Press release

No chance of microbial contamination in water-soluble cooling lubricant (wsCL/MWF)

The best, economical and environmentally friendly method for preventing microbial growth in the coolant lubricant in coolant maintenance stores is the electrolytic method.In principle, only one electrolysis installation is required for a volume of a good 50 m3 of MWF - this applies to all types of MWF - even where the oil has been replaced by viscous water. The annual electricity consumption for medium-sized industry is only around 18 cent/ kWh. This results in annual costs of EUR 1,576.80 (1800 USD).

The use of biocides (e.g. variously substituted iso-thiazolinones) results in purchase costs of €2,200 to €2,400 per tonne as an annual requirement. The costs for free delivery, storage and dosing must be recognised separately as a surcharge. However, other chemical substances such as glutaraldehyde are not only potentially irritating to the skin and cause allergic reactions, but also the group of iso-thiazolinones.

With special electrodes, which also form oxygen species and thus prevent an anaerobic environment, short-lived radicals and H2O2 are formed, in addition to HOCl. HOCl is now commonly used in swimming pools but, unbeknown to many people, it is produced by the body's own cells. Hydrogen peroxide decomposes back into water and oxygen.

Electrolytic disinfection is an efficient and sustainable method, especially where continuous germ reduction is required. It combines chemical effectiveness with low operating costs compared to conventional methods.

Direct contact with DSA electrodes leads to combined damage through ROS, (ROS = reactive oxygen species) electrochemical oxidation and chlorinated by-products - a synergistic effect that kills (permanently inactivates) bacteria (microbes) more efficiently than chemical disinfection alone.

By introducing hydroxyl radicals (HO·) to the anode surface, reactive chlorine species are formed, including chlorine radicals (Cl·) and dichlorine radicals (Cl2·). The presence of Cl- leads to the formation of free chlorine, which reacts with water to form HOCl.

The further advantage is that no resistance formation occurs, as there is combined physical-chemical destruction instead of inhibition. Studies show that bacteria such as E. coli or Legionella are killed within seconds to minutes on contact with DSA electrodes (dimen-sionally stable anodes) - even without significant hypochlorite formation.

The combination of ROS and direct current flow also decomposes matrix structures (EPS), which makes the removal of biofilms - normally very difficult - possible.

In the presence of chloride in the water / emulsion, HOCl and HOCl- is formed, which penetrates the bacteria through the membrane and breaks down metabolic processes. Bacteria (microbes) that touch or adhere to the anode surface are oxidised by direct electron release and lead to irreversible damage to the cell structure - similar to electroporative effects.

The effect on bacteria can be described in detail as follows: ROS oxidise lipids and proteins of the cell envelope (membrane), resulting in a permeability disorder which further leads to cell lysis. There is also an inactivation of enzymes, e.g. ATPase and DNA damage due to radicals that attack the nucleic acids and block replication.

The electrochemical oxidation at the anodes (often a titanium matrix as a carrier with metal oxides of rare earths such as ruthenium/iridium) and other elements generate highly reactive oxygen species (ROS) and other radicals, such as hydroxyl radicals, which oxidatively destroy lighter living matter such as microbes when voltage is applied. Atomic oxygen and ozone also attack cell membranes and proteins.

As the formation of disinfectants in the disinfection of wsCL / synth. wsCL is regulated depending on the current strength, a balance is created between the consumption by microorganisms and the new formation of these substances. This means that power consumption is only required at intervals.

The power consumption of electrolytic disinfection units depends on the voltage and current strength, conductivity in mS/cm at °C, electrode surface - (S = I/A); current density) and is low. This emphasises the cost-effectiveness and environmental friendliness of this application. One, of the main reasons for dispensing with biocides is the easier electrolytic cleaning, as natural water without biocides has a lower COD value. Our groundwater levels fall and recycling the water for reuse is unavoidable.

Electrolytic disinfection for all wsCL/MWF therefore offers many advantages, as it is automatic, environmentally friendly and economical.

