Press release

Metallography: Understanding the Microstructure of Metals

Metallography is the subdivision of materials science that deals with the study of the microstructure of metals and alloys. It is the study of the internal structure of metallic materials to learn of their composition, their grain size and any influence by different manufacturing or heat treatment processes. With metallography, scientists and engineers are able to determine the quality, performance and reliability of metals used in various industries like automotive, aerospace, construction, and manufacturing.What Is Metallography?

Fundamentally, metallography (https://www.metkon.com/what-is-metallography/) refers to the study of the structure of metals at the inside to appreciate the formation of the microstructure on the mechanical and physical properties of these materials. Each metal possesses a certain arrangement of grains, phases, and inclusions that directly influence the hardness, strength, ductility and corrosion resistance. Metallography enables scholars to view these microscopic characteristics and correlate them to the behavior of a material in various conditions.

The procedure normally includes a preparation of a sample, polishing the sample to mirror finish and the sample then being etched using a chemical reagent that exposes internal arrangement. After the sample is prepared, this is examined using an optical or electron microscope to examine the details of the surface of the metal.

The Metallographic Examination Process.

Metallography involves a number of processes that are highly managed to achieve precise and credible results. The main stages include:

Sectioning: A sample of the material is sectioned with precision saws or abrasive cutters. This should be done in a manner that the amount of heat and deformation is at minimum so that it does not distort the original structure.

Mounting: This is done by placing the specimen in the resin block to facilitate the ease of handling it in the grinding and polishing process. Mounting ensures that the sides of the sample are not damaged as well.

Grinding: The sample is ground so that the fine abrasive paper of a gradually decreasing grit size is used. This procedure eliminates sectioning deformities or irregularities.

Polishing: The specimen on the ground is polished by using fine abrasives, e.g. by diamond or alumina suspensions until a smooth reflective surface is achieved. It is important to have perfect polish to observe it correctly.

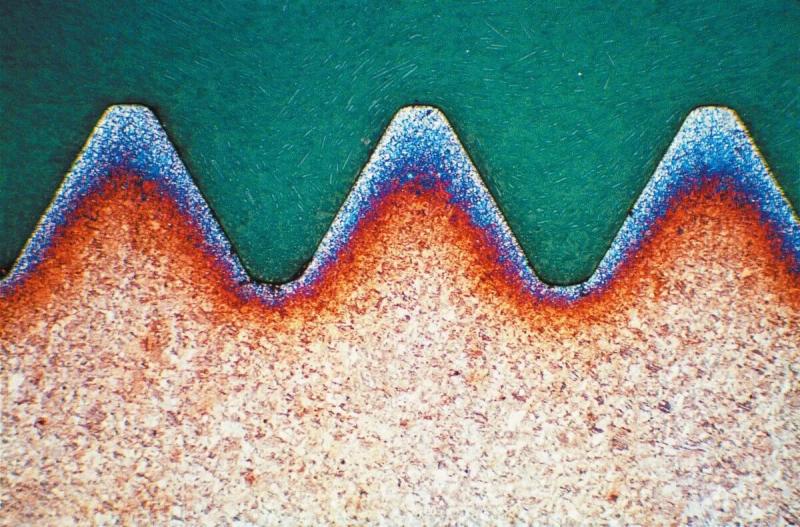

Etching: The work is polished with an appropriate chemical etchant. Selective Etching selectively attacks phases or grain boundaries to show the microstructural features that are otherwise not visible.

Microscopic Examination: Lastly, the prepared specimen is viewed on an optical or electron microscope. The step enables the metallographers to examine the grain structure, various phases, and determine inclusions or defects.

Uses of Metallography.

Metallography is of great importance in many areas whose performance and reliability of metals are crucial. It is widely used in:

Quality Control: This is the control of the manufacturing standards and specifications of the metals.

Failure Analysis: The study of causes of components failures, fractures or fatigue.

Research and Development: Testing of new alloys and heat treatment.

Process Optimization: The influence of forging, welding or casting on the microstructure.

Education and Training: Educating students and engineers on the behavior of materials.

Metallography aids industries to come up with stronger, safer and more durable materials by showing how they transform under various processes.

Significance of Metallography in Materials Science.

Metallography is not only important in visual observation. It connects the theory and practical metallurgy(https://www.metkon.com/what-is-metallography/). To illustrate, the grain size and shape of a material affect its mechanical properties, i.e. fine grains tend to enhance strength, whereas coarse grains enhance ductility. Through the analysis and quantification of these characteristics, metallography offers good information in terms of streamlining production and enhancing the quality of products.

Furthermore, metallography can be used to spot manufacturing flaws as porosity, inclusions, or heat treatment. Such problems are avoided early and lead to expensive failures avoided and increase the reliability of the metal components deployed in essential applications.

Conclusion

Metallography has continued to be a critical instrument in the study and enhancement of metals. It is a combination of careful specimen preparation and modern microscopy to reveal the microscopic characteristics which characterize the behavior of a given material. In laboratories, in production plants, or in research centers, metallography allows one to learn more about the way metals perform, and how they can be improved. In this scientific method, industries keep on improving materials that are useful to sustaining modern technology and infrastructure.

