Press release

Spice Processing Cost Report 2025: Plant Layout, Machinery and Financial Outlook

Spice processing is a vital agricultural industry that transforms raw spices into value-added products through various processing techniques such as cleaning, grinding, blending, and packaging. It involves the conversion of fresh or dried spices like turmeric, coriander, cumin, black pepper, and chili into powdered, whole, or blended forms suitable for culinary, medicinal, and industrial applications. Spice processing serves as an essential bridge between agricultural production and consumer markets, enhancing shelf life, quality, and convenience while maintaining the nutritional and aromatic properties of spices. The industry plays a crucial role in food preservation, flavor enhancement, and serves various sectors including food manufacturing, restaurants, households, and pharmaceutical industries, promoting sustainable agricultural value chains worldwide.Setting up a spice processing plant involves several key steps. First, selecting suitable raw materials like fresh or dried spices from reliable suppliers is essential. The spices undergo various processing stages including cleaning, sorting, drying, grinding, blending, and standardization to achieve desired quality parameters. The processed products are then packaged using appropriate materials and techniques to maintain freshness, flavor, and extend shelf life. Critical infrastructure includes cleaning equipment, drying systems, grinding mills, blending machines, packaging units, and quality control laboratories. Efficient supply chain management and adherence to food safety standards are vital for regulatory compliance. The plant's scale, raw material availability, target markets, and local regulations influence investment and operational costs. Integrating modern processing technologies and automation can improve efficiency, reduce contamination risks, and enhance product consistency, making the spice processing plant a profitable and sustainable agribusiness venture.

IMARC Group's report, titled "Spice Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a spice processing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/spice-processing-plant-project-report/requestsample

Spice Industry Outlook 2025

The global spice processing industry is poised for robust growth in 2025, driven by increasing consumer demand for convenient food products, rising awareness about health benefits of spices, and expanding food processing sectors worldwide. The market size is projected to reach approximately USD 19.2 billion in 2025, with expectations to grow at a compound annual growth rate (CAGR) of 5.8% over the next decade. This expansion is fueled by changing lifestyle patterns, growing preference for ethnic cuisines, advancements in processing technologies, and increasing export opportunities in international markets. Asia-Pacific region is anticipated to maintain a dominant market share, while regions like North America and Europe are expected to experience steady growth due to rising demand for organic and premium spice products. In India, the spice processing sector is gaining significant momentum, particularly in states like Gujarat, Rajasthan, and Andhra Pradesh. The government's focus on food processing through various schemes and export promotion initiatives has spurred substantial investments. Companies are establishing modern processing facilities with advanced cleaning, grinding, and packaging technologies to meet international quality standards. These initiatives not only contribute to agricultural value addition but also offer economic benefits, including enhanced farmer incomes, rural employment opportunities, and foreign exchange earnings through exports.

Key Insights for setting up a Spice Processing Plant

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Buy now: https://www.imarcgroup.com/checkout?id=8692&method=1911

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components

Raw Material Costs

• The largest cost driver, including various spices like turmeric, coriander, cumin, black pepper, red chili, and other specialty spices. Raw material prices fluctuate based on seasonality, weather conditions, regional availability, and global market dynamics.

• Processing Equipment and Machinery

• Costs for cleaning machines, grinding mills, blending equipment, and packaging machinery used in various processing operations, particularly for achieving consistent quality and particle size.

• Processing and Packaging Equipment

• Investment in destoners, graders, pulverizers, sifters, and automated packaging systems for converting raw spices into finished products and ensuring proper packaging standards.

• Utilities and Energy Consumption

• Energy demand for grinding, drying, and packaging processes. Electricity consumption for machinery operations and water usage for cleaning contribute significantly to operating costs.

• Labor and Maintenance

• Skilled labor is required for plant operation, quality control, and maintenance. Ongoing upkeep of processing equipment and machinery is a continuous expenditure.

• Capital Expenditure (CapEx)

• Includes cost of land, construction, infrastructure, and machinery. Advanced spice processing technologies may have higher CapEx but offer long-term efficiencies and better product quality.

• Quality Control and Testing

• Costs related to laboratory testing, quality assurance, microbiological testing, and ensuring compliance with food safety standards and export requirements.

• Packaging and Transportation

• Expenses for various packaging materials (pouches, containers, bulk bags), labeling, and transportation to distribution centers and retail outlets.