Bioway Consulting SL

C. / Tirant Lo Blanc 4, office 19

ES-03750 Pedreguer / Alicante - Spain

www.biowayconsulting.com

contact@biowayconsulting.com

Phone: 0034 965 030 786

Contact: Norbert Pautz - General Manager

Bioway has been in existence for almost 40 years and was founded as a sole proprietorship in Germany. A limited liability company was established in Switzerland with a subsidiary in Germany and later as a private limited on shares in Cyprus. Now since November 2024 Bioway Consulting SL is incorporated

Bioway deals with electrolysis-based wastewater treatment technologies, incorporating complementary technologies such as membrane filtration. Furthermore, a system for air purification / disinfection was developed to inactivate infectious biological particles such as viruses and bacteria.

Bioway works as a consultant mainly in D, A, CH - German-speaking countries, whereby new technologies are further developed and sold on the market in co-operation with system manufacturers.

The main task is to advise customers, solve problems, implement technology to solve tasks and sell systems / equipment for the purification of liquids (e.g. cooling lubricants) and industrial waste water. R & D take place in an own laboratory is Spain.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release No chance of microbial contamination in water-soluble cooling lubricant (wsCL/MWF) here

News-ID: 4076612 • Views: …

More Releases from Bioway Consulting SL

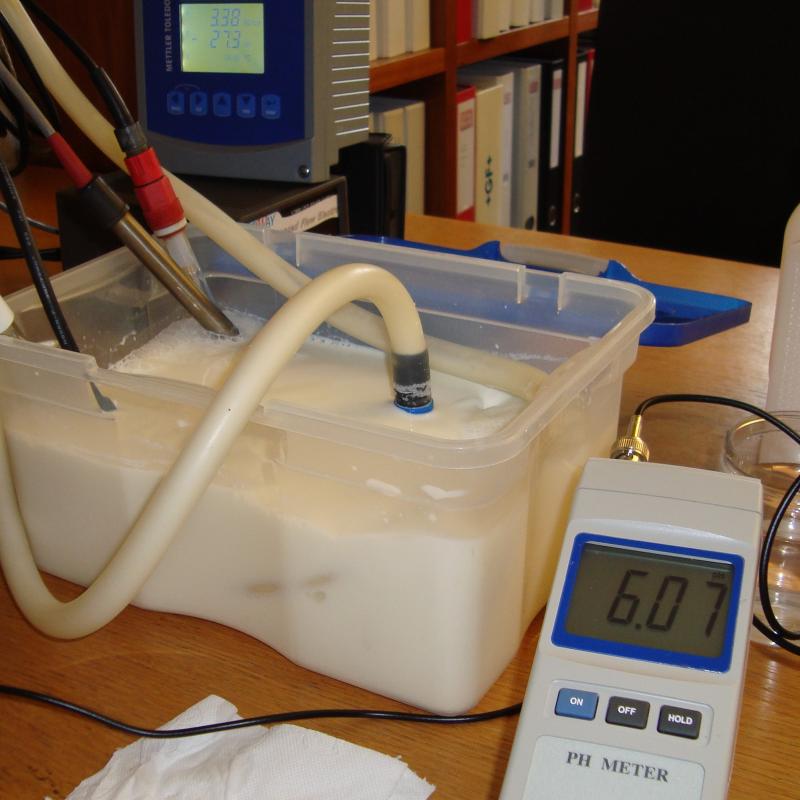

The advantage of advanced flow electrolysis in isolating protein from whey

Electrolysis technology dates back to Faraday and encompasses many technologies such as electrocoagulation, electrooxidation, electrodialysis, disinfection and many more.

Classic electrolysis in an aqueous system is a redox reaction where H+ ions are formed anodically: 2H2O → O2 + 4H+ + 4e- and cathodically: OH- -ions - 2H2O + 2e- → H2↑ + 2 OH-, which means that the pH value rises or falls. Electrolytic processes preferably use clear…

Lactoferrin extraction from whey filtrate - a low-cost technology

Protein extraction is now an established state-of-the-art process that enables protein to be extracted from various sources. However, it is mainly used in the dairy industry, where large quantities of whey filtrate are produced.

