Press release

Insulated Glass Units Manufacturing Plant: Setup Guide & Profitability Forecasts

Insulated Glass Units (IGUs), also known as double glazing, consist of two or more panes of glass separated by a spacer and sealed to create an insulating air or gas-filled space between them. This structure improves thermal efficiency, reduces energy consumption, minimizes noise, and enhances overall comfort in residential, commercial, and industrial applications. IGUs are widely used in windows, facades, and curtain walls due to their durability and energy-saving properties.Setting up an Insulated Glass Units manufacturing plant requires advanced glass processing equipment, quality sealing materials, and skilled labor to ensure precision assembly. Key considerations include plant layout, automated machinery for cutting, washing, and sealing, as well as compliance with energy-efficiency and safety standards. A medium-scale facility can be established with controlled investment, focusing on regional demand and supply chain integration to maximize competitiveness.

IMARC Group's report, titled "Insulated Glass Units Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up an insulated glass units manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/insulated-glass-units-manufacturing-plant-project-report/requestsample

Insulated Glass Units Industry outlook 2025:

The Insulated Glass Units (IGUs) industry outlook for 2025 indicates strong growth, driven by rising demand for energy-efficient building materials and stricter environmental regulations worldwide. With increasing urbanization and the adoption of green building standards, IGUs are becoming essential for residential, commercial, and industrial construction projects. Technological advancements, such as low-emissivity coatings and automated production lines, are further enhancing product performance and reducing costs. Additionally, government incentives promoting sustainable construction are boosting market adoption. Asia-Pacific and North America are expected to lead market expansion, supported by infrastructure development, renovation projects, and heightened consumer preference for energy savings and comfort.

Key Insights for Insulated Glass Units Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Insulated Glass Units Plant:

• Land and Infrastructure - Acquisition or leasing of land, construction of factory buildings, utilities setup, and layout planning.

• Machinery and Equipment - Cutting tables, glass washers, spacer applicators, sealing machines, gas-filling systems, and handling equipment.

• Raw Materials - Float glass sheets, spacers, desiccants, sealants, and inert gases such as argon or krypton.

• Labor and Training - Skilled workforce recruitment, technical training, and ongoing labor costs.

• Energy and Utilities - Electricity, water, compressed air, and gas supply.

• Quality Control and Testing Systems - Equipment for durability, thermal, and safety testing.

• Packaging and Logistics - Crating, protective materials, and distribution infrastructure.

• Licenses and Certifications - Regulatory approvals, safety certifications, and compliance with energy-efficiency standards.

• Working Capital - Inventory management, daily operational expenses, and contingency reserves.

Economic Trends Influencing Insulated Glass Units Plant Setup Costs 2025:

• Raw Material Price Volatility - Fluctuations in the cost of float glass, sealants, and spacers directly affect capital and operating expenses.

• Energy and Utility Costs - Rising electricity and fuel prices increase production costs, especially in energy-intensive processes.

• Technological Advancements - Adoption of automated machinery reduces labor dependency but raises initial investment requirements.

• Labor Market Dynamics - Higher wages in skilled manufacturing sectors impact operating costs, while shortages of trained technicians may drive up training expenses.

• Regulatory and Compliance Costs - Stricter energy-efficiency and environmental standards add to certification and quality-control expenditures.

• Global Supply Chain Shifts - Disruptions and freight cost variations influence the sourcing of raw materials and equipment.

• Government Incentives and Subsidies - Support for sustainable construction and green technologies may offset some setup costs.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=17884&flag=C

Challenges and Considerations for Investors in Insulated Glass Units Plant Projects:

• High Initial Capital Investment - Significant expenditure is required for advanced machinery, infrastructure, and quality-control systems.

• Technological Expertise - Precision manufacturing demands skilled labor and training to maintain consistent product quality.

• Regulatory Compliance - Meeting energy-efficiency standards, environmental regulations, and safety certifications can increase costs and timelines.

• Supply Chain Dependence - Availability and pricing of float glass, sealants, and spacers may be impacted by global market volatility.

• Market Competition - Increasing presence of established manufacturers can challenge new entrants in terms of pricing and market share.

• Maintenance and Quality Assurance - Continuous equipment servicing and rigorous testing are critical to avoid product defects and customer dissatisfaction.

