Press release

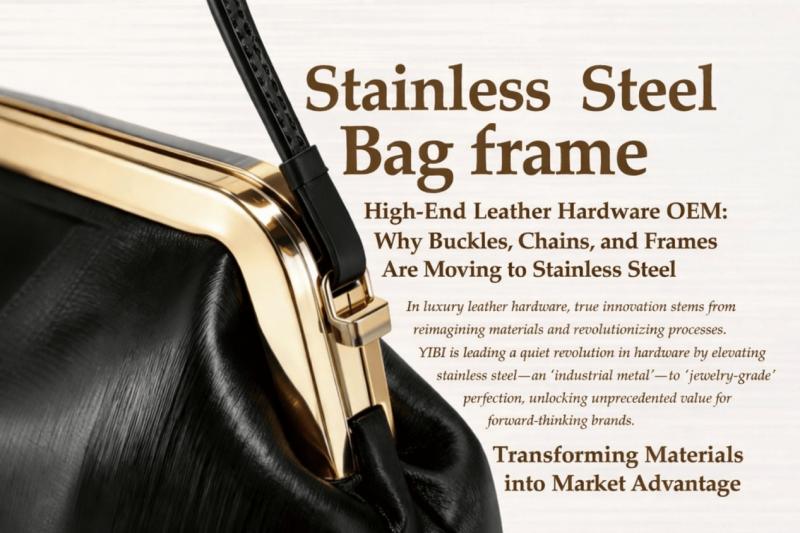

High-End Leather Hardware OEM: Why Buckles, Chains, and Frames Are Moving to Stainless Steel

As luxury and premium accessory brands face rising expectations for durability, structural precision, and long-term quality stability, the leather goods hardware industry is undergoing a clear material shift. In the mid-to-high-end segment, functional components such as buckles, chains, zipper pulls, snap hooks, and especially bag frames (Bag Frames) are no longer treated as interchangeable metal parts. As a China Luxury Bag Frame Hardware Manufacturer(https://www.chinayibi.com/product_category/product/), YIBI works closely with international brands navigating this transition, supporting the move from traditional alloys to engineered stainless steel solutions that deliver higher structural strength, consistent precision, and long-term performance for modern luxury handbags.Today, brands are explicitly transitioning from traditional copper-based alloys and zinc alloys to stainless steel, seeking stronger structural performance, more stable surface behavior, and reduced long-term risk in daily use. In this transformation, YIBI positions itself as a high-end leather hardware manufacturer specializing in stainless steel materials, supporting premium brands with engineered hardware systems designed for modern luxury handbags.

Industry Shift: Why Stainless Steel Is Replacing Brass and Zinc Alloys

For decades, brass and zinc alloy have been widely used in leather hardware due to their ease of casting and traditional weight perception. However, as bag sizes increase and usage scenarios diversify, the limitations of these materials are becoming increasingly evident.

Compared with stainless steel:

Copper-based alloys (brass)

Softer material structure, more prone to deformation under long-term mechanical stress

Susceptible to surface oxidation and discoloration, especially in humid or high-contact environments

Plating layers are more likely to wear or peel after extended use

Zinc alloy

Lower structural strength

Higher risk of cracking or distortion in large-format or load-bearing components

Less suitable for repeated opening-and-closing mechanisms

In contrast, stainless steel-especially 316L stainless steel-offers significantly higher tensile strength, superior corrosion resistance, and long-term dimensional stability. This makes it increasingly favored for hardware components that must maintain precision, alignment, and surface quality throughout the product lifecycle.

As a result, stainless steel is no longer viewed as a "material upgrade option," but rather as a strategic choice for premium and luxury leather goods, particularly in structural hardware categories.

Bag Frames and Stainless Steel: A Structural-Level Upgrade

Among all leather hardware components, bag frames represent one of the most demanding applications. Unlike decorative buckles or logo plates, bag frames define the opening structure, closure precision, and long-term shape retention of a handbag.

In practical use, bag frames must withstand:

Thousands of opening and closing cycles

External pressure during travel and storage

The weight of larger bag bodies and internal contents

When manufactured with traditional alloys, bag frames are more likely to suffer from gradual deformation, misalignment, or inconsistent closure performance over time.

Compared with traditional deformation-prone metals, 316L stainless steel provides significantly higher structural strength, ensuring that large-format bag frames maintain precise alignment and tight closure even after long-term repeated use. This material stability helps ensure that the frame edges remain perfectly fitted, delivering the "clean closure feel" that luxury consumers expect.

For this reason, stainless steel bag frames are becoming the preferred solution for:

Large-capacity handbags

Structured fashion bags

Travel-oriented premium leather goods

Designs requiring slim profiles but high rigidity

YIBI Positioning: A Stainless Steel-Focused High-End Leather Hardware Manufacturer

YIBI is a high-end leather hardware manufacturer with a clear focus on stainless steel materials. Rather than offering mixed-material solutions, YIBI concentrates on engineering stainless steel components that meet the structural, aesthetic, and durability standards of premium leather brands.

