Press release

IMARC Group's Report on Maize/Corn Processing Plant 2025 - Investment, Infrastructure, and Profit Breakdown

Maize (Corn) is one of the most widely cultivated cereal crops in the world, serving as a key raw material for producing food, feed, and a variety of industrial products. A Maize/Corn Processing Plant converts raw corn into multiple value-added products, including corn flour, starch, glucose, ethanol, and animal feed, making it an essential segment of the agro-processing industry.Setting up a Maize/Corn Processing Plant involves establishing cleaning, degermination, milling, and refining units, along with efficient storage and packaging systems. The plant design should ensure optimal yield, low energy consumption, and compliance with food safety standards.

IMARC Group's "Maize/Corn Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive roadmap for entrepreneurs and investors looking to enter this thriving industry. The report covers essential aspects such as raw material procurement, machinery selection, process flow, quality assurance, investment cost, and financial projections.

This detailed report acts as a strategic guide for setting up a profitable maize (corn) processing facility capable of producing multiple downstream products for domestic and export markets.

See the Data First: Download Your Sample Report: https://www.imarcgroup.com/maize-corn-processing-plant-project-report/requestsample

Maize/Corn Processing Industry Outlook 2025:

The global maize processing industry is expanding rapidly due to rising demand for food-grade starches, sweeteners, bioethanol, and animal feed ingredients. The growing adoption of processed corn products in the food, beverage, and biofuel sectors is driving substantial market growth.

Additionally, increasing investments in agricultural value chains, the rise of bio-based products, and government incentives for ethanol blending are fueling the expansion of corn processing plants worldwide. However, the industry faces challenges related to raw material price volatility, high energy consumption, and the need for advanced processing technologies.

Key Insights for Maize/Corn Processing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements, and Costs Involved:

• Land, Location, and Site Development

• Plant Layout and Design

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging and Storage Requirements

• Transportation and Logistics Costs

• Utility Requirements (Power, Water, Steam)

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit and Margin

• Net Profit and Margin

Secure Your Access: Buy Now and Start Instantly: https://www.imarcgroup.com/checkout?id=8561&method=1911

Key Cost Components of Setting Up a Maize/Corn Processing Plant:

• Raw Materials: Maize grains, water, enzymes, and processing chemicals.

• Machinery and Equipment: Cleaning machines, degerminators, hammer mills, centrifuges, dryers, starch separators, fermenters, and packaging units.

• Infrastructure Development: Land acquisition, building construction, and setup of utilities such as boilers and effluent treatment systems.

• Labor and Staffing: Skilled operators, engineers, quality control personnel, and maintenance staff.

• Safety and Compliance: Adherence to HACCP, ISO, and environmental safety standards.

• Licensing and Regulatory Approvals: FSSAI certification, pollution control clearance, and local manufacturing permits.

• R&D and Quality Control: Laboratory setup for testing starch content, moisture, purity, and microbial safety.

• Logistics and Supply Chain: Efficient collection, storage, and distribution network for raw and finished products.

Economic Trends Influencing Maize/Corn Processing Plant Setup Costs 2025:

• Rising Global Demand: Increased consumption of corn-based sweeteners, bioethanol, and feed ingredients.

• Raw Material Fluctuations: Corn price volatility impacting production costs.

• Energy and Transportation Costs: High operational expenses due to fuel and energy use in drying and refining.

• Technological Innovations: Adoption of advanced separation and fermentation technologies improving yields and efficiency.

• Sustainability Shift: Growing focus on bio-based and waste-free production processes.

Challenges and Considerations for Investors:

• Ensuring consistent raw material supply and storage.

• Managing process efficiency and waste reduction.

• Balancing production between food, industrial, and biofuel segments.

• Navigating trade policies and government ethanol mandates.

• Competing with large-scale integrated agro-industries.

Resolve Your Doubts: Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=8561&flag=C

Conclusion:

Investing in a Maize/Corn Processing Plant offers lucrative opportunities driven by rising demand across multiple sectors including food, energy, and feed. With strategic planning, technology adoption, and focus on product diversification, investors can build a sustainable and profitable venture in the rapidly growing corn processing market.

Report Also Coverge:

• Plant Location: Selection of an industrial site with strong safety and logistics infrastructure.

