Press release

The fractionation of milk proteins - a new low cost technology

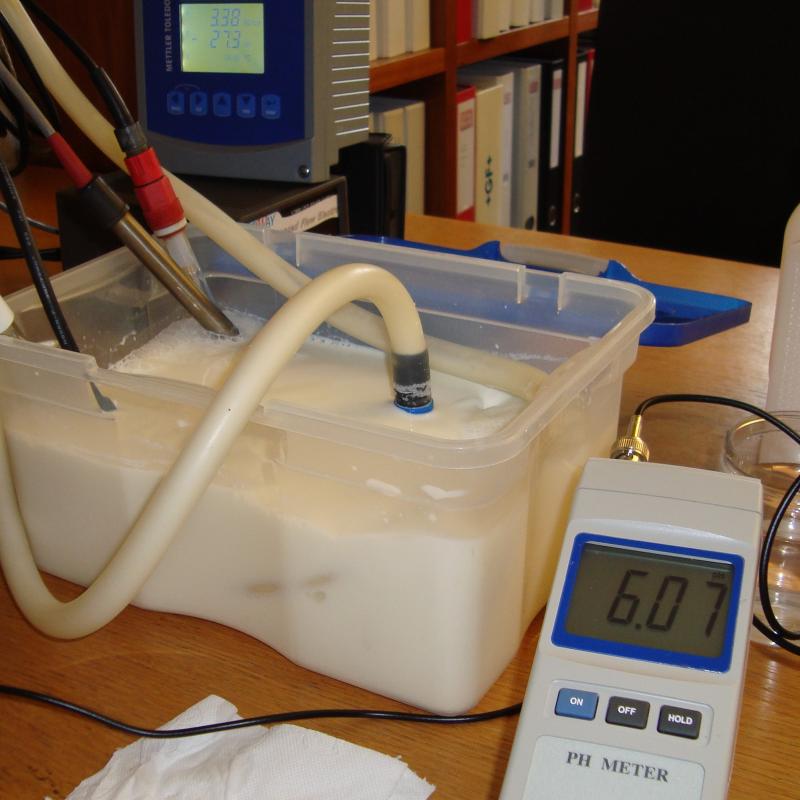

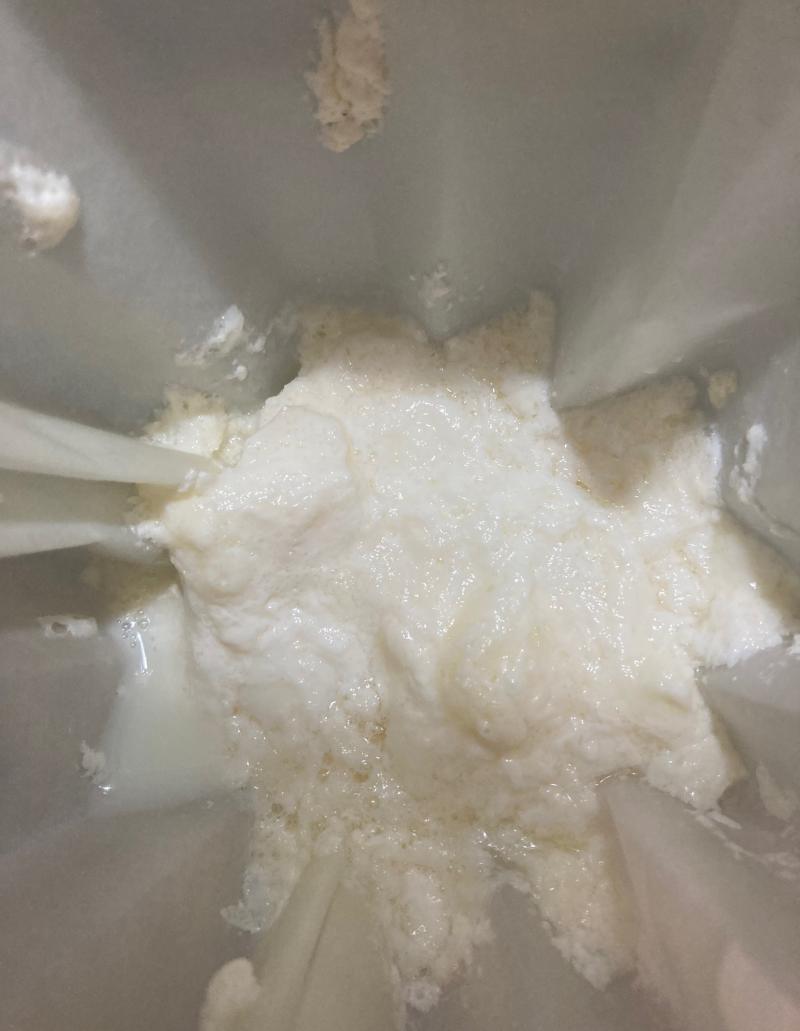

The fractionation of milk proteins by isoelectric precipitation separates proteins based on their isoelectric point (pI) - the pH value at which they have no net charge and thus their solubility is lowest. By acidifying the milk to the pI value of casein (around 4.6), it precipitates and can be separated from other milk proteins, such as whey proteins, enabling fractionation.Milk powder consists mainly of the fat- and water-soluble components of milk. Since casein is insoluble in water, it precipitates at the isoelectric point at pH 4.6, but whey proteins are soluble in water, allowing fractionation. Milk powder also contains a wealth of important vitamins (including A, B12 and C), minerals (such as potassium and magnesium) and trace elements such as iron and zinc.

During the drying process, water is removed from milk in spray towers. This process does not involve cooling, which means that native proteins lose their biological activity. There is a need to re-enrich milk powder with native proteins.

If this structure is destroyed by physical or chemical influences (such as heat or strong acids), this is referred to as denaturation, and the protein loses its function and biological activity. Biological activity can manifest itself in various forms, such as enzymatic catalysis in enzymes, a defensive function in antibodies, or a regulatory function in hormones.

The standard methods for protein extraction (casein/whey protein) today are membrane filtration processes/ion exchange processes and acid precipitation at the isoelectric point around pH 4.6.

Ion exchange (IEX) for whey protein isolate, abbreviated as WPI is a process in which the whey is passed through a resin to which the protein molecules attach themselves due to their charge. Impurities (lactose, fat) are washed out. The proteins are then released from the resin. Advantages: very high purity with the highest protein content (≥90%) and very low lactose and fat content.

The trend towards the use of membrane filtration technology has undoubtedly prevailed, as the biological activity and purity of the proteins are highest, given that the method used to extract the protein must be declared.

For the food technology industry, which relies on certain functional properties (solubility, gelling ability), native MPC or casein via microfiltration is often the premium solution. The trend in the industry is clearly towards gentle, physical membrane processes (UF, MF), as they do not require chemicals and preserve the quality of the protein that is needed.

