Press release

Superhard Tools for Aerospace Industry Market to Reach USD 310 Million by 2031 Top 20 Company Globally

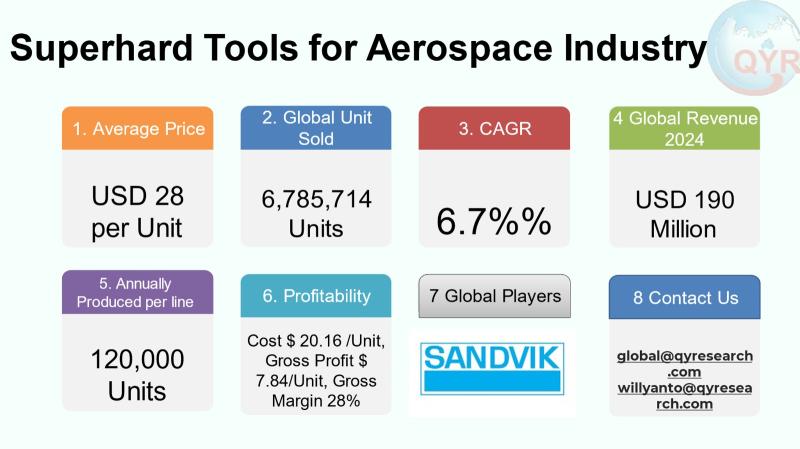

The global superhard tools market for aerospace encompassing cubic boron nitride (CBN), polycrystalline diamond (PCD), CVD diamond, and related bonded and sintered superhard cutting and grinding tools used to machine titanium, nickel-based superalloys, hardened steels and advanced composites supports precision manufacture and repair of airframe, engine and structural components where tool life, thermal stability and surface integrity are critical. This specialized segment is driven by the ongoing need to machine hard-to-cut alloys, rising aircraft production and expanded MRO activity worldwide.The 2024 superhard tools for aerospace industry market size is USD 190 million and the provided CAGR of 6.7% to 2031, reaching market size USD 310 million by 2031. With average selling price of USD 28, the market corresponds to approximately 6,785,714 units sold globally in 2024. Typical cost-of-goods-sold (COGS) for a production unit in this sector is modelled here at USD 20.16 per unit, producing a factory gross profit of USD 7.84 per unit and a factory gross margin of 28%. The COGS breakdown is raw superabrasive/diamond/CBN material, direct labor, plant overhead (energy, consumables), toolbody/holder and secondary tooling, and packaging & logistics. A single line full machine production capacity is at 120,000 units per line per year. Downstream demand concentration for these aerospace-grade superhard tools is heavily skewed toward aerospace OEMs and tier-1/2 suppliers (the primary users), with aerospace OEMs & tier suppliers, MRO and aftermarket, defense-specialized machining, and other industrial users.

Latest Trends and Technological Developments

The industry is seeing three clear technological currents: wider adoption of CBN/PCBN for high-temperature, hard-turning applications on superalloys and hardened steels; advances in sintering and brazing techniques that extend bond life and edge stability for diamond and CBN composites; and integration of advanced tool coatings and digitally tracked tool-life systems for predictive replacement and enhanced process control. Recent, relevant news items illustrating these trends include a July 2025 case release describing how Stanford Advanced Materials (SAM) provided CBN solutions to an aerospace manufacturer to mitigate rapid tool wear in hardened-ferrous machining (demonstrating practical CBN deployment in aerospace tooling). On September 2025 a product launch highlighted new diamond and CBN dicing blades optimized for high-precision cutting of ceramics and composites a sign of tooling firms expanding product lines for advanced materials common in modern aircraft. Industry technical articles and supplier announcements in 2025 continue to emphasize CBNs role in dressing-free skiving and internal gear finishing for aviation components and the push toward smarter, data-linked tooling for process stability. These items reflect ongoing R&D and productization that are directly relevant to aerospace supply chains.

A leading aerospace manufacturer like Spirit AeroSystems purchases large quantities of polycrystalline diamond (PCD) inserts and end mills from a specialist supplier like Kennametal for an annual contract valued in the range of $500,000 to $1 million USD. This procurement is critical for their machining of high-volume components, such as aluminum and carbon composite structural parts for airframes. The demanding production schedules for aircraft like the Boeing 737 or Airbus A320 require tools that can maintain extreme precision and finish over long production runs, which standard carbide tools cannot provide without frequent, costly changes. The investment in superhard tools is justified by a significant reduction in machine downtime and a dramatic increase in parts produced per tool, directly lowering the cost-per-part.

