Press release

Shenzhen Jewellok Technology Co., Ltd. Launches Cutting-Edge VMB Gas Cabinet Solutions for Ultra-High Purity Gas Delivery in High-Tech Industries

Shenzhen, Guangdong, China - August 11, 2025 - Shenzhen Jewellok Technology Co., Ltd., a pioneering manufacturer and supplier of ultra-high purity (UHP) gas delivery systems, control valves, and pressure regulators, today announced the expansion of its innovative gas cabinet product line. Designed to meet the rigorous demands of semiconductor fabrication, pharmaceuticals, biotechnology, and other high-tech sectors, these advanced gas cabinets ensure precise, safe, and reliable handling of hazardous and specialty gases. With models like the fully automated JW-300-GC gas cabinet, semi-automatic JW-200-GC gas cabinet, and semi-automatic VMB JW-100-GC, Jewellok is setting new standards in gas delivery technology, emphasizing automation, safety, and customization to support the evolving needs of global industries.In an era where precision and purity are paramount, Jewellok's gas cabinets address critical challenges in gas management, such as preventing contamination, minimizing leaks, and ensuring uninterrupted supply. The company's commitment to innovation stems from its deep expertise in fluid equipment development, offering solutions that are not only ultra-reliable but also cost-effective. "At Jewellok, we are dedicated to pushing the boundaries of what's possible in UHP gas systems," said Dr. Li Wei, CEO of Shenzhen Jewellok Technology Co., Ltd. "Our new gas cabinet lineup represents a leap forward in automation and safety, empowering industries to achieve higher efficiency and compliance in their operations."

The flagship JW-300-GC Fully Automated Gas Cabinet stands out for its seamless integration of advanced automation features. This model supports precise UHP gas delivery with automatic switching and purging capabilities, ensuring minimal downtime during cylinder changes. Its explosion-proof design includes an anti-leaving cabinet, self-locking door, and glass observation window, all engineered to withstand hazardous environments. Key safety elements such as leakage alarms, remote cut-off, and negative pressure alarms provide real-time monitoring and rapid response to potential risks. The cabinet features a user-friendly 10-inch color touch screen interface, allowing operators to manage operations intuitively.

Technical specifications of the JW-300-GC highlight its versatility: available in single or double bottle configurations, with dimensions of W800D633H2172 for double bottles and W600D661H2104 for single. It operates on a 220VAC, 50HZ power supply, with control at 500W and heating up to 1-6KW. Connections include PN2 purge at 1/4" MVCR, high-pressure holding with HPN2, vacuum GN2, and a 1/2" MVCR VENT drain pipe. Pneumatic air sourcing uses a CDA driver at 1/4" SWG, while cabinet ventilation supports OD 150MM ducts, delivering 810m3/hr for silane and 204m3/hr for other gases. Customization options abound, including UV/IR flame detectors, cylinder shutboys, panel heating, Ethernet communication modules, CGA guarders, excess flow switches, pneumatic cylinder controls, weight scales, and cylinder heating. These features make the JW-300-GC ideal for applications requiring high purity, such as nitrogen trifluoride (NF3) handling in semiconductor etching and chemical vapor deposition (CVD) processes.

Complementing the fully automated model is the JW-200-GC Semi-Automatic Gas Cabinet, which balances automation with operational flexibility. Sharing many features with the JW-300-GC, including automatic switching, purging, explosion-proof construction, and the 10-inch touch screen, this model is tailored for high purity gas panels. Its dimensions mirror the JW-300-GC, ensuring compatibility in space-constrained facilities. Safety is enhanced through the same suite of alarms and remote controls, while optional add-ons like flame detectors and Ethernet modules allow for tailored enhancements. This cabinet excels in environments where semi-automation reduces human error without fully eliminating manual oversight, making it suitable for R&D labs, universities, and standard testing facilities in industries like optoelectronics and new energy.

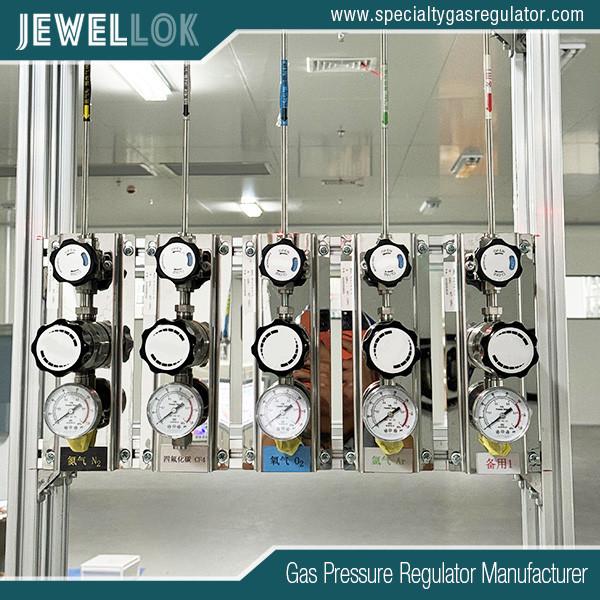

The semi-automatic VMB Gas Cabinet (JW-100-GC) integrates a semiconductor valve manifold box with diaphragm valves and gas pressure regulators, providing a secure enclosure for gas cylinders in demanding processes. This model emphasizes worker protection and equipment integrity, featuring an anti-corrosion frame and stainless steel base for durability. Configurations support single (W500D520H1957) or double (W800D520H1957) bottles, with power supplies identical to its counterparts. Diaphragm valves ensure tight seals to prevent leaks and contamination, while pressure regulators maintain consistent flow for processes like etching and CVD. The semi-automatic design automates gas flow adjustments but requires manual cylinder handling, striking a balance between efficiency and safety. Applications span semiconductor manufacturing, where precise gas distribution is crucial, and extend to pharmaceuticals and biotechnology for sterile gas handling.

