Press release

Electric Fan Manufacturing Plant Setup Report 2025: Business Plan, Project Details and Investment Opportunities

An electric fan is a household and industrial appliance designed to create airflow using an electric motor that drives rotating blades. It helps in ventilation, cooling, and air circulation across diverse environments such as homes, offices, factories, and outdoor spaces. electric fans come in various types, including ceiling fans, table fans, pedestal fans, exhaust fans, and industrial fans, each serving specific purposes. Known for being energy-efficient, affordable, and easy to operate, electric fans are among the most widely used appliances globally, especially in regions with hot and humid climates.Establishing an electric fan manufacturing plant requires investment in raw materials like motors, blades, and casings, along with assembly machinery, testing equipment, and packaging facilities. A skilled workforce, quality assurance systems, and adherence to safety and efficiency standards are crucial. Efficient distribution channels and innovation in design and energy-saving technology can enhance competitiveness and profitability.

Request for a Sample Report: https://www.imarcgroup.com/electric-fan-manufacturing-plant-project-report/requestsample

IMARC Group's report, titled "Electric Fan Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a electric fan manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

This comprehensive business plan outlines every critical step involved in setting up a electric fan manufacturing plant successful unit - from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as electric fan manufacturing plant setup, cost breakdown, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Electric Fan Industry Outlook 2025:

The electric fan industry in 2025 is projected to expand steadily, driven by rising urbanization, higher demand for energy-efficient appliances, and increasing residential and commercial infrastructure development. Growing consumer preference for smart, stylish, and eco-friendly fans will further shape market growth.

Key Insights for Electric Fan Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=14928&flag=C

Key Cost Components of Setting Up an Electric Fan Plant:

• Raw Material Procurement - Cost of motors, blades, casings, wiring, switches, and other components.

• Land and Infrastructure - Expenses for land acquisition, factory construction, and utility installations.

• Machinery and Equipment - Investment in assembly lines, molding machines, winding machines, testing equipment, and packaging units.

• Labor and Workforce - Salaries, training, and recruitment of engineers, technicians, and factory workers.

• Energy and Utilities - Electricity and water consumption for production processes and machinery operations.

• Quality Control and Testing - Setting up laboratories and systems to ensure product safety and efficiency standards.

• Packaging Materials - Costs for boxes, labeling, and protective packaging for retail and bulk supply.

• Transportation and Logistics - Distribution of finished fans and sourcing of raw materials.

• Regulatory Compliance - Certifications, safety standards, and licensing requirements for electrical appliances.

• Maintenance and Overheads - Regular machinery servicing, insurance, and administrative costs.

Economic Trends Influencing Electric Fan Plant Setup Costs 2025:

• Rising Urbanization & Housing Demand - Growth in residential and commercial construction boosts demand for electric fans.

• Shift Toward Energy Efficiency - Demand for energy-saving and star-rated fans requires investment in advanced motor technologies.

• Smart Appliance Integration - Increasing popularity of smart and IoT-enabled fans raises R&D and production costs.

• Raw Material Price Volatility - Fluctuations in the cost of metals, plastics, and electronic components impact procurement expenses.

• Labor Cost Inflation - Rising wages and shortage of skilled workers increase overall operational costs.

• Global Supply Chain Challenges - Import tariffs, shipping delays, and geopolitical issues affect machinery and component sourcing.

• Sustainability Regulations - Stricter environmental norms require eco-friendly materials and greener manufacturing practices.

• Energy Price Fluctuations - Variability in electricity and fuel costs influences plant operations and profitability.

• E-commerce & Retail Expansion - Growth in online retail requires additional spending on packaging and logistics.

• Competition & Innovation Pressure - Strong market competition drives continuous investment in design, technology, and branding.

Challenges and Considerations for Investors in Electric Fan Plant Projects:

• Rising Urbanization & Housing Demand - Growth in residential and commercial construction boosts demand for electric fans.

• Shift Toward Energy Efficiency - Demand for energy-saving and star-rated fans requires investment in advanced motor technologies.

• Smart Appliance Integration - Increasing popularity of smart and IoT-enabled fans raises R&D and production costs.

• Raw Material Price Volatility - Fluctuations in the cost of metals, plastics, and electronic components impact procurement expenses.

• Labor Cost Inflation - Rising wages and shortage of skilled workers increase overall operational costs.

• Global Supply Chain Challenges - Import tariffs, shipping delays, and geopolitical issues affect machinery and component sourcing.

• Sustainability Regulations - Stricter environmental norms require eco-friendly materials and greener manufacturing practices.

• Energy Price Fluctuations - Variability in electricity and fuel costs influences plant operations and profitability.

• E-commerce & Retail Expansion - Growth in online retail requires additional spending on packaging and logistics.

• Competition & Innovation Pressure - Strong market competition drives continuous investment in design, technology, and branding.

Buy Now: https://www.imarcgroup.com/checkout?id=14928&method=1911

Conclusion:

The electric fan industry holds strong potential, supported by rising demand for energy-efficient appliances, urbanization, and smart home adoption. However, investors in electric fan plant projects must carefully address challenges such as intense competition, raw material price fluctuations, regulatory compliance, and the need for continuous innovation. Establishing efficient supply chains, adopting modern manufacturing technologies, and focusing on product differentiation are crucial for long-term success. With strategic planning and alignment to evolving consumer preferences, electric fan plants can achieve profitability and secure a competitive position in the global appliances market.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Electric Fan Manufacturing Plant Setup Report 2025: Business Plan, Project Details and Investment Opportunities here

News-ID: 4179080 • Views: …

More Releases from IMARC Group

India Digital Health Market is Expected to Reach USD 84,076.5 Million by 2034 | …

Introduction

According to IMARC Group's report titled "India Digital Health Market Size, Share, Trends and Forecast by Type, Component, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including India digital health market share, growth, trends, and regional insights.