• Regulatory and Food Safety Compliance

• Costs associated with licenses, FSSAI certification, export certifications, quality control systems, and adherence to food safety standards and international quality requirements.

Economic Trends Influencing Spice Processing Plant Setup Costs 2025

• Volatility in Raw Spice Prices

• Fluctuating prices of turmeric, coriander, cumin, and other spices due to climate change, monsoon patterns, and global supply-demand dynamics are impacting raw material costs and planning certainty.

• Rising Construction and Equipment Costs

• Global inflation in materials like steel, stainless steel, and specialized processing equipment is driving up capital expenditure (CapEx) for new spice processing plants.

• Energy Price Instability

• High electricity costs are increasing operational expenditure (OpEx), especially in energy-intensive processes like grinding, drying, and packaging operations.

• Government Policies and Subsidies

• Supportive schemes like PM-FME (Pradhan Mantri Formalisation of Micro Food Processing Enterprises), PMKSY, and export promotion incentives are encouraging investment and offsetting some setup costs, especially in India and other developing countries.

• Technological Advancements

• Modern processing technologies (e.g., cryogenic grinding, steam sterilization) are more efficient but often require higher initial investment, shifting financial planning dynamics for better quality and longer shelf life.

• Food Safety and Quality Compliance

• Increasing pressure to meet international food safety standards like HACCP, ISO 22000, and organic certifications adds to costs through regulatory compliance, monitoring systems, and certifications.

• Supply Chain Disruptions

• Delays in importing specialized processing equipment and rising logistics costs are affecting timelines and budgeting for plant construction and commissioning.

• Interest Rates and Financing Conditions

• Higher global interest rates in 2025 are increasing the cost of capital, affecting project feasibility and financing options for spice processing ventures.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=8692&flag=C

Challenges and Considerations for Investors

• Raw Material Price and Supply Volatility

• Spice processing relies heavily on agricultural crops whose availability and prices fluctuate due to weather conditions, pest attacks, and seasonal variations in production.

• High Capital Investment Requirements

• Building a spice processing plant involves significant CapEx for cleaning equipment, grinding mills, packaging machinery, and quality control systems, with moderate payback periods.

• Regulatory and Food Safety Compliance

• While supportive policies exist, maintaining compliance with food safety standards, FSSAI regulations, and export requirements involves continuous monitoring and certification costs.

• Technology and Equipment Selection Risk

• Choosing between traditional and modern processing technologies involves trade-offs in cost, efficiency, and product quality. Advanced technologies may offer better margins but come with higher technical complexity and CapEx.

• Quality Control and Contamination Risks

• Spice processing requires stringent quality control to prevent contamination, maintain flavor profiles, and meet food safety standards, leading to operational scrutiny and potential quality issues.

• Market Competition and Pricing Pressure

• Growing competition from established brands, private labels, and imported products may influence pricing strategies and market share, affecting project profitability.

• Storage and Inventory Management

• Proper storage of raw materials and finished products requires controlled environments to prevent deterioration, pest infestation, and quality degradation, increasing infrastructure costs.

• Export Market Requirements

• Meeting international quality standards, obtaining export certifications, and maintaining consistent quality for export markets adds operational complexity and compliance costs.

Conclusion

The spice processing industry stands at a promising juncture in 2025, offering excellent opportunities for sustainable growth amidst rising global demand for processed spice products and convenience foods. With supportive government policies, technological innovations, and increasing consumer preference for quality spices, the industry is becoming an integral part of the food processing sector. However, investors and developers must carefully address challenges such as raw material price volatility, quality control requirements, and food safety compliance. IMARC Group's detailed project report serves as a vital resource, offering in-depth insights and actionable guidance for successful plant setup and long-term profitability in the evolving spice processing market.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Spice Processing Cost Report 2025: Plant Layout, Machinery and Financial Outlook here

