Press release

Cutting Wheel Market Size Worth US$ 3.88 Billion with 4.5% CAGR by 2034: Fact.MR Report

In 2024, the global cutting wheel market size is expected to reach a valuation of US$ 2.5 billion and climb to US$ 3.88 billion by the end of 2034. Worldwide demand for cutting wheels is forecasted to increase at a CAGR of 4.5% from 2024 to 2034.Increasing industrialization across several regions is driving the need for advanced cutting discs and other industrial equipment. Rising construction activities, growing metal cutting operations in industries such as aerospace, marine, and automotive, and technological advancements in grinding wheel manufacturing are further fueling cutting wheel market growth.

Market Overview

Cutting wheels are essential tools used in material removal, shaping, and cutting operations across a wide range of industries. They are primarily categorized into straight cutting wheels and depressed center cutting wheels, designed to cater to different cutting requirements and operational conditions.

Straight cutting wheels are ideal for precise and controlled cuts in materials such as metals, ceramics, and composites. Depressed center cutting wheels, on the other hand, are designed for versatility and are commonly used in angle grinders for surface finishing, masonry cutting, and notching applications. The versatility of cutting wheels makes them indispensable in industries like metal fabrication, construction, automotive manufacturing, and shipbuilding.

Drivers of Market Growth

Several factors are propelling the global cutting wheel market. Industrial expansion and urban development have led to increased demand for metal cutting and masonry operations. The growth of manufacturing sectors, particularly in automotive, aerospace, and heavy machinery, has driven the need for durable and efficient cutting solutions.

Additionally, technological innovations in abrasive materials, bonding techniques, and precision grinding have improved cutting wheel efficiency, durability, and safety. Advancements such as reinforced wheels, diamond-tipped edges, and heat-resistant composites are enhancing performance while extending service life. These innovations are also reducing operational downtime, improving productivity, and lowering overall production costs.

Applications Driving Market Expansion

Cutting wheels find wide applications across metal cutting, masonry, ceramic cutting, and notching operations. In metalworking industries, they are used for shaping, trimming, and precise material separation. Masonry applications involve cutting bricks, concrete, and stone, while ceramic cutting wheels are used for tile and glass cutting operations. Notching cutting wheels are employed in creating grooves or slots in metal and composite materials, enhancing versatility and efficiency in fabrication processes.

The rising adoption of automation and computer-aided manufacturing (CAM) technologies in fabrication units has also increased the demand for high-performance cutting wheels, enabling consistent precision and faster operations.

Recent Developments and Competitive Landscape

The cutting wheel market has witnessed several innovations and strategic initiatives by key players. Manufacturers are focusing on producing specialized wheels with higher strength, improved thermal resistance, and enhanced cutting efficiency. Companies are also investing in R&D to develop eco-friendly and longer-lasting wheels that reduce waste and operational costs.

Recent developments include the launch of diamond-coated and ceramic-reinforced cutting wheels tailored for high-precision applications in aerospace, automotive, and electronics industries. Major players are expanding distribution networks, forging partnerships with industrial suppliers, and offering customized solutions to meet industry-specific demands.

Competitive analysis indicates that market players are differentiating their products through quality, safety certifications, and technological advancements. Emphasis on after-sales support, training, and safety compliance is also helping companies strengthen their position in the global market.

Full Market Report available for delivery. For purchase or customization, please request here - https://www.factmr.com/connectus/sample?flag=S&rep_id=534

Regional Insights

North America and Europe hold significant market shares due to advanced manufacturing infrastructure, stringent quality standards, and high adoption of cutting-edge industrial equipment. Asia Pacific is emerging as the fastest-growing region, driven by rapid industrialization, infrastructure development, and increasing construction and automotive activities in countries such as China, India, and Japan. Latin America and the Middle East are gradually expanding their market presence, supported by growing metal fabrication and construction projects.

