Press release

UK Polymer Emulsion Market Poised for Sustainable Growth to 2035

The UK polymer emulsion market is entering a decade of opportunity, expected to achieve a valuation of USD 1.8 billion by 2035, with a compound annual growth rate of 5.2%. This trajectory is shaped by manufacturers' increasing need for sustainable, high-performance solutions that comply with stringent regulations while delivering cost-effective results. Polymer emulsions stand out as the versatile answer, meeting the dual demands of industrial performance and environmental responsibility.Click Here for More Information:- https://www.futuremarketinsights.com/reports/united-kingdom-polymer-emulsion-market

For manufacturers across construction, packaging, automotive, and textiles, this market outlook signals not just growth but a pathway to align with consumer expectations, industry standards, and the nation's net-zero ambitions.

The Sustainability Imperative

Sustainability is no longer an option; it is a mandate. The UK's regulatory framework, including measures to curb carbon emissions and the Clean Air Strategy, is pushing industries to embrace low-VOC and water-based polymer emulsions. For manufacturers, these emulsions represent more than regulatory compliance-they offer an opportunity to innovate responsibly.

Water-based polymer emulsions, with their lower carbon footprint, allow manufacturers to design coatings, adhesives, and laminates that perform under demanding conditions while safeguarding air quality and public health. By adopting these materials, businesses can stay ahead of compliance challenges, strengthen their sustainability credentials, and secure long-term growth.

Building a Greener Future

In construction, polymer emulsions are becoming indispensable. They are essential in architectural coatings, sealants, and adhesives that provide superior durability, thermal resistance, and long-term environmental benefits. The rise of green buildings and the retrofitting of infrastructure are driving demand for materials that balance performance with sustainability.

For manufacturers, this creates an opening to supply eco-conscious products that help contractors and developers meet evolving sustainability certifications. By integrating polymer emulsions into their product portfolios, companies can directly contribute to lowering carbon footprints while meeting the market's rising expectations for resilient, energy-efficient building solutions.

Innovation in Packaging

The UK packaging industry is undergoing a transformation, driven by consumer preferences for recyclable, biodegradable, and sustainable materials. Polymer emulsions are a key enabler of this shift. By improving gloss, strength, and printability in coatings, laminates, and adhesives, they allow manufacturers to create packaging that is both visually appealing and environmentally responsible.

This presents an immediate growth avenue for packaging manufacturers. Embracing polymer emulsions not only satisfies regulatory requirements but also aligns with the wider push toward circular economy principles. Companies that invest in this transition will secure a competitive edge as sustainable packaging becomes a defining feature of brand reputation and consumer trust.

Driving Performance in Automotive and Textiles

Automotive and textiles industries in the UK are adopting polymer emulsions to push performance boundaries while addressing sustainability goals. In automotive, these emulsions contribute to lighter, more fuel-efficient vehicles by enabling high-quality coatings and adhesives that reduce overall weight without compromising durability.

In textiles, they enhance water resistance, flexibility, and longevity, ensuring fabrics can withstand environmental challenges while remaining comfortable and versatile. For manufacturers in these sectors, polymer emulsions provide a route to deliver superior products that meet the rising demand for both innovation and eco-consciousness.

Market Segmentation and Opportunities

By 2035, acrylic emulsions are expected to dominate with over 50% share, driven by their widespread use in paints, coatings, and adhesives. Vinyl acetate emulsions will see strong uptake in packaging and adhesives due to their superior bonding properties. Meanwhile, styrene-butadiene emulsions will remain critical for industrial applications requiring elasticity and abrasion resistance.

Applications in paints and coatings are set to account for nearly half the market, underpinned by demand for low-VOC solutions in green building projects. Adhesives and sealants will represent a quarter of the market, boosted by sustainable construction and packaging trends. Textiles and nonwovens, making up 15%, will grow steadily as durable and flexible fabrics gain traction in both consumer and industrial markets.

For manufacturers, this segmentation underscores the diversity of opportunities. By tailoring polymer emulsion solutions to specific applications, businesses can position themselves at the forefront of demand-driven innovation.

