Press release

The Ultimate Guide to Seamless Pipe Manufacturing: Hot-Rolled vs. Cold-Drawn

Image: https://ecdn6.globalso.com/upload/p/3937/image_other/2025-09/hot-rolled-vs-cold-drawn-seamless-pipe-comparison.jpgIntroduction

The mandated design of seamless steel pipe [https://www.cortecsteel.com/seamless-steel-pipe-hot-rolled-cold-drawn-product/] is the unquestionable option for applications requiring excellent pressure retention capacity and inherent form. As this is evident, not all seamless pipes are equal. The last manufacturing process step, either hot-rolling or cold-drawing, greatly affects the width tolerance, surface finish, mechanical properties, and price of the pipe itself. This document provides a culmination of the comparison between hot-rolled and cold-drawn seamless pipes so you can make an informed decision to find the best and most economical seamless pipe for your engineering design.

The Foundation: How Seamless Pipe is Made

Both processes start with the same basic step: a solid cylindrical steel billet is heated in a furnace and pierced with a mandrel. The heat permits the transformation of the steel bilateral structure into a rough thick-walled hollow tube called "hollow shell." All the processes implemented after shaping the "hollow shell" determines whether the pipe is a hot rolled or cold drawn product.

Hot-Rolled Seamless Pipe: The Industry Workhorse

Once the piercing is complete, the hollow shell is processed by a set of rollers while still at high temperature (generally one is over 930degree C). This rolling process will shape the shell to a longer length and less wall thickness and diameter. The speed of the hot rolling process and low cost contributes to the popularity of hot-rolled pipe in applications where extreme dimensional tolerances are not critical such as general industrial pipe, structural members, and in lower pressure oil and gas pipelines.

Image: https://ecdn6.globalso.com/upload/p/3937/image_other/2025-09/cold-drawing-process-for-seamless-steel-pipe.jpg

Cold-Drawn Seamless Pipe: The Precision Product

Cold drawing starts with a finished hot rolled seamless pipe. The pipe is then lubricated and drawn through a high tolerance die and over a mandrel plug at room temperature. The cold drawing process improves all of the pipe's important properties, making it the necessary selection for precision measurements/threads such as hydraulic cylinders, automotive, heat exchanged tubes, and high performance mechanical tubing.

Technical Head-to-Head Comparison

Feature

Hot-Rolled Seamless Pipe

Cold-Drawn Seamless Pipe

Technical Significance

Dimensional Tolerance

Standard (e.g., OD plus-minus 1%)

Excellent (e.g., OD plus-minus 0.1%)

Cold-drawing offers up to 10x greater precision, critical for mechanical parts.

Wall Thickness Tol.

+/- 12.5% (Typical)

+/- 10% or better

Tighter wall control improves pressure rating consistency and reduces weight.

Surface Finish

Scaled / Rough (Ra 3.2-12.5m)

Smooth / Polished (Ra < 3.2m)

A smooth finish is essential for hydraulic seals and reducing flow friction.

Mechanical Strength

Standard (as-rolled)

Enhanced (up to 20-30% higher)

Cold working increases yield and tensile strength.

Production Cost

Lower

Higher

The additional drawing, annealing, and handling steps increase the cost.

Conclusion: Which Method is Right for You?

The decision is a classic engineering trade-off. If your project requires pourable and affordable pipe for typical structural or transport applications, a hot-rolled seamless pipe is warranted. If your application requires a high degree of accuracy, an improved surface finish, and better strength for high-performance mechanical or hydraulic systems, it will be worth the extra cost to procure cold-drawn seamless pipe.

Copyright Notice: This article was originally created by CORTEC STEEL LIMITED and first published on the official website www.cortecsteel.com. Reproduction Notice: Unauthorized reproduction is strictly prohibited. For citation or reproduction, please credit the source and include a link to this article. All rights reserved.

