Press release

Industrial Foam Guns Market, Transforming Precision Cleaning and Coating Applications Worldwide

The Industrial Foam Guns Market has emerged as a vital component within industrial manufacturing, construction, and automotive applications. These devices are primarily designed to deliver polyurethane foams and other insulation materials with accuracy and efficiency. The adoption of foam guns has grown rapidly in recent years as industries prioritize precision, reduced material waste, and improved insulation performance. Industrial foam guns are now integral tools for sealing, bonding, filling, and insulating tasks, ensuring operational efficiency and compliance with modern environmental and performance standards.Get a Sample PDF Brochure of the Report: https://www.persistencemarketresearch.com/samples/24793

This consistent growth can be attributed to several key drivers, including the rising demand for energy-efficient insulation solutions, the boom in global infrastructure development, and the increasing focus on sustainability and construction efficiency. The shift toward automated foam application tools in industrial manufacturing further accelerates the market's expansion, particularly in high-precision sectors like automotive assembly and aerospace fabrication.

Among the product segments, manual foam guns continue to dominate the market, favored for their simplicity, affordability, and broad application range in both industrial and commercial construction. However, automatic and pneumatic foam guns are rapidly gaining traction, especially in large-scale industrial settings requiring consistent output and minimized human error. Regionally, Asia-Pacific leads the global market, driven by the exponential growth in construction activities, manufacturing expansion, and urbanization across major economies such as China, India, South Korea, and Southeast Asia.

Key Highlights from the Report

• Manual foam guns remain the most preferred product type due to cost efficiency and easy operation.

• Asia-Pacific dominates the market, supported by robust industrialization and infrastructure growth.

• Construction applications account for the largest share, followed by automotive and manufacturing sectors.

• Technological advancements, including ergonomic and anti-drip designs, enhance precision and usability.

• Growing environmental concerns are propelling the development of sustainable and recyclable foam gun materials.

Market Segmentation

The industrial foam guns market is segmented by product type, application, and foam compatibility, each contributing distinctly to the market's evolution.

By product type, the market primarily includes manual foam guns and automatic or pneumatic foam guns. Manual foam guns dominate global sales, largely due to their versatility and affordability. They are ideal for smaller projects, on-site construction tasks, and renovation works, where portability and cost control are essential. On the other hand, automatic foam guns are increasingly adopted in high-volume industrial settings. These guns are preferred for consistent foam application, automation compatibility, and enhanced control, making them popular in large-scale manufacturing and prefabrication facilities.

By application, the market covers construction, automotive, manufacturing plants, aerospace, and public safety sectors. Among these, the construction industry holds the lion's share of the market. Foam guns are widely used for insulation, sealing joints, gap-filling, and improving energy efficiency in buildings. The automotive segment also represents a key growth area, where foam guns are used for bonding, noise reduction, vibration control, and sealing applications. Manufacturing and aerospace sectors leverage these tools for applying advanced foams in production lines, ensuring precision and process reliability.

By foam compatibility, industrial foam guns are categorized based on their ability to handle polyurethane foam, polyurea foam, elastomeric foam, and adhesive foams. Polyurethane-based foam guns dominate this segment, given their broad industrial use and availability. However, with advancements in polymer chemistry and sustainability initiatives, foam guns compatible with bio-based and low-emission materials are gaining traction. These eco-friendly solutions are particularly favored in regions adopting stringent environmental regulations.

Overall, segmentation provides a comprehensive understanding of evolving user preferences and guides manufacturers toward innovative product development tailored to industry-specific requirements.

Read More In Detail: https://www.persistencemarketresearch.com/market-research/industrial-foam-guns-market.asp

Regional Insights

Asia-Pacific

Asia-Pacific represents the largest and most dynamic region in the global industrial foam guns market. This dominance is primarily driven by rapid urbanization, strong industrial expansion, and extensive infrastructure projects across China, India, Japan, and Southeast Asia. The construction boom, coupled with an emphasis on energy efficiency, has significantly increased the adoption of foam guns in building insulation and sealing applications. Moreover, growing automotive production and industrial automation have accelerated foam gun utilization for precise assembly processes. The region also benefits from a large base of local manufacturers offering cost-effective foam gun solutions, enhancing accessibility and market penetration.

