Press release

A Comprehensive Guide to Jewellok Ultra High Purity Diaphragm Valves

A Comprehensive Guide to Jewellok Ultra High Purity Diaphragm ValvesIntroduction

In the realm of high-tech industries such as semiconductor manufacturing, pharmaceuticals, and biotechnology, maintaining ultra-high purity (UHP) in gas and fluid delivery systems is paramount. Contaminants, even at trace levels, can compromise product quality, yield, and safety. This is where ultra-high purity diaphragm valves come into play, serving as critical components that ensure hermetic sealing, minimal particle generation, and precise flow control. Jewellok Technology, a leading manufacturer based in Shenzhen, China, has established itself as a key player in this niche with its innovative range of UHP diaphragm valves. These valves are engineered to meet the stringent demands of precision industries, offering reliability, cleanliness, and performance that align with global standards like ASME and CE.

Jewellok's UHP diaphragm valves are designed for applications involving high-purity gases, aggressive chemicals, and sensitive processes. They feature advanced materials and construction techniques that minimize entrapment areas, facilitate purging, and maximize flow capacity. This guide provides a comprehensive overview of Jewellok's UHP diaphragm valves, covering their design, types, features, specifications, applications, and best practices for use. By delving into these aspects, we aim to equip engineers, technicians, and decision-makers with the knowledge needed to select and implement these valves effectively.

Design and Construction

At the core of Jewellok's UHP diaphragm valves is a commitment to material excellence and precision engineering. The body is typically constructed from 316L VIM-VAR (Vacuum Induction Melting-Vacuum Arc Remelting) stainless steel, a material renowned for its ultra-low inclusion content and superior corrosion resistance. This choice ensures the valves can withstand harsh environments while maintaining purity levels essential for semiconductor fabrication and other clean processes. The inner surface of the valve body achieves an exceptional roughness average (Ra) of 5 μin (0.13 μm), which minimizes particle adhesion and allows for complete cleaning of the flow channel.

The diaphragm itself is a standout feature, crafted from high-strength, corrosion-resistant alloys such as Hastelloy C-22 or cobalt-based superalloys (UNS R30003). This design optimizes cycle life, enabling the valve to endure over 100,000 operations without degradation. The diaphragm provides a hermetic seal, isolating the process media from the actuator and external environment, thus preventing contamination. Jewellok employs a fully contained PCTFE (Polychlorotrifluoroethylene) seat design, which offers excellent resistance to swelling, contamination, and particle generation. This seat material enhances helium leak test performance, with every valve undergoing rigorous helium testing before shipment to guarantee leak-tight integrity.

Assembly and packaging occur in high-cleanliness environments, adhering to protocols suitable for the semiconductor industry. This meticulous process ensures that the valves arrive ready for immediate integration into UHP systems, reducing downtime and contamination risks. Additionally, Jewellok's valves incorporate advanced spool designs for precise pressure control, with output fluctuations limited to ±1%, making them ideal for stable gas delivery.

Types and Models

Jewellok offers a diverse lineup of UHP diaphragm valves to cater to various operational needs, including manual, pneumatic, and electronic actuation options. The HD Series stands out as a flagship line, encompassing high-pressure pneumatic and manual variants.

The HD Series High Pressure Pneumatic Diaphragm Valve is engineered for demanding applications requiring pneumatic operation under high pressure and temperature conditions. It features a robust stainless steel construction and is optimized for ultrahigh-purity gas systems. A companion model, the HD Series High Pressure Manual Diaphragm Valve, provides manual control for scenarios where simplicity and direct operator intervention are preferred.

For lower pressure environments, Jewellok provides the Low Pressure Pneumatic Diaphragm Valve and Low Pressure Manual Diaphragm Valve. These models maintain the same high-purity attributes but are tailored for applications with reduced pressure requirements, such as laboratory gas lines or secondary distribution systems.