Generally speaking, the process (state of the art) involves around seven (7) steps, but compared to AFE technology, it is lengthy, complex and expensive.

This is reflected in the investment required for a plant (several million euros for…

New ways to replace cumbersome, lengthy and expensive processes for the producti …

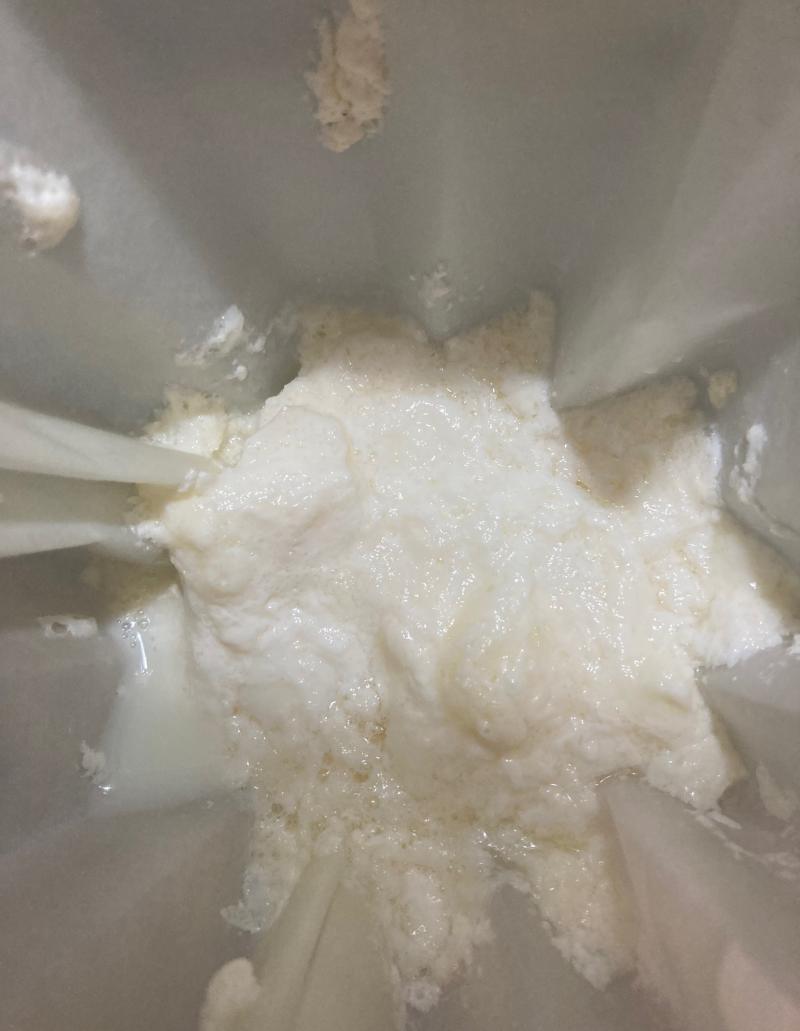

The fractionation of milk proteins by means of isoelectric precipitation separates proteins based on their isoelectric point (IEP) - at a specific pH value at which they have no net charge and thus their solubility is at its lowest. By acidifying the milk to the IEP value of casein at 4.6, it precipitates and can be separated from other milk proteins, such as whey proteins, as these are water-soluble, enabling…

The fractionation of milk proteins - a new low cost technology

The fractionation of milk proteins by isoelectric precipitation separates proteins based on their isoelectric point (pI) - the pH value at which they have no net charge and thus their solubility is lowest. By acidifying the milk to the pI value of casein (around 4.6), it precipitates and can be separated from other milk proteins, such as whey proteins, enabling fractionation.