Get Sample Report: - https://www.futuremarketinsights.com/reports/sample/rep-gb-20217

Competitive Landscape

The UK polymer emulsion market is moderately fragmented, with global giants like BASF SE, Arkema S.A., Celanese Corporation, and Dow Inc. holding around 60% of market share. These firms lead with continuous investment in R&D, developing new formulations tailored to local sustainability goals.

Domestic companies such as Synthomer Plc remain vital players, offering region-specific solutions that address UK market demands, particularly in paints, coatings, and adhesives. Emerging innovators, including startups developing bio-based emulsions, are also making their mark with niche solutions in packaging and textiles.

For manufacturers, this competitive landscape highlights the importance of differentiation. Whether through local expertise, sustainable innovation, or specialty applications, companies that adapt quickly will capture growth in this evolving market.

Future Outlook

Looking ahead, the UK polymer emulsion market promises robust growth fueled by four core drivers: regulatory push for eco-friendly products, the green construction boom, innovation in sustainable packaging, and advances in automotive and textiles. Each of these factors creates clear opportunities for manufacturers to align products with long-term industrial and environmental priorities.

By 2035, the industry will not only be larger but also more sustainable, innovative, and performance-driven. Manufacturers that invest in polymer emulsions today are investing in their ability to thrive tomorrow, shaping the future of materials for a greener, more resilient UK economy.

Chemicals & Materials Industry Analysis:-

Nitroglycerin Market

https://www.futuremarketinsights.com/reports/nitroglycerin-market

Professional Potting Soil Market

https://www.futuremarketinsights.com/reports/professional-potting-soil-market

Feed Electrolytes Market

https://www.futuremarketinsights.com/reports/feed-electrolytes-market

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analystsworldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release UK Polymer Emulsion Market Poised for Sustainable Growth to 2035 here

News-ID: 4182958 • Views: …

More Releases from Future Market Insights

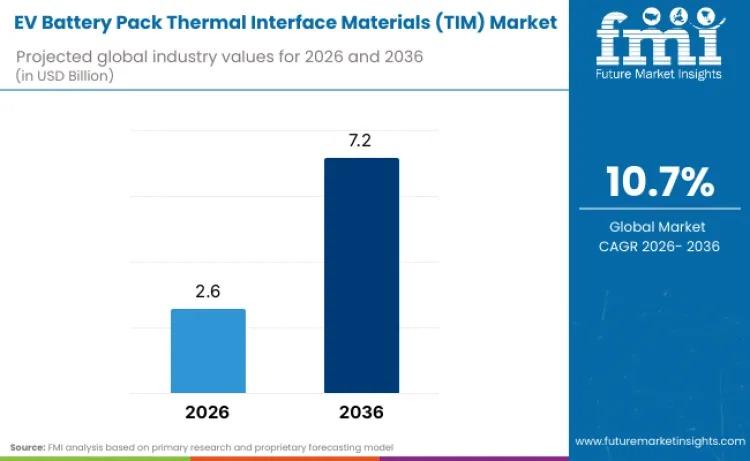

Global EV Battery Thermal Interface Materials Market to Reach USD 7.2 Billion by …

The global EV battery pack thermal interface materials (TIM) market is projected to grow from USD 2.6 billion in 2026 to USD 7.2 billion by 2036, advancing at a robust CAGR of 10.7%, according to recent analysis by Future Market Insights. This expansion reflects the accelerating electrification of transportation, rising energy density in battery systems, and increasingly stringent safety requirements that position thermal management as a critical determinant of vehicle…