Metallography is in fact more than a laboratory process; it is a critical connection between the inner world of materials and t

Office 7602 182-184 High Street North East Ham London E6 2JA

Finixio Digital is a UK-based remote-first Marketing & SEO Agency helping clients worldwide. In only a few short years, we have grown to become a leading Marketing, SEO, and Content agency.

Contact:

Mail: Media.finixiodigital@gmail.com

Phone: +44 7577 509325

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metallography: Understanding the Microstructure of Metals here

News-ID: 4231286 • Views: …

More Releases from Finixio Digital

Hiddence.net: Premium Anonymous VPS & VDS Hosting

In today's world of constant digital surveillance, finding a hosting provider that combines high-performance hardware with genuine privacy is rare. Hiddence.net (http://Hiddence.net) redefines hosting by offering powerful VPS and VDS solutions designed to keep your identity completely anonymous. Whether you're running privacy-focused projects, mission-critical applications, or specialized workloads, Hiddence ensures your digital footprint remains fully protected-without sacrificing speed or reliability.

● Privacy Meets Performance

Most hosting providers require personal information during…

Conditions for Umrah in Islam: Requirements Every Pilgrim Must Know

Umrah is a sacred religious practice for Muslims all over the world that must be offered with wise planning. When you start planning your holy trip, begin it by searching for Umrah Packages 2026 (https://duatravels.co.uk/special-umrah-packages/) for an uplifted experience which must align around the conditions based on the Islamic theory. These are not just some requirements; they are divine conditions which are meant to maintain the peace of worship and…

3 Lite Double Steel Door Price Guide: Cost Factors, Glass Options, and Installat …

A 3 Lite Double Steel Door has become a popular option for both residential and commercial settings because it offers strength, security, and modern style in one package. Whether you are planning a renovation or building a new property, understanding the cost of this door helps you make a smart investment. Prices can vary depending on design, material quality, glass type, customization, and installation costs. This guide explains every key…

Illuminating Interior Design: Elevate Every Space with Thoughtful Lighting

Lighting is more than a functional necessity-it is the soul of interior design. The right lighting transforms spaces, enhances architecture, and creates atmosphere. From dramatic Vorelli Staircase Chandeliers (https://www.vorelli.co.uk/collections/luxury-staircase-chandeliers) to minimalist floor lamps, curated lighting choices define how a home looks, feels, and flows.

Chandeliers: The Statement of Elegance

Vorelli Chandeliers remain the ultimate symbol of luxury and sophistication. Whether classic crystal or modern sculptural designs, chandeliers anchor a room and draw…

More Releases for Metallography

Global Metallography Equipment Market Research Report 2025-2031

The global market for Metallography Equipment was estimated to be worth US$ 647 million in 2024 and is forecast to a readjusted size of US$ 933 million by 2031 with a CAGR of 5.4% during the forecast period 2025-2031.

Global Market Research Publisher QYResearch announces the release of its lastest report "Metallography Equipment - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031". Based on historical analysis (2020-2024)…

Grinding and Polishing Machines for Metallography Market Expansion Analysis Repo …

The global market for Grinding and Polishing Machines for Metallography was estimated to be worth US$ million in 2024 and is forecast to a readjusted size of US$ million by 2031 with a CAGR of %during the forecast period 2025-2031.

QY Research (Market Research Report Publisher) announces the release of its lastest report "Grinding and Polishing Machines for Metallography - Global Market Share and Ranking, Overall Sales and Demand Forecast…

Metallography Sample Preparation Equipment Market Analysis, Size, Regional Outlo …

LOS ANGELES, United States: QY Research offers an encyclopedic study of the global Metallography Sample Preparation Equipment market with holistic insights into vital factors and aspects that impact future market growth. The global Metallography Sample Preparation Equipment market has been analyzed for the forecast period 2022-2028 and historical period 2017-2021. In order to help players to gain comprehensive understanding of the Global Metallography Sample Preparation Equipment market and its critical…

Global Metallography Equipment Market Analysis by 2020-2025

Scope of the Report:

The global Metallography Equipment market size is expected to gain market growth in the forecast period of 2020 to 2025, with a CAGR of xx%% in the forecast period of 2020 to 2025 and will expected to reach USD xx million by 2025, from USD xx million in 2019.

Market segmentation

Metallography Equipment market is split by Type and by Application. For the period 2015-2025, the growth among segments…

Global Metallography Equipment Market Insights, Forecast 2018 to 2025: By Produc …

The recently published report titled Global Metallography Equipment Industry 2018 Market Research Report is an in depth study providing complete analysis of the industry for the period 2018 – 2025. It provides complete overview of Global Metallography Equipment Market considering all the major industry trends, market dynamics and competitive scenario.

The Global Metallography Equipment Industry Report 2018 is an in depth study analyzing the current state of the Global Metallography Equipment…

Metallurgist Joins the Metallography Department at Laboratory Testing Inc.

HATFIELD, PA, September 26, 2011 – Laboratory Testing Inc. (LTI) of Hatfield, PA USA recently hired Alan Fabiszewski as a Metallurgist in the company’s Metallography Department. His responsibilities include microscopic, macroscopic and microhardness examinations of test samples, failure analysis and weld qualification.

Fabiszewski is a Drexel University graduate with a B.S. degree in Mechanical Engineering and has completed courses through ASM International and NACE International. He brings over 20 years of…