North America

North America holds a significant market share, backed by strong construction standards, high consumer awareness of insulation benefits, and the presence of advanced manufacturing industries. The region's focus on sustainability, particularly in building energy efficiency, supports demand for high-performance foam guns compatible with eco-friendly foam materials. The automotive and aerospace industries in the U.S. and Canada are also major contributors, employing foam guns for lightweight bonding and sealing applications. The market here is mature yet continues to evolve with innovations in ergonomics, material compatibility, and digital monitoring capabilities.

Europe

Europe's industrial foam guns market is shaped by stringent environmental regulations and a deep-rooted commitment to energy-efficient construction. European countries prioritize sustainable building materials, leading to rising demand for reusable and low-waste foam guns. The region's strong presence of leading foam and adhesive manufacturers supports steady market growth. Advanced economies such as Germany, France, and the U.K. are seeing high adoption of automatic foam guns for precision-driven manufacturing processes, further propelling regional expansion.

Middle East & Africa

The Middle East and Africa are emerging as promising markets, supported by rapid infrastructure development and industrial diversification. The Gulf countries, particularly Saudi Arabia and the UAE, are investing heavily in energy-efficient construction as part of their sustainability initiatives. As these regions modernize industrial and commercial structures, the demand for professional-grade foam guns continues to rise.

Latin America

Latin America's industrial foam guns market is growing steadily, with Brazil and Mexico at the forefront. Increasing construction investments, government support for affordable housing, and rising automotive assembly activities are creating fresh opportunities for market participants. As the region's economies stabilize and industrial sectors modernize, the demand for high-quality insulation and sealing tools is expected to grow substantially.

Market Drivers

The growth of the industrial foam guns market is underpinned by several powerful drivers. One of the most prominent is the global demand for energy-efficient and sustainable construction practices. Foam guns play an essential role in applying insulating foams that help reduce energy loss in buildings and industrial plants. As governments worldwide tighten regulations on building energy performance, demand for precise and efficient foam application tools continues to soar.

Another key driver is the expanding automotive industry, where manufacturers seek to enhance vehicle durability, thermal insulation, and acoustic comfort. Foam guns are indispensable in achieving these objectives through precise application of sealing foams in body panels, doors, and engine compartments.

Technological advancement is another catalyst for growth. Modern foam guns now feature ergonomic handles, flow-control adjustments, anti-drip mechanisms, and durable stainless-steel components, significantly improving user experience and reliability. Moreover, the integration of digital sensors and automation compatibility is paving the way for intelligent foam dispensing systems that improve accuracy and minimize material waste.

Finally, the growing popularity of DIY construction and renovation activities has expanded foam gun adoption among consumers and small-scale contractors. The availability of cost-effective manual foam guns through online retail platforms has further accelerated this trend, diversifying the market's end-user base.

Market Restraints

Despite its positive outlook, the industrial foam guns market faces certain restraints that could temper growth. A key challenge lies in the volatility of raw material prices, particularly those linked to polyurethane and metal components. These fluctuations impact both foam gun manufacturers and end-users, often leading to increased production costs and pricing pressures.

Environmental concerns also pose challenges. Many foams used in conjunction with these guns contain volatile organic compounds (VOCs) or chemicals with limited recyclability, prompting stricter regulations in developed markets. Compliance with such standards increases manufacturing costs and requires continuous R&D investment to develop greener alternatives.

Another restraint stems from market competition with alternative sealing technologies, such as preformed gaskets, sealant tapes, or advanced adhesive applicators. These options can sometimes offer quicker or cheaper solutions, particularly in low-demand industrial environments. Additionally, the high upfront cost of automated foam guns and the need for skilled operators can deter smaller businesses from adoption.

Finally, the lack of standardization in foam gun design across regions can create interoperability issues, limiting the global adoption of specific products. Manufacturers must therefore invest in adaptable designs to suit diverse foam materials and application systems.

Do You Have Any Query Or Specific Requirement? Request Customization of Report: https://www.persistencemarketresearch.com/request-customization/24793

Market Opportunities

The future of the industrial foam guns market is rich with opportunities. The most promising lies in the development of eco-friendly and recyclable foam guns designed to meet sustainability goals. Manufacturers are increasingly using biodegradable materials and reusable components to minimize environmental impact. Foam guns that enable precise foam dispensing while reducing excess waste will find significant traction as industries embrace circular economy principles.