In the production of the LEAP jet engine, CFM International (a joint venture between GE Aerospace and Safran Aircraft Engines) extensively uses cubic boron nitride (CBN) grinding wheels supplied by companies like Saint-Gobain. These superabrasive wheels are installed on precision grinding machines to finish the turbine blades manufactured from nickel-based superalloys. A single automated grinding cell, equipped with multiple CBN wheels, represents a capital and tooling investment of several hundred thousand dollars. The application is critical as it ensures the blades' complex aerodynamic profiles and surface integrity can withstand the extreme temperatures and centrifugal forces within the engine's hot section, directly impacting performance, fuel efficiency, and durability.

Asia continues to be a central manufacturing base and growth engine for superhard tooling, driven by concentration of precision machining capacity, materials suppliers and downstream aerospace component manufacture in China, Japan, South Korea, Taiwan and India. China supplies large volumes of abrasive substrates and bonded tools and has increasing domestic suppliers moving upstream into CBN/diamond synthesis and tool fabrication; Japan and South Korea remain technology leaders for high-performance inserts and brazing/sintering know-how; Taiwan and India provide high-value contract machining and tier-supplier work that consumes aerospace-grade superhard tools. Supply-chain localization in Asia is reinforced by regional aerospace investments, and increasing on-shoring by global OEMs seeking diversified suppliers. The Asia regions combination of material supply, tool-making capability and large customer-base yields both volume manufacturing and fast adoption of process innovations for superhard tooling applications.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5319075

Superhard Tools for Aerospace Industry by Type:

Cubic Boron Nitride

Diamond

Superhard Tools for Aerospace Industry by Type:

Weldable Type

Inverter Type

Integrated Type

Superhard Tools for Aerospace Industry by Size:

Micro Tools (20 mm)

Tool Assemblies / Sets

Others

Superhard Tools for Aerospace Industry by Features:

High-Temperature Resistant Tools

Wear-Resistant Coatings

Smart Sensor-Enabled Tools

Precision Balanced Tools

Others

Superhard Tools for Aerospace Industry by Market Segment:

Online Sales

Offline Sales

Superhard Tools for Aerospace Industry by Application:

Engine Structural Parts

Heat Shields

Rail Components

Others

Global Top 20 Key Companies in the Superhard Tools for Aerospace Industry Market

Sumitomo

Kennametal

Mitsubishi

Mapal

Sandvik

Beijing World Diamond Tools

Iscar

Funik

Shanghai Nagoya Precision Tools

Ingersoll Cutting Tools

YG-1

Kyocera

Weihai Weiying Tools

TaeguTec

Shenzhen Zhongtian Superhard Tools

Preziss Tool

Sifangda

Tungaloy

CERATIZIT S.A.

Zhuzhou Diamond

Regional Insights

Within Southeast Asia, ASEAN hubs such as Malaysia, Thailand, Vietnam and Indonesia are growing as centers for aerospace component manufacturing, MRO and light-assembly operations that create rising demand for superhard tools, while Singapore plays an outsized role in design, testing and high-value services. Indonesia in particular is emerging with an expanding supplier base and MRO capacity driven by regional airline fleets and government modernization programs; this produces a growing procurement stream for superhard cutting and grinding solutions used in both OEM prototypes and sustained MRO cycles. Local demand in ASEAN tends to favor suppliers who can combine competitive unit pricing with reliable logistics and after-sales technical service; as a result, international toolmakers increasingly develop regional distribution and service partnerships to capture market share. While ASEAN volumes are smaller than Greater China or Japan, growth rates are comparatively high because of new MRO and light-manufacturing projects.

Key challenges for the superhard-tool segment in aerospace include raw material cost volatility (synthetic diamond and high-purity CBN feedstocks), long qualification cycles demanded by OEMs that slow adoption of new tool grades, capacity constraints in high-precision finishing lines (sintering and dressing equipment), and competitive pressure from lower-cost producers that can undercut margin-sensitive contracts. Environmental and regulatory considerations including energy-intensive sintering processes and responsible sourcing of superabrasive feedstocks are increasingly affecting procurement and capital planning. Additionally, the transition toward more carbon-fiber composite components in some aircraft structures changes tooling requirements (abrasive wear patterns differ), forcing toolmakers to broaden product portfolios and invest in R&D to maintain relevance.

