Press release

Pan Liners for Foodservice Market to Reach USD 337 Million by 2031 Top 10 Company Globally

Pan liners are single-use or reusable liners sized to fit standard foodservice pans (steam table pans, baking pans, transport trays) and are made from materials such as HDPE, PET, nylon, coated paper, or thin aluminum. Their primary function in commercial kitchens is to reduce cleaning time, prevent cross-contamination, extend pan life, and improve operational throughput in high-turnover environments (restaurants, catering, institutional kitchens, and food delivery). In foodservice channels they are sold as commodity pack formats (rolls, folded interleaved packs, or fitted contour liners) and are consumed by downstream industries including institutional catering, hotels, quick-service restaurants (QSR), and food processors. Product variants range from low-temperature steam table liners to oven- and freezer-safe nylon/PET liners for cook-chill workflows.The global pan liners for foodservice market valued USD 223 million in 2024 and the supplied CAGR of 6.2% to 2031. The global unit consumption baseline supplied is 2,682 million pieces in 2024 with a price benchmark of USD 83.27 per K pieces. The factory gross margin per K pieces is 15.67% which implies a factory gross profit of USD 13.05 per K pieces and a cost of goods sold of USD 70.22 per K pieces. The COGS composition typical for thin-film/liner converting in the proportions of raw materials 55%, direct labor 20%, manufacturing overhead 15%, packaging 5%, logistics 5%. Based on industry channel behaviour and global foodservice structure, an indicative downstream split (volume share) for pan liners is: institutional catering & education 28%, hotels & banqueting 18%, restaurants & QSR 30%, food processors & commissaries 15%, retail & others 9%. A single line full machine capacity production is around 41,320 pieces per line per year.

Latest Trends and Technological Developments

The pan-liner sector has seen three converging trend lines in 20242025: (1) continued operational adoption driven by labor constraints in institutional foodservice (pan liners reduce labor for cleanup), (2) material and regulative pressure pushing producers toward higher-temperature nylon and barrier films for cook-chill and reheating use, and (3) sustainability innovation that seeks compostable or recyclable liner formats (either via material change or take-back programs). A practical industry story illustrating the labor-driven demand: a MarchApril 2025 trade/marketing piece highlighted how pan liners materially reduce hands-on cleaning time in education foodservice, easing staff burnout and improving throughput. Separately, machinery and material suppliers continue to promote higher-temperature film solutions and contour-fit liner designs that reduce product waste and improve consumer convenience; equipment OEMs publish blown-film and converting line performance metrics showing much higher throughput and multi-layer capability (enabling heat-resistant or barrier laminates). On broader market sizing, an April 2025 industry forecast from a market research publisher reported larger pan-liner market estimates in adjacent analyses, underscoring that market definition (liners alone vs. liners + trays + disposable pans) materially changes headline figures a useful caution for investors and strategists relying on single published totals.

Asia represents a major growth engine for pan liners driven by rapid expansion of institutional catering, large QSR chains and the growing cook-chill and commissary kitchen model in markets such as China, India, South Korea and Japan. Demand in Asia is a mix of value and premium segments: value chains and local catering operators favor low-cost HDPE steam-table liners and coated paper liners, while modern foodservice groups and cloud kitchens increasingly source higher-temperature nylon/PET liners for oven-to-service and cook-chill operations. Cost sensitivity in many Asian markets means price competitiveness (raw material purchasing, local film extrusion capacity and labor efficiency) is a key determinant of market share. Equipment imports (blown-film and high-speed converting lines) are common, but an increasing number of local OEMs and converters in Asia are closing the gap on high-speed capacity, enabling regionalized supply and shorter lead times.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5054483

Pan Liners for Foodservice by Type:

Disposable

Reuseable

Pan Liners for Foodservice by Application:

