Press release

Industrial High-Temperature Graphitization Furnaces Market to Reach USD 793.8 Million by 2035, Driven by EV Battery and Aerospace Boom

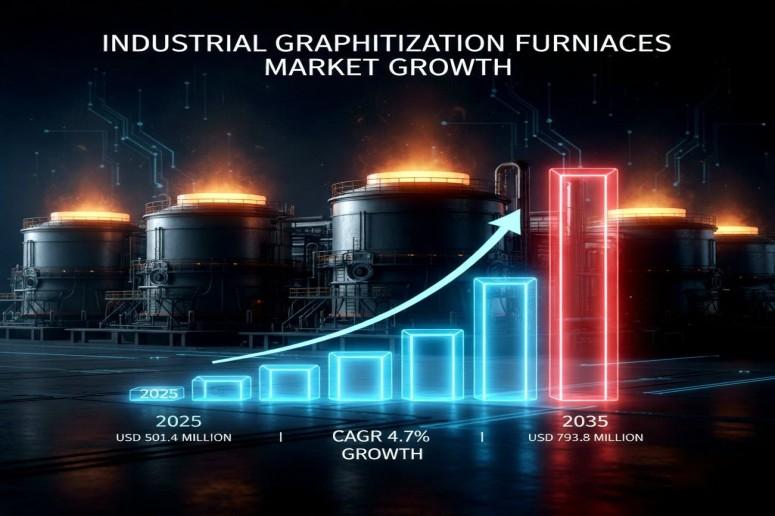

The global Industrial High-Temperature Graphitization Furnaces Market is on a solid growth trajectory, projected to increase from USD 501.4 million in 2025 to USD 793.8 million by 2035, according to a new market forecast.This growth represents a robust Compound Annual Growth Rate (CAGR) of 4.7%, fueled primarily by the explosive demand for high-quality graphite materials in the electric vehicle (EV) battery sector and expanding applications within the aerospace industry. The overall market size is expected to nearly double, growing approximately 1.6 times over the forecast period.

Get the Complete Story-Read More About Our Latest Report!

https://www.futuremarketinsights.com/reports/industrial-high-temperature-graphitization-furnaces-market

Market Dynamics: EV Batteries and Aerospace Powering Expansion

The surge in demand is fundamentally driven by the materials industry's urgent need for consistent, high-purity graphite. Graphitization furnaces are critical, operating at temperatures often exceeding 2800∘C to transform carbon structures into high-performance graphite, essential for competitive materials production.

Key Growth Drivers:

• Electric Vehicle Market Expansion: The massive growth of lithium battery production-with major regions seeing annual growth of 25-30%-is the single largest driver. High-temperature graphitization furnaces are indispensable for manufacturing the specialized anode materials required for EV batteries.

• Aerospace and Defense Industry Growth: The mandatory adoption of high-performance carbon fiber materials in aerospace, with manufacturers targeting 40-50% weight reduction by 2030, necessitates advanced furnace systems for achieving superior mechanical and structural properties.

• Technological Advancements: Innovation in furnace design, including energy recovery systems and advanced temperature control, is making processing more efficient and reliable, which helps mitigate the challenge of high operational energy costs.

Market Challenges:

Despite the strong tailwinds, the market faces restraints, notably the high energy consumption costs for continuous high-temperature operations and the substantial capital investment requirements that may limit adoption for smaller manufacturers, particularly in developing regions. Furthermore, the complexity of integrating and operating these specialized systems demands specific expertise and training.

Segmental Analysis Highlights Continuous Furnace Dominance

The market is segmented by Furnace Type, Application, and Region. Analysis shows a clear preference for high-volume processing solutions.

Furnace Type Analysis:

The Continuous Graphitization Furnace segment is poised to account for a dominant 58.6% share of the market in 2025. This technology is favored in high-volume production environments, such as battery material processing and industrial graphite manufacturing, due to its efficiency, cost-effectiveness, and ability to maximize throughput.

The Batch Graphitization Furnace systems hold a significant 34.7% market share, primarily serving specialized processing and research facilities that require precise control over individual processing cycles and customized atmospheric conditions for high-purity applications.

