Press release

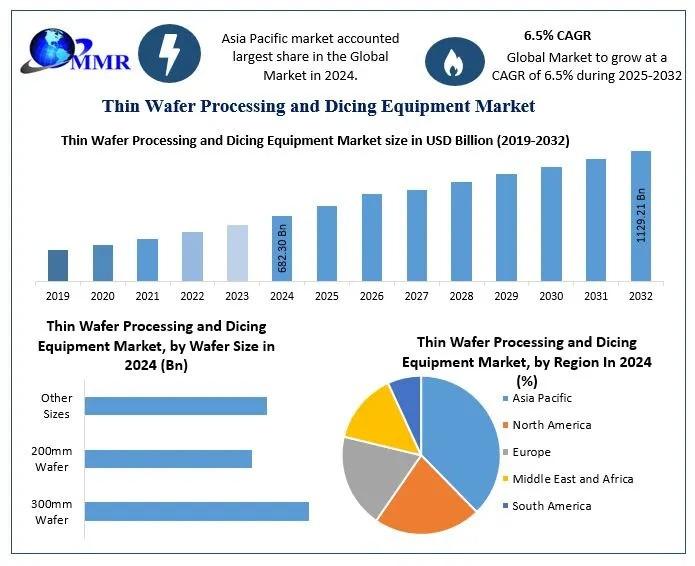

Thin Wafer Processing and Dicing Equipment Market to Reach USD 1,129.21 Billion by 2032 | CAGR 6.5%

Thin Wafer Processing and Dicing Equipment Market size was valued at USD 682.30 Billion in 2024 and the total Thin Wafer Processing and Dicing Equipment revenue is expected to grow at a CAGR of 6.5% from 2025 to 2032, reaching nearly USD 1129.21 Billion.Thin Wafer Processing and Dicing Equipment Market Overview:

The thin wafer processing and dicing equipment market is a critical segment within the semiconductor industry, focusing on the production and handling of ultra-thin wafers used in advanced electronics. These wafers form the backbone of devices such as smartphones, tablets, automotive electronics, and industrial sensors. With the increasing demand for miniaturized and high-performance semiconductor components, wafer thinning and precision dicing equipment have become essential to maintain accuracy, reduce material wastage, and enhance yield rates. The market includes solutions for grinding, back grinding, wafer thinning, and laser or mechanical dicing, offering manufacturers precise control over wafer dimensions. Growing adoption of advanced packaging technologies, including 3D stacking and system-in-package designs, has further boosted equipment demand. Additionally, rising investments in semiconductor fabrication facilities, particularly in regions with high electronics manufacturing activity, are driving the requirement for high-throughput, automated wafer processing equipment to support mass production efficiently.

Download a Free Sample Report Today: https://www.maximizemarketresearch.com/request-sample/35357/

Thin Wafer Processing and Dicing Equipment Market Outlook and Future Trends:

The outlook for the thin wafer processing and dicing equipment market is highly promising due to the expanding semiconductor industry and increasing adoption of advanced electronic devices. Future trends indicate growing investments in automation and AI-based solutions to optimize wafer handling, reduce defects, and increase throughput. Laser-based dicing and hybrid equipment technologies are gaining prominence for their precision and minimal material loss. Moreover, as consumer demand shifts toward smaller, thinner, and more energy-efficient electronic devices, wafer processing equipment manufacturers are innovating to support ultra-thin wafer production. Integration with smart manufacturing systems, predictive maintenance, and IoT-enabled monitoring is also expected to enhance operational efficiency. Additionally, emerging applications in automotive electronics, Internet of Things (IoT), 5G, and wearable devices are creating new growth opportunities. Strategic collaborations, technological upgrades, and increased research and development activities will continue to drive market expansion in the coming years.