Restaurant

Reuseable

Global Top 10 Key Companies in the Pan Liners for Foodservice Market

LK Packaging

Paterson Paper

NorPak

Novolex

McNairn Packaging

AmerCareRoyal

FoodHandler®

Victoria Bay

M&Q Packaging

Hoffmaster

Regional Insights

Within Southeast Asia, Indonesia shows both strong volume demand (large institutional feeding programs, hotel & tourism recovery pockets) and a structural shift toward outsourced food production (commissaries/cloud kitchens), which raises liner demand per meal served. ASEAN demand profiles vary: Singapore and Malaysia favor premium/regulated products (heat tolerant and food-safety validated films), while Indonesia, the Philippines and Vietnam currently trend toward cost-effective HDPE/PET liners but are ripe for upgrades to higher-value liners as foodservice centralization continues. Local regulatory emphasis on food contact safety and waste management in several ASEAN countries is also nudging buyers toward certified materials and more recyclable formats. Distribution in ASEAN is fragmented: local foodservice distributors, national catering suppliers, and e-commerce/restaurant supply platforms all play roles in time-to-market. Market entrants that pair localized production (to cut logistics cost) with region-tailored product ranges (steam-only vs oven-capable) will have an advantage.

The primary challenges facing the pan-liner industry are: raw material volatility (polyethylene, nylon and PET resin prices are linked to petrochemical feedstock movements), regulatory and ESG pressure (demand for compostable or recyclable options while maintaining food-safety and high-temperature performance), and margin compression in value segments where buyers prioritize lowest landed cost. For converters, capital intensity (investment in blown-film extrusion and high-speed converting lines), quality control for food contact certification and contamination risk management are operational stresses. Downstream, foodservice operators face mixed incentives: labor savings encourage liner adoption but sustainability targets and procurement policies sometimes restrain single-use growth. Finally, product definition inconsistency across reports (what counts as a pan liner vs. trays or pans) complicates benchmarking and investor comparability.

Producers and investors should prioritize (1) vertical cost control on resin sourcing or backward integration, (2) flexible converting lines that can run multiple film materials (HDPE, nylon, PET) to chase premium applications, (3) validated food-contact certifications (FDA/EU standards or local equivalents) to sell into institutional and export channels, and (4) targeted downstream partnerships with cloud-kitchen platforms and large catering groups to lock in recurring volume contracts. For ASEAN/Indonesia, a hybrid strategy combining local converting capacity (to reduce logistics cost) with regionalized R&D on compostable or recyclable liner formulations is defensible. Sellers should also quantify total cost of ownership benefits for buyers (labor savings, reduced water/energy cleaning costs) to justify any price premium for higher-performance liners.

Product Models

Pan liners for foodservice are essential kitchen solutions designed to improve hygiene, reduce food sticking, and simplify cleanup in commercial kitchens.

Reusable pan liners, which are made from durable, heat-resistant materials for multiple uses. Notable products include:

Duraflex Reusable Pan Liner Winco: Heat-resistant silicone-coated liner, designed for long-lasting use.

EcoBake PTFE Pan Liner EcoBake Europe: Reusable non-stick PTFE liner, ideal for baking and roasting.

Matfer Bourgeat Reusable Liner Matfer Bourgeat: Professional-grade reusable liner used in European foodservice kitchens.

KitchenCraft Non-Stick Reusable Liner KitchenCraft: Durable liner suitable for multiple cooking and baking applications.

Nordic Ware Reusable Baking Liner Nordic Ware: Heavy-duty liner designed for repeated use in commercial ovens.

Disposable pan liners which provide a quick, single-use solution for busy foodservice operations. Examples include:

Wilton Disposable Bake-Easy Liner Wilton Brands: Affordable disposable liner for bakery and catering use.

Novacart Pan Liner Novacart USA: Paper-based disposable liner ideal for bakery and pastry shops.

Choice Disposable Steam Pan Liner WebstaurantStore Brand: Cost-effective disposable liner widely used in foodservice.

Durkee Disposable Pan Liner Durkee-Atwood: Heat-resistant single-use liner for busy kitchens.

Pactiv Evergreen Pan Liner Pactiv Evergreen Inc.: Disposable liner designed for high-volume foodservice operations.