Jewellok's gas cabinets are built on a foundation of excellence in UHP systems, utilizing materials and designs that guarantee leak integrity, high cycle life, and low particle generation. These products operate effectively under extreme temperatures and pressures, handling a wide array of media including nitrogen, oxygen, hydrogen, and specialty gases like NF3. The company's expertise extends beyond gas cabinets to include compression tube fittings, UHP regulators, diaphragm valves (electronic, pneumatic, manual, and air-actuated), and pressure control panels. All products are assembled with high cleanliness standards, particularly for semiconductor applications, and feature electropolished 316L stainless steel for superior surface finishes up to 5Ra.

Industries served by Jewellok reflect the broad applicability of its technologies. In semiconductor fabrication, the gas cabinets support integrated circuits and flat panel displays by delivering uncontaminated gases essential for microelectronics. Pharmaceuticals and biotechnology benefit from sterile environments maintained through precise valve and regulator systems. Energy sectors, including hydrogen and new energy, rely on Jewellok's solutions for safe gas handling in R&D and production. Chemical production, aerospace, automotive, optical fibers, fine chemicals, laboratories, research institutes, and environmental protection also leverage these systems for their reliability and customization options-offered without minimum order quantities to accommodate diverse market needs.

This launch underscores Jewellok's mission to provide innovative fluid equipment that maximizes benefits for clients worldwide. By focusing on CAD and 3D prototyping services, the company enables rapid customization of control valves and regulators, ensuring solutions fit specific requirements. "Our gas cabinets are more than just storage solutions; they are intelligent systems that enhance productivity and safety," added Dr. Li. "We are excited to partner with industries driving technological advancement, helping them achieve purity levels that were once thought unattainable."

As global demand for high-tech manufacturing surges, Jewellok's gas cabinet solutions position the company as a leader in UHP gas delivery. The products comply with stringent industry standards, though specific certifications are tailored per client needs. Future developments may include enhanced IoT integration for remote monitoring, further automating gas management in smart factories.

For more information on Jewellok's gas cabinet product line or to request a customized quote, visit https://www.jewellok.com/product-category/gas-cabinet/ or contact the sales team at info@jewellok.com.

About Shenzhen Jewellok Technology Co., Ltd.

Shenzhen Jewellok Technology Co., Ltd. is a leading manufacturer and supplier of ultra-high purity gas delivery systems, control valves, and pressure regulators. With a focus on innovation and reliability, Jewellok serves high-tech industries worldwide, offering cost-effective, customizable solutions for semiconductor, pharmaceutical, energy, and other sectors. Headquartered in Shenzhen, China, the company is committed to advancing fluid equipment technology to meet the challenges of modern manufacturing.

Contact:

James Yuan

Shenzhen Jewellok Technology Co., Ltd.

Building A3, No. 440, Hedong Village, Hengkeng, Guancheng Community, Guanhu Street, Longhua District, Shenzhen City, China

Phone: +86-13380377051

Email: info@jewellok.com

Website: https://www.jewellok.com/product-category/gas-changeover-manifold/

Media Contact:

James Yuan

Shenzhen Jewellok Technology Co., Ltd.

Building A3, No. 440, Hedong Village, Hengkeng, Guancheng Community, Guanhu Street, Longhua District, Shenzhen City, China

Phone: +86-13380377051

Email: info@jewellok.com

Website: https://www.jewellok.com

Jewellok specializes in fully automatic and semi-automatic GC gas cabinets, BSGS gas cabinets, VMB gas cabinets, TMA gas cabinets, Scrubber tail gas treatment cabinets, gas distribution cabinets, VDB gas cabinets, and VDP gas cabinets, suitable for gases such as SiH4, NF3, NH3, N2O, and HCI.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Shenzhen Jewellok Technology Co., Ltd. Launches Cutting-Edge VMB Gas Cabinet Solutions for Ultra-High Purity Gas Delivery in High-Tech Industries here

News-ID: 4139656 • Views: …

More Releases from Shenzhen Jewellok Technology Co., Ltd

Jewellok Unveils 316L SS High-Purity Gas Regulators, Valves, Manifolds & Cabinet …

Shenzhen, China - January 8, 2026 - Shenzhen Jewellok Technology Co., Ltd., a leading innovator in high-purity gas supply systems, today announced the expansion of its comprehensive portfolio of specialty gas equipment, designed to meet the stringent demands of semiconductor manufacturing, laboratory analysis, and industrial applications. With a focus on precision, reliability, and cost-effectiveness, the company's latest offerings include a wide array of 316L stainless steel high-purity specialty gas pressure…