Media Contact

Company Name: CORTEC STEEL LIMITED

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=the-ultimate-guide-to-seamless-pipe-manufacturing-hotrolled-vs-colddrawn]

Country: China

Website: https://www.cortecsteel.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Ultimate Guide to Seamless Pipe Manufacturing: Hot-Rolled vs. Cold-Drawn here

News-ID: 4179973 • Views: …

More Releases from ABNewswire

Worldwide Biomass Sensor Market Report 2026: $450.00 Million Global Market with …

PW Consulting released a focused research report on the Worldwide Biomass Sensor Market, positioning it as a timely guide for stakeholders navigating the convergence of bioenergy expansion, circular-economy policies, and rapidly improving sensing technologies.

PW Consulting released a focused research report on the Worldwide Biomass Sensor Market, positioning it as a timely guide for stakeholders navigating the convergence of bioenergy expansion, circular-economy policies, and rapidly improving sensing technologies. Rather than treating…

BIS Market IQ: US AI & Hyperscale Data Center Operator Intelligence

BIS Research has launched BIS Market IQ: U.S. AI & Hyperscale Data Center Operator Intelligence, delivering structured, decision-ready insights into GPU procurement across U.S. data centers. The platform tracks 8.1 million GPU units scheduled for deployment between 2025 and 2027 across 62 operators, with 2027 projected as the peak year at 3.6 million units.

BIS Research announces new structured intelligence from BIS Market IQ: U.S. AI & Hyperscale Data Center Operator…

Freight and Logistics Market to Reach USD 8.49 Trillion by 2031 Amid Steady Trad …

Mordor Intelligence has published a new report on the freight and logistics market, offering a comprehensive analysis of trends, growth drivers, and future projections.

Freight and Logistics Market Overview

According to Mordor Intelligence, the freight and logistics market [https://www.mordorintelligence.com/industry-reports/freight-logistics-market-study?utm_source=abnewswire] is set to grow from USD 6.37 trillion in 2025 to USD 6.68 trillion in 2026 and is forecast to reach USD 8.49 trillion by 2031, registering a CAGR of 4.91% during the…

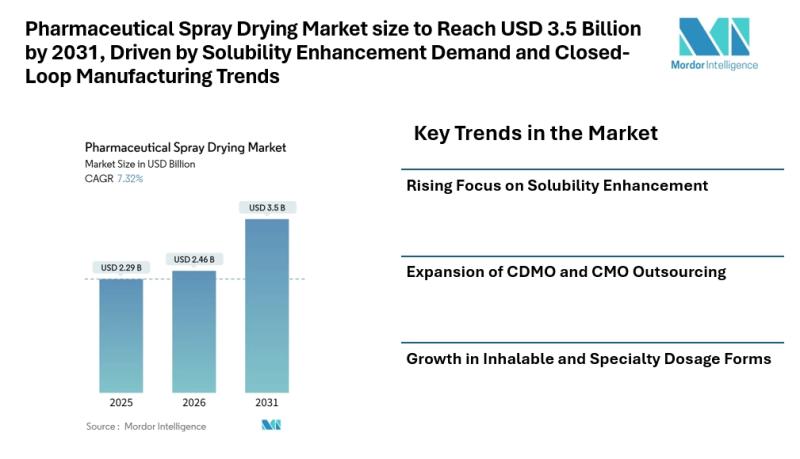

Pharmaceutical Spray Drying Market size to Reach USD 3.5 Billion by 2031, Driven …

Mordor Intelligence has published a new report on the pharmaceutical spray drying market, offering a comprehensive analysis of trends, growth drivers, and future projections.

