Press release

Reducing Waste and Downtime with Automated Visual Inspection

In manufacturing, profitability isn't just about what you make; it's about what you don't lose. Two of the greatest silent killers of profit are waste and downtime. Waste-in the form of bit, rework, and raw materials-is a direct hit to your bottom line. Downtime-the unscheduled stops, slow troubleshooting, and line bottlenecks-cripples your efficiency and output.For decades, quality control (QC) was often part of the problem. A manual inspection process is inherently slow, subjective, and reactive. It catches defects after they've already consumed materials and after the problem has already occurred, often leading to more downtime for troubleshooting.

This is precisely why AI-powered Automated Visual Inspection (https://opsiocloud.com/automated-visual-inspection/) (AVI) has evolved from a simple QC tool into a core operational strategy. It's no longer just about finding flaws. It's about creating an intelligent, data-driven system that proactively prevents waste and predicts downtime. Forward-thinking manufacturers are leveraging partners like Opsio Cloud (https://opsiocloud.com/) to turn their quality data into their most powerful weapon against inefficiency.

The "Old Way": How Manual QC Creates Waste and Downtime

To understand the solution, we must first admit the problem. The traditional manual inspection model is a fundamental source of both waste and downtime.

How it Creates Waste: A human inspector is subjective. They get fatigued. An inspector at 4:00 PM on a Friday is less accurate than they were at 9:00 AM on Monday. This leads to two types of waste:

Missed Defects (pieces): A flawed part is passed, sent downstream, and assembled into a high-value final product (e.g., a $2 faulty chip on a $500 circuit board), forcing the entire unit to be wisped.

False Positives (wisp): A perfectly good part with a minor, acceptable cosmetic variation is rejected and thrown in the wisp bin out of an abundance of caution.

How it Creates Downtime: Manual inspection is a bottleneck. The entire production line can only move as fast as the slowest human checkpoint. Furthermore, when a defect is found, it's a historical event. The inspector finds a bad part, but the machine that made it might have produced thousands more in the interim. This triggers an emergency, line-stopping "all hands on deck" search to find the root cause.

Pillar 1: How AVI Actively Reduces Waste

AI-powered Automated Visual Inspection Services (https://opsiocloud.com/automated-visual-inspection/) attack waste at its source. By integrating high-speed, intelligent "eyes" directly into the production line, waste is minimized in three powerful ways.

1. Catching Defects at the Point of Origin

The most significant way AVI reduces waste is by catching a defect the instant it is created.

Instead of inspecting a batch of 10,000 parts at the end of the line, an AVI system inspects each part in real-time. The moment a machine (like a printer, mold, or CNC machine) produces a single item out of specification, the AVI system detects it.

This triggers an immediate alert or even an automated line stop. The result is that you wisp one bad part, not ten thousand. This saves all the raw materials, energy, and machine time that would have been wasted on the subsequent 9,999 flawed products.

2. Eliminating Costly False Positives

Traditional, rule-based automation was notoriously "brittle." It could only check for exact pixel matches, leading it to reject good products with harmless variations, like a slight change in a material's texture or a harmless reflection.

AI-powered AVI is different. It is "trained," not just "programmed." By showing the AI model thousands of examples of "good" parts-with all their acceptable variations-the system learns the subtle difference between a harmless cosmetic anomaly and a critical functional defect. This intelligence means fewer good products are thrown into the wisp bin, directly improving your First Pass Yield (FPY) and reducing material waste.

3. Guaranteeing 100% Inspection to Protect Downstream Value

In complex assemblies, "statistical sampling" (checking 1 in 100 parts) is a high-stakes gamble. If one flawed component slips through, it can compromise a final product that is 1,000 times more valuable.

AVI makes 100% inspection a reality. By verifying every single component, you can be certain that no flawed part ever makes it to the next, more valuable stage of assembly. This eliminates the "compounded waste" where a $0.10 faulty resistor forces the wisping of a $1,000 finished electronic assembly.