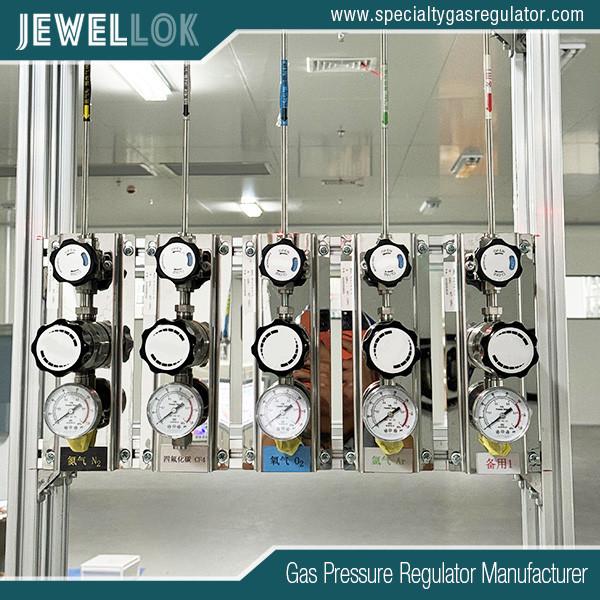

Additionally, Jewellok's High Purity Diaphragm Reducing Valves integrate pressure regulation with diaphragm sealing. These valves feature a double-seat structure and are available in configurations like SF (Standard Flow), HF (High Flow), and FC (Flow Control), with maximum flow rates ranging from 800 to 1500 SLPM (Standard Liters Per Minute). Connection options include rear seat mounting or panel mounting, enhancing flexibility in system design.

All models support customization, including OEM services and modifications based on specific designs. This versatility allows Jewellok to address unique requirements in gas pipeline engineering, from semiconductor fabs to biomedical research facilities.

Features and Benefits

Jewellok's UHP diaphragm valves boast an array of features that translate into tangible benefits for users. The hermetic seal and contamination-free construction ensure utmost purity, making them guardians of hygiene in aseptic production processes. The low surface roughness and fully swept flow paths minimize entrapment areas, facilitating efficient purging and reducing the risk of process media carryover.

Optional intelligent enhancements, like digital pressure gauges or IoT remote monitoring modules, enable real-time data feedback for predictive maintenance and process optimization. These smart capabilities are particularly valuable in high-tech fields where downtime can be costly.

In terms of performance, the valves offer precise pressure control across a broad range, from 0.1 MPa to 20 MPa, with high-pressure special models available for applications exceeding 1 MPa. The contained seat design improves leak performance and minimizes particle generation, contributing to higher yields in semiconductor manufacturing.

Looking ahead, Jewellok is investing in research and development to further enhance its ultra high purity diaphragm valves offerings. Future iterations may incorporate advanced IoT integration for predictive maintenance and enhanced data analytics, ensuring clients stay ahead in fast-evolving industries. For more about Jewellok ultra high purity diaphragm valves, you can pay a visit to https://www.jewellok.com/product-category/ultra-high-purity-diaphragm-valves/ for more info.

About Shenzhen Jewellok Technology Co., Ltd.

Shenzhen Jewellok Technology Co., Ltd. is a premier manufacturer and supplier of ultra high purity diaphragm valves, control valves, and pressure regulators. Serving industries including semiconductors, aerospace, automotive, hydrogen energy, chemicals, pharmaceuticals, biotechnology, and more, Jewellok provides comprehensive solutions for high-purity and extreme application environments. With a dedication to innovation, customization, and reliability, Jewellok empowers global clients to achieve operational excellence.

For more information about Jewellok ultra high purity diaphragm valves and other products, please contact the sales team.

Contact Information:

James Yuan

Shenzhen Jewellok Technology Co., Ltd.

Longguang Technology Innovation Park, No. 4 Zhen'an East Road, Xiaobian Community, Chang'an Town, Dongguan City, China

Phone: +86-13380377051

Email: info@jewellok.com

Website: https://www.jewellok.com/about/

James Yuan

Shenzhen Jewellok Technology Co., Ltd.

Longguang Technology Innovation Park, No. 4 Zhen'an East Road, Xiaobian Community, Chang'an Town, Dongguan City, China

Phone: +86-13380377051

Email: info@jewellok.com

Website: https://www.jewellok.com/

Shenzhen Jewellok Technology Co., Ltd. is a premier manufacturer and supplier of ultra-high purity (UHP) gas and chemical delivery systems. Headquartered in Shenzhen, China, the company specializes in high-performance components such as regulators, valves, and control systems for industries requiring precision, safety, and reliability. Serving clients in semiconductor manufacturing, biotechnology, pharmaceuticals, research, and other high-tech sectors globally, Jewellok is dedicated to innovation and quality.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release A Comprehensive Guide to Jewellok Ultra High Purity Diaphragm Valves here

News-ID: 4233860 • Views: …

More Releases from Shenzhen Jewellok Technology Co., Ltd

Jewellok Unveils 316L SS High-Purity Gas Regulators, Valves, Manifolds & Cabinet …