Manufacturers and investors should prioritize vertical integration options (secure high-quality abrasive/CBN feedstock), develop faster OEM qualification pathways through joint development agreements, and expand regional service networks in Asia and ASEAN to reduce lead times and support MRO customers. Investing in digital tool-life monitoring, lifecycle service contracts, and hybrid material solutions (e.g., graded CBN + coated substrates) can create recurring revenue streams and defend margins. For suppliers targeting ASEAN, building local inventory and technical training capabilities is essential to capture MRO and tier-supplier growth. Sustainability efforts such as energy-efficient furnaces and recycled abrasive programs are both a compliance and differentiation lever.

Product Models

In the aerospace industry, machining and finishing components made of advanced materials require tooling that can sustain extreme conditions of temperature, wear, and precision. Super-hard tool materials such as cubic boron nitride (CBN) and diamond (or diamond coatings) provide dramatically improved tool life, higher machining speeds, and tighter surface finishes compared to conventional carbide tools.

Cubic Boron Nitride is a synthetic super-hard material second only to diamond in hardness in many contexts, but with superior chemical stability when machining ferrous materials. Notable products include:

CoroCut 1 CBN Insert Sandvik: A cutting-off/grooving insert in CBN grade for hard turning of high-hardness steels; designed for long tool life and high stability.

GITM 6.00K-0.40 IB50 CBN Insert ISCAR: A grooving/turning insert in CBN grade IB50, suited for turn-groove operations in very hard materials.

EZ-Cube Solid CBN Grade NTK: A line of solid CBN tools (grades B16, B22, etc) designed for ultra-hard material finish-cutting (HRC ≈ 60+).

PCBN Grade IB55 Turning Insert - ISCAR: A fine-grain CBN insert grade for continuous turning of hardened steels; offers high dimensional stability.

CBN Insert Series MT Type Mini-Tipped ISCAR: A multi-corner one-use CBN tip design optimized for cost-effective hard turning.

Diamond are tools whose cutting surfaces are composed of diamond or diamond layers which offer the highest hardness and extreme wear resistance. Examples include:

Diamond-Coated End Mill for CFRP Kyocera: A solid carbide end-mill with high-performance diamond coating, designed for machining CFRP in aerospace stacks.

PCD/PCD-tipped End Mill HPSL Series Telcon Diamond Ltd.: PCD end-mill series (spiral LH) designed for composites and hard materials in aerospace manufacturing.

CVD Diamond Drill SCDR Series Telcon: A CVD diamond-coated drill series geared to high demands on CFRP/stacked materials in aerospace.

Diamond-Coated Milling Cutter FT Series KOMET: A series of diamond-coated carbide milling cutters for composite parts (CFRP/GFRP) and aerospace use.

Diamond-Tipped Drill for CFRP/AL/Ti stacks PREZISS: A solid PCD/diamond drill specifically built for composite and metal stack drilling in aircraft manufacturing

The aerospace-focused superhard tools segment is a specialized but steadily growing niche, anchored on the performance advantages of CBN and diamond-based tooling when machining modern aerospace alloys and composites. With a 2024 market base of USD 190 million and a projected expansion at a 6.7% CAGR to 2031, growth will be shaped by aircraft production cycles, rising MRO activity, regional supply-chain localization in Asia and ASEAN, and continued technological progress in tool materials and digital lifecycle services. Margin sustainability will depend on securing feedstock, improving production efficiencies, and offering value-added service and qualification support for aerospace customers.