Another key opportunity arises from digital integration and automation. The next generation of foam guns is expected to feature smart sensors, Bluetooth connectivity, and real-time performance monitoring, allowing for predictive maintenance and optimized foam usage. Such advancements will particularly benefit high-precision sectors like aerospace, electronics, and advanced manufacturing.

Emerging markets also offer vast potential. Rapid urbanization and industrialization in Asia-Pacific, Africa, and Latin America create new demand for efficient insulation tools. Local manufacturing partnerships and cost-effective distribution networks can help global players penetrate these high-growth regions.

Finally, strategic collaborations between foam gun manufacturers and foam material suppliers can result in integrated product solutions that offer end-users improved compatibility and performance. This vertical integration can serve as a strong competitive differentiator in an increasingly crowded marketplace.

Company Insights

Prominent companies shaping the industrial foam guns market include:

• 3M Company - Known for innovation in industrial tools, adhesives, and foam application systems.

• Carlisle Fluid Technologies - Specializes in precision fluid handling and foam dispensing systems.

• Soudal Group - A leading global producer of sealants and foams, offering a wide range of foam guns.

• Huntsman Corporation - Provides materials and equipment for polyurethane foam applications.

• Premier Building Solutions - Manufactures high-performance foam guns integrated with insulation systems.

• Hilti Group - Offers durable professional-grade foam guns used across construction and manufacturing sectors.

• Makita Corporation - Develops power tools and accessories, including ergonomic foam gun solutions.

Recent Developments:

Leading manufacturers have introduced recyclable aluminum-bodied foam guns to reduce environmental impact and improve durability.

Several key players have invested in digital dispensing technologies, integrating flow sensors and mobile app connectivity to enhance precision in industrial applications.

Related Reports:

https://www.persistencemarketresearch.com/market-research/flow-conditioners-market.asp

https://www.persistencemarketresearch.com/market-research/rotary-limit-switch-market.asp

https://www.persistencemarketresearch.com/market-research/hydraulic-bolt-tensioner-market.asp

https://www.persistencemarketresearch.com/market-research/horizontal-belt-filters-market.asp

https://www.persistencemarketresearch.com/market-research/industrial-hooks-market.asp

Persistence Market Research

Second Floor, 150 Fleet Street, London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Industrial Foam Guns Market, Transforming Precision Cleaning and Coating Applications Worldwide here

News-ID: 4241768 • Views: …

More Releases from Persistence Market Research

Event Tourism Market Set for Exponential Growth through 2032 - PMR Research

The global Event Tourism Market is poised for remarkable expansion, driven by sustained demand for live experiences, increased business travel, hybrid event adoption, and a rebound in international tourism. According to industry projections, the market is expected to grow from an estimated US$1,538.3 billion in 2025 to US$2,631.5 billion by 2032, registering a CAGR of 7.3% over the forecast period.

This robust growth underscores the evolution of event tourism into one…

Residential Lighting Fixtures Market Set for Robust Growth Through 2032

The global residential lighting fixtures market is poised for strong expansion over the coming decade, underpinned by shifting consumer preferences toward energy efficient, smart, and design centric lighting solutions. According to a comprehensive market analysis by Persistence Market Research, the market was valued at US$ 20.4 billion in 2025 and is projected to reach US$ 32.2 billion by 2032, growing at a CAGR of 5.9 % from 2025 to 2032.

➤…

Active Modified Atmospheric Packaging Market to Reach US$ 37.9 Billion by 2033 - …

The active modified atmospheric packaging market is gaining strong traction as food manufacturers retailers and logistics providers focus on extending product shelf life while maintaining freshness quality and safety. Active modified atmospheric packaging integrates gas flushing scavengers and moisture regulators to actively control the internal atmosphere of a package thereby slowing microbial growth oxidation and spoilage. Unlike passive packaging this advanced technology continuously interacts with the packaged product creating an…

