Press release

Metal Injection Molding Market is Set to Globally Reach US$ 9.55 Billion at 5.5% CAGR by 2035

The global metal injection molding market is estimated to value at US$ 5.59 billion in 2025 and is forecasted to expand at a CAGR of 5.5% to reach US$ 9.55 billion by 2035.The metal injection molding industry outlook is positively impacted due to growing demand from different end‐user sectors. Furthermore, it is projected that technological developments in the industry will support market expansion.

Market Overview & Material-wise Segmentation

The MIM (Metal Injection Molding) market is projected to grow steadily over the 2025‐2035 period. The key material segments covered include Stainless Steel, Low Alloy Steel, Soft Magnetic Materials, Cobalt Alloy, Tungsten Alloy, and Others. Among these, stainless steel dominates in terms of demand and market share. Soft magnetic materials and other specialized alloys (including cobalt and tungsten) are gaining interest especially in applications that require magnetic performance or high wear/temperature resistance.

Low alloy steels serve markets that require moderate strength, reasonably good performance, and lower cost compared to higher‐end alloys. The "Others" category includes materials like tool steel, titanium, copper alloys, which are used in more specific, niche applications.

End‐Use Industries & Drivers

The automotive industry is one of the major drivers for the MIM market. With increasing electrification, lightweighting, and demand for precision components in drive trains, transmissions, brakes, and sealing/magnet components, automotive OEMs are turning more to MIM to reduce cost, weight, and the number of machining steps.

Other sectors such as medical & orthodontics, electrical & electronics, consumer products, industrial machinery, and defense/firearms are also important. For example, medical devices often require small, complex, high‐tolerance components with biocompatible materials, making MIM a suitable manufacturing route.

Geographically, Asia‐Pacific is expected to be the fastest‐growing region over the forecast period, thanks to rapid industrialization, strong automotive production, cost advantages, and growing electronics and medical device manufacturing. North America also holds a significant share, led by demand in medical, automotive, and high precision electronics.

Recent Developments & Technological Trends

Advancements in Materials: Research is ongoing into new alloy types and combinations. For instance, work on high entropy alloys (HEAs) using commodity powders has shown promise in achieving single‐phase FCC structures with good mechanical performance.

Biodegradable and Functional Materials: Introduction of biodegradable Fe‐Mn alloy with low carbon addition offers both corrosion performance and mechanical strength.

Better Process Control & Tolerances: To meet automotive and medical industry requirements, MIM producers are improving densification, tolerance, and surface finishes. Tighter specifications demand innovations in feedstock preparation, debinding, and sintering.

Miniaturization and Complex Geometries: There is increasing demand for smaller, more complex metal parts which are difficult or expensive to machine. MIM's ability to produce near‐net shape parts with minimal waste is being leveraged.

Key Players & Competitive Landscape

The market has several established players and new entrants, with competition focused on materials innovation, process efficiency, geographic expansion, and industry partnerships. Some of the prominent companies are:

CMG Technologies

Indo‐MIM (India)

Dean Group International

Dynacast International

Phillips‐Medisize

NetShape Technologies

ARC Group Worldwide

Smith Metal Products

Many of these firms are focusing on R&D (new alloys, process refinement), capacity expansions in key regions (especially Asia‐Pacific), and entering or strengthening their presence in medical or automotive sectors.

Full Market Report available for delivery. For purchase or customization, please request here - https://www.factmr.com/connectus/sample?flag=S&rep_id=487

Challenges & Potential Risks

Raw Material Price Fluctuations: Prices for metal powders, binders, energy for sintering etc. are volatile, which increases cost risk.

Tooling and Setup Costs: High initial investment in tooling, mold design, debinding, sintering furnaces may deter new entrants or smaller firms.

Quality & Regulatory Requirements: Especially in medical and automotive, the parts must meet strict safety, performance, and biocompatibility standards, imposing higher R&D, certification, and testing costs.