Browse Full Report: https://www.factmr.com/report/534/cutting-wheels-market

Conclusion

The global cutting wheel market is poised for steady growth between 2024 and 2034, fueled by industrialization, technological advancements, and expanding applications across multiple sectors. Strategic initiatives such as innovation in abrasive materials, precision cutting technologies, and regional market expansion are shaping the competitive landscape. With rising demand from automotive, aerospace, construction, and metal fabrication industries, cutting wheels are set to remain a critical component of industrial operations worldwide, ensuring efficiency, safety, and precision.

Check out More Related Studies Published by Fact.MR:

Centrifugal Industrial Dryer Market

https://www.factmr.com/report/centrifugal-industrial-dryer-market

Solid Board Market

https://www.factmr.com/report/solid-board-market

Dock Leveler Market

https://www.factmr.com/report/dock-leveler-market

Acoustic Emission-based NDT Market

https://www.factmr.com/report/acoustic-emission-based-ndt-market

- Contact Us -

11140 Rockville Pike, Suite 400, Rockville,

MD 20852, United States

Tel: +1 (628) 251-1583 | sales@factmr.com

About Fact.MR

We are a trusted research partner of 80% of fortune 1000 companies across the globe. We are consistently growing in the field of market research with more than 1000 reports published every year. The dedicated team of 400-plus analysts and consultants is committed to achieving the utmost level of our client's satisfaction.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cutting Wheel Market Size Worth US$ 3.88 Billion with 4.5% CAGR by 2034: Fact.MR Report here

News-ID: 4199097 • Views: …

More Releases from Fact.MR

Organic Rice Syrup Market is forecasted to increase at a CAGR of 5.1% and US$ 1. …

The global Organic Rice Syrup Market is projected to expand steadily over the coming decade, driven by rising consumer demand for natural, clean-label sweeteners and growing awareness of health and wellness trends. Industry analysts estimate that the organic rice syrup market, valued at approximately USD 450 million in 2025, is expected to reach nearly USD 880 million by 2035, registering a compound annual growth rate (CAGR) of about 7.1% during…

Compound Horse Feedstuff Market is Estimated to Grow at a CAGR of 4.6%, Reaching …

The global compound horse feedstuff market is galloping toward steady growth, projected to expand from a valuation of USD 3.8 billion in 2026 to approximately USD 5.4 billion by 2036. This represents a compound annual growth rate (CAGR) of 3.6% over the ten-year forecast period.

The market is being driven by the "humanization" of equine companions, the professionalization of equestrian sports, and a significant shift toward specialized performance nutrition that…

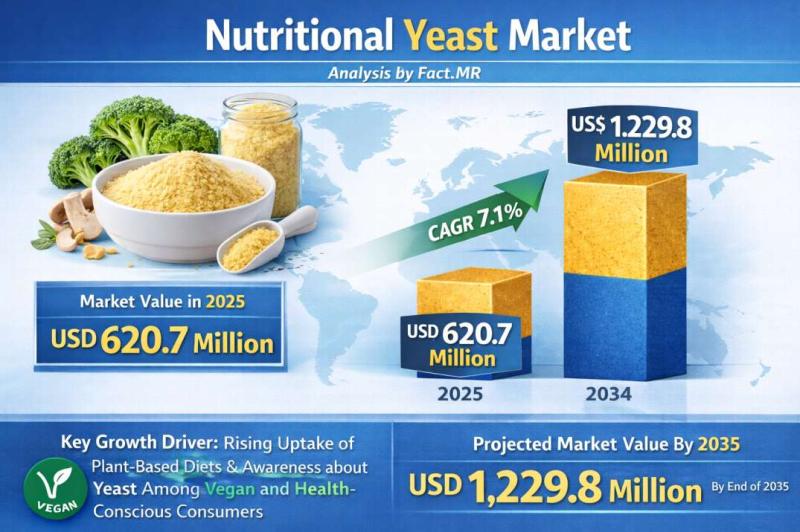

Nutritional Yeast Market Forecasted CAGR is 7.1% by 2035 | Fact.MR Report

The global nutritional yeast market is experiencing a significant surge in demand, projected to grow from a valuation of USD 515.2 million in 2026 to approximately USD 1.2 billion by 2036. This represents a robust compound annual growth rate (CAGR) of 8.8% over the ten-year forecast period.