Pillar 2: How AVI Proactively Prevents Downtime

This is where modern AI-powered AVI truly separates itself from simple inspection. It doesn't just find defects; it generates data. This data is the key to transforming your maintenance from reactive to predictive, directly cutting downtime.

1. A Powerful Engine for Predictive Maintenance

An AVI system is the most powerful data-collection tool on your factory floor. It doesn't just see "pass" or "fail." It sees trends.

A human inspector can't tell you that a drilled hole is drifting 0.01mm to the left every hour. An AI system can. It logs this "data drift" and can raise an alert long before the hole is actually out of specification.

This alert is an early warning signal that a machine bearing is wearing out, a jig is loosening, or a tool needs calibration. This allows you to schedule maintenance during a planned stop instead of suffering a catastrophic, line-stopping failure mid-shift. This is the essence of predictive maintenance, and it turns unplanned downtime into manageable, scheduled upkeep.

2. Instant Root Cause Analysis

When a critical, unexpected failure does happen, the worst part of the downtime is the troubleshooting. A team of engineers and technicians might spend hours trying to find the source of the problem.

With an AVI system, the root cause is often found in seconds. The system provides an immediate data-rich report: "At 10:15 AM, a new 'smudge' defect began appearing on 100% of parts coming from Nozzle 3 on Machine B."

Your team doesn't have to guess. They know exactly where to go and what to fix. This cuts troubleshooting and diagnosis time from hours to minutes, getting the line back up and running exponentially faster.

Conclusion: A New Strategy for Efficiency

Automated Visual Inspection is no longer just a quality control function. It is a strategic tool for operational excellence. It is a direct assault on the two biggest enemies of profitability: waste and downtime.

It transforms your factory from a reactive model to a proactive, data-driven one. It stops waste at the source and provides the predictive insights needed to eliminate unplanned downtime. In the factory of the future, quality and efficiency are not separate goals-they are one and the same, driven by intelligent data.

To make this transformation a reality, manufacturers need a partner who understands both the industrial hardware and the complex cloud and AI infrastructure behind it. The expert Automated Visual Inspection Services provided by Opsio Cloud (https://opsiocloud.com/) are designed to integrate this intelligence seamlessly into your operations, turning your quality data into your single greatest weapon against inefficiency.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Reducing Waste and Downtime with Automated Visual Inspection here

News-ID: 4258152 • Views: …

More Releases from Finixio Digital

Commercial vs industrial dehumidifiers - what's the difference?

Commercial dehumidifiers and industrial dehumidifiers sound like they should be the same thing. Both are just devices that extract water from the air, correct?

Well, not quite. When you find yourself needing to dry out large spaces like warehouses, factories, or even office buildings you need something much bigger than your residential dehumidifier.

Commercial and industrial models were made for these situations. But what exactly is the difference between commercial…

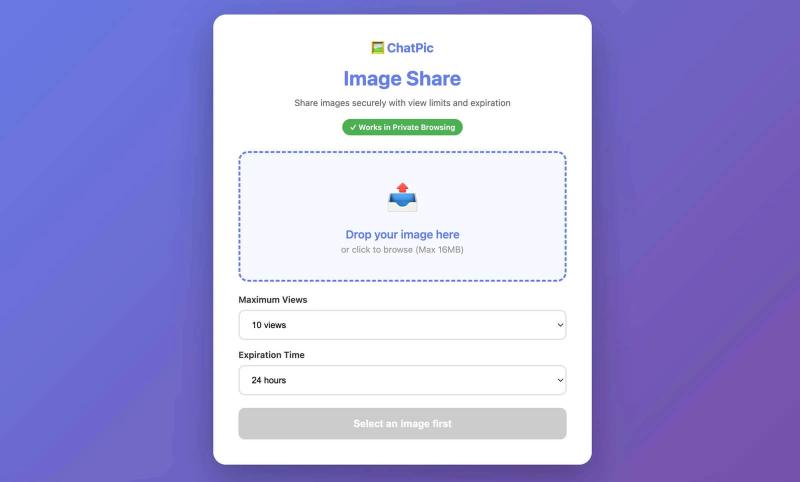

ChatPic Review (ChatPic.co.uk): The Smartest Way to Share Images Online - With V …

● Stop Sharing Images That Live Forever Online

Every time you send a photo through a standard image hosting platform, that image can potentially exist online indefinitely - saved to servers, cached by browsers, screenshotted and reposted, or simply sitting in someone's cloud storage long after it was relevant.

