Press release

Sodium Ascorbate Production Cost Analysis 2025: Feasibility Study and Profit Margins

Setting up a sodium ascorbate production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Sodium Ascorbate Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a sodium ascorbate production plant cost, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/sodium-ascorbate-manufacturing-plant-project-report/requestsample

What is Sodium Ascorbate?

A sodium ascorbate production plant is an industrial facility designed to produce sodium ascorbate, the sodium salt of ascorbic acid (Vitamin C), which plays a critical role in the global food and beverage, pharmaceutical, nutraceutical, and animal feed industries. Sodium ascorbate is primarily derived from L-ascorbic acid through neutralization reactions using sodium hydroxide, sodium carbonate, or sodium bicarbonate under controlled pH and temperature conditions. In some cases, it can also be produced through direct fermentation processes using genetically modified microorganisms or through chemical synthesis starting from glucose via the Reichstein process followed by salt formation. A sodium ascorbate production plant is equipped with specialized units for ascorbic acid handling, neutralization reactors, crystallization systems, filtration, drying, and packaging to ensure the required purity, particle size, and stability of sodium ascorbate, which can vary depending on its end use. The main product grades include food-grade sodium ascorbate for use as an antioxidant and preservative, pharmaceutical-grade for vitamin supplements and injectable formulations, and feed-grade for animal nutrition applications. Food-grade sodium ascorbate is widely used in processed foods, beverages, and baked goods to prevent oxidation and extend shelf life, while pharmaceutical-grade material serves as an active ingredient in vitamin C supplements and parenteral nutrition solutions. These facilities also emphasize strict quality control, contamination prevention, and stability testing due to the vitamin's sensitivity to light, heat, and oxidation. With their broad range of applications in food preservation, dietary supplements, cosmetics, and animal nutrition, a sodium ascorbate production plant serves as a cornerstone in the global vitamins and food additives supply chain.

What is Driving the Sodium Ascorbate Market?

The sodium ascorbate production plant market is being driven by growing health consciousness, expanding functional food and beverage industry, and increasing demand for natural antioxidants across the globe. One of the primary growth drivers is the rapidly expanding nutraceuticals and dietary supplements market, as sodium ascorbate serves as a preferred form of vitamin C due to its superior stability, reduced acidity, and better bioavailability compared to ascorbic acid alone. The rising global awareness of immune health and preventive healthcare, particularly following recent health crises, has significantly increased consumer demand for vitamin C supplements and fortified foods. Additionally, the food and beverage industry's steady growth, coupled with increasing consumer preference for natural preservatives over synthetic alternatives, is boosting the demand for sodium ascorbate as a clean-label antioxidant in processed foods, juices, and bakery products. Technological advancements in fermentation processes and crystallization techniques have improved yield efficiency and product quality while reducing production costs, further supporting market growth. Moreover, the expanding animal feed industry and the growing focus on animal health and nutrition are driving demand for feed-grade sodium ascorbate to enhance immune function and stress resistance in livestock and aquaculture. Regulatory approvals for new food applications and the development of specialized delivery systems for vitamin C are encouraging investments in sodium ascorbate production capacity. Furthermore, the growing cosmetics and personal care industry's interest in antioxidant ingredients and anti-aging formulations is creating additional market opportunities. Together, these factors make the sodium ascorbate production plant market a crucial segment in the global vitamins, food additives, and functional ingredients landscape.

Buy now: https://www.imarcgroup.com/checkout?id=10161&method=1911

Key Steps Required to Set Up a Sodium Ascorbate Plant

1. Market Analysis

The report provides insights into the landscape of the sodium ascorbate industry at the global level. The report also provides a segment-wise and region-wise breakup of the global sodium ascorbate industry. Additionally, it also provides the price analysis of feedstocks used in the production of sodium ascorbate, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the sodium ascorbate production plant project is elaborated in the report.

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for sodium ascorbate production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for sodium ascorbate production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=10161&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up a sodium ascorbate production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Sodium Ascorbate Production Cost Analysis 2025: Feasibility Study and Profit Margins here

News-ID: 4175152 • Views: …

More Releases from IMARC Group

Cost of Setting Up a PET Bottle Manufacturing Plant & DPR 2026

The global PET bottle industry is experiencing sustained growth propelled by rising packaged beverage consumption, pharmaceutical packaging expansion, increasing demand for ready-to-drink products, and the lightweight, recyclable advantages of PET packaging. As urbanization accelerates, consumer lifestyles shift toward convenience packaging, and regulatory frameworks increasingly mandate recyclable materials, establishing a PET bottle manufacturing plant positions investors in one of the most stable and essential segments of the consumer packaging value chain.