Application Analysis:

Carbon Fiber Manufacturing applications lead the market, representing a commanding 41.8% share in 2025. This reflects the essential role of graphitization in achieving the superior structural performance required for aerospace, automotive lightweighting, and advanced composite materials.

The next largest segment is Lithium Battery Anode Material Processing, accounting for 28.4% of the market share. This concentration underscores the immediate impact of the electric vehicle industry on high-temperature processing equipment demand. Graphite Electrode Production follows at 16.2%.

Geographic Growth Anchored by Asia-Pacific

Geographically, the market's highest growth rates are concentrated in the Asia-Pacific region, driven by rapid industrialization and ambitious EV targets.

China demonstrates the strongest growth potential with a 6.3% CAGR through 2035, cemented by government-backed advanced materials development programs. Closely following, India is projected to grow at a 5.9% CAGR, propelled by industrial modernization and efforts to establish itself as a strategic Asia-Pacific manufacturing hub.

In Europe, Germany leads with a 5.4% CAGR, reflecting its leadership in advanced manufacturing and strong automotive/aerospace sectors. The U.S. market is accelerating with a 4.5% CAGR, primarily through innovation in intelligent furnace systems and the modernization of its materials processing infrastructure.

Competitive Landscape and Innovation

The Industrial High-Temperature Graphitization Furnaces Market is moderately concentrated, with the top three companies controlling roughly 35-40% of global market share. Competition is centered on technological innovation, energy efficiency capabilities, and process optimization expertise over price.

Market Leaders: Companies like Thermconcept, Carbolite Gero, and HTM Reetz GmbH maintain their competitive edge through comprehensive solution portfolios, global service networks, and deep industry expertise, creating high switching costs for customers.

Key Trends Shaping the Future:

1. Energy-Efficient Design: A definitive shift towards furnace solutions incorporating heat recovery systems, advanced insulation, and integrated process monitoring to reduce operational costs and environmental impact.

2. Automation and AI Integration: Increasing focus on integrating automation and Artificial Intelligence for optimizing processing parameters and enabling predictive maintenance across manufacturing networks.

3. Specialized Solutions: Growing demand for specialized systems, including atmosphere-controlled processing and vacuum graphitization, tailored for ultra-high purity materials in applications like semiconductor and nuclear industries.

The market dynamics favor equipment manufacturers who successfully integrate advanced thermal processing technologies with comprehensive service offerings, supporting the entire furnace lifecycle from design through maintenance and process optimization. The need for precise temperature control and process repeatability ensures that advanced graphitization furnaces will remain a critical technology for the future of high-performance materials manufacturing.

Get this Report at $5,000 Only | Exclusive Discount Inside!

https://www.futuremarketinsights.com/reports/sample/rep-gb-26803

Have a Look at Related Research Reports on the Industrial Automation Domain:

Temporary Road Covers Market - https://www.futuremarketinsights.com/reports/temporary-road-covers-market

Automatic Glue Machine Market - https://www.futuremarketinsights.com/reports/automatic-glue-machine-market

Book Binding Machines Market - https://www.futuremarketinsights.com/reports/book-binding-machines-market

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Industrial High-Temperature Graphitization Furnaces Market to Reach USD 793.8 Million by 2035, Driven by EV Battery and Aerospace Boom here

News-ID: 4210664 • Views: …

More Releases from Future Market Insights Inc

Sweat Resistant Apparel Market to Reach USD 358.0 Billion by 2035, Growing at 4. …

The Sweat Resistant Apparel Market is projected to expand from USD 226.1 billion in 2025 to USD 358.0 billion by 2035, registering a steady CAGR of 4.7% over the forecast period. The Market's growth reflects rising demand for moisture-wicking, odor-resistant, and thermoregulating garments across fitness, workwear, travel, and casual segments.