Thin Wafer Processing and Dicing Equipment Market Dynamics:

Several factors are influencing the dynamics of the thin wafer processing and dicing equipment market. Key growth drivers include the rising adoption of high-performance and miniaturized semiconductor devices, which necessitate precise wafer thinning and dicing processes. Increasing investments in semiconductor fabs and electronics manufacturing facilities are also boosting equipment demand. However, high costs associated with advanced processing equipment and the need for skilled operators can be a constraint for new entrants and smaller manufacturers. Technological innovations, such as non-contact laser dicing and automated wafer handling, are helping to overcome these challenges while enhancing efficiency and reducing material wastage. Competitive dynamics are also evolving, with established players focusing on developing highly automated, energy-efficient, and scalable solutions. Moreover, regulatory standards and quality requirements in semiconductor production drive continuous innovation in equipment design, ensuring consistency, reliability, and higher yields across production lines.

Thin Wafer Processing and Dicing Equipment Market Key Recent Developments:

Recent developments in the thin wafer processing and dicing equipment market highlight a strong focus on innovation, automation, and high-precision solutions. Manufacturers are increasingly adopting laser-based dicing technology, which minimizes wafer damage and allows for finer pitches required in modern semiconductor packaging. Several companies are investing in smart factory integrations, enabling real-time monitoring, predictive maintenance, and process optimization through IoT and AI-based analytics. Equipment capable of handling ultra-thin wafers, below 50 microns, is being developed to meet the rising demand from consumer electronics, automotive, and 5G applications. Strategic partnerships and acquisitions among equipment providers are also accelerating technological advancements and expanding service portfolios. Furthermore, research is focusing on reducing operational costs, increasing throughput, and enhancing wafer handling precision. These developments collectively indicate a market driven by innovation, technological upgrades, and the growing need for highly reliable wafer processing solutions across multiple semiconductor applications.

To Gain More Insights into the Market Analysis, Browse Summary of the Research Report: https://www.maximizemarketresearch.com/request-sample/35357/

Thin Wafer Processing and Dicing Equipment Market Segmentation:

by Type of Wafer

Material Silicon

Compound Semiconductors

Glass

by Technology Type

Dicing Equipment

Thin Wafer Processing Equipment

by Wafer Size

300mm Wafer

200mm Wafer

Other Sizes

by Application

MEMS (Micro-Electro-Mechanical Systems)

CMOS Image Sensors

RF Devices

Memory Devices

Logic and Power Devices

by End-User

Semiconductor Manufacturing

Electronics

Automotive

Healthcare

Aerospace Industries)

Some of the current players in the Thin Wafer Processing and Dicing Equipment Market are:

North America:

1. Dynatex International, Petaluma, California, United States

2. Modutek Corporation, San Jose, California, United States

3. Technotronix Corporation, San Jose, California, United States

4. Axus Technology, Chandler, Arizona, United States

5. Plasma-Therm LLC, Saint Petersburg, Florida, United States

Europe:

1. Advanced Dicing Technologies Ltd., Yokneam, Israel

2. Loadpoint Ltd., Rye, United Kingdom

3. SUSS MicroTec SE, Garching, Germany

4. Microdiamant AG, Lengwil, Switzerland

5. Meyer Burger Technology AG, Thun, Switzerland

Asia-Pacific:

1. Disco Corporation, Tokyo, Japan

2. Accretech, Tokyo, Japan

3. Hanmi Semiconductor Co., Ltd., Chungcheongbuk-do, South Korea

4. Nagase Integrex Co., Ltd., Tokyo, Japan

5. Tokyo Seimitsu Co., Ltd., Tokyo, Japan

For additional reports on related topics, visit our website:

♦ Water Bath Heater Market https://www.maximizemarketresearch.com/market-report/water-bath-heater-market/148668/

♦ Paper drying systems market https://www.maximizemarketresearch.com/market-report/paper-drying-systems-market/148689/

♦ Global Industrial Parts Washer Market https://www.maximizemarketresearch.com/market-report/global-industrial-parts-washer-market/91244/

♦ Pick to Light Market https://www.maximizemarketresearch.com/market-report/pick-light-market/2697/

♦ Global Low Power Wearable Chips Market https://www.maximizemarketresearch.com/market-report/global-low-power-wearable-chips-market/78394/

MAXIMIZE MARKET RESEARCH PVT. LTD.