Outlook & Strategic Implications

Given the forecasted growth (from ~US$ 5.59 billion in 2025 to ~US$ 9.55 billion by 2035 at 5.5% CAGR) and supportive trends, companies should consider:

Investing in advanced alloys and materials (soft magnetic, cobalt, tungsten) for high‐performance/ niche applications.

Enhancing process technologies (debinding, sintering, precision molding) to improve yields, tolerances, and surface finishes.

Geographical expansion, especially deeper presence in Asia‐Pacific, as that region is expected to capture a growing share.

Collaborations/joint R&D for novel materials and for meeting regulatory / certification requirements.

Exploring niche end‐use sectors such as defense, medical implants, where margins are generally higher though volumes may be smaller.

Browse Full Report: https://www.factmr.com/report/487/metal-injection-molding-market

Conclusion

The metal injection molding market is poised for steady growth over the next decade, driven by demand for precision, lightweight, high‐performance parts across automotive, medical, electronics and other industries. Stainless steel remains the backbone of material demand, but soft magnetic, tungsten, cobalt, and specialized alloys are rapidly expanding into niche and high‐spec applications. Key players who invest in innovation, material development, process optimization, and regional growth are likely to emerge as market leaders. While there are challenges-especially around material costs and tooling investments-the long‐term outlook remains strong as industries increasingly seek manufacturing techniques that deliver complexity, precision, and cost efficiency.

Check out More Related Studies Published by Fact.MR:

Inland Waterways Vessels Market

https://www.factmr.com/report/3505/inland-waterways-vessels-market

Micro Inverter Market

https://www.factmr.com/report/3506/micro-inverter-market

Screw Washer Market

https://www.factmr.com/report/3507/screw-washer-market

Automotive V-belts Market

https://www.factmr.com/report/3508/automotive-vbelts-market

Contact:

US Sales Office

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583, +353-1-4434-232

Email: sales@factmr.com

About Fact.MR

We are a trusted research partner of 80% of fortune 1000 companies across the globe. We are consistently growing in the field of market research with more than 1000 reports published every year. The dedicated team of 400-plus analysts and consultants is committed to achieving the utmost level of our client's satisfaction.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Injection Molding Market is Set to Globally Reach US$ 9.55 Billion at 5.5% CAGR by 2035 here