News-ID: 4177057 • Views: …

More Releases from IMARC Group

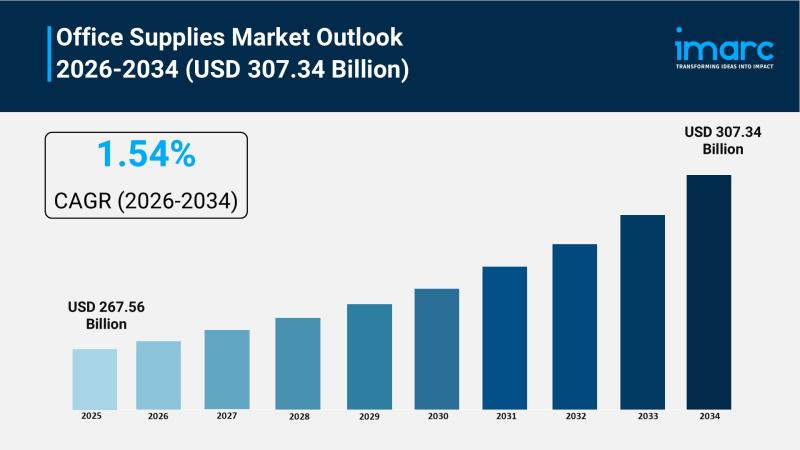

Office Supplies Market Set to Surge to USD 307.34 Billion by 2034 at a 1.54% CAG …

Market Overview:

According to IMARC Group's latest research publication, "Office Supplies Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The global office supplies market size was valued at USD 267.56 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD 307.34 Billion by 2034, exhibiting a CAGR of 1.54% from 2026-2034.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and…

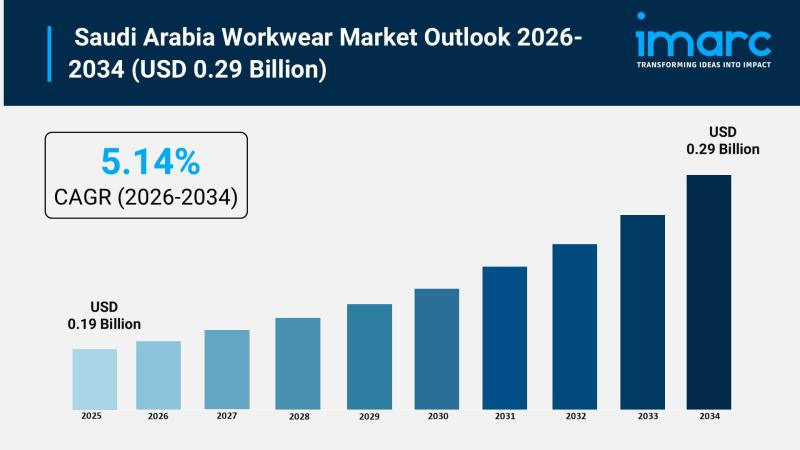

Saudi Arabia Workwear Market Size To Worth USD 0.29 Billion in 2034 | Grow CAGR …

Saudi Arabia Workwear Market Overview

Market Size in 2025: USD 0.19 Billion

Market Size in 2034: USD 0.29 Billion

Market Growth Rate 2026-2034: 5.14%

According to IMARC Group's latest research publication, "Saudi Arabia Workwear Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The Saudi Arabia workwear market size was valued at USD 0.19 Billion in 2025 and is projected to reach USD 0.29 Billion by 2034, growing at a compound annual growth…

Liquid Carbon Dioxide Prices, Latest Trend, Demand, Index & Uses Jan 2026

USA Liquid Carbon Dioxide Prices Movement Q3 2025:

In Q3 2025, Liquid Carbon Dioxide Prices in the USA averaged USD 798/MT. Strong demand from beverage carbonation, food processing, and medical-grade applications supported pricing. Stable production rates and balanced inventories helped maintain supply, while localized logistics constraints occasionally influenced short-term market adjustments.

Get the Real-Time Prices Analysis: https://www.imarcgroup.com/liquid-carbon-dioxide-pricing-report/requestsample

India Liquid Carbon Dioxide Prices Movement Q3 2025:

India recorded liquid carbon dioxide prices at USD 325/MT…

Ethylene Oxide Prices January 2026 | Latest Price Index, Market Analysis & Forec …

Northeast Asia Ethylene Oxide Prices Movement January 2026:

Northeast Asia ethylene oxide prices in January 2026 were recorded at USD 0.9/kg, rising by 2.3% due to improved downstream chemical and surfactant demand. The ethylene oxide price trend remained positive, while the ethylene oxide price index strengthened slightly. The ethylene oxide price chart reflected upward momentum. The ethylene oxide price forecast indicates stable-to-firm pricing if demand remains steady.

Get the Real-Time Prices Analysis:…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…