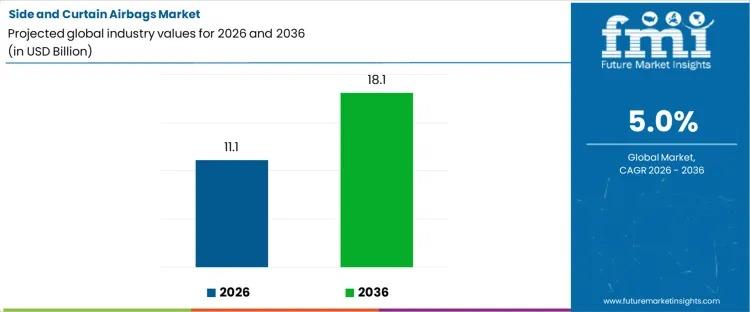

Global Side and Curtain Airbags Market to Reach USD 18.2 Billion by 2036 as Safe …

The global side and curtain airbags market is poised for sustained expansion as automotive manufacturers prioritize occupant protection and compliance with stringent crash safety regulations. According to the latest analysis by Future Market Insights, the market is projected to grow from USD 11.1 billion in 2026 to USD 18.2 billion by 2036, advancing at a CAGR of 5.0% during the forecast period.

This growth reflects the automotive industry's increasing emphasis on…

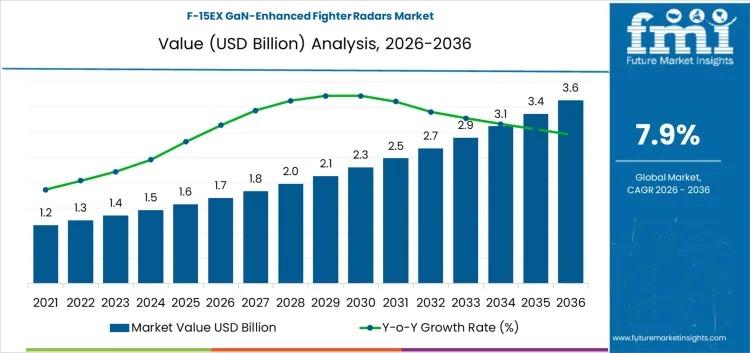

F-15EX GaN-Enhanced Fighter Radars Market to Reach USD 3.6 Billion by 2036 as De …

The global F-15EX GaN-enhanced fighter radars market is projected to grow from USD 1.7 billion in 2026 to USD 3.6 billion by 2036, registering a compound annual growth rate (CAGR) of 7.9% during the forecast period. This growth trajectory reflects the increasing integration of Gallium Nitride (GaN) semiconductor technology into advanced airborne radar systems, enabling superior detection, tracking, and electronic warfare resistance for modern fighter aircraft such as the F-15EX.

The…

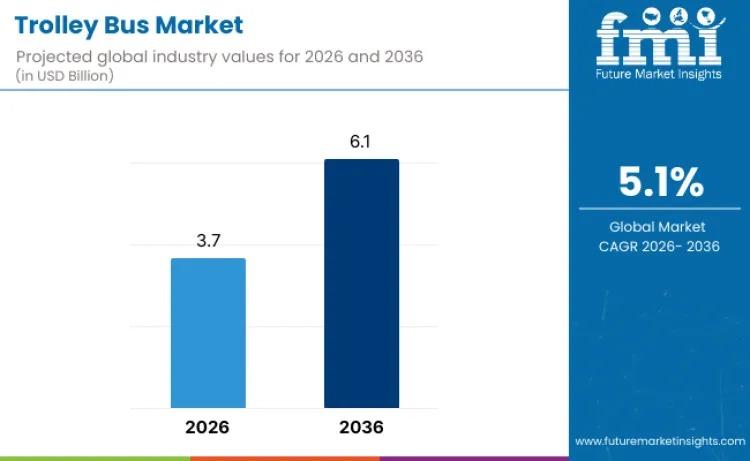

Global Trolley Bus Industry to Reach USD 6.1 Billion by 2036 as Urban Electrific …

The global trolley bus industry is entering a phase of sustained expansion, with market valuation projected to grow from USD 3.7 billion in 2026 to USD 6.1 billion by 2036, reflecting a steady compound annual growth rate (CAGR) of 5.1%. This upward trajectory is being driven by accelerating urban electrification programs, stringent zero-emission mandates, and mounting investment in sustainable public transportation infrastructure across major metropolitan regions worldwide.