The market is being propelled by the global explosion of plant-based diets and the "clean-label" movement, with nutritional yeast emerging as the primary…

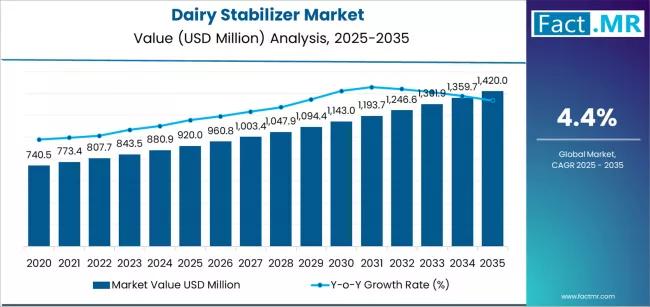

Dairy Stabilizer Market is Expected to Reach USD 1,420.0 million by 2035 | Resea …

The global Dairy Stabilizers Market is projected to sustain solid growth over the next decade as consumer demand for high-quality dairy and dairy-based products continues to expand across foodservice and retail sectors. Industry analysts estimate that the dairy stabilizers market, valued at approximately USD 2.4 billion in 2025, is expected to reach around USD 4.3 billion by 2035, registering a compound annual growth rate (CAGR) of about 6.5% during the…

More Releases for Cutting

Comparing CO2 Laser Cutting to Other Fabric Cutting Methods

Choosing the Right Tool for Precision and Efficiency

Choosing the correct focal length for your CO2 laser is crucial for achieving precise cuts, especially when working with laser cutting fabric. The focal length determines the laser beam's spot size and depth of focus, directly impacting cutting quality. Shorter focal lengths (e.g., 1.5" to 2") are ideal for fine details on thin materials, while longer focal lengths (e.g., 4" to 5") suit…

Cutting Edge Solutions: Analyzing the Booming Cutting Fluid Market

The global cutting fluid industry is poised for significant growth, with projections indicating a Compound Annual Growth Rate (CAGR) of 4.1% from 2023 to 2033. By 2033, the market is expected to achieve a valuation of USD 16.3 billion, underscoring its critical role in industrial manufacturing and machining processes.

Cutting fluids, often referred to as coolants or lubricants, play a pivotal role in industrial metalworking. These fluids are designed to reduce…

Is Die Cutting The Same As Cricut? What Is The Difference Between Die Cutting An …

Die cutting and Cricut are related but not exactly the same. Die cutting is a general term for the process of using a die to cut out shapes from various materials, such as paper, fabric, or metal. This can be done manually with a die cutting machine or press, or with the help of electronic die cutting machines like the Cricut.

Cricut is a brand of electronic die cutting machines that…

Profboard launches cutting-edge cutting board on Kickstarter

Image: https://www.getnews.info/wp-content/uploads/2024/06/1718783865.png

Revolutionizing Kitchen Safety and Convenience for Home Chefs

Profboard, the premier manufacturer of innovative cutting board systems, is proud to announce the launch of the Profboard Private edition. Since 2006, Profboard has been a trusted name among chefs and culinary enthusiasts worldwide. Now, the same professional-grade quality and innovation can be experienced in home kitchens.

Profboard sets a new standard with its cutting-edge cutting board system designed to revolutionize your kitchen.…

Fiber Laser Metal Cutting Machines Market Cutting-Edge Technology for Efficient …

Global Fiber Laser Metal Cutting Machines Market Overview:

The Fiber Laser Metal Cutting Machines market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the Fiber Laser Metal Cutting Machines market has experienced significant growth, driven by factors such as increasing consumer demand,…

Metal Cutting Fluids Market Report 2018: Segmentation by Type (Emulsion Metal Cu …

Global Metal Cutting Fluids market research report provides company profile for Blaser, Idemitsu Kosan, Daido Chemical Industry, COSMO Oil, Master, Exxon Mobil Corporation, Houghton (Gulf Oil), BP, Fuchs, Yushiro Chemical, Quaker and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for…