IMARC…

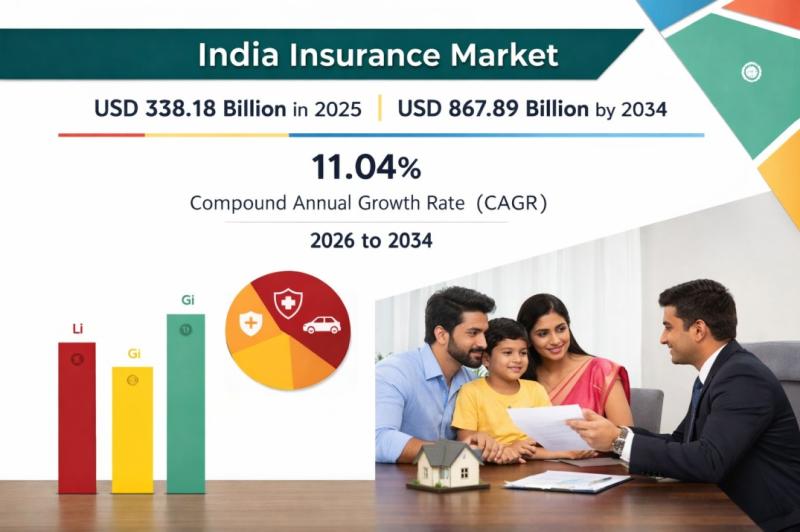

India Insurance Market Forecast 2026: Industry Size, Expansion & Future Scope 20 …

India Insurance Market Overview 2026-2034

According to IMARC Group's report titled India Insurance Market Size, Share, Trends and Forecast by Type of Product, Distribution Channel, End User, and Region, 2026-2034 the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

The India insurance market size was valued at USD 338.18 Billion in 2025 and is projected to reach USD 867.89 Billion by 2034, growing at…

Global Diammonium Phosphate (DAP) Prices January 2026: Asia Gains, Europe Steady …

What is Diammonium Phosphate (DAP)?

Diammonium Phosphate (DAP) is a widely used phosphorus-based fertilizer crucial for global agriculture. Monitoring Diammonium Phosphate (DAP) prices helps manufacturers, distributors, and buyers make informed procurement decisions and manage costs amid fluctuating demand and supply conditions.

Global Price Overview

The global Diammonium Phosphate (DAP) market shows moderate stability with regional supply differences affecting prices. The Diammonium Phosphate (DAP) price trend has remained mixed, while the price index and…

Titanium Prices, Index, Supply Factors & Uses | Jan 2026

North America Titanium Prices Movement Jan 2026

In January 2026, Titanium prices in North America reached USD 7.09/KG, reflecting a 3.1% increase. The upward movement was supported by firm demand from aerospace, automotive, and defense industries. Stable raw material supply and improving manufacturing activity strengthened market sentiment, contributing to positive pricing momentum across the region.

Regional Analysis: The price analysis can be extended to provide detailed Titanium price information for the following…

More Releases for Sodium

Global Sodium Sulbactam And Sodium Ampicillin API Market Size by Application, Ty …

According to Market Research Intellect, the global Sodium Sulbactam And Sodium Ampicillin API market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The market for sodium sulbactam and sodium ampicillin API is steadily expanding because to…

Global Sodium Acetate Trihydrate And Sodium Acetate Anhydrous Market Size by App …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to Market Research Intellect, the global Sodium Acetate Trihydrate And Sodium Acetate Anhydrous market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The sodium acetate trihydrate and sodium acetate anhydrous market is experiencing steady growth, driven by their wide-ranging applications in industries…

Sodium Percarbonate Market Report 2024 - Sodium Percarbonate Market Trends And D …

"The Business Research Company recently released a comprehensive report on the Global Sodium Percarbonate Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

Sodium Formate Market

Introduction

Sodium formate, a chemical compound with the formula HCOONa, plays a significant role in various industries. It is a white, water-soluble solid that is primarily used in leather tanning, de-icing, and as a buffering agent in various chemical processes. The versatility of sodium formate has made it an essential component in many industrial applications. Over the years, its demand has grown steadily, driven by its effectiveness and cost-efficiency. This post…

Sodium Diacetate (Sodium Hydrogen Diacetate) Market to see Rapid Growth by 2029|

-The report comes out as an intelligent and thorough assessment tool as well as a great resource that will help you to secure a position of strength in the global Sodium Diacetate (Sodium Hydrogen Diacetate) market. It includes Porter's Five Forces and PESTLE analysis to equip your business with critical information and comparative data about the Global Sodium Diacetate (Sodium Hydrogen Diacetate) Market. We have provided deep analysis of the…

Global Sodium Metasilicate Pentahydrate Market, Global Sodium Metasilicate Penta …

The Sodium Metasilicate Pentahydrate market is expected to grow from USD X.X million in 2020 to USD X.X million by 2026, at a CAGR of X.X% during the forecast period. The Global Sodium Metasilicate Pentahydrate Market report is a comprehensive research that focuses on the overall consumption structure, development trends, sales models and sales of top countries in the global Sodium Metasilicate Pentahydrate market. The report focuses on well-known providers…