Pharmaceutical Spray Drying Market Analysis

According to Mordor Intelligence, the pharmaceutical spray drying market size [https://www.mordorintelligence.com/industry-reports/global-pharmaceutical-spray-drying-market?utm_source=abnewswire] was valued at USD 2.46 billion in 2026 to reach USD 3.5 billion by 2031, registering a CAGR of 7.32% during the forecast period. The steady rise in poorly soluble drug candidates,…

More Releases for Seamless

Seamless Pipe Surface Roughness

The surface roughness of seamless pipes (https://www.eastern-steels.com/product/seamless-steel-pipe.html) is generally required to be between Ra 0.4 and 6.3 μm, depending on the application. Roughness affects the flow velocity and resistance of fluids within the pipe, thus affecting transport efficiency and stability. Excessive roughness can also increase the pipe's corrosion tendency and shorten its service life.

Seamless pipes have wide applications in industrial production, and their surface roughness is an important quality indicator.…

Otter Exteriors Seamless Gutters Introduces Comprehensive Gutter Cleaning and Se …

With a reputation for excellence in exterior home solutions, Otter Exteriors Seamless Gutters continues to provide homeowners with long-lasting, efficient, and aesthetically pleasing gutter systems designed to withstand the toughest weather conditions.

Otter Exteriors Seamless Gutters, a leading provider of high-quality gutter solutions, is proud to announce the expansion of its services, offering seamless aluminum gutter installation alongside its well-known gutter cleaning service. With a reputation for excellence in exterior home…

Van Winkle Seamless Gutter Outlines Key Considerations During Seamless Gutter In …

Image: https://www.getnews.info/wp-content/uploads/2024/06/1718907856.jpeg

Van Winkle Seamless Gutter is a premier gutter installation company. In a recent update, the company outlined key considerations during seamless gutter installation.

Owensboro, KY - In a website post, Van Winkle Seamless Gutter outlined key considerations during seamless gutter installation.

Image: https://lh7-us.googleusercontent.com/docsz/AD_4nXct9HoaPQ6BRqyMoRBcMvpTOdHzVXFO17RC2R9JJgA6BkMteBdlf1R2buAjncU8zTQAL5ydsqp9mP13iroxaEVovIs200PKznJts7s8HAbNd3TvYGWT7qcUV_iBWvh73Vxn2vStsFfU-3d0ibE0ZmvOz9wBxtdsyGkO_13a?key=Z_OtEqTCG3pY_olDX2S7yw

The experts asserted that the quality of the materials used in the installation process is crucial. Opting for high-grade aluminum or copper can significantly affect the durability and…

Seamless Events, Seamless Service: OneStop AV Introduces Unrivaled Tech Rentals …

Image: https://www.getnews.info/wp-content/uploads/2024/05/1716540113.jpeg

OneStop AV [https://onestopav.com/], a leading provider of audio-visual equipment rental and services, is proud to announce its latest initiative aimed at delivering unmatched tech rentals for seamless events in Boston and beyond. With a focus on reliability, quality, and impeccable service, OneStop AV ensures that event planners have access to the latest technology for their needs, whether it's a corporate conference, a trade show, or any other event requiring…

Van Winkle Seamless Gutter Outlines the Advantages of Seamless Gutters

Image: https://www.getnews.info/wp-content/uploads/2024/04/1713367210.jpeg

Van Winkle Seamless Gutter is a top-rated gutter installation company. In a recent update, the company outlined the advantages of seamless gutters.

Owensboro, KY - In a website post, Van Winkle Seamless Gutter outlined the advantages of seamless gutters.

The technicians asserted that one of the greatest advantages of seamless gutters Owensboro [https://www.google.com/maps?cid=5587474428412425196] is their durability and longevity. Traditional gutters are susceptible to leaks and damage at the joints, but…

Carbon steel seamless tube vs Stainless steel seamless tube

The difference between carbon steel seamless tube and stainless steel seamless tube mainly refers to the difference in design rules between carbon steel and stainless steel, which means that the design rules of these two types of steel cannot be used in common. These differences are summarized as follows:

Carbon steel

1. Ordinary steel is carbon steel, that is, iron-carbon alloy. According to the level of carbon content, it is divided into…