Milk powder consists mainly of the fat- and water-soluble components…

More Releases for HOCl

Leading Companies Fueling Growth and Innovation in the Hypochlorous Acid Market

The hypochlorous acid market is on a promising trajectory, with significant expansion expected over the coming years. Driven by diverse applications and increasing awareness about hygiene and sustainability, this market is set to evolve strongly by 2030. Let's explore its current state, key players, emerging trends, and market segmentation to understand the forces shaping its future.

Projected Market Size and Growth Outlook for the Hypochlorous Acid Market

The hypochlorous acid…

Exco East Launches Enhanced Website to Better Serve Industry Needs

Image: https://www.abnewswire.com/upload/2025/11/f40d3cf0f887a36af091bf9acc58b63e.jpg

Conway, SC - Nov 24, 2025 - Exco East, LLC, a premier supplier of bulk hypochlorous acid (HOCl) solutions, today announced the launch of its completely revamped website at ExcoEast.com [https://excoeast.com/]. The updated site aligns with the company's mission to be a trusted partner across a wide spectrum of industries - from healthcare and veterinary to food processing, hospitality, transportation, water treatment, and more.

Exco East specializes in providing high-quality,…

Era Organics Hypochlorous Acid Spray: Era Organics Launches Medical-Grade HOCL T …

Image: https://www.abnewswire.com/upload/2025/05/5d319467bf78cf6f73447af5afbf677f.jpg

Clearwater, FL - May 26, 2025 - Era Organics, the family-owned skincare brand known for its clean, plant-powered formulations, proudly announces the launch of its latest innovation: Era Organics Hypochlorous Acid Spray [https://www.eraorganics.com/products/hypochlorous-acid-spray] (8oz, MSRP $24.99). This powerful, dermatologist-approved skin toner is crafted to deliver medical-grade benefits with the purity and gentleness Era Organics is known for.

Inspired by the body's own immune defense system, this extra-strength yet featherlight mist…

Hypochlorous Acid Market Forecast to Hit USD 20.06 Million by 2030, Fueled by Ri …

Hypochlorous Acid market was valued at US$ 18.62 Mn. in 2023 and it is expected to reach US$ 20.06 Mn. by 2030 at a CAGR of 1.07% during the forecast period.

Hypochlorous Acid Market Overview:

The Hypochlorous Acid Market is witnessing robust growth, fueled by rising demand across various sectors including healthcare, water treatment, and food safety. Hypochlorous acid (HOCl), known for its powerful antimicrobial properties, is gaining traction as a safer,…

Global Hypochlorous Acid Market Trends: From USD 18.62 Mn. in 2023 to US$ 20.06 …

𝐆𝐥𝐨𝐛𝐚𝐥 𝐇𝐲𝐩𝐨𝐜𝐡𝐥𝐨𝐫𝐨𝐮𝐬 𝐀𝐜𝐢𝐝 𝐌𝐚𝐫𝐤𝐞𝐭 was valued at US$ 18.62 Mn. in 2023 and it is expected to reach US$ 20.06 Mn. by 2030 at a CAGR of 1.07% during the forecast period.

𝐆𝐥𝐨𝐛𝐚𝐥 𝐇𝐲𝐩𝐨𝐜𝐡𝐥𝐨𝐫𝐨𝐮𝐬 𝐀𝐜𝐢𝐝 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰:

The global hypochlorous acid market is experiencing significant growth, driven by its increasing adoption across various industries, such as healthcare, food and beverage, agriculture, and water treatment. Hypochlorous acid (HOCl) is a powerful disinfectant and…

Hypochlorous Acid Market 2021: Business Trends, Market Strategies,and Forecasts …

North America To Dominate The Global Hypochlorous Acid Market

The global hypochlorous acid market has been estimated to reach USD XX.XX in 2021 and is estimated to reach a CAGR of 4.3% during the forecast period. The global hypochlorous acid market is growing at a rapid rate over the last few years and is further estimated to grow significantly in the forecasted period. The global hypochlorous acid market report offers a…