Pan liners are a steady, operationally driven niche in foodservice with stable per-unit economics and predictable volume demand linked to institutional feeding, QSR expansion, and the rise of centralized food production (commissaries and cloud kitchens). The market is not homogeneous: material, temperature rating, and regulatory compliance create distinct product tiers. For producers, the value proposition is lowering buyer total cost of ownership (labor/time savings) while navigating sustainability expectations and resin price volatility. In Asia and ASEAN, volume growth and centralization of foodservice create favorable demand dynamics if manufacturers can localize production and offer tiered product portfolios.

Investor Analysis

The critical datapoints are the baseline market size , supplied unit volumes and unit economics.These quantify market scale, throughput needs and per-unit profitability which are necessary inputs for valuation and capex planning.

Investors should use the per-K economics to model factory roll-out scenarios (number of lines required to achieve target volumes), sensitivity to resin price swings, and payback of automation investments that increase throughput and reduce direct labor share. Use regional demand mixes to size market entry and distribution channels; for example, prioritizing QSR and commissary contracts in dense urban ASEAN hubs can accelerate volume uptake.

These data points directly drive valuation (EBITDA per ton or per million pieces), capital-expenditure needs (how many lines to hit scale), and risk analysis (material price exposure and regulatory risk). For a private equity or strategic buyer, the attractiveness increases if: (a) the target has secured low-cost resin contracts or local resin access, (b) production lines are flexible by material/format, and (c) there are offtake agreements with large foodservice chains which de-risk demand. In short, the unit economics and capacity mapping transform a market narrative into investable KPIs (IRR, payback, margin expansion levers).

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5054483

5 Reasons to Buy This Report

Provides a clear factory-level unit economics snapshot to support valuation and capex planning.

Regionally focused insights for Asia and ASEAN to prioritize market entry and distribution.

Practical production capacity benchmarks tied to real converting and blown-film equipment performance.

Latest trend and news collection to inform product roadmap and ESG positioning.

Channel & downstream demand splits to target high-value customers for recurring contracts.

5 Key Questions Answered

What are the factory-level economics per K pieces for pan liners?

Which downstream channels drive the largest volume demand and where should sales focus in Asia/ASEAN?

What are realistic full-line production capacities for blown-film + converting setups?

What market and regulatory risks will most affect margins?

Which operational levers deliver the fastest margin uplift?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pan Liners for Foodservice Market to Reach USD 337 Million by 2031 Top 10 Company Globally here

News-ID: 4200444 • Views: …

More Releases from QY Research

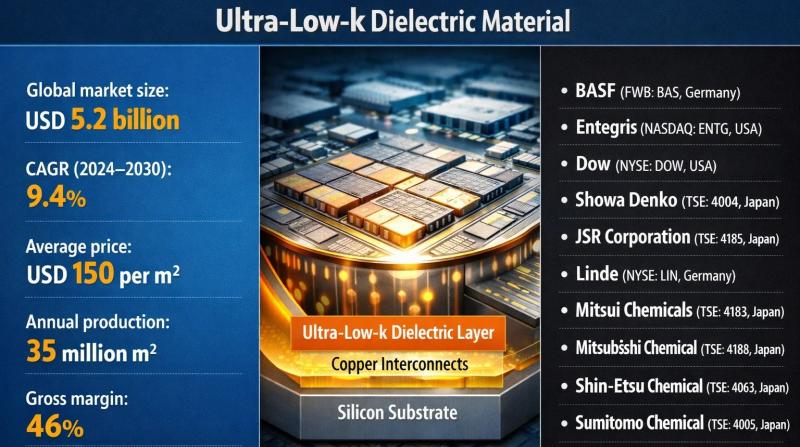

Market Overview - Ultra-low-k Dielectric Material

QY Research has recently published a comprehensive market study on Ultra-low-k Dielectric Material, a critical class of advanced insulating materials engineered to reduce parasitic capacitance and signal delay in advanced semiconductor interconnects. Ultra-low-k dielectrics are essential enablers for sub-7 nm logic nodes, advanced memory, high-performance computing, and AI accelerators, where interconnect RC delay increasingly limits device performance and power efficiency.

The market is transitioning from dense SiO2 and conventional low-k materials…

Global and U.S. Quadruped Mobile Robots Market Report, Published by QY Research.