For the food technology industry, which relies on certain functional properties (solubility, gelling capacity), native MPC or casein via microfiltration is often the premium solution. The trend in the industry is clearly towards gentle, physical membrane processes (UF, MF), as they do not require chemicals and preserve the quality of the protein that is needed.

Our new technology is set to replace the above methods, as it is simpler and more economi-cal - even without the use of chemicals. We are talking about savings (according to initial estimates) of roughly 50% of the investment, with operating costs of the same magnitude. It is intended to replace membrane processes/ion exchange, which have significant disadvan-tages, with a very simple process technology without the addition of acids, salts or other chemicals. The process is currently being documented for patent application.

Bioway Consulting SL

C./ Tirant Lo Blanc 4 , office 19

ES-03750 Pedreguer / Alicante - Spain

www.biowayconsulting.com

Mail: contact@biowayconsulting.com

Phone: 0034 965030786

Mr. Norbert Pautz (Presscontact)

Bioway Consulting SL is an engineering company in the consulting business, active in research and development of new technologies in many fields often based on electrolysis technologies.

It was founded in 1989 in Germany as a sole proprietorship and later continued in Switzerland as Bioway GmbH. The main activity at that time was initially as a distributor for renowned companies from abroad (e.g. Charm Sciences / USA and Malthus Instruments Ltd / UK etc.). This was followed by own developments with production such as the IGDS (Intelligent Gravimetric Dilution System) and devices for water disinfection. Bioway did deep research working with emulsions like soluble oil and milk as well pharmaceutical formulations.

The focus on water / emulsion disinfection / water and waste water purification was intensified. In addition, a system for the inactivation of airborne germs (viruses/bacteria) was developed and manufactured (Corona Wave).

Today Bioway is active in the consulting business and co-operates with other European companies in the field of waste water purification and develops processes by testing customer waste water samples in its own laboratory.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The fractionation of milk proteins - a new low cost technology here

News-ID: 4176079 • Views: …

More Releases from Bioway Consulting SL

Lactoferrin extraction from whey filtrate - a low-cost technology

Protein extraction is now an established state-of-the-art process that enables protein to be extracted from various sources. However, it is mainly used in the dairy industry, where large quantities of whey filtrate are produced.

