Press release

CaCO3 Filler Masterbatch for Blow Molding Market to Reach USD 601 Million by 2031 Top 20 Company Globally

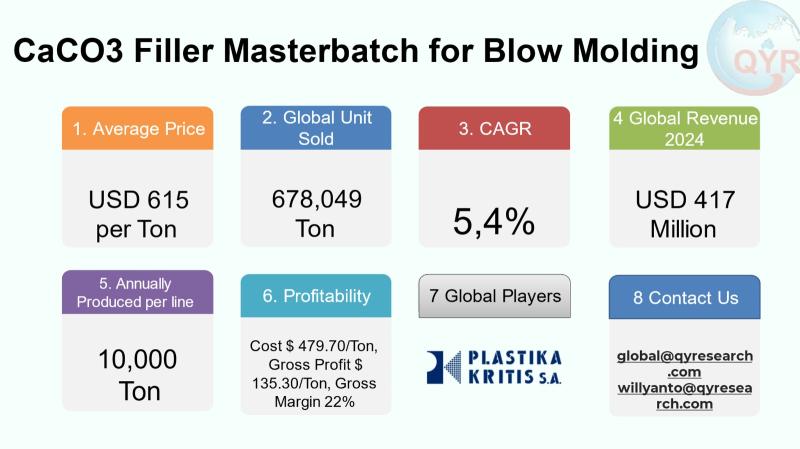

Calcium carbonate (CaCO3) filler masterbatch is a concentrated blend of CaCO3 mineral, carrier polymer and processing additives formulated to be dosed into polymer melts for extrusion and blow molding processes; it reduces the amount of virgin polymer required while improving stiffness, dimensional stability and cost per part. In blow molding applications CaCO3 masterbatches are widely used for blow-molded bottles, large hollow parts, household containers and certain industrial components where stiffness, opacity and cost reduction are priorities. The formulation and dispersion quality of CaCO3 masterbatches strongly influence melt flow, surface finish and mechanical performance, so producers differentiate on particle treatment, coupling agents and carrier resin compatibility.The global market for CaCO3 filler masterbatch for blow molding is USD 417 million in 2024 and is forecast to grow at a CAGR of 5.4% through 2031 reaching market size USD 601 million by 2031. With an average selling price of USD 615 per ton, the implied global volume sold in 2024 is approximately 678,049 tons. The factory gross margin is 22% equals to factory gross profit of about USD 135.30 per ton and cost of goods sold of USD 479.70 per ton. A COGS breakdown is raw CaCO3 feedstock as the largest component, carrier resin, additives and surface treatments, energy/processing, labor and packaging/logistics/overhead. A single line full machine production capacity for a medium-scale CaCO3 masterbatch extrusion/blending line used for blow molding grades varies by equipment and throughput but commonly ranges from roughly 1,000 tons per line per year. Downstream demand is concentrated in packaging and consumer containers followed by consumer durables, certain automotive/industrial applications and construction/household specialties.

Latest Trends and Technological Developments

Sustainability and carbon-reduction messaging from mineral producers and masterbatch makers is a central trend: large mineral suppliers and masterbatch companies are promoting CaCO3-based lightweighting and partly bio-based/carbon-reduced masterbatches to lower product carbon footprints. For example, Omya publicized polymer-focused, sustainability-oriented product launches and distribution initiatives including presence at K Show 2025 where Omya highlighted decarbonization and lightweighting advances (company news and event material, K-Show 2025 coverage). Imerys has continued investment and product promotion for calcium carbonate solutions for plastics and rubber (Imerys press activity AprilSept 2025), signaling continued R&D and capacity focus in functional mineral solutions. Consolidation and portfolio reshaping among mineral and specialty compounds players continued in 2024 to 2025: J.M. Huber announced acquisition activity in May 2024 (Huber acquisition announcement, May 2024), reflecting active M&A and integration moves in the active minerals and masterbatch space. These items reflect productization toward low-carbon supply chains, incremental capacity investments and inorganic growth strategies across major suppliers.

Polytain Inc., a leading manufacturer of rigid plastic containers, has entered into a 12-month supply agreement with Plastichem Solutions Co. for their high-performance CaCO3 Filler Masterbatch, specifically formulated for HDPE blow molding applications. To secure a competitive price and ensure a steady supply for their high-volume production lines, Polytain Inc. purchases this masterbatch in bulk quantities of 25-ton container loads. The agreed-upon price for this contract is USD 1,150 per metric ton, a cost-effective solution that allows them to reduce their overall resin consumption by approximately 15-20% while maintaining the required stiffness and dimensional stability for their dairy and juice bottles.

