Press release

How to Choose the Best OEM Stainless Steel Bag Hardware for Your Brand

When selecting a hardware supplier, every luxury brand owner or product director asks: How do I pick the best OEM stainless steel bag hardware for my design, durability, and brand promise? One name emerges increasingly in that conversation: China Best Pvd Stainless Steel Leather Hardware Manufacturer(https://www.chinayibi.com/)- YIBI. YIBI provides custom stainless steel bag components such as frames, clasps, buckles, connectors, and snap hooks, finished with advanced PVD or plating, tailored to your brand's design language and performance standards.This Q&A-style press release will help prospective brands navigate the decision process. The first half outlines the macro trends influencing bag hardware choices; the second half presents how YIBI distinguishes itself, its core product portfolio, usage scenarios, technical advantages, and real-world client positioning.

Part I. Industry Trends & What Brands Should Watch

Q1: Why is stainless steel gaining ground over traditional brass or zinc hardware?

A: The trend is clear: designers and consumers demand hardware that lasts and resists visual degradation. Stainless steel offers high corrosion resistance, resistance to fading, non-oxidation, and excellent durability - qualities many brass or zinc alloys can't match over time. YIBI promotes these advantages on its stainless steel hardware pages.

Additionally, stainless steel allows more refined finishing (mirror polish, brushing, PVD coatings) with stable adhesion, enabling high-end aesthetics that endure. As manufacturers push product lifespans and guarantee quality, stainless steel is increasingly seen as a contemporary premium material.

Q2: What role do finishing technologies (like PVD) now play in hardware selection?

A: Finishes are no longer secondary; they are critical brand touchpoints. PVD (Physical Vapor Deposition), ionic plating, micro-grain polishing, surface texture, and gradient color effects are expected in premium lines. A hardware piece may have perfect mechanics, but if its finish fades or scratches, the brand is compromised. The "PVD Stainless Steel Leather Hardware" descriptor signals that these finishing layers must be both beautiful and durable.

Q3: How important is customization and agility in the current OEM hardware market?

A: Very important. Brands want flexibility to adapt to trend cycles without being locked into standard parts. Hardware suppliers must not only fulfill but co-develop, offering 3D modeling, prototyping, design iteration, small-run changes, and rapid turnaround. Basic commodity hardware can no longer suffice in high-end or niche collections.

Q4: Why do sustainability, traceability, and certification matter for metal hardware?

A: ESG is no longer optional. While sustainability pressure often focuses on fabrics and packaging, savvy brands are now demanding traceable recycled content and credible certifications even at the hardware level. Hardware is increasingly scrutinized for raw material sourcing, chain-of-custody, and whether a vendor can support recycled or certified alloys. Suppliers lacking transparency risk exclusion. The hardware that houses logos, clasps, and structure can become a weak spot in a brand's sustainability story.

Q5: In short, what should a brand demand from a hardware OEM in 2025?

A: Key capabilities include:

High-precision tolerance and structural integrity (especially for frames and hinges) Aesthetic finishes that resist fading, scratching, and tarnish Deep customization and design collaboration Lead-time flexibility and responsiveness Sustainability credentials or traceability Excellent quality control and vertical integration to reduce risk

Brands that ignore these evolving expectations often end up with hardware that undermines their product quality, reliability, or brand image.

Part II. YIBI: How It Stacks Up & What It Brings to the Table

Q6: Who is YIBI, and how do they position themselves vs. typical hardware vendors?

A: YIBI, headquartered in Shenzhen, China, is an OEM/ODM manufacturer focusing on precision stainless steel and zirconia ceramic hardware components for luxury bags, leather goods, and accessories.

What makes YIBI distinct is its alignment as a technical partner, not just a parts supplier: it handles concept, prototyping, finish development, and mass manufacturing under consistent quality control. It holds certifications including SMETA 4P, GRS, RCS, RJC, ISO9001, and TS/16949.

