Press release

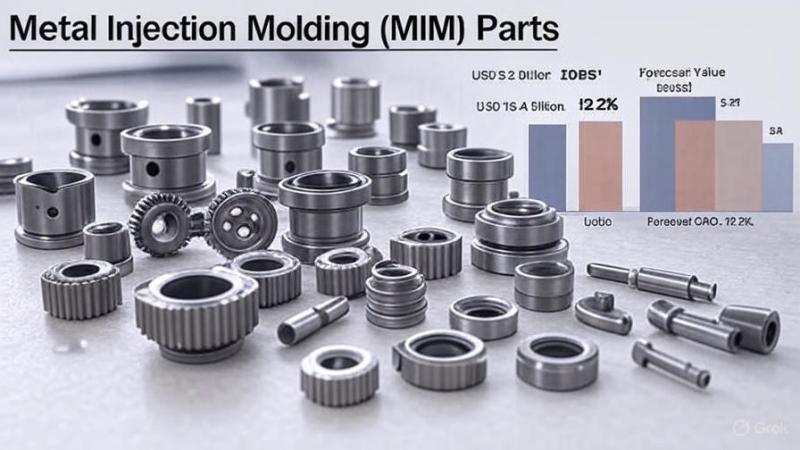

Metal Injection Molding (MIM) Parts Market to Reach USD 16.4 Billion by 2035 with Strong Global Expansion

The global metal injection molding (MIM) parts market is entering an exciting growth phase, with its value projected to rise from USD 5.2 billion in 2025 to USD 16.4 billion by 2035, registering a strong CAGR of 12.2%. Manufacturers, both established players and new entrants, are actively expanding their capabilities and investing in breakthrough technologies to capitalize on this momentum.By 2030, the market is forecast to exceed USD 8.2 billion, supported by rising demand for high-precision, complex-shaped, and lightweight components across industries. The decade from 2031 to 2035 is expected to accelerate even further, with innovations in powder metallurgy, hybrid additive-MIM processes, and an expanding role in aerospace and industrial machinery shaping the future of this market.

Full Market Report available for delivery. For purchase or customization, please request here: https://www.futuremarketinsights.com/reports/sample/rep-gb-25050

Market Drivers and Opportunities

The surge in demand for MIM parts is driven by the need for miniaturization, design flexibility, and cost-effective production of high-volume, intricate components. Automotive manufacturers are increasingly using MIM to produce lightweight and complex engine and transmission components, enhancing efficiency and durability. Medical device makers are adopting MIM for orthopedic implants, surgical instruments, and dental tools, where dimensional accuracy and biocompatibility are essential.

Consumer electronics and precision engineering industries are also key contributors, leveraging MIM for sensors, connectors, and casings where repeatability and tight tolerances are critical. At the same time, aerospace and defense applications provide additional opportunities, particularly as the industry seeks lightweight, high-strength materials for demanding environments.

Insights into Materials and End-Use

Among materials, stainless steel dominates the market, accounting for 46.8% of the share in 2025. Its combination of strength, corrosion resistance, and adaptability makes it a preferred choice for large-scale MIM applications. Continuous advances in binder systems and sintering technologies are further enhancing its performance and sustainability profile.

In terms of end-use, automotive remains the leading segment at 41.5%, followed by medical devices at 25% and consumer electronics at 20%. Industrial machinery, aerospace, and defense collectively represent nearly 20% of demand, adding steady growth to the market. These sectors underscore the versatility of MIM in producing small yet critical components that traditional machining struggles to deliver economically.

Regional Growth Outlook

Geographically, Asia-Pacific leads the charge, with China projected to grow at a CAGR of 16.5% and India at 15.3% between 2025 and 2035. These countries benefit from high-volume manufacturing, rapid EV adoption, and cost-effective production ecosystems. Europe, led by Germany at a 14.0% CAGR, is focusing on high-performance aerospace and industrial applications, while North America continues to drive innovation in precision alloys and process automation, with the U.S. expected to grow at 10.4% CAGR.

Global supply chains are evolving as manufacturers pursue nearshoring strategies and partnerships with OEMs to strengthen scalability and meet regional demand efficiently.

Competitive Landscape

The MIM parts market is highly competitive, characterized by innovation in alloys, binder systems, and scalable production capabilities. Leading companies such as ARC Group Worldwide, Inc., Smith Metals, and Advanced Materials Technologies Pte. Ltd. are setting benchmarks in high-performance components for automotive, aerospace, and industrial use.