⮝ 3rd Floor, Navale IT park Phase 2,

Pune Banglore Highway, Narhe

Pune, Maharashtra 411041, India.

✆ +91 9607365656

🖂 sales@maximizemarketresearch.com

Maximize Market Research is a leading market research and consulting company, recognized for delivering reliable insights and strategies across diverse industries such as healthcare, pharmaceuticals, technology, automotive, and many more. Our expertise lies in providing in-depth market analysis, trend forecasting, competitive benchmarking, and strategic consulting tailored to client needs. We are committed to empowering organizations with actionable intelligence that enhances decision-making, strengthens market positioning, and fuels sustainable business growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Thin Wafer Processing and Dicing Equipment Market to Reach USD 1,129.21 Billion by 2032 | CAGR 6.5% here

News-ID: 4161654 • Views: …

More Releases from MAXIMIZE MARKET RESEARCH PVT. LTD.

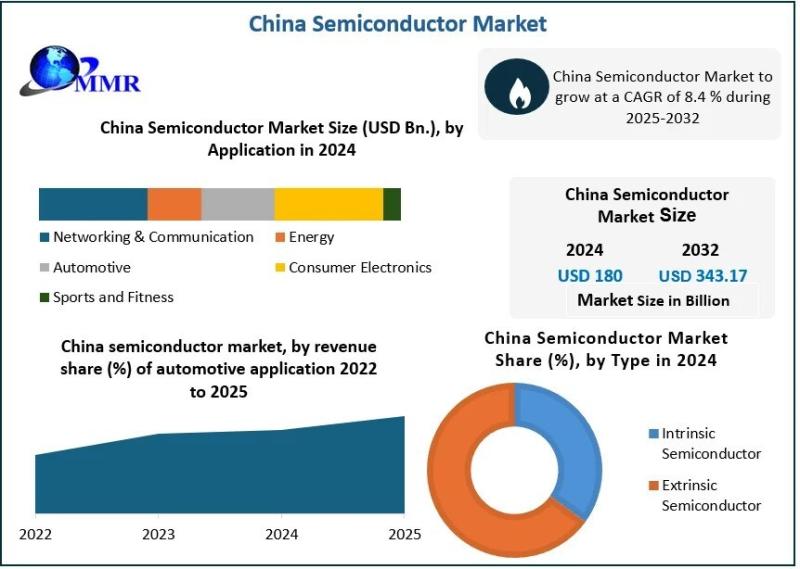

China Semiconductor Market Analysis: Projected to Grow from USD 180 Billion in 2 …

China Semiconductor Market size was valued at USD 180 Bn. in 2024, and the total China Semiconductor revenue is expected to grow by 8.4 % from 2025 to 2032, reaching nearly USD 343.17 Bn.

china-semiconductor-market Overview:

The China semiconductor market is one of the largest and most dynamic in the world, driving significant growth in the global tech industry. As China continues to expand its influence in high-tech manufacturing, the semiconductor market…

