Press release

Hydroxycitric Acid Plant Cost 2025: Business Plan, Machinery Details and Industry Trends

Setting up a hydroxycitric acid production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Hydroxycitric Acid Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a hydroxycitric acid production plant cost, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/hydroxycitric-acid-manufacturing-plant-project-report/requestsample

What is Hydroxycitric Acid?

The cost of setting up a hydroxycitric acid (HCA) production plant depends on multiple factors, including plant capacity, raw material availability, location, and technological integration. Typically, the capital investment covers expenses such as land acquisition, civil construction, machinery installation, utilities, and infrastructure setup. Major machinery includes extraction units, filtration systems, drying equipment, crystallizers, packaging machines, and quality control laboratories. Operating costs involve raw materials such as Garcinia cambogia fruit rind, solvents, labor, utilities like water and electricity, and maintenance services. Additional expenses may include waste management, compliance with regulatory standards, and automation for higher efficiency. Transportation and logistics costs also influence the total project expenditure. Small- to medium-scale plants generally require moderate investments, while large-scale commercial facilities with advanced technology and automation systems demand significantly higher capital outlays. Investors must also factor in working capital to cover initial raw material procurement, staff salaries, and marketing activities before revenue generation begins. Furthermore, fluctuations in raw material supply and global demand for HCA-based products such as dietary supplements and weight management formulations can impact cost considerations. Overall, a hydroxycitric acid production plant requires careful financial planning, balancing capital investment with expected returns to ensure long-term profitability and sustainability.

What is Driving the Hydroxycitric Acid Market?

The hydroxycitric acid production plant cost market is driven by several interlinked factors associated with global demand, raw material dynamics, and industrial trends. Increasing consumer interest in natural weight loss supplements and nutraceuticals has boosted demand for hydroxycitric acid, directly influencing the need for production facilities. Rising awareness of Garcinia cambogia's role in appetite suppression and fat metabolism has encouraged manufacturers to invest in scalable and efficient production technologies. This, in turn, affects costs as producers adopt modern extraction and purification processes to enhance product quality and yield. On the supply side, fluctuations in Garcinia fruit availability and agricultural output impact raw material pricing, leading to variable production costs. Additionally, regulatory requirements for food and nutraceutical-grade HCA push companies to invest in advanced quality assurance and compliance systems, adding to operational expenses. Energy costs, labor wages, and environmental compliance measures further shape the cost structure. Moreover, global market competition drives companies to optimize costs through process automation and sustainable practices. The rising preference for clean-label, plant-based supplements also encourages investment in eco-friendly production methods, which can require higher upfront capital. Overall, the hydroxycitric acid plant cost market is shaped by a mix of consumer-driven demand and supply chain economics.

Buy Now: https://www.imarcgroup.com/checkout?id=10954&method=1911

Key Steps Required to Set Up a Hydroxycitric Acid Plant

1. Market Analysis

The report provides insights into the landscape of the hydroxycitric acid industry at the global level. The report also provides a segment-wise and region-wise breakup of the global hydroxycitric acid industry. Additionally, it also provides the price analysis of feedstocks used in the production of hydroxycitric acid, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the hydroxycitric acid production plant project is elaborated in the report.

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for hydroxycitric acid production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for hydroxycitric acid production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=10954&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up a hydroxycitric acid production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Hydroxycitric Acid Plant Cost 2025: Business Plan, Machinery Details and Industry Trends here