• Demand Fluctuations - Construction sector cycles, economic slowdowns, and housing market trends directly influence sales volumes.

Conclusion:

The Insulated Glass Units (IGU) industry presents strong opportunities for growth, driven by increasing demand for energy-efficient and sustainable building solutions worldwide. Establishing an IGU manufacturing plant requires careful consideration of capital investment, technological expertise, regulatory compliance, and supply chain management. While initial setup costs can be significant, long-term returns are supported by rising construction activity, stricter environmental standards, and consumer preference for enhanced comfort and energy savings. With strategic planning, adoption of advanced technologies, and alignment with green building initiatives, investors can position IGU projects as competitive and profitable ventures in the evolving global construction materials market.

Buy Now: https://www.imarcgroup.com/checkout?id=17884&method=1911

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Insulated Glass Units Manufacturing Plant: Setup Guide & Profitability Forecasts here

News-ID: 4155383 • Views: …

More Releases from IMARC Group

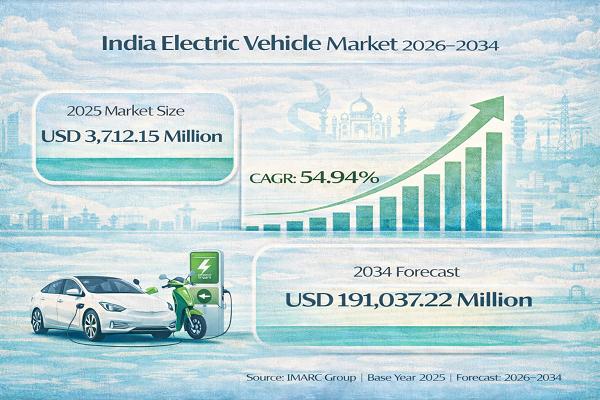

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Unit

Global Transcutaneous Electrical Nerve Stimulation Unit Market, Transcutaneous E …

Global Transcutaneous Electrical Nerve Stimulation Unit Market Overview:

The Transcutaneous Electrical Nerve Stimulation Unit market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the Transcutaneous Electrical Nerve Stimulation Unit market has experienced significant growth, driven by factors such as increasing consumer demand,…

Glycol Dehydration Unit Market Glycol Dehydration Unit Market 2028

Persistence Market Research delivers key insights on the global glycol dehydration unit market, in its report titled, 'Glycol Dehydration Unit Market: Global Industry Analysis 2013-2017 and Forecast 2018-2028'. Over the forecast years, the global glycol dehydration unit market is expected to show a positive outlook.

The market value is expected to increase at a healthy pace over the forecast period. Based on the glycol type segment, the triethylene glycol segment is…

Biodiesel Processing Unit

While reserves of petroleum are decreasing every passing day, energy consumption is increasing at 6.5% per annum. And for solving this issue many countries are implementing new policies for minimizing the usage of fossil fuels and increase the use of alternative sources like solar power and Biodiesel. Biodiesel is a diesel fuel substitute made from a variety of oils, fats, and greases which can become a cheaper alternative to fossil…

Jackfruit Processing Unit

The fruit processing sector has some undoubtedly potential Business Ideas, and Jackfruits processing is highly recommended because jackfruits are highly perishable tropical fruits, which helps in improving the immunity, replenishes the energy, cardiovascular health, regulates Blood Pressure, Digestion, treats the skin diseases, prevent/control asthma and many more awesome advantages of jackfruit consumption.

Rising demand for processed fruit product for secondary preparations, rising income, and resultant increased spending on food items is…

Pomegranate Processing unit

India is the second largest producer of Pomegranates in the world after Iran, still contributes only 5% pomegranate related international trades. India produces the finest edible Pomegranates, which are available almost throughout the year, which provides a tremendous potential for export of Pomegranate and its products from India.

Processing of the Pomegranates becomes essential in order to increase the utilization and reduce the wastage of the fruit. Pomegranates being rich in…

Coconut Processing Unit

Coconut is an important fruit in the Indian economy as the country is listed among the top Coconut producing countries in the world. The contribution of Coconut is about ₹27900 crore to India’s Gross Domestic Product (GDP).

Today's improved economic stability, spending power, nutritional requirements, and awareness are pushing consumers to shift their preferences.

Currently, Coconut water, Coconut milk/cream and Virgin Coconut Oil (VCO) are expected to be main growth drivers for…