Press release

Ethylene Glycol Production Setup Cost Report 2025: Future Outlook and Projections

Ethylene glycol is an organic compound widely used as an industrial coolant, antifreeze, and a raw material in the production of polyester fibers and resins. It is a colorless, odorless, sweet-tasting liquid with strong hygroscopic properties, making it valuable in automotive, textile, and chemical industries. Its global demand is largely driven by applications in polyethylene terephthalate (PET) production for packaging and textiles.Setting up an ethylene glycol production plant requires careful planning of feedstock sourcing, primarily ethylene oxide, along with advanced process technology for efficient conversion. Key considerations include safety systems, environmental compliance, plant location, and integration with downstream polyester manufacturing.

IMARC Group's "Ethylene Glycol Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a detailed and practical guide for entrepreneurs and businesses looking to enter the production industry. The report includes in-depth analysis of capital investment requirements, project financing options, working capital needs, and projected returns.

This comprehensive business plan outlines every critical step involved in setting up a successful production plant unit from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as ethylene glycol production plant cost, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Request for a Sample Report: https://www.imarcgroup.com/ethylene-glycol-manufacturing-plant-project-report/requestsample

Ethylene Glycol Industry Outlook 2025:

The ethylene glycol industry outlook for 2025 indicates steady growth, driven by rising demand from the textile, automotive, and packaging sectors. Increasing consumption of polyester fibers and polyethylene terephthalate (PET) in emerging markets is expected to be a key growth factor. However, the industry may face challenges from fluctuating raw material prices and tightening environmental regulations. Advancements in bio-based ethylene glycol production and sustainability initiatives are likely to influence market dynamics, while Asia-Pacific remains the dominant regional hub due to strong industrial activity and expanding consumer markets.

Key Insights for Ethylene Glycol Production Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up an Ethylene Glycol Plant:

• Feedstock Procurement: Cost of ethylene or ethylene oxide as the primary raw material.

• Plant Construction & Infrastructure: Expenses for land acquisition, civil works, utilities, and storage facilities.

• Process Equipment & Technology: Investment in reactors, distillation units, heat exchangers, and proprietary process technologies.

• Utilities & Energy Supply: Costs for electricity, steam, water, and cooling systems.

• Labor & Workforce: Skilled and unskilled labor for construction, operations, and maintenance.

• Environmental & Safety Compliance: Expenditure on waste treatment, emission control, and safety systems.

• Logistics & Distribution: Transportation, storage, and supply chain management costs.

• Working Capital: Funds for raw materials, operations, and inventory during initial production phases.

Economic Trends Influencing Ethylene Glycol Plant Setup Costs 2025:

• Volatility in Crude Oil Prices: As ethylene glycol is derived from ethylene, fluctuations in crude oil directly impact feedstock costs.

• Rising Construction and Labor Costs: Global inflationary pressures are driving up expenses for plant infrastructure and skilled workforce.

• Technological Advancements: Adoption of energy-efficient and sustainable production technologies may require higher upfront investment but reduce long-term operating costs.

• Environmental Regulations: Stricter compliance standards are increasing expenditure on emission control, waste management, and green certifications.

• Regional Industrial Policies: Government incentives, tax benefits, and trade tariffs are influencing capital investment decisions and project viability.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7708&flag=C

Challenges and Considerations for Investors in Ethylene Glycol Plant Projects:

• Raw Material Price Fluctuations: Dependence on ethylene or ethylene oxide exposes projects to volatility in petrochemical markets.

• High Capital Intensity: Significant upfront investment is required for infrastructure, process technology, and compliance systems.

• Regulatory Compliance: Stringent environmental and safety standards increase both initial and ongoing operational costs.

• Market Demand Uncertainty: Shifts in polyester and PET consumption trends may affect long-term profitability.

• Competition and Overcapacity: Expanding production in Asia-Pacific may lead to pricing pressures and reduced margins.

• Supply Chain Risks: Transportation, storage, and distribution challenges can affect plant efficiency and market reach.

• Sustainability Pressures: Growing demand for bio-based alternatives may affect competitiveness of conventional production routes.

Conclusion:

The establishment of an ethylene glycol production plant presents both significant opportunities and notable challenges for investors. Rising global demand, particularly from polyester and PET applications, ensures a strong market outlook, while technological advancements and regional industrial growth further support long-term potential. However, factors such as raw material price volatility, regulatory compliance costs, and increasing sustainability pressures must be carefully managed to ensure profitability. Strategic planning, efficient resource allocation, and adoption of modern, eco-friendly production methods will be critical for achieving competitive advantage and ensuring the success of new projects in 2025 and beyond.

Buy Now: https://www.imarcgroup.com/checkout?id=7708&method=1911

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Ethylene Glycol Production Setup Cost Report 2025: Future Outlook and Projections here

News-ID: 4175181 • Views: …

More Releases from IMARC Group

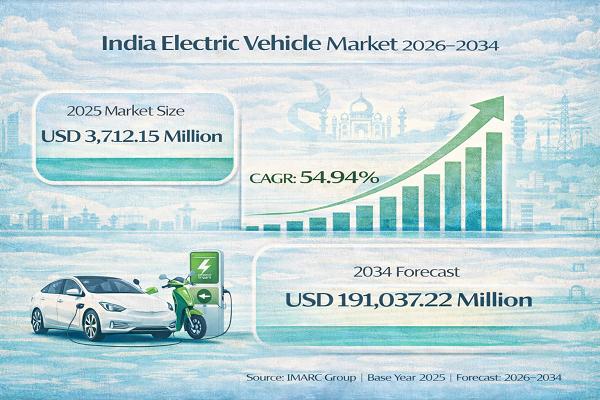

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…