Press release

Layer Palletizers Market is to Reach USD 3.4 billion by 2035, Growth Accelerates Across APAC, Europe, USA

The global layer palletizers market is entering a transformative decade, blending automation, robotics, and sustainable design into one of the most vital material handling segments. Valued at USD 2.0 billion in 2025 and projected to reach USD 3.4 billion by 2035 at a CAGR of 5.5%, the market reflects an industry that is not only scaling but also adapting to the rapid shifts in manufacturing, warehousing, and logistics worldwide. For established global leaders and emerging manufacturers alike, the opportunities to expand, innovate, and capture market share have never been greater.Market Dynamics and Cost Structure

The economics of the layer palletizers market are closely tied to its core components and integration requirements. Hardware remains the largest cost driver, with conveyors, robotic arms, and pallet handling modules representing significant investments. Alongside hardware, advanced automation software adds another layer of value, enabling programmable flexibility and precision stacking. Labor, assembly, and long-term service commitments continue to shape operational expenditures, especially in regions where semi-automated systems still coexist with advanced robotics.

Within the value chain, upstream suppliers of motors, sensors, and control systems provide essential inputs that drive efficiency, while system integrators bring customization and installation expertise. OEMs dominate the midstream, while distributors and service providers form the critical downstream link, ensuring reliability and customer support. Modular designs and advanced controls are steadily improving cost competitiveness, helping manufacturers balance affordability with performance.

Market Position and Growth Potential

Layer palletizers occupy an important position across the wider automation ecosystem. They account for nearly 5.1% of the palletizing equipment industry, 3.8% of the broader packaging automation market, and 3.3% of warehouse automation systems. Their role is especially pronounced in food and beverage packaging machinery, where they secure a 4.2% share due to the high standards of speed, hygiene, and handling consistency demanded by the sector.

The continued rise of e-commerce, distribution hubs, and logistics networks further boosts demand, as companies seek efficient, reliable, and safe material handling solutions. This convergence of packaging, warehousing, and supply chain optimization places layer palletizers firmly at the heart of modern industrial operations.

Driving Forces Behind Growth

The adoption of layer palletizers is being fueled by a global push for automation in packaging and logistics. Companies are investing to reduce labor dependency, enhance workplace safety, and maintain consistent product handling. Robotics, AI-driven vision systems, and advanced control software are enabling machines to adapt to different product formats with higher speed and accuracy.

Operational safety, ergonomic designs, and space optimization have become defining considerations for companies, leading to stronger adoption of robotic palletizers over traditional manual stacking. Moreover, Industry 4.0 integration is accelerating growth, with real-time monitoring, predictive maintenance, and digital twin technology reshaping operational efficiency.

Segmental Insights

Among product types, robotic palletizers dominate with 49.5% of market revenue in 2025. Their ability to handle high-speed, multi-line operations with precision and flexibility is unmatched, making them the preferred choice for industries requiring adaptability and uptime.

In terms of capacity, the medium segment holds 47.3% of revenue, providing the right balance between throughput and investment costs. This category is particularly attractive to mid-to-large scale manufacturers that demand efficiency without the footprint of high-capacity systems.

For applications, boxes and cases lead with 44.6% of market share, reflecting the universal need for secure, stable, and efficient handling of packaged goods across industries.

Regional Outlook

China stands at the forefront of global growth with a forecast CAGR of 7.4%, supported by massive industrial automation and packaging demand. India follows closely at 6.9%, driven by booming FMCG, pharmaceutical exports, and the integration of smart factory technologies. Germany, with a CAGR of 6.3%, remains Europe's powerhouse, leveraging engineering standards and Industry 4.0 adoption. The United States shows steady expansion at 4.7%, where palletizers are central to food, beverage, and e-commerce warehousing operations. Meanwhile, the UK, Brazil, and other emerging markets continue to drive regional opportunities through modernization and logistics optimization.

Technological Advancements

Recent innovations are shaping the next generation of palletizers. Advanced HMIs and intuitive programming are reducing training needs, while collaborative robots are being deployed to improve flexibility in handling mixed loads. Energy-efficient systems are minimizing operational costs, and IoT-enabled predictive maintenance is ensuring higher asset utilization.

Manufacturers are also designing compact and modular palletizers to suit facilities with limited floor space. Compatibility with recyclable and lightweight packaging further aligns with global sustainability goals. These advancements demonstrate the industry's move toward smarter, greener, and more adaptable operations.

Full Market Report available for delivery. For purchase or customization, please request here: https://www.futuremarketinsights.com/reports/sample/rep-gb-25268

Buy Now Report Here: https://www.futuremarketinsights.com/checkout/25268

Competitive Landscape

The layer palletizers market is shaped by a mix of global giants and specialized innovators. KUKA AG, Honeywell International Inc, and Körber AG are setting benchmarks with robotic and AI-driven palletizers designed for speed and precision. Premier Tech and Scott Automation focus on flexible, modular systems for diverse industries. BW Flexible Systems, Concetti SpA, and Mollers Packaging Technology GmbH offer tailored solutions for cartons, bags, and bulk goods.

Emerging players like COSMAPACK, TMI, Segbert Palletizing and Automation, and PHS Innovate are making strides with cost-efficient, turnkey solutions that improve regional competitiveness. Companies such as Brolla and SMB are carving niches by addressing specific packaging and material handling needs. Across the board, sustainability, digitalization, and warehouse optimization are central to competitive strategies.

Conclusion

The decade ahead promises sustained growth for the layer palletizers market, fueled by automation, robotics integration, and the global demand for efficiency. Both established leaders and emerging manufacturers are investing in technologies that prioritize productivity, adaptability, and sustainability. As industries evolve under the pressure of global trade, supply chain resilience, and consumer demand, layer palletizers will remain a cornerstone of industrial packaging and logistics operations worldwide.

Related Reports:

Cathodic Protection Market- https://www.futuremarketinsights.com/reports/cathodic-protection-market

Industrial Battery Chargers Market- https://www.futuremarketinsights.com/reports/industrial-battery-charger-market

Industrial Condensing Units Market- https://www.futuremarketinsights.com/reports/industrial-condensing-units-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Layer Palletizers Market is to Reach USD 3.4 billion by 2035, Growth Accelerates Across APAC, Europe, USA here

News-ID: 4259954 • Views: …

More Releases from Future Market Insights

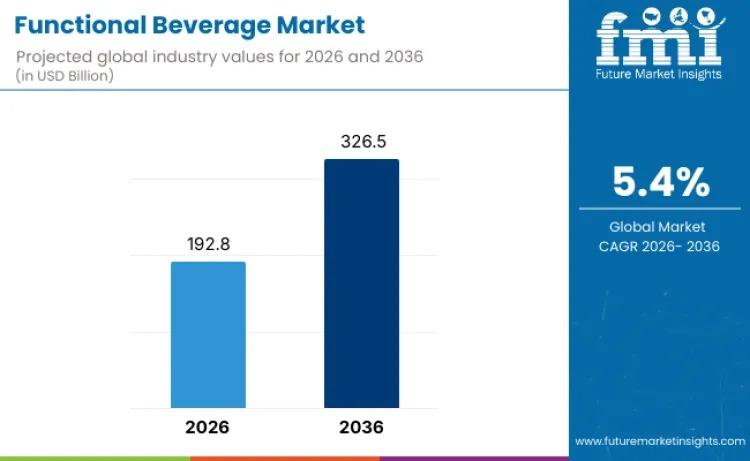

Functional Beverage Market Forecast 2026-2036: Global Industry to Reach USD 326. …

The global functional beverage industry is projected to reach USD 192.8 billion in 2026, reflecting sustained momentum driven by preventive healthcare awareness and consumer demand for health-enhancing drink formulations. According to Future Market Insights (FMI), total revenue is forecast to expand at a CAGR of 5.4% from 2026 to 2036, elevating the market value to USD 326.5 billion by 2036.

Growth is underpinned by rising wellness-oriented consumption patterns, the rapid expansion…

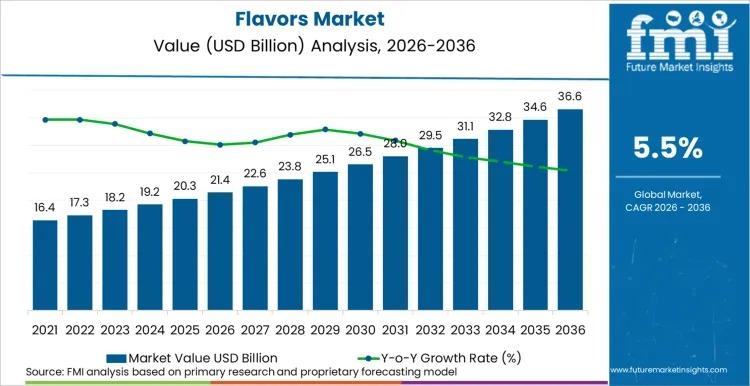

Flavors Market Forecast 2026-2036: Global Industry to Reach USD 36.6 Billion by …

The global flavors industry is poised for sustained expansion, with valuation projected to reach USD 21.4 billion in 2026. According to the latest assessment, revenues are expected to grow at a steady 5.5% CAGR through 2036, pushing the total market value beyond USD 36.6 billion by the end of the forecast period. Rising consumption of processed food and beverages, combined with increasing consumer demand for authentic taste experiences, continues to…

Hybrid Paper-Polymer Material System for Lightweight Structural Components Marke …

Market Overview: Structural Lightweighting Gains Commercial Momentum

The Hybrid Paper-Polymer Material Systems for Lightweight Structural Components Market is witnessing sustained growth as manufacturers prioritize lightweighting, material efficiency, and predictable mechanical performance. Valued at USD 740.0 million in 2026, the market is forecast to reach USD 1,788 million by 2036, expanding at a CAGR of 9.1%. Growth is driven by redesign strategies that integrate stiffness control, impact tolerance, and reduced material intensity…

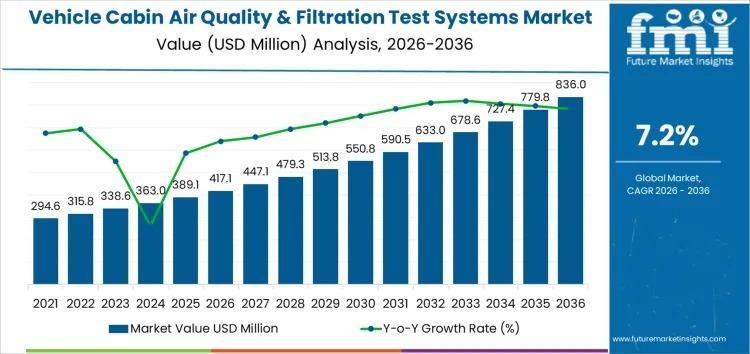

Global Vehicle Cabin Air Quality & Filtration Test Systems Market Growth Outlook …

Global Vehicle Cabin Air Quality & Filtration Test Systems Market Forecast and Outlook 2026-2036

The Vehicle Cabin Air Quality & Filtration Test Systems Market is projected to expand from USD 417.1 million in 2026 to USD 836 million by 2036, reflecting a steady CAGR of 7.20%. This surge is driven by growing consumer awareness about in-vehicle air quality, increasing adoption of electric vehicles (EVs), and stringent regulations governing cabin air pollution.…

More Releases for Layer

BlockchainFX and LivLive Presales Lose Traction As Layer Brett Announces Layer 2 …

BlockchainFX (BFX) and LivLive (LIVE) are losing traction as traders shift focus to Layer Brett. https://layerbrett.com The Ethereum Layer 2 project recently announced its public Layer 2 crypto testnet date, opening new opportunities for early backers.

LBRETT, the native token, delivers fast transactions, low gas fees, and DeFi coin-style staking rewards. Investors are exploring alternatives to traditional altcoins, attracted to Layer Brett's community-driven approach and real utility.

With the public…

Ethereum News: Shiba Inu Rival Layer Brett Nears Lightning-Fast Layer 2 Testnet

As Layer 2 innovation changes the way meme coins develop, the Ethereum ecosystem is seeing a new surge in interest. Previously concentrating only on conventional ETH-based tokens, investors are increasingly investigating meme projects with faster and more scalable infrastructure.

This shift has highlighted Layer Brett https://layerbrett.com as a rising contender, capturing increasing attention from Shiba Inu holders.

Ethereum (ETH) Market Update

Ethereum is currently trading at roughly $3,120 at the time of…

Multi‐layer Stacking HBM3E Market Share Driven by 12‐Layer and 16‐Layer Ad …

Multi-layer Stacking HBM3E Market Size

The global market for Multi-layer Stacking HBM3E was valued at US$ 43 million in the year 2023 and is projected to reach a revised size of US$ 80.8 million by 2030, growing at a CAGR of 8.7% during the forecast period.

View sample report

https://reports.valuates.com/request/sample/QYRE-Auto-38A18331/Global_Multi_layer_Stacking_HBM3E_Market_Research_Report_2024

The Multi layer Stacking HBM3E market is progressing rapidly as the demand for high-bandwidth memory solutions escalates in advanced computing domains. With its elevated…

2-Layer PCB vs 4-Layer PCB: A Comprehensive Comparison of Advantages and Disadva …

Printed Circuit Boards [https://www.allwinpcba.com/onlineorder.html] (PCBs) are the backbone of modern electronics, enabling the connectivity of various electronic components in an organized and efficient manner. When it comes to designing PCBs, one of the fundamental decisions to make is choosing between a 2-layer PCB and a 4-layer PCB. The number of layers in a PCB has a profound impact on its functionality, performance, and cost. In this comprehensive essay, we will…

3D Printing Construction Market Building the Future, Layer by Layer

3D Printing Construction Market to reach over USD 508.07 billion by the year 2031- Exclusive Report by InsightAce Analytic

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global 3D Printing Construction Market Size, Share & Trends Analysis Report by Construction Method (Extrusion, Powder Bonding), Material Type (Concrete, Metal, Composite) And End User (Building And Infrastructure)- Market Outlook And Industry Analysis 2031"

The global 3D printing…

Membrane Touch Switch Material Market Segmented By material type Polycarbonate, …

Market Introduction

Membrane touch switch materials are used in manufacturing of various membrane touch switches. The membrane touch switch materials form different layers in the construction of a membrane switch. A membrane touch switch can have two or more layers depending on the application and the membrane touch switch materials used. The membrane touch switch materials vary according to the layer type. The most preferred membrane touch switch materials in the…