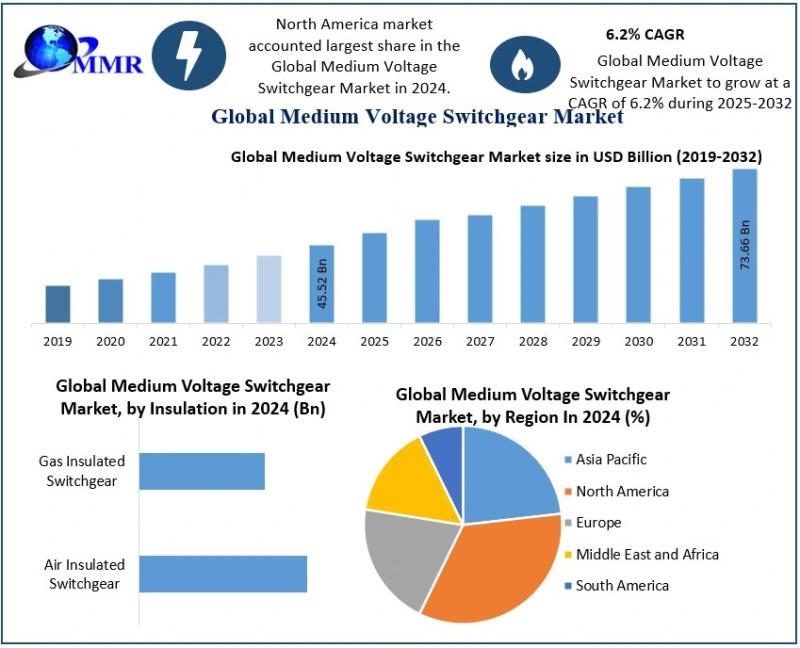

Medium Voltage Switchgear Market Analysis: 6.2% CAGR Driving Growth from USD 48. …

Medium Voltage Switchgear Market size was valued at USD 48.34 Billion in 2025 and the total Medium Voltage Switchgear revenue is expected to grow at a CAGR of 6.2% from 2025 to 2032, reaching nearly USD 73.65 Billion by 2032.

Medium-voltage Switchgear Market Overview:

The medium-voltage switchgear market plays a pivotal role in the global energy distribution landscape. These switchgear devices, typically operating between 1 kV and 72.5 kV, are critical for…

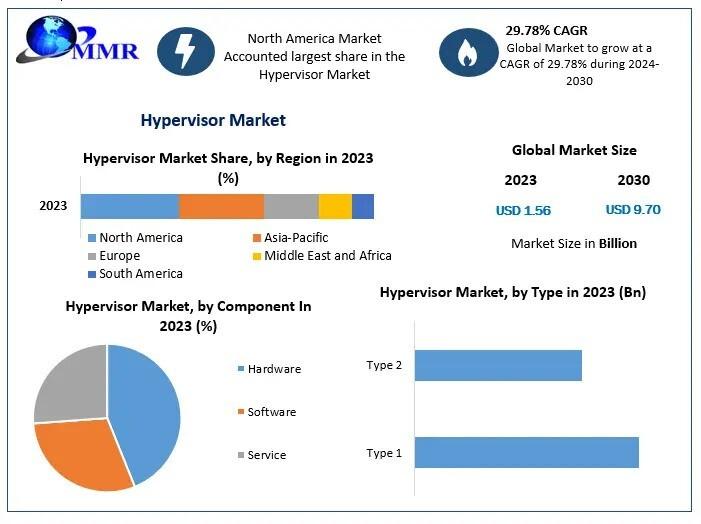

Hypervisor Market Analysis 2025-2030: Growth Rate of 29.78% and Market Value of …

Hypervisor Market size is estimated to grow at a CAGR of 29.78%. The market is expected to reach a value of US $ 9.70 Bn. in 2030.

Hypervisor Market Overview:

The hypervisor market, a critical component of virtualization technology, plays an essential role in the expansion of cloud computing, data centers, and IT infrastructure. By enabling multiple operating systems to run concurrently on a single physical machine, hypervisors streamline resource allocation and…

Cider Market Poised for Steady Growth, Expected to Reach USD 26.90 Billion by 20 …

The global Cider Market is witnessing a significant transformation driven by evolving consumer preferences, premiumization trends, and innovation in flavors and formats. Valued at USD 17.42 Billion in 2025, the market is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2025 to 2032, reaching nearly USD 26.90 Billion by 2032. This growth reflects cider's rising appeal as a refreshing, gluten-free, and lower-calorie alcoholic beverage alternative…

More Releases for Wafer

Semiconductor Silicon Wafer Market Is Going to Boom |• Silicon Wafer • Globa …

Worldwide Market Reports has released a new in-depth research study on the "Semiconductor Silicon Wafer Market," highlighting strong growth potential in the coming years. The report delivers a structured and data-driven analysis of the market landscape, combining robust research methodology, market sizing, validated data modeling, and insights sourced from reliable primary and secondary channels.