The CaCO3 Filler Masterbatch is a critical raw material used in the production of "AquaPure" 5-gallon water bottles manufactured by National Water Brands. In their state-of-the-art blow molding facility, the masterbatch is blended with virgin HDPE at a let-down ratio of 1:4. This specific formulation, which costs National Water Brands approximately USD 0.85 per finished bottle in raw material costs for the masterbatch component, is essential for achieving the bottle's required crush resistance and preventing deformation during stacking and transport, while also providing a significant cost saving over using 100% virgin polymer.

Asia (and especially Asia-Pacific) is the largest regional market for filler masterbatches and the dominant manufacturing base for blow-molded plastics where demand is concentrated in packaging, household goods and industrial containers. Asias leadership is driven by a dense plastics converting base, proximity to CaCO3 mineral resources in many local supply chains, and cost-competitive manufacturing infrastructure. Local calcium carbonate mineral producers and masterbatch compounders in China, India and Southeast Asia both supply converters and increasingly offer value-added and sustainability-branded grades tailored to regional needs; the Asia-Pacific region accounted for the largest share of the filler masterbatch market in recent analyses. Growth in Asia will be supported by ongoing packaging demand, municipal and industrial plastic consumption growth, and regional investment in compounder capacity and specialty treatments.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5376705

CaCO3 Filler Masterbatch for Blow Molding by Type:

Polypropylene (PP) Filler Masterbatch

Polyethylen(PE) Filler Masterbatch

Other

CaCO3 Filler Masterbatch for Blow Molding by Product Category:

High Concentration Type

Standard Type

CaCO3 Filler Masterbatch for Blow Molding by Market Segment:

Micrometer Level

Nanometer Level

CaCO3 Filler Masterbatch for Blow Molding by Product Division:

Ground Calcium Carbonate (GCC)

Precipitated Calcium Carbonate (PCC)

CaCO3 Filler Masterbatch for Blow Molding by Size:

Micro CaCO3 Particles

Fine CaCO3 Particles

Standard Filler

Coarse Filler

Others

CaCO3 Filler Masterbatch for Blow Molding by Application:

E-commerce & Packaging

Agricultural & Industrial

Others

Global Top 10 Key Companies in the CaCO3 Filler Masterbatch for Blow Molding Market

Plastika Kritis.S.A

Teknor Apex Company

Ferro Corporation

Colortek

Polyplast Müller GmbH

Hitech Colour Polyplast

A.SchulmanInc

CPI Vite Nam Plastic

Dolphin Poly Plast

Clariant Ag

Ampacet Corporation

SA Masterbatch

Colourists Plastic Product Company

Formosa Plastics

INNOVATION COMPOUND MATERIAL

Zhongyi Rubber-Plastic

Yancheng Changyuan Plastics

Suzhou Hanfeng New Material

Plastichemix Inc

Huber Corporation

Regional Insights

In Southeast Asia (ASEAN) the CaCO3 filler masterbatch opportunity is driven by fast-growing consumer packaging demand (bottles and containers), expansion of local blow-molder capacity and rising adoption of filler loading to control costs. Indonesia, as the largest ASEAN economy by population and a substantial plastics converting market, is an important regional hub; international mineral suppliers have announced or expanded onsite plants and supply arrangements for paper and polymer customers in the Asia-Pacific region (investments mentioned for China and Indonesia in previous release notices), which supports reliable feedstock supply for local masterbatch compounders. Smaller ASEAN markets are also attractive for regional converters because CaCO3 masterbatches allow converters to reduce resin costs while maintaining acceptable product properties. The ASEAN market tends to favor competitively priced, easily-dosed masterbatches and services such as local technical support, color/compatibility tuning and regulatory compliance documentation for food contact where applicable.

The CaCO3 filler masterbatch segment faces multiple challenges: first, maintaining surface finish and aesthetic quality in high-end consumer packaging when substituting high levels of filler requires well-treated CaCO3 and precise dispersion technology; second, regulatory and food-contact compliance in various jurisdictions creates additional testing and documentation workload; third, energy and logistics cost volatility can compress margins because CaCO3 is a bulk commodity and masterbatches are heavy and transport-sensitive; fourth, raw material quality variation across regional mines demands careful supplier qualification to deliver consistent masterbatch performance; and finally, the sustainability narrative raises expectations for circularity and recycled-content solutions, pressuring suppliers to invest in greener feedstocks and processes.