How Big is the India Digital Health Market?

The India digital health market size reached USD 19,145.3 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 84,076.5…

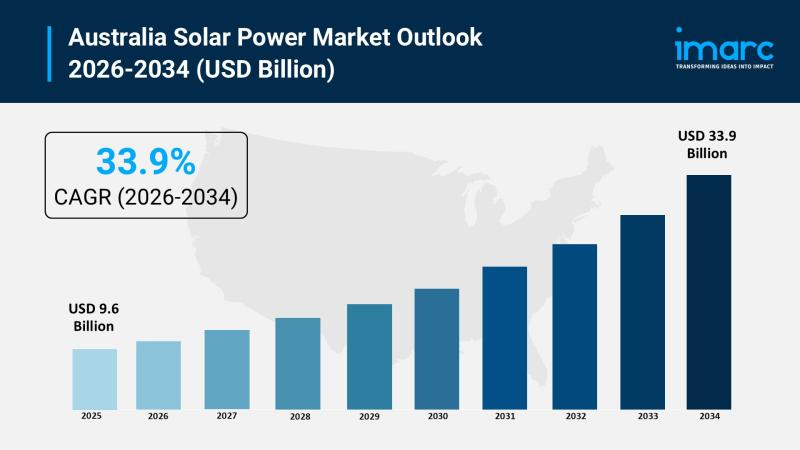

Australia Solar Power Market 2026 | Projected to Reach USD 33.9 Billion by 2034

Market Overview

The Australia solar power market reached USD 9.6 Billion in 2025 and is forecast to grow to USD 33.9 Billion by 2034. The market exhibits a robust growth rate of 15.00% during the forecast period 2026-2034. This expansion is driven by supportive government policies, technological advancements, and increasing adoption across residential, commercial, and utility sectors, positioning solar energy as a cornerstone of Australia's clean energy future.

Grab a sample PDF…

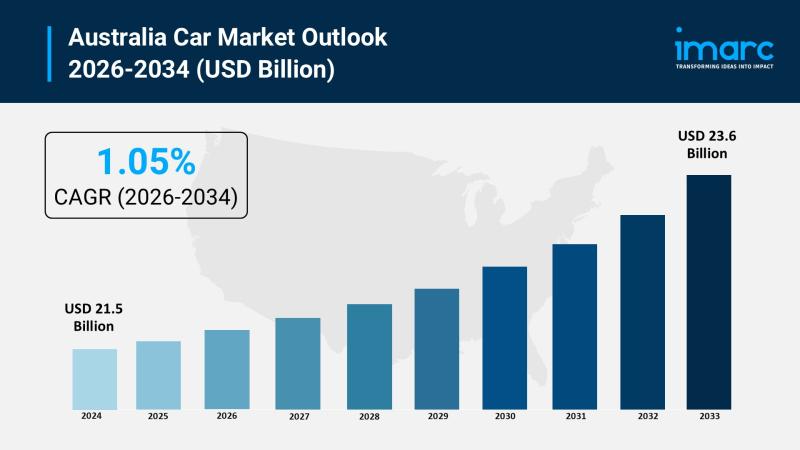

Australia Car Market 2026 | Surge to Grow to USD 23.6 Billion by 2034

Market Overview

The Australia car market reached a size of USD 21.5 Billion in 2025 and is forecasted to grow to USD 23.6 Billion by 2034. The market is expected to expand at a CAGR of 1.05% throughout the forecast period from 2026 to 2034. Growth is driven primarily by increasing demand for electric vehicles, SUVs, and connected car technologies, spurred by environmental awareness, lifestyle changes, and technological innovation toward sustainable…

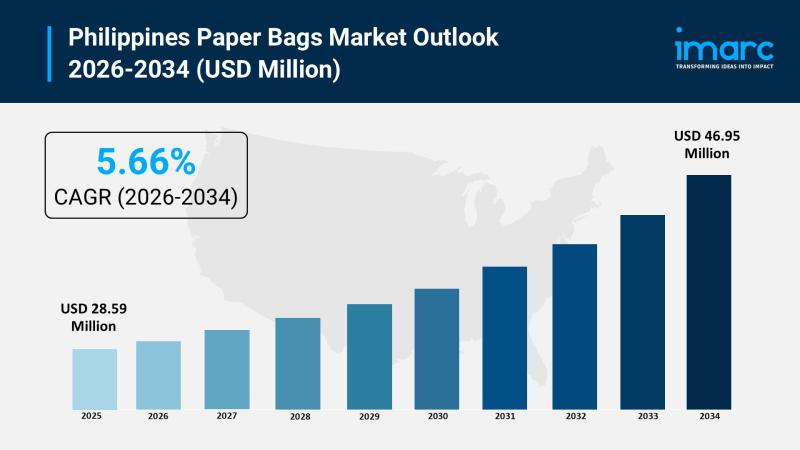

Philippines Paper Bags Market 2026 | Expected to Reach USD 46.95 Million by 2034

Market Overview

The Philippines paper bags market size was valued at USD 28.59 Million in 2025 and is expected to reach USD 46.95 Million by 2034, with a growth rate of 5.66% CAGR from 2026 to 2034. This growth is driven by increasing environmental concerns, government bans on single-use plastics, and rising adoption by retailers and foodservice providers. The expanding food and beverage sector, coupled with heightened awareness of plastic pollution,…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…