Investor Analysis

This research highlights market size, unit economics, COGS structure and regional demand patterns (Asia and ASEAN), plus recent technological and supplier developments that materially affect sales cycles and margin realization. How: Investors can use the data to assess capital deployment (for capacity expansion or acquisitions of local service partners), to model margin sensitivity (given COGS and price points), and to prioritize R&D or vertical-integration moves that shorten OEM qualification times. Why: Aerospace tooling demand is relatively stable and premium-priced because of strict performance needs; targeted investments (e.g., in sintering capacity, localized service footprints in ASEAN, or supply agreements for high-quality CBN/diamond feedstock) reduce lead-time risk and can protect margins while capturing the rising share of OEM and MRO spend all of which creates predictable, defensible returns in a niche with substantial technical barriers to entry. Investors seeking exposure to higher-margin specialty manufacturing with technical moats should view this segment as an attractive, lower-volatility manufacturing opportunity within aerospace supply chains.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5319075

5 Reasons to Buy This Report

It provides a focused 20242031 market sizing and unit-level economics specifically for aerospace superhard tooling.

The report analyzes Asia and ASEAN regional dynamics and identifies where demand and supplier capabilities are concentrated.

It summarizes the latest technological developments and verifiable supplier/product news that affect adoption timelines and qualification.

It gives actionable strategic recommendations for manufacturers and investors on vertical integration, service expansion and R&D priorities.

It lists top industry players and competitive positions to inform M&A, distribution partnerships or supplier selection decisions.

5 Key Questions Answered

What was the 2024 market size and how many units were sold globally at the stated unit price?

What is a representative per-unit cost structure and what factory gross profit/margin can be expected?

Which Asian and ASEAN markets are most important for both supply and demand, and how is Indonesia positioned?

What recent product launches, case studies or supplier announcements indicate technological direction and near-term adoption?

Which leading companies and regional specialists should be tracked for partnerships, supply security or acquisition?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Related Report Recommendation

Global Superhard Tools for Aerospace Industry Market Research Report 2025

https://www.qyresearch.com/reports/5319075/superhard-tools-for-aerospace-industry

Superhard Tools for Aerospace Industry - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

https://www.qyresearch.com/reports/5319076/superhard-tools-for-aerospace-industry

Global Superhard Tools for Aerospace Industry Market Outlook, InDepth Analysis & Forecast to 2031

https://www.qyresearch.com/reports/5319074/superhard-tools-for-aerospace-industry

Global Superhard Tools for Aerospace Industry Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

https://www.qyresearch.com/reports/5319073/superhard-tools-for-aerospace-industry

Global Superhard Round Tool Market Research Report 2025

https://www.qyresearch.com/reports/4526420/superhard-round-tool

Global Superhard Cutting Tool Market Research Report 2025

https://www.qyresearch.com/reports/3425982/superhard-cutting-tool

Global Superhard Tool Material Market Research Report 2025

https://www.qyresearch.com/reports/3526615/superhard-tool-material

Global Superhard Alloy Cutting Tools Market Research Report 2025

https://www.qyresearch.com/reports/4451214/superhard-alloy-cutting-tools

Global Diamond Superhard Cutting Tool Market Research Report 2025

https://www.qyresearch.com/reports/3758039/diamond-superhard-cutting-tool

Global Superhard Cutting Tool Material Market Research Report 2025

https://www.qyresearch.com/reports/4486227/superhard-cutting-tool-material

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Superhard Tools for Aerospace Industry Market to Reach USD 310 Million by 2031 Top 20 Company Globally here

News-ID: 4249377 • Views: …

More Releases from QY Research

Top 30 Indonesian Coal Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Alamtri Resources Indonesia Tbk (formerly Adaro Energy)

PT Bumi Resources Tbk

PT Bayan Resources Tbk

PT Indo Tambangraya Megah Tbk

PT Bukit Asam Tbk (PTBA)

PT Golden Energy Mines Tbk (GEMS)

PT Dian Swastatika Sentosa Tbk (DSSA)

PT Indika Energy Tbk (INDY)

PT Akbar Indo Makmur Stimec Tbk (AIMS)

PT Atlas Resources Tbk (ARII)

PT Borneo Olah Sarana Sukses Tbk (BOSS)

PT Baramulti…

From Sugar to Profit: Economics of the Global Ready-to-Roll Icings Industry

Ready-to-roll icings (also known as rolled fondant or sugar paste) are pre-formulated sugar-based sheets used for cake covering, decorative modeling, and bakery finishing in commercial and artisan baking.

Products are supplied in bulk slabs, sheets, and blocks and are valued for: Consistent elasticity, Reduced preparation time, Uniform finish, Extended shelf stability.

Industrial buyers include industrial bakeries, frozen dessert processors, QSR chains, supermarkets, and cake studios.