Jewellok Technology Unveils Advanced UHP Diaphragm Valve for High-Purity Gas Sys …

Shenzhen, China - December 24, 2025 - Shenzhen Jewellok Technology Co., Ltd., a leading innovator in high-purity and ultra-high-purity special gas supply systems, today announced the launch of its latest UHP Diaphragm Valve series, designed to meet the stringent demands of semiconductor manufacturing and other high-tech industries. This cutting-edge product reinforces Jewellok's commitment to delivering precision-engineered solutions for fluid and gas control, ensuring unparalleled purity, reliability, and performance in critical…

Jewellok Technology Unveils Advanced Ultra-High Purity Gas Delivery Solutions fo …

Shenzhen, China - December 3, 2025 - Shenzhen Jewellok Technology Co., Ltd., a leading innovator in fluid equipment and gas control systems, today announced the expansion of its comprehensive portfolio of ultra-high purity (UHP) gas delivery systems, pressure regulators, and control valves. This strategic enhancement, showcased across its flagship platforms at https://www.specialtygasregulator.com, underscores the company's commitment to delivering precision-engineered solutions for high-tech industries such as semiconductors, pharmaceuticals, and renewable energy.…

A Comprehensive Guide to Jewellok Ultra High Purity Diaphragm Valves

A Comprehensive Guide to Jewellok Ultra High Purity Diaphragm Valves

Introduction

In the realm of high-tech industries such as semiconductor manufacturing, pharmaceuticals, and biotechnology, maintaining ultra-high purity (UHP) in gas and fluid delivery systems is paramount. Contaminants, even at trace levels, can compromise product quality, yield, and safety. This is where ultra-high purity diaphragm valves come into play, serving as critical components that ensure hermetic sealing, minimal particle generation, and precise flow…

More Releases for UHP

UHP Graphite Electrode (600MM) Price Trend: Market Analysis

The UHP Graphite Electrode (600MM) Price Trend has become a critical focal point in the industrial landscape, particularly for sectors relying on electric arc furnaces (EAF) and ladle furnaces. Understanding these price trends requires diving into various market factors, regional dynamics, historical data, and future forecasts. Procurement Resource offers in-depth insights into the price movements and market behavior of UHP Graphite Electrodes.

UHP Graphite Electrode (600MM) Price Trend: https://www.procurementresource.com/resource-center/uhp-graphite-electrode-600mm-price-trends

Latest Price Analysis

The…

UHP Graphite Electrode Market Size, Share and Growth Report, 2034

"The global ultra-high-power (UHP) graphite electrode market is projected to reach a value of approximately $5.1 billion in 2024. Looking ahead, the market is expected to grow significantly, with a projected value of around $7.8 billion by 2034, reflecting a robust Compound Annual Growth Rate (CAGR) of 4.5% during the forecast period from 2025 to 2034."

Exactitude Consultancy., Ltd. released a research report titled "UHP Graphite Electrode Market". This report covers…

UHP Regulator and UHP High and Low Diaphragm Valves | UNILOK

UNILOK offers UHP diaphragm valves, UHP high- and low-diaphragm valves, and UHP regulators for ultra-high-purity applications. It controls fluid or gas flow without leaks and precise flow control.

UNILOK Low Pressure Diaphragm Valve

The UNILOK low pressure diaphragm valve is engineered for precise control and reliable shut-off in low-pressure fluid systems. It is particularly well-suited for applications where cleanliness, leak-tight sealing, and corrosion resistance are critical requirements, such as semiconductor manufacturing, pharmaceutical…

Global UHP Gas Cabinets Companies Analysis 2025

On 2025-2-26, the latest report 【Global UHP Gas Cabinets Market 2025 by Manufacturers, Regions, Types and Applications, Forecast to 2031】from Global Info Research provides a detailed and comprehensive analysis of the global UHP Gas Cabinets market. The report provides both quantitative and qualitative analysis by manufacturers, regions and countries, types and applications. As the market is constantly changing, this report explores market competition, supply and demand trends, and key factors…

Global UHP Gas Panels Market Restraints Analysis 2025

Ultra-high pressure gas panels receive gas from one or more bulk sources and distribute it to multiple outlets according to various downstream processes. However, UHP gas panels are made for microelectronics, semiconductor and photovoltaic module production, and certain aerospace environments. These applications require piping systems and components constructed to a higher standard to ensure the purity of the gas or fluid being transported.

This report is a detailed and comprehensive analysis…

UHP Tubings Market Dominance CAGR 7.4%, Revenue $1824 Million Forecast by 2030 | …

CALIFORNIA, (UNITED STATES) - According to QYResearch New Study Report 'UHP Tubings Market 2024' provides a comprehensive analysis of the industry with market insights will definitely facilitate to increase the knowledge and decision-making skills of the business, thus providing an immense opportunity for growth. Finally, this will increase the return rate and strengthen the competitive advantage within. Since it's a personalised market report, the services are catered to the particular…