Many vendors focus on brass or zinc alloy parts with standard plating. YIBI, by contrast, emphasizes stainless steel, ceramic, and high-grade finishing, backed by MIM (metal injection molding) and powder metallurgy capacities for high-precision parts.

Q7: What are YIBI's core advantages when compared to competitors?

1.Vertical Integration & Control

YIBI controls stages from raw material sourcing, MIM/CIM, plating, finishing, inspection, to assembly - reducing external dependency and ensuring consistency.

2.Finishing Precision and Jewelry-Inspired Craft

Drawing from its hardware and jewelry domain, YIBI applies micro-polishing, tight PVD color control, and fine surface textures that many hardware-only firms cannot match.

3.Certification-Driven Credibility

YIBI's pursuit of GRS and RCS certifications enables brands to credibly claim recycled content or supply-chain traceability at the metal component level - a serious differentiator many competitors lack.

4.Design Collaboration & R&D Strength

The firm provides engineering support, 3D modeling, prototyping, tolerance simulation, and iterative revisions - helping brands reduce risk and maintain design integrity.

5.Lead Time & Agility

With in-house tooling and dual-factory structure, YIBI can offer faster pilot runs and respond to small adjustments, essential in fast-paced fashion cycles.

6.Broad Portfolio of Specialized Hardware

YIBI doesn't just do frames - it covers buckles, snap hooks, sliders, connectors, logo accents, ceramic-metal hybrid pieces, and more, often to matching aesthetic standards.

Q8: What product lines and application scenarios does YIBI address?

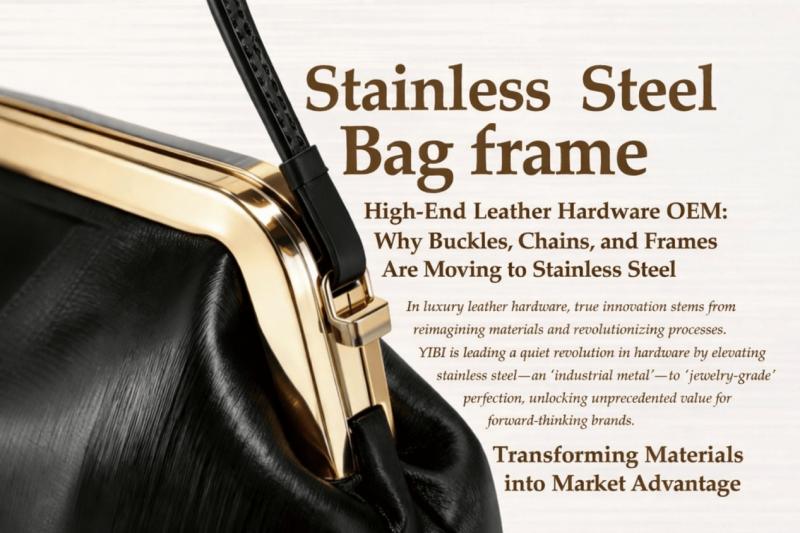

. Custom Stainless Steel Bag Frames: As structural components for frame-style bags, YIBI ensures hinge smoothness, dimensional stability, and longevity, combining design and function.

Zirconia Ceramic & Steel Buckles: Combining ceramic and stainless steel, these buckles offer scratch resistance, color depth, and premium texture. Snap Hooks / Dog Clips: YIBI offers powder metallurgy 316 stainless steel dog clip snap hardware, optimized for durability and plating performance. 316 Stainless Steel Belt Buckles: With mirror polish, matte effects, or brushed finishes, YIBI's buckles are tailored for bags and belts. Zippers, Pullers, Sliders & Connectors: Coordinated with bag frames and decorative hardware, enabling unified aesthetics across the piece. Decorative Logo Plates & Accents: Small but brand-significant metal components finished to tight tolerances.

These parts find usage in luxury handbags, clutches, belts, structured accessories, and any leather goods where both mechanical robustness and design harmony are required.

Q9: Are there concrete client or market references that show YIBI's standing?