• Plant Capacity: Customization based on target market requirements.

• Machinery: Options available for semi-automated or fully automated systems.

• List of Machinery Providers: Identification of verified equipment suppliers.

Services:

• Market Entry and Opportunity Assessment

• Competitive Intelligence and Benchmarking

• Procurement Research

• Pricing and Cost Research

• Sourcing Partner Identification

• Distribution Partner Identification

• Contract Manufacturer Identification

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201-971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release IMARC Group's Report on Maize/Corn Processing Plant 2025 - Investment, Infrastructure, and Profit Breakdown here

News-ID: 4217468 • Views: …

More Releases from IMARC Group

Green Hydrogen Production Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/O …

The global energy sector stands at an inflection point driven by the imperative to decarbonize industrial processes, reduce greenhouse gas emissions, and transition from fossil fuel dependence to sustainable, zero-emission energy carriers. At the forefront stands green hydrogen-a transformative fuel produced using renewable energy sources such as solar or wind power to split water into hydrogen and oxygen through electrolysis. Unlike conventional hydrogen production relying on fossil fuels through steam…

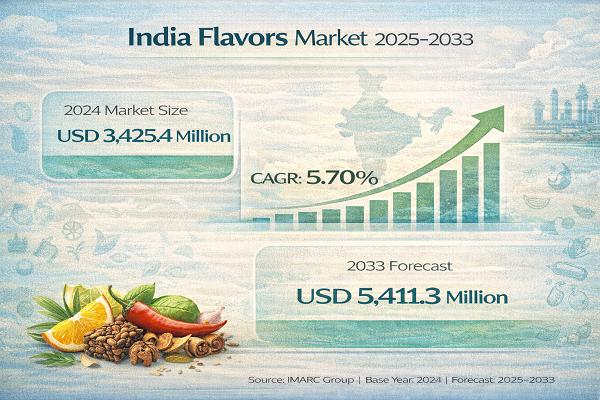

India Flavors Market on a Fast Growth Path, Reach at INR 8,512.5 Crore by 2033, …

India Flavors Market: Report Introduction

According to IMARC Group's report titled "India Flavors Market Size, Share, Trends and Forecast by Product Type, Form, Application, and Region, 2025-2033" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Note : We are in the process of updating our reports to cover the 2026-2034 forecast period. For the most recent data, insights, and industry updates, please click…

Intravenous (IV) Fluid Bag Manufacturing Plant DPR - 2026: Investment Cost, Mark …

The global intravenous (IV) fluid bag manufacturing industry is witnessing robust growth driven by the rapidly expanding healthcare sector and increasing demand for sterile fluid delivery systems. At the heart of this expansion lies a critical medical device: the intravenous fluid bag. As healthcare systems transition toward enhanced patient safety protocols and advanced infusion therapy methods, establishing an intravenous (IV) fluid bag manufacturing plant presents a strategically compelling business opportunity…

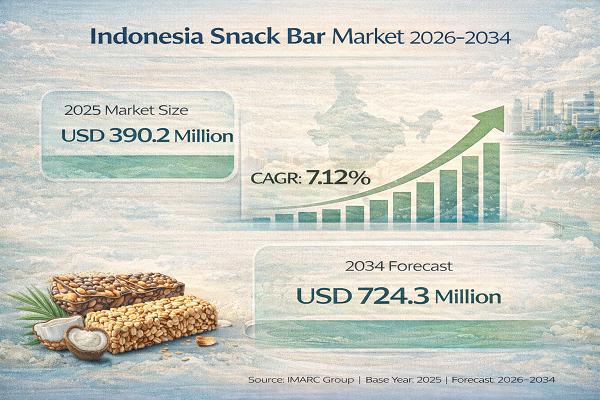

Indonesia Snack Bar Market Set for Robust Growth, Market to Reach USD 724.3 Mill …

Introduction of Indonesia Snack Bar Market Report

According to IMARC Group's report titled "Indonesia Snack Bar Market Size, Growth and Report 2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Download your free sample PDF for fresh data and expert insights: https://www.imarcgroup.com/indonesia-snack-bar-market/requestsample

Overview of Indonesia Snack Bar Market (2026-2034)

The Indonesia snack bar market size reached USD 390.2 Million in 2025. It is projected…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…