News-ID: 4168418 • Views: …

More Releases from IMARC Group

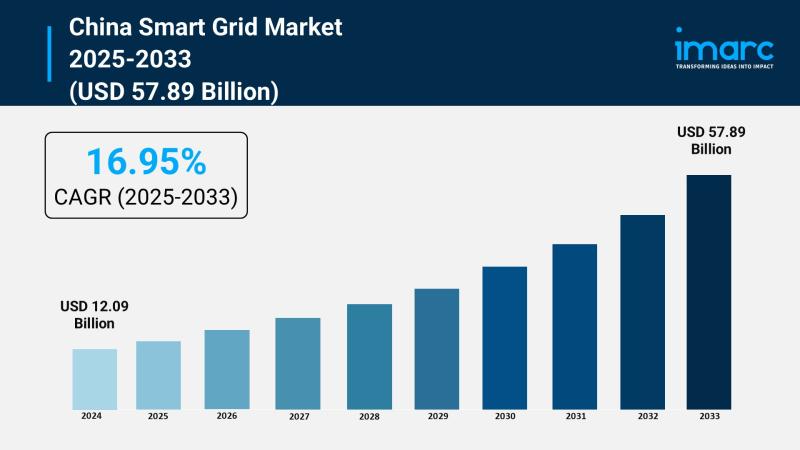

China Smart Grid Market Report: Industry Size, CAGR of 16.95% and Future Outlook …

Market Overview

The China Smart Grid Market reached USD 12.09 Billion in 2024 and is projected to reach USD 57.89 Billion by 2033, growing at a CAGR of 16.95% during the forecast period 2025-2033. This growth is driven by rapid urbanization, rising electricity demand, and strong governmental support aimed at energy efficiency and integrating renewable sources. Technological advancements such as IoT, AI, and big data analytics are further enhancing grid automation…

Ammonia Prices Update 2026: Global Price Index, Trend Shifts & Forecast

Global Ammonia Prices recorded mixed movement toward late 2025 and early 2026 as fluctuating energy costs, supply-side adjustments, and fertilizer demand reshaped market sentiment. The Ammonia Price Index remains a key benchmark for tracking these changes, reflecting regional cost pressures and trade dynamics. As ammonia continues to play a critical role in fertilizers, chemicals, and clean energy applications, market participants are closely monitoring price trends, historical patterns, and near-term forecasts…

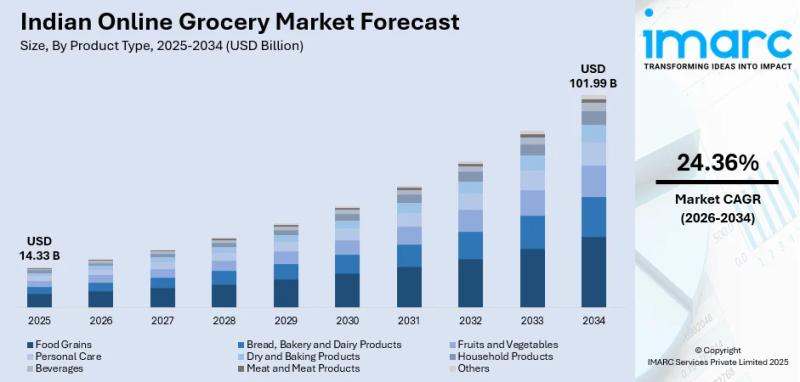

Indian Online Grocery Market Size to Surpass USD 101.99 Billion by 2034 | Expand …

Indian Online Grocery Market Overview 2026-2034:

According to IMARC Group's report titled "Indian Online Grocery Market Size, Share | Report 2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

The Indian online grocery market was valued at USD 14.33 Billion in 2025 and is projected to reach USD 101.99 Billion by 2034. It is expected to grow at a robust compound annual growth…

