Press release

Global and U.S. High Pressure Tungsten Carbide Market Report, Published by QY Research.

High Pressure Tungsten Carbide is a sintered composite material composed mainly of tungsten carbide (WC) particles bonded with metallic cobalt or nickel under extremely high temperature and pressure. This process produces a dense, ultra-hard structure with outstanding wear resistance, compressive strength, and toughness. It is commonly used in high-pressure applications such as drilling tools, seal rings, dies, cutting inserts, and nozzles operating under harsh environments. The material maintains its hardness and dimensional stability even at elevated temperatures, making it indispensable in oil and gas exploration, mining, metalworking, and aerospace industries. High pressure tungsten carbide's combination of extreme durability and chemical inertness provides superior performance in abrasive and corrosive conditions.https://www.qyresearch.com/reports/5276787/high-pressure-tungsten-carbide

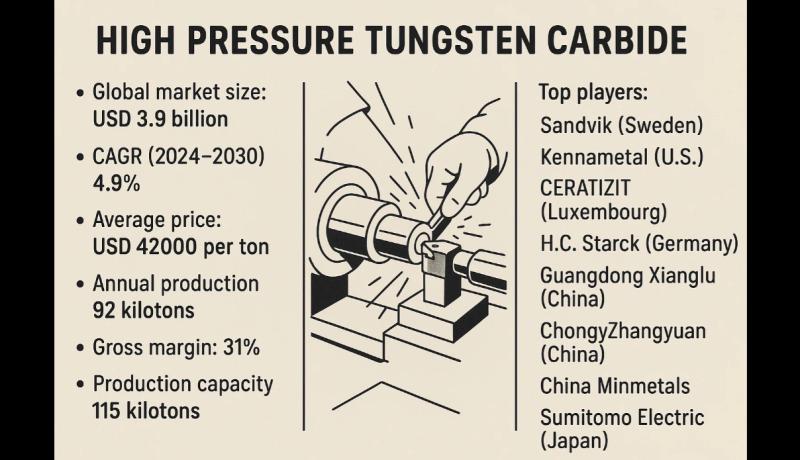

Core market data:

Global market size: USD 3.9 billion

CAGR (2024-2030): 4.9%

Average price: USD 42000 per ton

Annual production: 92 kilotons

Gross margin: 31%

Production capacity: 115 kilotons

List of Main players:

Sandvik (Sweden)

Kennametal (U.S.)

CERATIZIT (Luxembourg)

H.C. Starck (Germany)

Guangdong Xianglu (China)

Chongyi Zhangyuan (China)

China Minmetals (China)

Sumitomo Electric (Japan)

Tungaloy (Japan)

Federal Carbide (U.S.)

1. By Binder Type

Cobalt-Bonded Tungsten Carbide

Nickel-Bonded Tungsten Carbide

Iron-Based Binder Alloys

2. By Grain Size

Ultrafine

Submicron

Conventional

3. By Form

Rods and Bars

Cutting Inserts and Dies

Nozzles and Sealing Rings

Powder and Preforms

4. By Application

Oil & Gas Drilling Equipment

Mining and Quarrying Tools

Precision Cutting and Machining

High-Pressure Sealing Components

Aerospace and Defense Systems

Case study for bidding

Time: July 2023

Supplier: CERATIZIT

Buyer: Halliburton

Product: High-Pressure Tungsten Carbide Nozzles (Co-bonded, submicron grain size)

Quantity: 1,800 tons

Contract Value: USD 86 million

Delivery Timeline: July 2024

Detailed Application Scenario

In this project, Halliburton adopted CERATIZIT's high-pressure tungsten carbide nozzles for use in hydraulic fracturing and oilfield drilling systems. The components were engineered to endure extreme erosive wear and pressure exceeding 1,000 bar, ensuring consistent fluid flow and extended service life in abrasive slurry environments.

The submicron-grain carbide provided superior hardness and corrosion resistance compared to standard grades, reducing downtime and maintenance costs. The cobalt binder ensured toughness and resistance under cyclic pressure loading.

Halliburton selected this solution over conventional steel and ceramic nozzles due to its higher wear resistance, thermal stability, and longer operational lifespan. It enabled improved drilling accuracy, minimized equipment replacement frequency, and enhanced overall process efficiency in high-pressure energy extraction operations. This case exemplifies the critical role of tungsten carbide in ensuring durability and performance under extreme industrial conditions.

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

For Inquiries:

USA: +1-626-295-2442

Canada: +1-778-907-6631

China: +86-150-1303-8387

Japan: +81-90-3800-9273

South Korea: +82-2883-1278

India: +91-866-9986-909

Indonesia: +62-818-510-991

Germany: +49-15788468916

Switzerland: +41-765899438

Portugal: +351-910983247

Email: global@qyresearch.com

www.qyresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global and U.S. High Pressure Tungsten Carbide Market Report, Published by QY Research. here

News-ID: 4239526 • Views: …

More Releases from QY Research

Top 30 Indonesian Food and Beverages Public Companies Q3 2025 Revenue & Performa …

1) Overall companies performance (Q3 2025 snapshot)

PT Indofood Sukses Makmur Tbk (INDF) Large diversified food parent with beverage exposure

PT Mayora Indah Tbk (MYOR) Coffee, tea, RTD beverages & snacks

PT Ultrajaya Milk Industry & Trading Company Tbk (ULTJ) Milk & drinks

PT Indofood CBP Sukses Makmur Tbk (ICBP) Integrated processed food & beverage mix

PT Garudafood Putra Putri Jaya Tbk (GOOD) Snack foods &…

Connected Strength Training: The New Growth Engine for the Gym Equipment Industr …

Multi station gyms (also called multi-function home or commercial strength stations) integrate several resistance training modulespress, lat pull-down, leg curl/extension, cable crossover, and functional trainer into one compact system.

Equipment is widely adopted across home fitness, corporate wellness, apartment gyms, hotel fitness centers, schools, and commercial fitness clubs.

Demand is driven by rising health awareness, urban space constraints, and preference for all-in-one solutions that reduce footprint and capex compared to multiple single…

Low Sodium, High Growth: The Next Big Opportunity in Food Reformulation

Food grade salt replacement ingredients are formulated compounds designed to partially or fully substitute sodium chloride in processed foods while maintaining taste, preservation, and texture functionality.

These solutions are increasingly adopted due to global sodium-reduction mandates, rising hypertension prevalence, and clean-label food reformulation.

Products typically include potassium chloride blends, yeast extracts, amino acid systems, mineral salts, fermentation-derived flavor enhancers, and encapsulated masking technologies.

Applications cover snacks, bakery, processed meat, instant noodles, sauces, ready…

High-Margin Specialty Chemicals: Investment Guide to Biofuel Lubricity Boosters

Biofuel lubricity boosting agents are specialty chemical additives blended into biodiesel, renewable diesel, HVO, and low-sulfur fuels to restore or enhance fuel lubricity and protect pumps, injectors, and fuel systems from wear.

With tightening sulfur regulations and increased biofuel blending mandates, natural lubricity has declined, making lubricity improvers a mandatory additive class across most commercial biofuel blends.

The industry sits at the intersection of:

Specialty fuel additives

Renewable fuels and biodiesel production

Refinery blending operations

Engine…

More Releases for Carbide

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…