Other notable players like CMG Technologies and Form Technologies Company specialize in precision micro-components for medical and electronic applications. CN Innovations Holdings Ltd., Akron Porcelain & Plastics Co., PSM Industries, and Nippon Piston Ring Co. Ltd. are expanding their footprints by focusing on advanced sintering, corrosion resistance, and high-strength components.

Both established leaders and emerging manufacturers are leveraging rapid prototyping, additive manufacturing integration, and in-line quality systems to reduce lead times and improve part consistency. The growing emphasis on sustainability, recyclability, and customization is also shaping competitive strategies.

Request a Draft Report Here: https://www.futuremarketinsights.com/reports/brochure/rep-gb-25050

Future Outlook

Looking ahead, the MIM parts market is expected to benefit from sustained investment in R&D, the diversification of end-use applications, and the adoption of hybrid manufacturing technologies. Manufacturers are prioritizing lifecycle support, customer-specific customization, and integration with automated production lines to meet evolving industrial needs.

As industries continue to seek miniaturized, high-strength, and cost-efficient solutions, MIM technology is well-positioned to outperform traditional casting and machining processes. With robust growth prospects across automotive, medical, electronics, and aerospace sectors, the MIM parts market is set to become a cornerstone of advanced manufacturing in the decade ahead.

Related Reports:

Charge Controller System Market- https://www.futuremarketinsights.com/reports/charge-controller-system-market

Soil Testing Market- https://www.futuremarketinsights.com/reports/soil-testing-equipment-market

Combined Cooling Heat and Power Plant Market- https://www.futuremarketinsights.com/reports/combined-cooling-heat-and-power-plant-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Injection Molding (MIM) Parts Market to Reach USD 16.4 Billion by 2035 with Strong Global Expansion here

News-ID: 4192215 • Views: …

More Releases from Future Market Insights

Japan Caramel Food Colors Industry Outlook to 2036: Strategic Insights for R&D, …

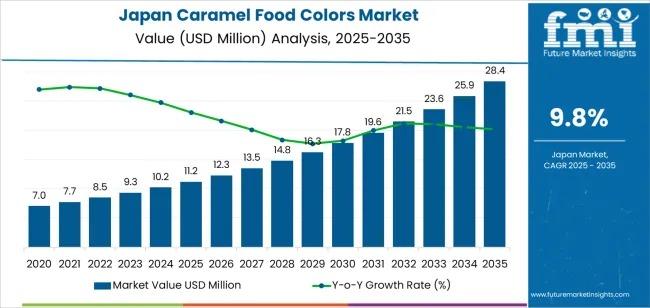

The Japanese caramel food colors market is on a steady growth trajectory, with demand projected to rise from USD 11.2 million in 2025 to USD 28.4 million by 2035, registering a CAGR of 9.8%. The initial phase of the forecast period (2025-2030) anticipates a steady increase in demand, reaching approximately USD 17.8 million by 2030, driven by the expanding use of caramel colors across confectionery, dairy, and baked goods.

The market's…

Comprehensive Analysis of the Japan Butter Flavor Market: Technology Evolution, …

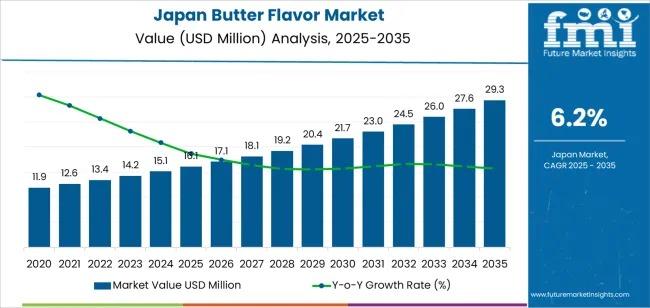

The demand for butter flavor in Japan is projected to rise from USD 16.1 million in 2025 to USD 29.4 million by 2035, reflecting a steady compound annual growth rate (CAGR) of 6.2%. This growth is underpinned by increasing adoption across bakery products, confectionery items, and dairy-based preparations, as manufacturers seek to enhance taste experiences and deliver authentic dairy character in a wide range of food offerings.