News-ID: 4183978 • Views: …

More Releases from Fact.MR

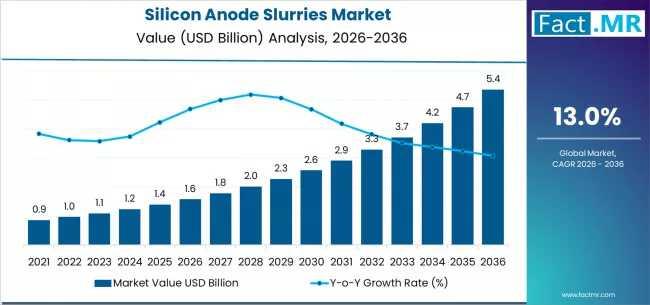

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

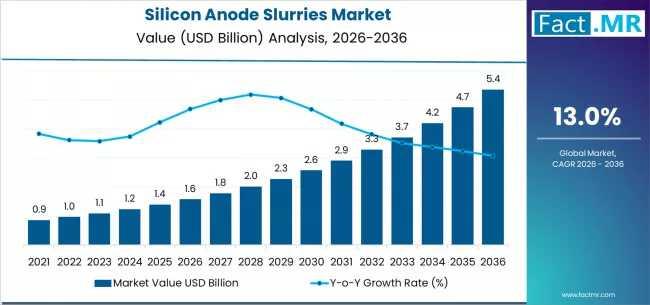

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

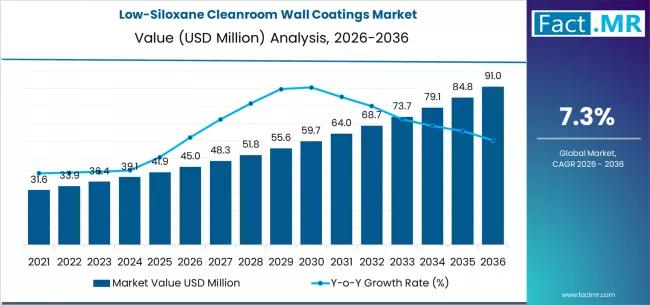

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

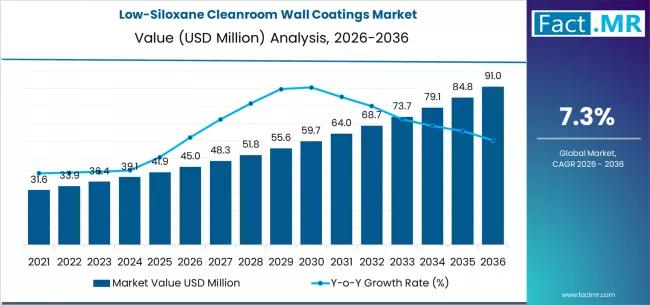

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

More Releases for MIM

Metal Powder Injection Molding (MIM) Market Size, Key Market Insights, Opportuni …

LOS ANGELES, United States: The report is a brilliant presentation of a highly detailed, comprehensive, and accurate research study on the global Metal Powder Injection Molding (MIM) market. The research study explores some of the important aspects of the global Metal Powder Injection Molding (MIM) market and shows how different factors such as price, competition, market dynamics, regional expansion, gross margin, and consumption are impacting market growth. The report includes…

Metal Injection Molding (MIM) Market: A Comprehensive Overview

Metal Injection Molding (MIM) is revolutionizing the manufacturing industry by combining the benefits of plastic injection molding with the unique properties of metals. This process allows for the production of complex, high-precision metal parts that are both cost-effective and efficient. As industries increasingly demand high-quality, intricately designed metal components, the MIM market has witnessed significant growth.

Browse More About This Research Report @ https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

Overview

Metal Injection Molding is a manufacturing technique…

Metal Injection Moulding (MIM) Technology Market Size in 2023 To 2029 | OPTIMIM, …

This report provides an in-depth analysis of the global market's competitive landscape, focusing on key players operating in the Metal Injection Moulding (MIM) Technology industry. It offers a comprehensive overview of their performance, highlighting important details such as market value, status, and revenue. By examining these factors, stakeholders gain valuable insights into the competitive advantages of the market. The report delves into the strategies and performance of major competitors, presenting…

AMTMIM Shifting Production to New MIM Plant in Jiangsu

Some of the old plant's business was transferred from Dongguan, in 2017, AMTMIM established a new MIM plant in Jiangsu, China.

The new MIM plant in Jiangsu, China, started up last September. AMTMIM recently said it designed the operation to serve the region's automotive, consumer electronics, and telecommunications manufacturers. AMTMIM manages its own 20,000 square meters modern manufacturing facility, though to date it operates ten injection molding machines, eight vacuum sintering…

Metal Injection Molding Parts (MIM Parts) Market is Projected to Gain Significan …

The Metal Injection Molding Parts (MIM Parts) Market research report Forcast 2023-2030 provides in-depth information on market trends, market capacity, industry size, growth factors, share, innovations, competitive environment, business problems, and more. This report's historical data confirms demand growth on a global, national, and regional scale. The studies on the global industry cover everything from comprehensive research to market size and forecasting to dynamics, growth factors, prospects, and hazards, as…

Metal Injection Molding Parts (MIM Parts) Market Size 2022 By Top Key Players - …

A three-dimensional CAD model is used as the basis for the metal injection moulding (MIM) manufacturing process, which produces parts using metal powder and a binder. In a hopper, the binder and metal powder are mixed, and the resulting material is then injected into a mould. The part is expelled from the mould after the mould has been heated until the binder has dried. When standard machining or casting would…