YIBI has been recognized in industry listings as a reliable manufacturer of bag hardware and complicated metal parts. Its public-facing product pages advertise that it serves international brands and can support mass production in 35-40 working days.

For example, in its ceramic & stainless steel buckle product listing, YIBI claims it is an "approved vendor of many International Brands" and offers OEM/ODM services.

In its hardware showcase, YIBI describes itself as one of the "best quality bag hardware suppliers and manufacturers in China," focusing on stainless steel and ceramic hardware via in-house advanced processes.

Though specific brand names may not always be public (often due to NDA), the combination of published capability, certification, technical detail, and product depth positions YIBI above commodity-level hardware houses.

Final Thoughts & Guidance

If you're a brand evaluating OEM stainless steel bag hardware, use the following checklist:

1.Material & Finish Integrity - Demand suppliers that use true stainless steel grades and advanced, stable finishing (e.g. PVD)

2.Tolerance & Mechanical Performance - Ensure hinge, clasp, and frame tolerances are tight; request life-cycle tests

3.Design & Prototyping Support - Prefer firms that co-develop, not just replicate drawings

4.Sustainability & Traceability - Ask for certificates, raw material traceability, or recycled content where relevant

5.Production Control & Lead Time - Favor manufacturers with vertical integration and agility

6.Portfolio Breadth - A vendor that covers frames, buckles, connectors, accent hardware allows cohesive design language

YIBI embodies these qualities by combining deep expertise in hardware, jewelry-level finishing techniques, sustainable credentials, and design collaboration. It is a strong option for brands seeking China's Best Pvd Stainless Steel Leather Hardware Manufacturer - not only in terms of parts, but as a partner aligned with design quality, performance, and ESG aspirations.

For further information or partnership inquiries, please visit YIBI's LinkedIn page:

https://www.linkedin.com/company/yibi-group/

Address: 2nd, Fl, Tongfu industrial Park, Dalang Village Dalang Street, Longhua District, Shenzhen, 518109, China

email: adam@chinayibi.com

YIBI is a jewelry manufacturer with a strong technical background and extensive experience, dedicated to providing high-quality OEM/ODM jewelry customization services for international brands. We work closely with designers from well-known global brands to help transform their creative concepts into reality, offering comprehensive technical support and solutions. Our professional team is skilled in jewelry design and production processes, with strong R&D capabilities and an independent manufacturing facility to ensure the highest quality and timely delivery of each piece.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Choose the Best OEM Stainless Steel Bag Hardware for Your Brand here

News-ID: 4226178 • Views: …

More Releases from Yibi Group

Metal Price Surge: How Fashion Jewelry Brands Shift from Brass & Silver to 316L …

With gold and silver prices remaining elevated and raw material volatility reshaping sourcing decisions, fashion jewelry brands worldwide are accelerating a strategic shift toward long-lasting, cost-stable materials such as 316L stainless steel. YIBI, a technically driven jewelry manufacturer and OEM/ODM partner for international brands, is supporting this transition by delivering scalable manufacturing, advanced finishing, and consistent quality for high-end fashion jewelry collections. In response to growing demand for durable and…

High-End Leather Hardware OEM: Why Buckles, Chains, and Frames Are Moving to Sta …

As luxury and premium accessory brands face rising expectations for durability, structural precision, and long-term quality stability, the leather goods hardware industry is undergoing a clear material shift. In the mid-to-high-end segment, functional components such as buckles, chains, zipper pulls, snap hooks, and especially bag frames (Bag Frames) are no longer treated as interchangeable metal parts. As a China Luxury Bag Frame Hardware Manufacturer(https://www.chinayibi.com/product_category/product/), YIBI works closely with international brands…