Suppliers should consider product differentiation via surface-treated CaCO3 and tailored carrier resin chemistry to enable higher loading levels without sacrificing surface finish, while investing in technical services to help blow-molders optimize dosing and processing conditions. Regional players in ASEAN can win by combining local logistics/technical support with competitive pricing; partnering with large mineral producers or establishing local grinding/pretreatment capacity reduces lead times and shipping cost exposure. Investing in low-carbon production claims (e.g., green electricity, lower-energy grinding, verified partial substitution targets) will be valuable when serving multinational converters with Scope-3 emissions goals.

Product Models

Calcium Carbonate (CaCO3) Filler Masterbatch for Blow Molding is a specialized additive compound used in the production of plastic films, bottles, and containers to enhance mechanical strength, reduce material costs, and improve processability.

Polypropylene (PP) Filler Masterbatch is a compound made by dispersing calcium carbonate (CaCO3) and additives into a PP resin carrier to enhance stiffness, dimensional stability, and opacity while reducing production costs and resin consumption. Notable products include:

Calpet MB-PP60 - Omya AG: A high-loading PP-based filler masterbatch offering excellent dispersion and improved rigidity for blow-molded containers.

Huasu CaCO3 PP Filler - Anhui Huasu Masterbatch Co., Ltd.: Designed for PP film and bottle production, providing good whiteness and reduced shrinkage.

Polyfill PP-70 - Polyfill Technologies (India): Offers smooth surface finish and higher tensile strength with cost-saving formulation.

Megaplast PP MB 65 - Megaplast Additives Co., Ltd.: A 65% CaCO3 loading filler suitable for PP bottles and containers.

Dongguan Yuye PP Filler MB - Yuye Plastic Masterbatch Co., Ltd.: Enhances toughness and process uniformity in PP extrusion blow molding.

Polyethylene (PE) Filler Masterbatch is a blend of finely ground calcium carbonate (CaCO3) in a PE carrier resin to improves the mechanical strength, printability, and processing efficiency of PE products. Examples include:

OmyaFill PE 65 - Omya AG: A premium CaCO3 PE masterbatch for HDPE blow molding with high whiteness and processing stability.

Europlas PE 60 Europlas (Vietnam): Delivers optimal dispersion and reduced melt viscosity for efficient PE bottle production.

Changsung PE Filler Changsung Masterbatch Co., Ltd. (Korea): Designed for PE film and blow molding with smooth extrusion behavior.

Megaplast PE MB 70 Megaplast Additives Co., Ltd.: Offers enhanced impact strength and surface brightness for HDPE/LDPE applications.

Shanxi PE-CaCO3 MB - Shanxi Plastic Masterbatch Co., Ltd.: Cost-effective filler with stable particle distribution for PE containers.

The CaCO3 filler masterbatch market for blow molding is a mid-sized but strategically important segment in polymer processing: it offers converters a credible route to lower material costs and to meet certain product performance targets, while giving mineral and masterbatch suppliers a stable, industrial demand stream. With a 2024 baseline of USD 417 million and steady mid-single-digit CAGR to 2031, Asia especially Asia-Pacific and ASEAN including Indonesia will remain the critical growth engine. Differentiation will come from formulation know-how, supply reliability, and the ability to demonstrate sustainable practices that align with global customer decarbonization goals.

Investor Analysis

This report highlights market size, unit volumes, COGS structure, margin profile and regional demand mix for CaCO3 masterbatch in blow molding, plus recent industry moves by major suppliers. How: Investors can use these inputs to model revenue and margin scenarios for incumbent compounders or for greenfield plant investments (capacity sizing, per-line throughput, expected gross profit per ton). Why: The combination of stable, packaging-led demand in Asia, relatively low technological risk, and visible M&A and capacity investment activity among major mineral and compounder players creates predictable cash-flow opportunities for strategically located assets or value-added service plays (technical support, treated CaCO3 specialties). The investor focus should be on capacity utilization (per-line cost leverage), feedstock security (mine or grinding access), and the ability to win share via low-carbon claims and local technical service in ASEAN markets.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5376705

5 Reasons to Buy This Report

Immediate regionally focused intelligence on Asia and ASEAN demand dynamics for CaCO3 masterbatch that are not covered in general filler reports.

Unit-level economics (price/ton, implied volumes, COGS and gross profit per ton) enabling quick financial modeling.

Supplier and competitive positioning top players and observable moves (M&A and product launches) that indicate consolidation and product trends.