As cities confront escalating…

More Releases for Polymer

MDR Certificate For Single Polymer Clip Applier And Multiple Polymer Clip Applie …

EU Quality Management System Certificate

Regulation (EU)2017/745, Annex Ix Chapter I and III

MDR 804963 R000

Manufacturer: Hangzhou Sunstone Technology Co., Ltd

Address:

2nd Floor of Building 1,

#460 Fucheng Rd, Qiantang Area

Hangzhou

Zhejiang

310018

China

Single Registration Number: CN-MF-000040501

EU Authorised Representative: MedPath GmbH

Address:

Mies-van-der-Rohe-Strasse 8

80807

Munich

Germany

Scope: See attached Device Schedule

On the basis of our examination of the quality system in accordance with Regulation (EU) 2017/745, Annex IX

Chapter I and lll, the quality system meets the requirements of the Regulation. For the…

Acrylic Polymer Market

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐩𝐨𝐥𝐲𝐦𝐞𝐫 𝐦𝐚𝐫𝐤𝐞𝐭 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝐔𝐒𝐃 𝟐𝟎 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐞𝐝 𝐭𝐨 𝐫𝐞𝐚𝐜𝐡 𝐔𝐒𝐃 𝟑𝟔.𝟗 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟐, 𝐠𝐫𝐨𝐰𝐢𝐧𝐠 𝐚𝐭 𝐚 𝐜𝐨𝐦𝐩𝐨𝐮𝐧𝐝 𝐚𝐧𝐧𝐮𝐚𝐥 𝐠𝐫𝐨𝐰𝐭𝐡 𝐫𝐚𝐭𝐞 (𝐂𝐀𝐆𝐑) 𝐨𝐟 𝟔.𝟒% 𝐟𝐫𝐨𝐦 𝟐𝟎𝟐𝟑 𝐭𝐨 𝟐𝟎𝟑𝟐.

𝐀𝐜𝐫𝐲𝐥𝐢𝐜 𝐏𝐨𝐥𝐲𝐦𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰

The acrylic polymer market has experienced significant growth due to its versatile applications across various industries, including paints and coatings, adhesives, textiles, and construction. Acrylic polymers are favored for…

Polymer Processing Aids: Enhancing Efficiency and Quality in Polymer Manufacturi …

Introduction

Polymer Processing Aids (PPAs) are indispensable additives used to improve the efficiency, quality, and cost-effectiveness of polymer manufacturing. These aids, often added in small quantities, significantly enhance polymer production by reducing surface defects, improving flow properties, and reducing wear on manufacturing equipment. Their role is critical in enabling smooth, uninterrupted processing, leading to higher-quality end products and improved manufacturing productivity. With the ever-growing demand for polymers across industries like automotive,…

What Are Lithium Polymer? Information About Lithium Polymer Batteries Guide

Did people know that Lithium Polymer power over 80% of the drones used in recreational and commercial applications today? Lithium Polymer (LiPo) batteries have become a staple in modern electronics. From powering smartphones and laptops to energizing drones and electric vehicles, these batteries offer a blend of high energy density and flexibility that makes them ideal for a wide range of applications. In this article, we'll dive deep into what…

Custom Polymer Synthesis Market 2023 Will Record Massive Growth, Trend Analysis …

The Custom Polymer Synthesis Market Trends Overview 2023-2030:

A new Report by Stratagem Market Insights, titled "Custom Polymer Synthesis Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," offers a comprehensive analysis of the industry, which comprises insights on the Custom Polymer Synthesis market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures, tables, and charts,…

Silyl Modified Polymer (MS Polymer) Market Forecast Research Reports Offers Key …

Silyl Modified Polymer (MS Polymer) Market: Introduction

MS polymers, also known as silyl modified polymers or silyl terminated polymers, are polymers with a silane group. A silyl modified polymer (MS polymer) usually refers to a hybrid polymer backbone, usually polyurethane or polyether and a silane end group. Formulators can change the backbone polymer in sealants and adhesives utilizing MS polymers to match the specified application, achieving silicone-like performance while avoiding the…