a central theme across the silicone industry. Market players are exploring bio-based and recyclable silicone materials to address growing environmental concerns. Additionally, companies are improving energy-efficient production methods and introducing eco-friendly catalysts to align with global climate targets. These initiatives are expected to reshape supply chains and drive innovation in green material science.

➤Stay ahead of the curve with the latest Liquid Silicone Rubber Market trends. Claim your sample report → https://www.researchnester.com/sample-request-5168

Recent Company Developments

1. Wacker Chemie AG expanded its LSR production capacity in China to meet growing regional demand from the medical and automotive industries, introducing new formulations with enhanced flowability and curing speed.

2. Dow Inc. launched a new line of high-consistency and liquid silicone rubbers designed for precision molding and healthcare applications, emphasizing material purity and durability.

3. Shin-Etsu Chemical Co., Ltd. announced investments in facility upgrades and R&D initiatives focused on high-transparency LSR for optical and wearable technologies.

4. Momentive Performance Materials Inc. entered into strategic collaborations to enhance the supply of LSR for electric vehicle components, emphasizing advanced material performance under high-voltage conditions.

5. Elkem ASA strengthened its sustainability profile by introducing bio-based silicone rubber grades, reinforcing its commitment to environmental responsibility and innovation.

➤Request Free Sample PDF Report @ https://www.researchnester.com/sample-request-5168

Related News

https://www.linkedin.com/pulse/how-microgrids-transforming-future-energy-management-zvyhe

https://www.linkedin.com/pulse/can-building-integrated-photovoltaics-bipv-replace-conventional-zlrac

Contact Data

AJ Daniel

Corporate Sales, USA

Research Nester

77 Water Street 8th Floor, New York, 10005

Email: info@researchnester.com

USA Phone: +1 646 586 9123

Europe Phone: +44 203 608 5919

About Research Nester

Research Nester is a one-stop service provider with a client base in more than 50 countries, leading in strategic market research and consulting with an unbiased and unparalleled approach towards helping global industrial players, conglomerates and executives for their future investment while avoiding forthcoming uncertainties. With an out-of-the-box mindset to produce statistical and analytical market research reports, we provide strategic consulting so that our clients can make wise business decisions with clarity while strategizing and planning for their forthcoming needs and succeed in achieving their future endeavors. We believe every business can expand to its new horizon, provided the right guidance at the right time is available through strategic minds.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Liquid Silicone Rubber Market Analysis, Applications, and Competitive Landscape Forecast 2035 here

News-ID: 4269162 • Views: …

More Releases from Research Nester Pvt. Ltd.

Neurorehabilitation Devices Market Dominance: Top Companies Strengthening Share …

The Neurorehabilitation Devices Market is expanding rapidly as healthcare systems prioritize advanced neurological recovery solutions, driven by rising incidences of stroke, spinal cord injuries, Parkinson's disease, and traumatic brain injuries. Technology-led transformation-powered by robotics, virtual reality (VR), wearable sensors, and AI-enabled therapy platforms-is reshaping rehabilitative care and improving patient outcomes. This strategic article explores the leading companies, their competitive strengths, and the latest investment trends influencing the future of neurorehabilitation…

Global Digital Pathology Market: Top Companies, Market Share Rankings & Investme …

The Digital Pathology Market is undergoing a major transformation as technology reshapes diagnostic workflows, improves clinical efficiency, and enables rapid telepathology across global healthcare networks. With the rise of whole slide imaging (WSI), AI-driven pathology platforms, cloud-based informatics, and integrated workflow solutions, leading companies are accelerating innovation and expanding into new geographies. This strategic article analyzes the power players driving the digital pathology ecosystem, their competitive strengths, and emerging investment…

Polydimethylsiloxane Market Key Players - Share Consolidation Trends & Capital G …

The Polydimethylsiloxane (PDMS) market continues to grow as industries seek advanced silicone materials known for their durability, thermal stability, and multifunctional performance. Applications across healthcare, personal care, automotive, construction, and electronics have expanded the relevance of PDMS in modern manufacturing. As competition rises, leading companies are refining strategies focused on innovation, specialty-grade development, and regional expansion, while investors are increasingly drawn to high-value segments and emerging technological enhancements.

➤ Request Free…

Key Players in the Multirotor Drone Market: Share Positioning & Investor Perform …

The Multirotor Drone Market is accelerating toward a new era defined by automation, AI-driven intelligence, and mission-critical applications across commercial, industrial, and defense sectors. From precision agriculture and energy asset inspections to security surveillance and logistics support, multirotor drones have become essential operational tools. As market competition intensifies, leading players are refining their portfolios with advanced flight-control systems, payload integration, autonomous navigation, and safety compliance features. Companies are also enhancing…

More Releases for LSR

LSR Injection Molding Machine Market Size, Trends, Growth: Global Forecast 2025- …

The global market for LSR Injection Molding Machine was estimated to be worth US$ 284 million in 2024 and is forecast to a readjusted size of US$ 532 million by 2031 with a CAGR of 9.4% during the forecast period 2025-2031.

Global Leading Market Research Publisher QYResearch announces the release of its latest report "LSR Injection Molding Machine - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031". Based…

LSR Molding: Understanding Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) molding is a specialized manufacturing process used to create flexible, durable, and heat-resistant silicone parts. This technique is widely used across industries such as automotive, medical, electronics, and consumer goods. Its ability to produce high-quality parts with precision and consistency makes it a top choice for many manufacturers.

• What Is LSR Molding?

LSR molding, or Liquid Silicone Rubber injection molding (https://www.newtopcustomsilicone.com/capabilities/liquid-silicone-injection-molding/), involves injecting two-component platinum-cured silicone into…

Construction Aggregate Market Is Booming Worldwide : Wharehine, Hanlon Concrete, …

Latest Study on Industrial Growth of Construction Aggregate Market 2023-2028. A detailed study accumulated to offer Latest insights about acute features of the Construction Aggregate market. The report contains different market predictions related to revenue size, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends and developments…

Liquid Silicone Rubber (LSR) Market: Competitive Analysis and Global Outlook 202 …

The new report published by Stratview Research, titled Liquid Silicone Rubber (LSR) Market, is Segmented by Molding Technology Type (Liquid Injection Molding System), by Grade Type (Industrial Grade, Medical Grade, and Food Grade), by Application Type (Automotive, Medical, Electrical & Electronics, Consumer Goods, and Others), and by Region (North America, Europe, Asia-Pacific, and Rest of the World).

COVID-19 Impact & Recovery:

The report suggests that the Liquid Silicone Rubber (LSR) Market…

Liquid Silicone Rubber (LSR) Market Report 2018: Segmentation by Product (Indust …

Global Liquid Silicone Rubber (LSR) market research report provides company profile for ShinEtsu, KCC Corporation, Laur Silicone, Tianci Materials, Guangdong Polysil, Shenzhen SQUARE Silicone, BlueStar Xinghuo, Wynca, Dow Corning, Wacker Chemicals, Momentive and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR…

Global Liquid Silicone Rubber (LSR) Market Outlook 2016-2021

Liquid Silicone Rubber, with its low compression set, fast cure cycles, great stability and ability to resist extreme temperatures of heat and cold makes it ideally suitable for the production of parts where high quality is a must. Unlike most thermoplastic elastomers (TPRs and TPEs), LSR remains flexible and elastic down to -70o F and retains its properties up to 450o F. In addition to these qualities, the wide range…