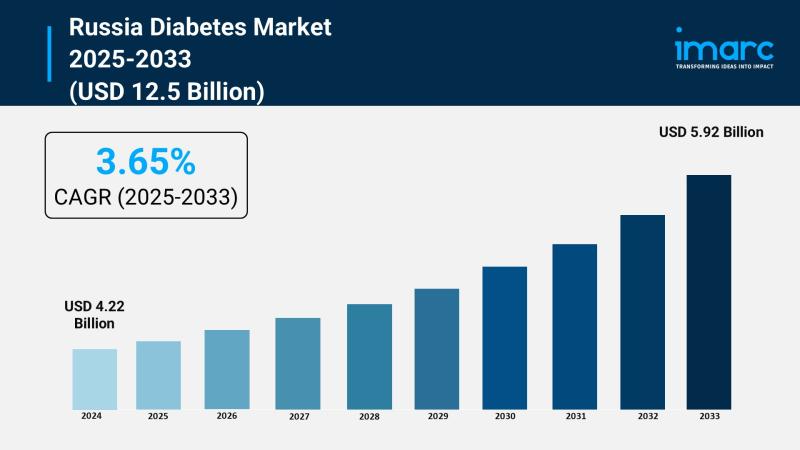

Russia Diabetes Market Therapeutics, Devices, and Care Pathways Analysis, 2025-2 …

Market Overview

The Russia diabetes market was valued at USD 4.22 Billion in 2024 and is projected to reach USD 5.92 Billion by 2033, growing at a CAGR of 3.65% during the forecast period of 2025-2033. This growth is driven by increasing diabetes prevalence, an aging population, and greater healthcare awareness supported by government initiatives. Technological advancements in diabetes care and expanded reimbursement policies also contribute to market expansion.

Study Assumption…

More Releases for Hydroxycitric

Hydroxycitric Acid Manufacturing Plant Setup Cost - Unit Operations and Machiner …

Setting up a hydroxycitric acid manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Hydroxycitric Acid Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a hydroxycitric…

Hydroxycitric Acid Production Cost Analysis Report, Manufacturing Process, Raw M …

The latest report titled "Hydroxycitric Acid Production" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of Hydroxycitric Acid.

Hydroxycitric Acid Production Report: https://www.procurementresource.com/production-cost-report-store/hydroxycitric-acid

Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, production cost details, economics for another…

Hydroxycitric Acid (HCA) Market to Witness Robust Expansion by 2024

LP INFORMATION offers a latest published report on Hydroxycitric Acid (HCA) Market Analysis and Forecast 2019-2024 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the Hydroxycitric Acid (HCA) market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2019.…

Garcinia Cambogia Extract Market Growth and Demand Research Report 2017-2027

Garcinia Cambogia a small, sweet tropical tree fruit also known as Malabar tamarind. Other names for Garcinia Cambogia are Assam Fruit, Gorakkapulli, Panampulli, Manda Huli, Goraka Pulli, Mangosteen, and Vadakkan Puli. Garcinia Cambogia is obtained in different colors depending on the spices such as yellow, green and red. Garcinia Cambogia extract is a hub of vitamins B, Thiamin, Folic Acid, Niacin, Magnesium, Vitamin C, Manganese, Potassium and Hydroxycitric Acid (HCA).…

Garcinia Cambogia Extract Market Volume Analysis, Segments, Value Share and Key …

Garcinia Cambogia a small, sweet tropical tree fruit also known as Malabar tamarind. Other names for Garcinia Cambogia are Assam Fruit, Gorakkapulli, Panampulli, Manda Huli, Goraka Pulli, Mangosteen, and Vadakkan Puli. Garcinia Cambogia is obtained in different colors depending on the spices such as yellow, green and red. Garcinia Cambogia extract is a hub of vitamins B, Thiamin, Folic Acid, Niacin, Magnesium, Vitamin C, Manganese, Potassium and Hydroxycitric Acid (HCA).…

Garcinia Cambogia Extract Market Revenue, Opportunity, Segment and Key Trends 20 …

Garcinia Cambogia a small, sweet tropical tree fruit also known as Malabar tamarind. Other names for Garcinia Cambogia are Assam Fruit, Gorakkapulli, Panampulli, Manda Huli, Goraka Pulli, Mangosteen, and Vadakkan Puli. Garcinia Cambogia is obtained in different colors depending on the spices such as yellow, green and red. Garcinia Cambogia extract is a hub of vitamins B, Thiamin, Folic Acid, Niacin, Magnesium, Vitamin C, Manganese, Potassium and Hydroxycitric Acid (HCA).…