Generally speaking, the process (state of the art) involves around seven (7) steps, but compared to AFE technology, it is lengthy, complex and expensive.

This is reflected in the investment required for a plant (several million euros for…

New ways to replace cumbersome, lengthy and expensive processes for the producti …

The fractionation of milk proteins by means of isoelectric precipitation separates proteins based on their isoelectric point (IEP) - at a specific pH value at which they have no net charge and thus their solubility is at its lowest. By acidifying the milk to the IEP value of casein at 4.6, it precipitates and can be separated from other milk proteins, such as whey proteins, as these are water-soluble, enabling…

The environmentally friendly, sustainable separation of used cooling lubricant e …

An 'environmentally friendly' label must be earned.

All metalworking companies use cooling lubricants (water soluble cooling lubricants - wsCL). Normally, little attention is paid to what happens to used cooling lubricants. After all, there are disposal companies that are responsible for this. However, disposal costs range from €140 to €200 per m3 of wsCL.

Bioway has been working on this issue for many years, which has led to a new, better and…

No chance of microbial contamination in water-soluble cooling lubricant (wsCL/MW …

The best, economical and environmentally friendly method for preventing microbial growth in the coolant lubricant in coolant maintenance stores is the electrolytic method.

In principle, only one electrolysis installation is required for a volume of a good 50 m3 of MWF - this applies to all types of MWF - even where the oil has been replaced by viscous water. The annual electricity consumption for medium-sized industry is only around 18…

More Releases for Protein

Cell-Free Protein Synthesis Market Forecast: Opportunities in High-Throughput Pr …

"Cell-Free Protein Synthesis Market" in terms of revenue was estimated to be worth USD 299.9 million in 2024 and is poised to reach USD 585.3 Million by the year 2034, growing at a CAGR of 7.0% from 2025 to 2034 according to a new report by InsightAce Analytic.

Get Free Access to Demo Report, Excel Pivot and ToC: https://www.insightaceanalytic.com/request-sample/1445

Latest Drivers Restraint and Opportunities Market Snapshot:

Key factors influencing the global cell-free…

Plant Protein Market : Latest Market Research Report for Strategic Advantage | S …

Global Plant Protein Market

Market Overview:

Global Plant Protein Market Report 2022 comes with the extensive industry analysis by Introspective Market Research with development components, patterns, flows and sizes. The report also calculates present and past market values to forecast potential market management through the forecast period between 2022-2028.This research study of Plant Protein involved the extensive usage of both primary and secondary data sources. This includes the study of various parameters…

Pea Protein Ingredients Market Prospects, Consumption, Cost Structure, Competiti …

The food industry is continuously searching for healthier and cheaper protein ingredients that can be replaced by animal-based and gluten-based proteins. Pea protein is beneficial due to its low allergenicity, availability, and high nutritional value. The Global Pea Protein Ingredients Market is witnessing a major rise in its revenue from US$ 2.35 Bn in 2021 to US$ 6.78 Bn by 2030. The market is recording a CAGR of 12.5% during…

Astonishing growth in Dairy Protein Market Growth? Milk Protein Isolates (MPIs), …

Dairy Protein Market Business Insights and Updates:

The latest Market report by a Data Bridge Market Research with the title [Global Dairy Protein Market - Industry Trends and Forecast to 2026] . Dairy Protein Market research analysis and data lend a hand to businesses for the planning of strategies related to COVID-19 impact on industry, investment, revenue generation, production, product launches, costing, inventory, purchasing and marketing. Dairy Protein market insights with…

Global Plant Protein Market 2019 – Soy Protein, Wheat Protein, Pea Protein | K …

The Global Pea Protein Market Research Report conducts a deep estimation on the present state of Pea Protein Industry with the definition, classification and market scope. The fundamental Pea Protein Industry aspects like competitive landscape structure, eminent industry players, Pea Protein Market size and value is studied. The Pea Protein Market growth trends, development plans, dynamic market driving factors and risk assessment is conducted. All the traders, dealers, distributors of…

Protein Packaging Market Report 2018: Segmentation by Product (Rigid packaging, …

Global Protein Packaging market research report provides company profile for Amcor Limited, DuPont, Flexifoil Packaging Pvt., Swiss Pac Private Ltd. and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018 to 2025, etc. The report also provides detailed…