The company specializes in OEM/ODM manufacturing of stainless steel hardware, including:

Bag frames (rigid and semi-rigid systems)

Chains and strap components

Buckles, clasps, and snap hooks

Zipper pulls and functional connectors

Coordinated stainless steel hardware sets

By focusing on stainless steel, YIBI supports brands that prioritize long-term quality consistency, structural reliability, and controlled surface performance, rather than short-term cost reduction.

Engineering Strength: Stainless Steel Bag Frames and Functional Hardware

1) Precision Stainless Steel Bag Frame Manufacturing

YIBI develops stainless steel bag frames with strict tolerance control, optimized hinge structures, and consistent surface finishing. These frames are designed to maintain dimensional accuracy and closure precision across extended usage cycles, even in large-size or heavy-use handbags.

2) Coordinated Stainless Steel Hardware Sets

To ensure visual and performance consistency, YIBI supplies complete stainless steel hardware sets-including frames, chains, buckles, and logo plates-allowing brands to maintain uniform tone, finish behavior, and tactile feel across multiple SKUs.

3) Performance Advantages of Stainless Steel in Daily Use

Stainless steel hardware offers:

Strong resistance to sweat, humidity, and corrosion

Reduced deformation risk under load

Stable surface performance with lower plating failure rates

These advantages directly reduce after-sales issues such as misalignment, surface wear, or functional complaints.

Collaboration Model: Supporting Premium Brands from Development to Mass Production

YIBI works closely with international brand teams through structured OEM/ODM workflows. From early-stage design evaluation to sampling, testing, and mass production, the company provides engineering-based feedback to ensure that stainless steel hardware designs are both aesthetically refined and structurally sound.

This approach is particularly valuable for bag frame development, where early material and structure decisions have long-term consequences for product quality and brand perception.

Conclusion: Stainless Steel as the New Standard for Premium Leather Hardware

The transition from brass and zinc alloy to stainless steel represents more than a material change-it reflects a broader shift in how premium brands define quality, durability, and value.

With its focus on stainless steel materials and high-end leather hardware engineering, YIBI positions itself as a long-term manufacturing partner for brands seeking structural reliability, refined finishing, and consistent performance in luxury leather goods hardware.

For more information and business inquiries, visit YIBI Group on LinkedIn:

https://www.linkedin.com/company/yibi-group/

Address: 2nd, Fl, Tongfu industrial Park, Dalang Village Dalang Street, Longhua District, Shenzhen, 518109, China

email: adam@chinayibi.com

YIBI is a jewelry manufacturer with a strong technical background and extensive experience, dedicated to providing high-quality OEM/ODM jewelry customization services for international brands. We work closely with designers from well-known global brands to help transform their creative concepts into reality, offering comprehensive technical support and solutions. Our professional team is skilled in jewelry design and production processes, with strong R&D capabilities and an independent manufacturing facility to ensure the highest quality and timely delivery of each piece.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release High-End Leather Hardware OEM: Why Buckles, Chains, and Frames Are Moving to Stainless Steel here

News-ID: 4362832 • Views: …

More Releases from Yibi Group

Metal Price Surge: How Fashion Jewelry Brands Shift from Brass & Silver to 316L …

With gold and silver prices remaining elevated and raw material volatility reshaping sourcing decisions, fashion jewelry brands worldwide are accelerating a strategic shift toward long-lasting, cost-stable materials such as 316L stainless steel. YIBI, a technically driven jewelry manufacturer and OEM/ODM partner for international brands, is supporting this transition by delivering scalable manufacturing, advanced finishing, and consistent quality for high-end fashion jewelry collections. In response to growing demand for durable and…

From YIBI: Achieving Excellence with RJC Certification

In the evolving landscape of luxury jewelry manufacturing, standards of quality and responsibility have never been higher. Today's brands require not only superior design execution but also ethical credibility across the supply chain. YIBI, a trusted OEM/ODM partner based in Shenzhen, has solidified its reputation as a Global Leading Custom Stainless Steel Jewelry Manufacturer(https://www.chinayibi.com/product_category/oem-stainless-steel-jewelry-manufacturing/), offering clients both unmatched craftsmanship and the assurance of internationally recognized certifications such as the Responsible…

YIBI: Setting the Standard as China's Best Stainless Steel Jewelry Manufacturer

In the fast-growing luxury jewelry market, selecting a trusted manufacturing partner is essential for brands seeking quality, innovation, and efficiency. Recognized as a Top 10 Premium Stainless Steel Jewelry Manufacturer In China(https://www.chinayibi.com/product_category/oem-stainless-steel-jewelry-manufacturing/), YIBI specializes in crafting high-quality stainless steel jewelry that combines durability, elegance, and modern design. Stainless steel, especially 316L stainless steel, is renowned for its corrosion resistance, hypoallergenic properties, and ability to maintain a polished, long-lasting finish. These…