Shenzhen, China - January 8, 2026 - Shenzhen Jewellok Technology Co., Ltd., a leading innovator in high-purity gas supply systems, today announced the expansion of its comprehensive portfolio of specialty gas equipment, designed to meet the stringent demands of semiconductor manufacturing, laboratory analysis, and industrial applications. With a focus on precision, reliability, and cost-effectiveness, the company's latest offerings include a wide array of 316L stainless steel high-purity specialty gas pressure…

Jewellok Technology Unveils Advanced UHP Diaphragm Valve for High-Purity Gas Sys …

Shenzhen, China - December 24, 2025 - Shenzhen Jewellok Technology Co., Ltd., a leading innovator in high-purity and ultra-high-purity special gas supply systems, today announced the launch of its latest UHP Diaphragm Valve series, designed to meet the stringent demands of semiconductor manufacturing and other high-tech industries. This cutting-edge product reinforces Jewellok's commitment to delivering precision-engineered solutions for fluid and gas control, ensuring unparalleled purity, reliability, and performance in critical…

Jewellok Technology Unveils Advanced Ultra-High Purity Gas Delivery Solutions fo …

Shenzhen, China - December 3, 2025 - Shenzhen Jewellok Technology Co., Ltd., a leading innovator in fluid equipment and gas control systems, today announced the expansion of its comprehensive portfolio of ultra-high purity (UHP) gas delivery systems, pressure regulators, and control valves. This strategic enhancement, showcased across its flagship platforms at https://www.specialtygasregulator.com, underscores the company's commitment to delivering precision-engineered solutions for high-tech industries such as semiconductors, pharmaceuticals, and renewable energy.…

Jewellok Unveils Advanced Specialty Gas Cabinet Solutions for High-Tech Industri …

Shenzhen, China - September 22, 2025 - Shenzhen Jewellok Technology Co., Ltd., a leading manufacturer and supplier of ultra-high purity gas delivery systems, today announced the expansion of its innovative product line with the latest advancements in Jewellok specialty gas cabinets. Designed to meet the rigorous demands of semiconductor manufacturing, optoelectronics, and other high-precision sectors, these cabinets represent a significant leap forward in safety, efficiency, and reliability for handling specialty…

More Releases for Diaphragm

Paper Acoustic Diaphragm Research:the global paper acoustic diaphragm market is …

QY Research Inc. (Global Market Report Research Publisher) announces the release of 2025 latest report "Paper Acoustic Diaphragm- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031". Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2025-2031), this report provides a comprehensive analysis of the global Wire Drawing Dies market, including market size, share, demand, industry development status, and forecasts for the next few years.

The…

Transformative Trends Impacting the Diaphragm Pump Market Landscape: Environment …

Stay ahead with our updated market reports featuring the latest on tariffs, trade flows, and supply chain transformations.

How Large Will the Diaphragm Pump Market Size By 2025?

The market for diaphragm pumps has seen a significant increase in size over the past few years, expanding from $6.58 billion in 2024 to an expected $7.13 billion in 2025, with a Compound Annual Growth Rate (CAGR) of 8.4%. Factors that have contributed to…

Emerging Trends Influencing The Growth Of The Diaphragm Coupling In Turbo Machin …

The Diaphragm Coupling In Turbo Machinery Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

How Big Is the Diaphragm Coupling In Turbo Machinery Market Size Expected to Be by 2034?

The Diaphragm Coupling In Turbo Machinery Market Report by The Business Research Company delivers a detailed…

Diaphragm Couplings Driving Turbo Machinery Efficiency

The Business Research Company recently released a comprehensive report on the Global Diaphragm Coupling In Turbo Machinery Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, The diaphragm…

Asia-Pacific Diaphragm Valves Market

Asia-Pacific Diaphragm Valves Market, By Type (Weir and Straight), Valve Type (Two-Way Valve, Forged-T Valve, Multi-Port Valve, Block-T Valve, Tandem Valve, Forged Tank Outlet Valve, Block Tank Outlet Valve, and Others), Controller (Manual, Pneumatic, Electric, Hydraulic, Others), End Connection (Flanged, Weld, Tri Clamp, and Others), Material (Metal, Rubber, Polytetrafluoroethylene (PTFE), Fluorine Plastic and Others), Size (Below 8", 8", 12", 14", 16", 18", 20" and Others, Body Material…

Diaphragm Hydrogen Compressors Market to Eyewitness Stunning Growth by 2027 Covi …

This detailed Industry Analysis, also known as a latest study, provides an overview of the industry in North America, Latin America, the Asia Pacific, and Europe. The research includes information on current market trends, prior accomplishments, and future possibilities. As a result, in this Diaphragm Hydrogen Compressors market report, it has all the major facts and figures. This Diaphragm Hydrogen Compressors market report, on the other hand, places great emphasis…