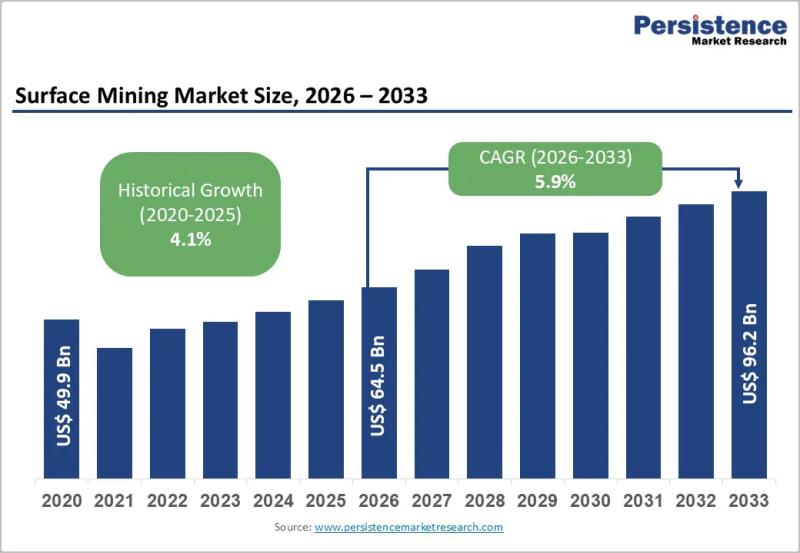

Surface Mining Market Size to Reach US$ 96.2 Billion by 2033 - Persistence Marke …

The surface mining market plays a critical role in the global extraction industry, enabling efficient recovery of minerals, metals, and fossil fuels located near the earth's surface. Surface mining techniques such as open pit mining, strip mining, mountaintop removal, and quarrying are widely used for coal, iron ore, copper, bauxite, and other industrial minerals. Compared to underground mining, surface mining offers higher production rates, lower operational risks, and improved cost…

More Releases for Foam

Foam Concentrate Market: High-growth Regions to Expand Geographic Footprint | Ch …

"This research study presents a comprehensive compilation of insightful findings concerning key aspects of the global Foam Concentrate industry, impacting its growth trajectory over the forecast period from 2023 to 2029. The report sheds light on the evolving sales trends of various tech products across different regions and countries, highlighting both growth and decline. A detailed regional analysis is a crucial part of this Foam Concentrate report, offering a meticulous…

Packaging Foams Market Report with Forecast 2020-2025 | Top Key Players: BASF, A …

Global Packaging Foams market would thus note a steady growth over the forecast period of 2020 - 2025. The robust CAGR (Compound Annual Rate Growth) will chart an upward growth curve and create lucrative growth opportunities in the global Packaging Foams market. In, turn, this will lead to improvement in market worth.

Request a PDF sample of this report: https://www.adroitmarketresearch.com/contacts/request-sample/1415

Global Packaging Foams Market: Notable Development

Global Packaging Foams market is set to…

Technical Foam Services Develops Innovative New Scaffold Foam

Northamptonshire, United Kingdom (8th February, 2013) - Technical Foam Services Ltd, a leading independent engineer-based manufacturer and foam producer, announces the creation of a new scaffold foam.

Technical Foam Services Ltd and their strategic construction partner have been working in unison to develop the Closed Cell PE Scaffold Foam, which uses high density polyethylene foam to offer protection against work equipment damage to decorated surfaces. The scaffold foam also uses a…

Technical Foam Services Creates Foam Inserts for Rak Ceramics

Northamptonshire, United Kingdom (18th February, 2013) - Technical Foam Services Ltd, a leading independent engineering-based manufacturer and foam producer, earlier this month secured a contract with leading ceramic tile design and manufacturer Rak Ceramics.

Rak Ceramics specialises in offering a range of high-quality ceramic tiles, distributing their products to DIY retailers and kitchen designers nationwide.

Sales representatives from the company were becoming increasingly concerned with the loss and damage of these tiles…

Technical Foam Services Manufactures Cancer Prevention Foam

Northamptonshire, United Kingdom (17 June, 2011) - Technical Foam Services, a leading independent engineering-based manufacturer and foam producer, is proud to have been part of an exciting new development in the world of cancer prevention.

A far cheaper and more patient-friendly method has been developed by the UK Medical Research Council, which involves the use of a reticulated foam sponge encapsulated within a pill. Once the pill is swallowed, it dissolves…

Technical Foam Services Expand Range of Foam Insert Fabrics

Northamptonshire, United Kingdom (19th May, 2011) – Technical Foam Services, a leading independent engineering-biased manufacturer and foam producer, has expanded their range of fabrics to be used with foam inserts.

Technical Foam Services have long been recognised as the UK’s leading supplier of foam inserts, producing them for a wide variety of applications, such as large suitcase inserts suitable for holding ceramics and glassware through to small inserts used…