QY Research has released a comprehensive new market report on Quadruped Mobile Robots, are four-legged robotic systems designed to move and operate in complex, unstructured environments by mimicking the locomotion of animals. They use a combination of advanced sensors, actuators, AI algorithms, and real-time control systems to maintain balance, navigate uneven terrain, climb obstacles, and adapt to dynamic conditions. Because of their high stability and mobility, quadruped robots are widely…

Global and U.S. Industrial Edge Cloud Devices Market Report, Published by QY Res …

QY Research has released a comprehensive new market report on Industrial Edge Cloud Devices, ruggedized computing platforms that bring cloud-native processing, storage, and AI analytics directly to the industrial edge-close to machines, sensors, and control systems. By executing latency-sensitive workloads locally while synchronizing with central or public clouds, these devices enable real-time decision-making, improved reliability, and secure data governance across factories, utilities, energy assets, and transportation infrastructure. As Industry 4.0,…

Top 30 Indonesian Ceramic Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Arwana Citramulia Tbk (ARNA)

PT Cahayaputra Asa Keramik Tbk (CAKK)

PT Intikeramik Alamasri Industri Tbk (IKAI)

PT Keramika Indonesia Assosiasi Tbk (KIAS)

PT Mulia Industrindo Tbk (MLIA)

PT Asahimas Flat Glass Tbk (AMFG) (glass & ceramic-adjacent)

PT Niro Ceramic Nasional Indonesia

PT Eleganza Tile Indonesia

PT Roman Ceramic International

PT Platinum Ceramics Industry

PT Granito (Citra Granito)

PT Diamond Keramik Indonesia

PT Indogress (Inti Keramik Sejahtera)

PT Indopenta Sakti Teguh

PT Sun Power Ceramics

PT Satyaraya Keramindo Indah…

More Releases for Liner

Global Liner Service Market Size by Application, Type, and Geography: Forecast t …

According to Market Research Intellect, the global Liner Service market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The liner service market is experiencing notable growth driven by the expansion of global trade and increasing demand…

Global Hydraulic Liner Hanger Systems Market Size by Application, Type, and Geog …

According to Market Research Intellect, the global Hydraulic Liner Hanger Systems market under the Aerospace and Defense category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The country's growing industrial sector, especially in the electronics, automotive, and construction sectors, is propelling the Malaysian…

Global Hydraulic Liner Hanger Systems Market Size by Application, Type, and Geog …

According to Market Research Intellect, the global Hydraulic Liner Hanger Systems market under the Aerospace and Defense category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The growing need for effective well completion technologies in both onshore and offshore drilling operations is driving…

Global Mill Liner Market Size - By Product Type(Metal Mill Liner,Rubber Mill Lin …

Mill Liner Market Insights: Trends, Drivers, and Outlook 2024 - 2031

Mill Liner Market Scope: Unveiling Today's Trends

Mill liners are protective linings within mills that enhance grinding efficiency and longevity. As industries focus on operational efficiency and cost reduction, the mill liner market is witnessing significant growth. Key trends include the increasing adoption of advanced materials, such as rubber and composite liners, which offer superior wear resistance and performance compared to…

Tailgate Liner Market Report- Technology, Top Companies and Trends | Rugged Line …

The Tailgate Liner Market research report examines the patterns in the parent market, alongside the common factors and market share by various segments and sub-segments. The Tailgate Liner Market report additionally predicts the impact of various industry aspects available in Tailgate Liner Market segments and geographies. Tailgate Liner Market research report moreover identifies the market situation and upcoming challenges of the worldwide market. Tailgate Liner…

Self-Adhesive Labels and Growing Demands 2019 | By Type: Release Liner Labels, L …

Ozone Market Reports projects that the Self-Adhesive Labels market size will grow from USD XX Million in 2018 to USD XX Million by 2024, at an estimated CAGR of XX%. The base year considered for the study is 2017, and the market size is projected from 2018 to 2023.

By Market Players:

Avery Dennison Corporation , CCL Industries Inc. , Constantia Flexibles Group GmbH , UPM-Kymmene Oyj , 3M Company , Henkel…