The Japanese bakery and…

Japan Casein Peptone Market Deep-Dive 2026-2036: Strategic Forecasts, Market Ent …

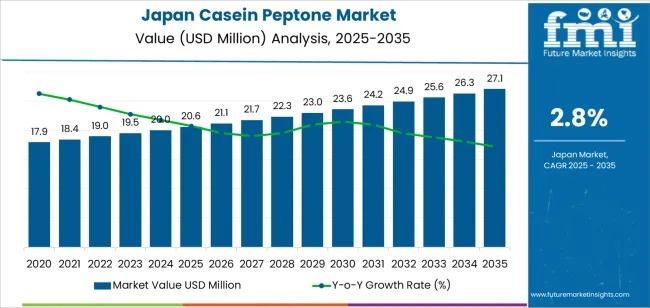

The demand for casein peptone in Japan is projected to grow steadily, reaching USD 27.1 million by 2035, up from USD 20.6 million in 2025, reflecting a compound annual growth rate (CAGR) of 2.8%. During the early forecast period (2025-2030), demand is expected to rise from USD 20.6 million to approximately USD 23.6 million, supported by its widespread applications in biotechnology, pharmaceuticals, and food industries. Casein peptone continues to play…

Global Boride Powder Market Size, Share & Forecast: High-Growth Segments, Value …

The global boride powder market is valued at USD 19.7 billion in 2025 and is projected to reach USD 32.2 billion by 2035, advancing at a steady 5.0% CAGR over the forecast period. This upward trajectory reflects increasing adoption of boride-based compounds in aerospace technology, high-temperature processing environments, and advanced coating applications, where exceptional thermal stability, corrosion resistance, and mechanical strength are essential for operational performance and product reliability.

Key Market…

More Releases for MIM

Metal Powder Injection Molding (MIM) Market Size, Key Market Insights, Opportuni …

LOS ANGELES, United States: The report is a brilliant presentation of a highly detailed, comprehensive, and accurate research study on the global Metal Powder Injection Molding (MIM) market. The research study explores some of the important aspects of the global Metal Powder Injection Molding (MIM) market and shows how different factors such as price, competition, market dynamics, regional expansion, gross margin, and consumption are impacting market growth. The report includes…

Metal Injection Molding (MIM) Market: A Comprehensive Overview

Metal Injection Molding (MIM) is revolutionizing the manufacturing industry by combining the benefits of plastic injection molding with the unique properties of metals. This process allows for the production of complex, high-precision metal parts that are both cost-effective and efficient. As industries increasingly demand high-quality, intricately designed metal components, the MIM market has witnessed significant growth.

Browse More About This Research Report @ https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

Overview

Metal Injection Molding is a manufacturing technique…

Metal Injection Moulding (MIM) Technology Market Size in 2023 To 2029 | OPTIMIM, …

This report provides an in-depth analysis of the global market's competitive landscape, focusing on key players operating in the Metal Injection Moulding (MIM) Technology industry. It offers a comprehensive overview of their performance, highlighting important details such as market value, status, and revenue. By examining these factors, stakeholders gain valuable insights into the competitive advantages of the market. The report delves into the strategies and performance of major competitors, presenting…

AMTMIM Shifting Production to New MIM Plant in Jiangsu

Some of the old plant's business was transferred from Dongguan, in 2017, AMTMIM established a new MIM plant in Jiangsu, China.

The new MIM plant in Jiangsu, China, started up last September. AMTMIM recently said it designed the operation to serve the region's automotive, consumer electronics, and telecommunications manufacturers. AMTMIM manages its own 20,000 square meters modern manufacturing facility, though to date it operates ten injection molding machines, eight vacuum sintering…

Metal Injection Molding Parts (MIM Parts) Market is Projected to Gain Significan …

The Metal Injection Molding Parts (MIM Parts) Market research report Forcast 2023-2030 provides in-depth information on market trends, market capacity, industry size, growth factors, share, innovations, competitive environment, business problems, and more. This report's historical data confirms demand growth on a global, national, and regional scale. The studies on the global industry cover everything from comprehensive research to market size and forecasting to dynamics, growth factors, prospects, and hazards, as…

Metal Injection Molding Parts (MIM Parts) Market Size 2022 By Top Key Players - …

A three-dimensional CAD model is used as the basis for the metal injection moulding (MIM) manufacturing process, which produces parts using metal powder and a binder. In a hopper, the binder and metal powder are mixed, and the resulting material is then injected into a mould. The part is expelled from the mould after the mould has been heated until the binder has dried. When standard machining or casting would…