The study thoroughly examines key market aspects, including growth drivers, restraints, challenges, emerging opportunities, technological advancements, innovation…

Semiconductor Wafer Electrostatic Chucks for 300mm Wafer Market Size, Trends & F …

Semiconductor Wafer Electrostatic Chucks for 300mm Wafer Market Size

The global Semiconductor Wafer Electrostatic Chucks for 300mm Wafer market is projected to grow from US$ 1227 million in 2024 to US$ 1672.7 million by 2030, at a Compound Annual Growth Rate (CAGR) of 5.3% during the forecast period.

Get Free Sample: https://reports.valuates.com/request/sample/QYRE-Auto-38F13137/Global_Semiconductor_Wafer_Electrostatic_Chucks_for_300mm_Wafer_Market_Research_Report_2023?utm_source=openpr&utm_medium=referral

The US & Canada market for Semiconductor Wafer Electrostatic Chucks for 300mm Wafer is estimated to increase from $ million in…

Wafer Hybrid Bonding Equipment Market Share Driven by Wafer-to-Wafer Technology …

Wafer Hybrid Bonding Equipment Market Size

The global market for Wafer Hybrid Bonding Equipment was valued at US$ 164 million in the year 2024 and is projected to reach a revised size of US$ 756 million by 2031, growing at a CAGR of 24.7% during the forecast period.

View sample report

https://reports.valuates.com/request/sample/QYRE-Auto-31W14822/Global_Wafer_Hybrid_Bonding_Equipment_Market_Insights_Forecast_to_2029

The Wafer Hybrid Bonding Equipment market is experiencing accelerated growth, driven by increasing demand for advanced semiconductor packaging technologies that enable higher…

Semiconductor Wafer Electrostatic Chucks for 300mm Wafer Market

Semiconductor Wafer Electrostatic Chucks for 300mm Wafer Market

The global Semiconductor Wafer Electrostatic Chucks for 300mm Wafer market was valued at US$ 1165 million in 2023 and is anticipated to reach US$ 1672.7 million by 2030, witnessing a CAGR of 5.3% during the forecast period 2024-2030.

View Sample Report

https://reports.valuates.com/request/sample/QYRE-Auto-38F13137/Global_Semiconductor_Wafer_Electrostatic_Chucks_for_300mm_Wafer_Market_Research_Report_2023

Report Scope

The Semiconductor Wafer Electrostatic Chucks for 300mm Wafer market size, estimations, and forecasts are provided in terms of output/shipments (Units) and revenue…

Automatic Mounter Wafer Equipment Market Report 2018: Segmentation by Type (100 …

Global Automatic Mounter Wafer Equipment market research report provides company profile for Lintec Corporation, Nitto Denko, Tokyo Electron, Technovision, Takatori, Ultron Systems, DISCO Corp., Syagrus Systems, Advanced Dicing Technologies, Longhill Industries and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for…

EMEA Solar Wafer Cutting Fluid PEG Market For Semiconductor, Solar Wafer, Crysta …

Latest industry research report on: EMEA (Europe, Middle East and Africa) Solar Wafer Cutting Fluid PEG Market : Industry Size, Share, Research, Reviews, Analysis, Strategies, Demand, Growth, Segmentation, Parameters, Forecasts

Request For Sample Report @ https://www.marketresearchreports.biz/sample/sample/1194694

Geographically, this report split EMEA into Europe, the Middle East and Africa, With sales (K MT), revenue (Million USD), market share and growth rate of Solar Wafer Cutting Fluid PEG for these regions, from 2012 to…