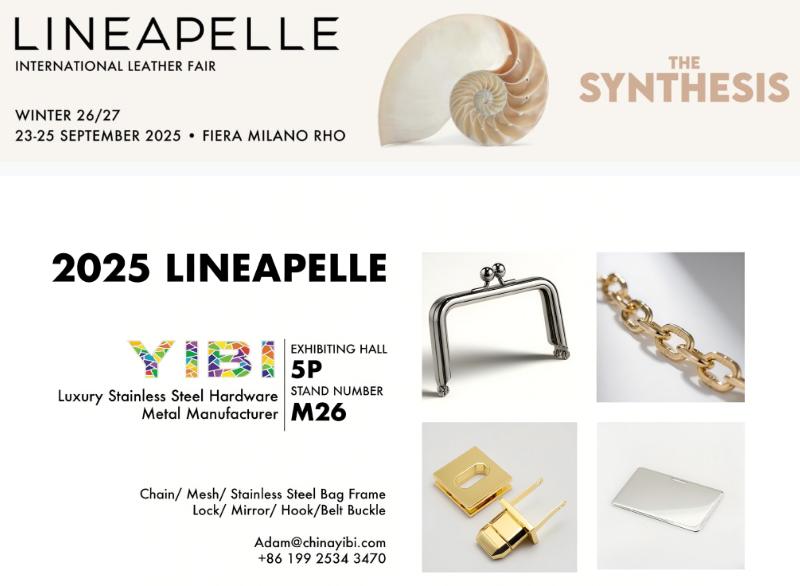

China Best Stainless Steel Leather Hardware Manufacturer at LINEAPELLE

The world of high-end fashion, leather goods, and accessories hinges on one crucial element often overlooked by the casual observer: hardware. These components-the buckles, clasps, zippers, and ornaments-are the functional anchors and final aesthetic touches that define quality and brand identity. As the global market increasingly demands superior durability, refined design, and ethical sourcing, the role of manufacturers specializing in these intricate components has become more pivotal than ever.

This…

More Releases for Stainless

Stainless Steel Market 2020 Growth by key players Jindal Stainless, Aperam Stain …

Global Market Insights, Inc., announces an ongoing comprehensive report on the Stainless Steel Market.

This report provides an exhaustive account of the industry including:

o Stainless Steel Market size, annual forecast from 2020 to 2026

o Major stainless steel industry trends, technology evolution, economic indicators and business challenges

o Regulatory and geopolitical trends impacting the industry

o Business drivers and pitfalls impacting key regional markets

o Competitive landscape of the industry and detailed profiles on the…

What's driving the Stainless Steel Market Growth? Jindal Stainless, ArcelorMitta …

North America led by U.S. stainless steel market may witness significant growth by increasing application scope in medical, oil & gas and heavy industries. High-grade stainless steel plays vital role in construction of valves, pipes, and storage tanks to provide resistance to corrosion over a wider range of temperatures. Growing adoption of stainless steel in oil & gas industry for off-shore oil rigs is expected to boost the overall market…

What's driving the Stainless Steel Market Growth? Jindal Stainless, ArcelorMitta …

Europe driven by France, UK and Germany stainless steel market may witness high growth owing to positive application outlook in automotive industry owing to its high strength that allows for thinner containers, saving fuel costs, whereas its resistance to corrosion helps in minimizing the maintenance and cleaning costs.

Asia Pacific led by China, India and Japan stainless steel market should witness significant growth owing to rise in demand for renewable energy…

Stainless Steel Welded Pipes Market | key player - Pohang Iron & Steel (Posco), …

Looking at the current market trends as well as the promising demand status of the “Stainless Steel Welded Pipes Market” it can be projected that the future years will bring out positive outcomes. This research report added by MRRSE on its online portal delivers clear insight about the changing tendencies across the global market. Readers can gather prime facets connected to the target market which includes product, end-use and application;…

Stainless Steel Market Scenario Highlighting Major Drivers & Trends, 2018 – 20 …

Adroit Market Research offers 2018 report on “Stainless Steel Market 2025” that evaluates industry growth trends through historical data and estimates future prospects based on comprehensive research. The report extensively provides the market share, growth, trends and forecasts for the period 2018-2025.

About the Stainless Steel Market:

Global stainless steel market trends augmented as its commendable properties -low maintenance, aesthetic appeal and ease of fabrication helps it to rank higher over the…

Stainless Steel Tube Market Global Forecast 2018| Studied By Outokumpu, Acerinox …

UpMarketResearch published an exclusive report on “ Stainless Steel Tube market” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 128 pages which highly exhibits on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability. This report focuses on the Stainless Steel Tube market, especially in North America, Europe and Asia-Pacific, South America,…