Growing demand for celebration cakes, premium bakery products,…

Sustainable Staples: Why Investors Are Targeting Organic Pulse Processing

Organic dry pulses include organically cultivated lentils, chickpeas, peas, mung beans, pigeon peas, and dry beans produced without synthetic pesticides, fertilizers, or GMOs.

Industry benefits from: Rising plant-protein adoption, Gluten-free and clean-label trends, Soil-friendly nitrogen-fixing crop rotation, Government organic agriculture subsidies across Asia.

Global trade dominated by exporters in India, Australia, Canada, and Turkey

Growing consumption in China, Japan, Indonesia, and Vietnam.

Global Overview

Market size (2025): USD 5,266 million

Market size (2032): USD 8,231 million

CAGR…

Baby Care Boom: USD 9.1B Global Bath & Shower Market Driven by Asia Growth

Baby bath and shower products include liquid cleansers, tear-free shampoos, head-to-toe washes, soaps, bath oils, foam washes, and sensitive-skin dermatological formulations designed specifically for infants and toddlers.

Products emphasize mild surfactants, hypoallergenic formulations, pH-balanced systems (5.56.0), and natural/plant-derived ingredients to minimize irritation and comply with pediatric dermatology standards.

Demand is driven by rising hygiene awareness, premiumization of infant care, urban middle-class expansion, and increased birth rates in emerging Asia.

Strong shift from bar…

More Releases for Tool

Data Annotation Tool Market Data Annotation Tool Market

The study on the Global Data Annotation Tool Market published by Fact.MR is a comprehensive analysis of the key factors that are likely to determine the growth of Data Annotation Tool Market in the upcoming years. Further, the study dives deep to investigate the micro and macro-economic parameters that are expected to influence the global scenario of the Data Annotation Tool Market during the forecast period (2022-2031).

The report examines the…

Research Report and Overview on Titanium Carbide Tool Market, 2020-2026 with Mit …

"Global Titanium Carbide Tool Industry Research Report” Provides Detailed Insight Covering all Important Parameters Including Development Trends, Challenges, Opportunities, Key Insights and Competitive Analysis of Titanium Carbide Tool Market.

COVID-19 can affect the global economy in 3 main ways: by directly affecting production and demand, by creating supply chain and market disturbance, and by its financial impact on firms and financial markets.

To know How COVID-19 Pandemic will impact this market/industry-DOWNLOAD sample…

Aluminum Carbide Tool Market Trend, Segmentation and Forecast to 2025| Mitsubish …

High speed steel tools and carbide tools are widely used machine tools. From which carbide tools are most popular for machining applications. Carbide tools have exceptional characteristics like wear resistance, material strength, chemical inertness and other superior properties.

The Aluminum Carbide Tool market was valued at xx Million US$ in 2018 and is projected to reach xx Million US$ by 2025, at a CAGR of xx% during the forecast period. In…

Titanium Carbide Tool Market Size Study and Regional Forecasts 2019-2025| Mitsub …

High speed steel tools and carbide tools are widely used machine tools. From which carbide tools are most popular for machining applications. Carbide tools have exceptional characteristics like wear resistance, material strength, chemical inertness and other superior properties.

The Titanium Carbide Tool market was valued at xx Million US$ in 2018 and is projected to reach xx Million US$ by 2025, at a CAGR of xx% during the forecast period. In…

What's driving the Solid Carbide Tool Market growth? Key Players are: Mitsubishi …

The worldwide market for Solid Carbide Tool is expected to grow at a CAGR of roughly over the next five years, will reach million US$ in 2024, from million US$ in 2019, according to a new Big Market Research study.

Get Discount Sample @ https://www.bigmarketresearch.com/request-for-discount/3009309?utm_source=SBL

This report focuses on the Solid Carbide Tool in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes…

Global Knurling Tool Market 2018-2025 Aloris Tool, Dorian Tool, Sassatelli

Recently added detailed market study "Global Knurling Tool Market" examines the performance of the Knurling Tool market 2018. It encloses an in-depth Research of the Knurling Tool market state and the competitive landscape globally. This report analyzes the potential of Knurling Tool market in the present and the future prospects from various angles in detail.

The Global Knurling Tool Market 2018 report includes Knurling Tool market Revenue, market Share, Knurling Tool…