Practical strategic guidance for plant siting, per-line capacity planning and downstream customer targeting (blow molding converters).

Actionable investor guidance tying technical/product trends to commercial value drivers (capacity utilization, sustainability premium potential)..

5 Key Questions Answered

What was the 2024 market size and the implied global volume sold?

What is the factory economics per ton (COGS and gross profit margin)?

Which regions and downstream sectors in Asia and ASEAN are driving demand, and what is the likely downstream split for blow-molding applications?

Who are the primary global players and what recent corporate moves (investments, acquisitions, product rollouts) provide signals about competitive strategy?

What are the principal operational and market risks (quality consistency, regulatory/food-contact compliance, freight/energy volatility) and how do they affect margin and investment decisions?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Related Report Recommendation

Global CaCO3 Filler Masterbatch for Blow Molding Market Research Report 2025

https://www.qyresearch.com/reports/5376705/caco3-filler-masterbatch-for-blow-molding

Global CaCO3 Filler Masterbatch for Blow Molding Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

https://www.qyresearch.com/reports/5376703/caco3-filler-masterbatch-for-blow-molding

Global CaCO3 Filler Masterbatch for Blow Molding Market Outlook, InDepth Analysis & Forecast to 2031

https://www.qyresearch.com/reports/5376704/caco3-filler-masterbatch-for-blow-molding

CaCO3 Filler Masterbatch for Blow Molding - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

https://www.qyresearch.com/reports/5376706/caco3-filler-masterbatch-for-blow-molding

Global CaCO3 Filler Masterbatch Market Research Report 2025

https://www.qyresearch.com/reports/5048677/caco3-filler-masterbatch

Global PE Filler Masterbatch Market Research Report 2025

https://www.qyresearch.com/reports/3799730/pe-filler-masterbatch

Global Talc Filler Masterbatch Market Research Report 2025

https://www.qyresearch.com/reports/3447866/talc-filler-masterbatch

Global Plastic Filler Masterbatch Market Research Report 2025

https://www.qyresearch.com/reports/3470300/plastic-filler-masterbatch

Global Polypropylene (PP) Filler Masterbatch Market Research Report 2025

https://www.qyresearch.com/reports/4206564/polypropylene--pp--filler-masterbatch

Global PP Calcium Carbonate Filler Masterbatch Market Research Report 2025

https://www.qyresearch.com/reports/4506854/pp-calcium-carbonate-filler-masterbatch

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release CaCO3 Filler Masterbatch for Blow Molding Market to Reach USD 601 Million by 2031 Top 20 Company Globally here

News-ID: 4255414 • Views: …

More Releases from QY Research

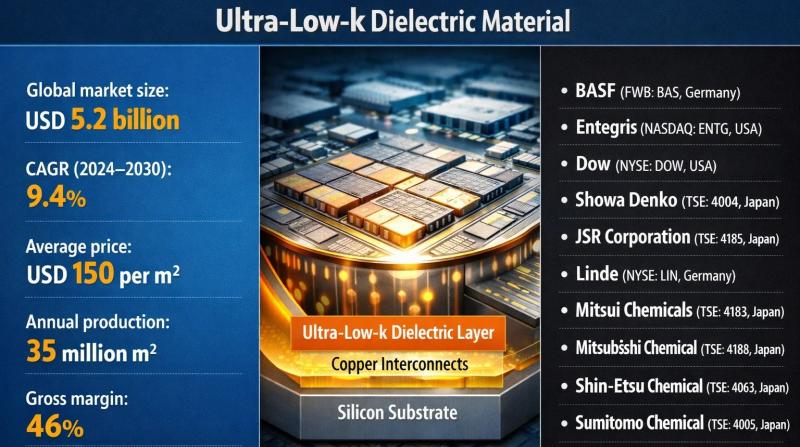

Market Overview - Ultra-low-k Dielectric Material

QY Research has recently published a comprehensive market study on Ultra-low-k Dielectric Material, a critical class of advanced insulating materials engineered to reduce parasitic capacitance and signal delay in advanced semiconductor interconnects. Ultra-low-k dielectrics are essential enablers for sub-7 nm logic nodes, advanced memory, high-performance computing, and AI accelerators, where interconnect RC delay increasingly limits device performance and power efficiency.

The market is transitioning from dense SiO2 and conventional low-k materials…

Global and U.S. Quadruped Mobile Robots Market Report, Published by QY Research.