From YIBI: Achieving Excellence with RJC Certification

In the evolving landscape of luxury jewelry manufacturing, standards of quality and responsibility have never been higher. Today's brands require not only superior design execution but also ethical credibility across the supply chain. YIBI, a trusted OEM/ODM partner based in Shenzhen, has solidified its reputation as a Global Leading Custom Stainless Steel Jewelry Manufacturer(https://www.chinayibi.com/product_category/oem-stainless-steel-jewelry-manufacturing/), offering clients both unmatched craftsmanship and the assurance of internationally recognized certifications such as the Responsible…

YIBI: Setting the Standard as China's Best Stainless Steel Jewelry Manufacturer

In the fast-growing luxury jewelry market, selecting a trusted manufacturing partner is essential for brands seeking quality, innovation, and efficiency. Recognized as a Top 10 Premium Stainless Steel Jewelry Manufacturer In China(https://www.chinayibi.com/product_category/oem-stainless-steel-jewelry-manufacturing/), YIBI specializes in crafting high-quality stainless steel jewelry that combines durability, elegance, and modern design. Stainless steel, especially 316L stainless steel, is renowned for its corrosion resistance, hypoallergenic properties, and ability to maintain a polished, long-lasting finish. These…

More Releases for OEM

OEM Partnership Guide: Working with a Touch-free Automatic Kitchen Garbage Can O …

With increasing global demand for smart home solutions, Sinoware International Ltd, a top provider in household products industry, is pleased to unveil expanded OEM partnership initiatives.

Sinoware has established itself in Jiangmen--China's premier stainless steel industry zone--as an indispensable touch-free automatic kitchen garbage can OEM manufacturer for global brands seeking to incorporate high-tech sanitation solutions into their portfolios.

By combining their decades-old tradition of metal craftsmanship with cutting-edge infrared and…

Revolutionizing OEM Coatings With Sustainable Solutions Trend: A Crucial Influen …

Which drivers are expected to have the greatest impact on the over the oem coatings market's growth?

The surge in requirements from final consumer industries is forecasted to boost the expansion of the OEM coatings market. These coatings, referred to as OEM, are utilized during the integration of other firms' products into the substrate process or application. They prove to be beneficial for a variety of end-user sectors, including automotive and…

OEM Technology Partnerships Launches Brokerage Specializing in 100+ OEM Technolo …

San Francisco, California, USA - February 13, 2025 - OEM Technology Partnerships is thrilled to announce the launch of its specialized brokerage focused on connecting businesses with a comprehensive portfolio of over 100 Original Equipment Manufacturer (OEM) technologies. This new venture is poised to revolutionize how companies access and implement cutting-edge solutions across diverse industries.

Leveraging deep industry expertise and a vast network of OEM partners, OEM Technology Partnerships offers a…

OEM or ODM Watches? What's the Difference?

When searching for a watch manufacturer for your store or watch brand, you may come across the terms OEM and ODM. But do you truly understand the difference between them? In this article, we will delve into the distinctions between OEM and ODM watches to help you better grasp and choose the manufacturing service that suits your needs.

Image: https://www.naviforce.com/uploads/15a6ba3911.png

What's OEM / ODM Watches [https://www.naviforce.com/products/]

OEM (Original Equipment Manufacturer) watches are produced…

OEM Partnership with Extreme Networks

ComputerVault announces an OEM partnership with Extreme Networks and has certified its switches for use with ComputerVault enterprise software to deliver virtual desktop infrastructure (VDI).

Extreme Networks industry leading switches deliver ComputerVault Virtual Desktops at faster than PC speeds in the LAN and WAN.

“ComputerVault is very excited to work with Extreme Networks. Not only are their switches very reliable, but their exceptional performance guarantees a great user experience”, said Marc…

Humidity Measurement Module for OEM Applications

The EE1900 humidity module from E+E Elektronik is optimised for the measurement of relative humidity (RH) or dew point temperature (Td) in climate and test chambers. With outstanding temperature compensation across the working range from -70 °C to 180 °C (-94 °F to 356 °F) and the choice of stainless steel and plastic probes, the module is suitable for a wide range of applications.

High Accuracy in Harsh Environment

The excellent…