As performance-driven apparel becomes mainstream, the Market is transitioning from niche athletic use to broader lifestyle integration. Innovations in synthetic fabrics,…

Bio-Fermented Skincare Actives Market to Reach USD 4,921.3 Million by 2035, Expa …

The Bio-Fermented Skincare Actives Market is projected to grow from USD 1,351.2 million in 2025 to USD 4,921.3 million by 2035, registering a CAGR of 13.8% during the forecast period. The Market is expected to expand nearly 3.6 times over the decade, generating an incremental opportunity of USD 3,570.1 million. This acceleration underscores a structural shift toward naturally derived, clinically validated, and microbiome-friendly skincare solutions.

Market Momentum

The Bio-Fermented Skincare Actives Market…

Football Merchandise Market Set to Reach USD 29.1 Billion by 2035, Expanding at …

The Football Merchandise Market is estimated at USD 15.8 billion in 2025 and is projected to reach USD 29.1 billion by 2035, expanding at a CAGR of 6.3% over the forecast period. Sustained fan engagement, global league popularity, and digital retail acceleration are reinforcing steady demand for licensed jerseys, footwear, collectibles, and lifestyle products. As football evolves into a year-round commercial ecosystem, merchandising remains central to club revenues and global…

French Doors Market to Surpass USD 45.8 Billion by 2035, Expanding at 4.6% CAGR …

The French Doors Market is estimated to be valued at USD 29.2 billion in 2025 and is projected to reach USD 45.8 billion by 2035, expanding at a compound annual growth rate (CAGR) of 4.6% over the forecast period. Steady gains in residential construction, renovation activity, and demand for energy-efficient architectural solutions are shaping long-term growth. As homeowners prioritize natural lighting, indoor-outdoor transitions, and premium finishes, the Market continues to…

More Releases for Furnace

Oil Furnace Market Size, Growth, Key Trends to 2033 Irving, Carrier, Armstrong F …

An oil furnace is a type of heating system that uses oil as a fuel source to generate heat. It works by burning oil in a combustion chamber, which heats a heat exchanger. The heated air or water is then circulated throughout the building to maintain a comfortable temperature. Oil furnaces are particularly useful in areas without access to natural gas and are known for their ability to provide consistent…

Metal Melting Furnace Market Future Trends Landscape 2031 || Meta Therm Furnace …

The metal melting furnace market is essential for various industries, including automotive, aerospace, construction, and manufacturing. These furnaces are used to melt different types of metals such as iron, steel, aluminum, and copper, playing a critical role in the production of metal products. The market for metal melting furnaces is driven by increasing demand for metals in various applications and technological advancements in furnace design and efficiency.

Market Size and Growth

The…

Semiconductor Monocrystalline Silicon Furnace Market: High-Precision Furnace for …

Global Semiconductor Monocrystalline Silicon Furnace Market Overview:

The Semiconductor Monocrystalline Silicon Furnace market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the Semiconductor Monocrystalline Silicon Furnace market has experienced significant growth, driven by factors such as increasing consumer demand, technological advancements, and…

Induction Furnace Melting Aluminum

The induction melting furnace working principle is that the power supply device converts the power frequency 50HZ alternating current into the medium frequency (from 300HZ to 1000HZ), converts the three-phase power frequency alternating current into the direct current after rectification, and then converts the direct current into the adjustable medium frequency current, supplies the medium frequency alternating current flowing through the capacitor and the induction coil, generates high-density magnetic lines…

Muffle furnace Market Future Growth Outlook: ThermoFisher Scientific, Brother Fu …

A new statistical surveying study titled Muffle furnace Market investigates a few critical features identified with Muffle furnace Market covering industry condition, division examination, and focused scene. Down to earth ideas of the market are referenced in a straightforward and unassuming way in this report. A far-reaching and exhaustive essential investigation report features various actualities, for example, improvement factors, business upgrade systems, measurable development, monetary benefit or misfortune to support…

Induction Furnace Market Foraying into Emerging Economies 2018 to 2028(Based on …

Induction Furnace Market: Introduction

Induction furnace is an electrical furnace in which the heat is generated by induction heat of the metal. Induction capacities range from less than one kilogram to one hundred tonnes, and widely used to melt iron, steel, copper, aluminium and precious metal. The main advantage of the induction furnace is a clean, energy-efficient and well-controllable melting process compared to most other means of metal melting.

Induction Furnace Market:…