QY Research has released a comprehensive new market report on Quadruped Mobile Robots, are four-legged robotic systems designed to move and operate in complex, unstructured environments by mimicking the locomotion of animals. They use a combination of advanced sensors, actuators, AI algorithms, and real-time control systems to maintain balance, navigate uneven terrain, climb obstacles, and adapt to dynamic conditions. Because of their high stability and mobility, quadruped robots are widely…

Global and U.S. Industrial Edge Cloud Devices Market Report, Published by QY Res …

QY Research has released a comprehensive new market report on Industrial Edge Cloud Devices, ruggedized computing platforms that bring cloud-native processing, storage, and AI analytics directly to the industrial edge-close to machines, sensors, and control systems. By executing latency-sensitive workloads locally while synchronizing with central or public clouds, these devices enable real-time decision-making, improved reliability, and secure data governance across factories, utilities, energy assets, and transportation infrastructure. As Industry 4.0,…

Top 30 Indonesian Ceramic Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Arwana Citramulia Tbk (ARNA)

PT Cahayaputra Asa Keramik Tbk (CAKK)

PT Intikeramik Alamasri Industri Tbk (IKAI)

PT Keramika Indonesia Assosiasi Tbk (KIAS)

PT Mulia Industrindo Tbk (MLIA)

PT Asahimas Flat Glass Tbk (AMFG) (glass & ceramic-adjacent)

PT Niro Ceramic Nasional Indonesia

PT Eleganza Tile Indonesia

PT Roman Ceramic International

PT Platinum Ceramics Industry

PT Granito (Citra Granito)

PT Diamond Keramik Indonesia

PT Indogress (Inti Keramik Sejahtera)

PT Indopenta Sakti Teguh

PT Sun Power Ceramics

PT Satyaraya Keramindo Indah…

More Releases for CaCO3

CaCO3 Filler Masterbatch for Blow Molding Market Report 2026: History, Forecast, …

Unlock the Future of the CaCO3 Filler Masterbatch for Blow Molding Market: Comprehensive Global Market Report 2025-2031

Global leading market research publisher QYResearch published the release of its latest report, "CaCO3 Filler Masterbatch for Blow Molding - Global Market Share, Ranking, Sales, and Demand Forecast 2025-2031". This in-depth report provides a complete analysis of the global CaCO3 Filler Masterbatch for Blow Molding market, offering critical insights into market size, share, demand,…

Caco3 Filler Masterbatch For Blow Molding Market is Going to Boom: Strategic Ins …

The latest report titled "CaCO3 Filler Masterbatch for Blow Molding Market" Trends, Share, Size, Growth, Opportunity, and Forecast 2025-2032. offering a comprehensive and in-depth analysis of the industry. As part of our Black Friday Limited-Time Discount, this premium research report is now available at up to 60% off, offering an exceptional opportunity for businesses, analysts, and stakeholders to access high-value insights at a significantly reduced cost. The report provides key…

Calcium Carbonate Market: Advancing Material Innovation Across Plastics, Paper, …

The Calcium Carbonate Market continues to expand as demand grows across plastics, paper, construction, paints and coatings, adhesives, pharmaceuticals, and environmental treatment industries. As one of the most widely used industrial minerals, calcium carbonate (CaCO3) offers versatility, cost efficiency, and performance enhancement in a wide range of applications. The global market is dynamic, driven by industrialization, sustainability trends, shifting manufacturing patterns, and rising consumption in developing regions.

Report Summary: https://www.marketresearchfuture.com/reports/calcium-carbonate-market-5383

Market Overview

Calcium…

Calcium Carbonate Production Cost: An In-Depth Analysis 2023-2028 | Syndicated A …

Syndicated Analytics' latest report titled "Calcium Carbonate Production Cost 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the calcium carbonate industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs,…

Palladium on Calcium Carbonate (Pd/CaCO3) Catalyst Market to Witness Huge Growth …

The study provides an in-depth analysis of the major market players in the Palladium on Calcium Carbonate (Pd/CaCO3) Catalyst market. It provides a detailed analysis of each segment and driving factors coupled with growth rate analysis. Furthermore, the report also provides regional analysis that offers insights on the market potential across each region to enable market players to leverage market opportunities. The Palladium on Calcium Carbonate (Pd/CaCO3) Catalyst research report…

Calcium Carbonate Production Cost 2022-2027: Price Trend, Plant Cost, Profit Mar …

Syndicated Analytics' latest report titled "Calcium Carbonate Production Cost Analysis 2022-2027: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the calcium carbonate industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating…