Press release

Linear Alkyl Benzene Production Cost Report 2025: Detailed Guide on Plant Setup, CapEx/OpEx and Profitability

Setting up a linear alkyl benzene production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Linear Alkyl Benzene Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a linear alkyl benzene production plant, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/linear-alkyl-benzene-manufacturing-plant-project-report/requestsample

What is Linear Alkyl Benzene?

Linear alkyl benzene (LAB) is an organic compound primarily used as a key raw material in the production of linear alkylbenzene sulfonate (LAS), a widely used surfactant in household and industrial detergents. LAB consists of a benzene ring attached to a long, straight-chain alkyl group, which distinguishes it from branched alkyl benzene and enhances its biodegradability. Its properties, including high solubility in oil and chemical stability, make it ideal for detergent formulations. LAB is produced through the alkylation of benzene with linear olefins derived from kerosene or naphtha, typically using a solid or liquid acid catalyst. Beyond detergents, it finds limited applications in lubricants, synthetic rubber, and specialty chemicals. Due to its environmentally favorable biodegradation profile compared to branched alternatives, LAB has become a preferred choice in regions with stringent environmental regulations, supporting the shift toward sustainable chemical manufacturing.

What is Driving the Linear Alkyl Benzene Market?

The global linear alkyl benzene market is being propelled by rising demand for eco-friendly cleaning products and growing industrialization. Household and commercial detergents, which constitute the largest end-use segment, are expanding rapidly, especially in emerging economies where urbanization and rising disposable incomes increase consumption. The push toward biodegradable and environmentally sustainable chemicals has led to regulatory support favoring LAB over branched alternatives, further stimulating demand. Additionally, the proliferation of industrial cleaning applications, such as in textiles, paper, and leather, contributes to market growth. The market is also influenced by fluctuations in feedstock prices, primarily naphtha and kerosene, which impact production costs and profitability. Technological advancements in refining and alkylation processes are improving LAB yield and quality, while investments in new production capacities by leading chemical companies are enhancing market availability. Collectively, these factors create robust growth prospects for LAB through 2025 and beyond.

Key Steps Required to Set Up a Linear Alkyl Benzene Plant

1. Market Analysis

The report provides insights into the landscape of the linear alkyl benzene industry at the global level. The report also provides a segment-wise and region-wise breakup of the global linear alkyl benzene industry. Additionally, it also provides the price analysis of feedstocks used in the production of linear alkyl benzene, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the linear alkyl benzene production plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for linear alkyl benzene production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for linear alkyl benzene production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=22822&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up a linear alkyl benzene production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

Buy Now: https://www.imarcgroup.com/checkout?id=22822&method=1911

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Linear Alkyl Benzene Production Cost Report 2025: Detailed Guide on Plant Setup, CapEx/OpEx and Profitability here

News-ID: 4213270 • Views: …

More Releases from IMARC Group

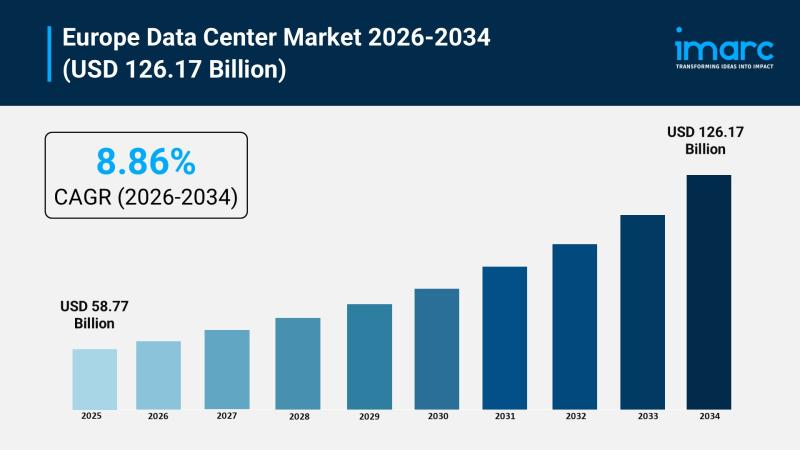

IMARC Group Forecasts 8.86% CAGR for Europe Data Center Market Amidst AI and Clo …

The Europe data center market is experiencing a critical phase of infrastructure evolution, having reached a valuation of USD 58.77 Billion in 2025. Propelled by the accelerating digitalization of the region's economy and sovereign cloud ambitions, the market is projected to reach USD 126.17 Billion by 2034. This growth trajectory represents a solid Compound Annual Growth Rate (CAGR) of 8.86% during the forecast period of 2026-2034.

Key Market Trends &…

Hot Sauce Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Proje …

Setting up a hot sauce manufacturing plant positions investors within one of the fastest-growing and flavor-driven segments of the global condiment industry, fueled by rising consumer appetite for spicy, bold, and ethnic flavors, increasing demand for clean-label and premium condiment products, and expanding utilization of hot sauce across food service, retail, and food processing applications. Made primarily from chili peppers, vinegar, salt, and complementary flavoring ingredients, hot sauce is recognized…

Glyoxylic Acid Prices Q4 2025: US Stable While Europe Remains High Price Trend

The Glyoxylic Acid Price Trend Analysis indicates dynamic shifts in global supply-demand balance, feedstock volatility, and regional trade flows. In 2026, Glyoxylic Acid Prices are reflecting fluctuations in raw material costs and downstream demand from pharmaceuticals, cosmetics, and agrochemicals. Market participants closely track the Glyoxylic Acid price index and forecast data to understand pricing momentum, risk exposure, and procurement strategies across key global regions.

Glyoxylic Acid Current Glyoxylic Acid Price Movements:

Recent…

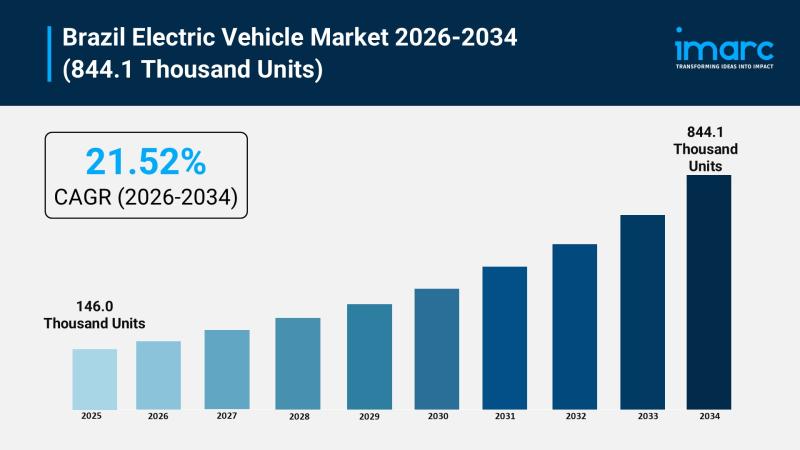

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

More Releases for Linear

Linear Devices Market

Linear Devices Market Overview

In an electric circuit, a linear device is an electrical element that maintains a proportional relationship between current and voltage. These components are widely used in various applications, including telecommunications, automotive, consumer electronics, and industrial electronics.

This report provides a deep insight into the global Linear Devices market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market…

Key Linear Actuator Market Trend for 2025-2034: Advancements in Linear Actuator …

"What Is the Future Outlook for the Linear Actuator Market's Size and Growth Rate?

The linear actuator market will grow from $41.25 billion in 2024 to $44.87 billion in 2025, at a CAGR of 8.8%. Growth is driven by the increased automation in manufacturing, advancements in robotics, miniaturization of devices, and rising demand for electric vehicles.

The linear actuator market will grow to $58.72 billion by 2029, supported by automotive industry applications,…

Electric Linear Actuators Market Report 2018: Segmentation by Type (DC Electric …

Global Electric Linear Actuators market research report provides company profile for Chiaphua Components, Tolomatic, TiMOTION, DewertOkin, Helix, Linear-Mech, Venture Mfg, Thomson, IAI, Parker, THK, LINAK, SKF, Moteck Electric and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018…

Global Mechanical Linear Actuators Market 2017 : Tolomatic, Timotion, Warner Lin …

Mechanical Linear Actuators Market 2017

A market study based on the " Mechanical Linear Actuators Market " across the globe, recently added to the repository of Market Research, is titled ‘Global Mechanical Linear Actuators Market 2017’. The research report analyses the historical as well as present performance of the worldwide Mechanical Linear Actuators industry, and makes predictions on the future status of Mechanical Linear Actuators market on the basis of…

High Precision Linear Positioners

A large variety of high precision linear positioners, XY stages and vertical linear stages is offered by PI miCos. These highly accurate systems are available with many different drive options from stepper motors to rotary servo motors and electromagnetic linear motors. Miniature stages with piezo motors are also offered.

Applications for these linear motion systems include semiconductor test equipment, photonics alignment, lab-automation, bio-nanotechnology, beam line instrumentation, aerospace technology,…

New Compact Linear Drive

PIShift drives are compact and cost-efficient piezo linear drives from PI (Physik Instrumente), the Karlsruhe specialist for positioning systems. The drives use the stick-slip effect and, due to the high operating frequency of more than 20 kHz, they are noiseless.

The load is coupled to the moving rod. Typical applications of drives operating with this principle are the adjustment of optical and opto-mechanical components, cell manipulation as well as industrial applications…