Most people accept this as just how image sharing works. ChatPic.co.uk proves that it doesn't have to be.

ChatPic (https://chatpic.co.uk/) is a free browser-based…

Why millions still lack clean water & how donations can help

Despite decades of development efforts, access to safe drinking water remains out of reach for billions of people. International estimates show that more than two billion individuals still lack reliably managed water services. For many communities, daily life involves uncertainty about whether clean water will be available tomorrow.

Many people searching for ways to donate to water are surprised to learn how widespread the crisis continues to be. It is not…

Why Your Foreign Company Is Still Taxable in the US

There's a moment most US expats remember clearly. You register a company abroad. The paperwork goes through. A local accountant confirms everything is compliant. You pay tax in your new country. It feels settled.

Then, months later, usually while dealing with your US tax return, a different question lands:

Why is the IRS still involved?

It feels unfair at first. Even a little absurd. The company isn't in the US. The clients…

More Releases for AVI

AV System Integration Market Trend, Size, Share, Forecast 2026 and Key Players A …

AV System Integration Market report gives the most appropriate and specific information to the decision-makers in the IT & Telecommunication industry which saves their time and result in excellent output. The report carefully analyses the potential of the market with respect to the current scenario and the future prospects with respect to several industry aspects. This AV System Integration Market report explains several market factors such as market estimates…

Pro AV Market Growth Analysis and Significant Trends Till 2027 | AVI Systems, AV …

Pro AV refers to audio-video products and services, which are utilized for numerous applications such as collaborative conferencing, including video, audio, web, command and control centers, virtual events, digital signage, tradeshow exhibitions, and corporate events. Innovation, as well as savvy customers who push audio-video solutions to accommodate novel ways of working and experiencing the world, continue to offer new and different opportunities. The pro AV industry to see greater acceptance…

Pro AV Market Growth Analysis and Significant Trends Till 2027 | AVI Systems, AV …

Pro AV refers to audio-video products and services, which are utilized for numerous applications such as collaborative conferencing, including video, audio, web, command and control centers, virtual events, digital signage, tradeshow exhibitions, and corporate events. Innovation, as well as savvy customers who push audio-video solutions to accommodate novel ways of working and experiencing the world, continue to offer new and different opportunities. The pro AV industry to see greater acceptance…

Enterprise System Integrators Market 2018 | Top Players - AVI Systems, Red Threa …

Enterprise System Integrators Market Research Report

Enterprise System Integrators are professional organizations that provide systems integration products and services to customers, usually corporate or corporate.

This report studies the Enterprise System Integrators market status and outlook of Global and major regions, from angles of players, countries, product types and end industries; this report analyzes the top players in global market, and splits the Enterprise System Integrators market by product type and applications/end…

Healthcare and Medical System Integrators Market 2017- AVI Systems, Red Thread S …

Healthcare and Medical System Integrators Market 2017 Industry research report provides important information to identify and analyze the market need, market size and competition. This market research report used in maintaining competitiveness over competitors.

System integration is defined in engineering as the process of bringing together the component sub-systems into one system (an aggregation of subsystems cooperating so that the system is able to deliver the overarching functionality) and ensuring…

MKV to AVI Converter 3.0 Released - A powerful video converter which can convert …

Sep. 01, 2006 -- DigitByte Studio has released MKV to AVI Converter 3.0, a powerful, a powerful video converter which can convert convert MKV to AVI DivX XviD, Convert other video formats MPEG, MPG, ASF, WMV, OGM, VCD, SVCD, DAT to AVI file also. MKV to AVI Converter is also a video splitter and editor.

The key features of MKV to AVI Converter include: Encode AVI with DIVX, XVID, Windows Media…