Press release

Acrylonitrile Styrene Acrylate Production Cost Analysis 2025: Industry Challenges, Competitive Landscape

Introduction:Acrylonitrile Styrene Acrylate (ASA) is a thermoplastic polymer known for its excellent weather resistance, UV stability, and durability. It's an amorphous terpolymer, meaning it's made from three different monomers: acrylonitrile (for chemical resistance and rigidity), styrene (for gloss and processing ease), and an acrylate rubber (for impact strength and weatherability). ASA is often used as a substitute for ABS (Acrylonitrile Butadiene Styrene) in outdoor applications, as it retains its color and mechanical properties much better when exposed to sunlight and moisture. It's commonly found in automotive exteriors, garden equipment, and outdoor furniture.

Setting up an ASA production plant involves several key steps. First, you'll need to secure the necessary raw materials: acrylonitrile, styrene, and butyl acrylate. The core of the plant is the polymerization process, typically a continuous mass polymerization or an emulsion polymerization system. You'll need reactors to mix and heat the monomers, followed by a devolatilization unit to remove unreacted monomers. The resulting polymer melt is then extruded into pellets. Quality control testing is crucial to ensure the final product meets specifications.

IMARC Group's report, titled "Acrylonitrile Styrene Acrylate Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up an acrylonitrile styrene acrylate production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/acrylonitrile-styrene-acrylate-manufacturing-plant-project-report/requestsample

Acrylonitrile Styrene Acrylate Industry Outlook 2025

The Acrylonitrile Styrene Acrylate (ASA) industry is poised for significant growth in 2025, driven by its exceptional weather resistance and durability. The demand for ASA is particularly strong in the automotive and construction sectors, where it's used for exterior components like car grilles and roofing materials that need to withstand outdoor exposure without degrading. Rapid industrialization in the Asia-Pacific region and a global push for sustainable materials and lighter, more fuel-efficient vehicles further fuel this expansion. Despite challenges like fluctuating raw material costs, the market continues to innovate with new bio-based and recyclable ASA formulations to meet evolving industry needs and environmental regulations.

Key Insights for Acrylonitrile Styrene Acrylate Production Plant Setup

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements, and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=24266&flag=C

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Buy Now: https://www.imarcgroup.com/checkout?id=24266&method=1911

Key Cost Components of Setting Up an Acrylonitrile Styrene Acrylate Plant

• Raw Materials: The largest operational cost includes styrene, acrylonitrile, and an acrylic ester elastomer. Prices for these can be volatile.

• Machinery and Equipment: A major capital expense, covering reactors, extruders, dryers, and control systems for the polymerization process. The level of automation directly impacts this cost.

• Infrastructure: Significant investment in land acquisition, civil construction for the plant and administrative buildings, and utilities like power and water supply.

• Labor: The ongoing cost of a skilled workforce for plant operations, maintenance, and management.

• Permits and Licenses: Regulatory costs to ensure compliance with environmental and safety standards.

Economic Trends Influencing Acrylonitrile Styrene Acrylate Plant Setup Costs 2025

• Raw Material Volatility: Expect fluctuating costs for key feedstocks like acrylonitrile and styrene, which are closely tied to crude oil and natural gas prices.

• Supply Chain & Logistics: Ongoing global supply chain challenges, including port congestion and trade disputes, will likely increase freight and import costs for equipment and materials.

• Geopolitical and Trade Tensions: Protectionist policies and tariffs between major economic regions can drive up import costs and favor localized production.

• Labor Costs: In some regions, a scarcity of skilled labor for chemical plant construction may increase wages and, consequently, project costs.

• Sustainability & Regulation: The push for green chemistry and stricter environmental regulations will necessitate investment in advanced technology to ensure compliance, adding to capital expenditure.

Challenges and Considerations for Investors

• Raw Material Price Volatility: ASA production relies on petrochemicals, so fluctuating crude oil prices can affect production costs and profit margins.

• Competition from Alternatives: ASA competes with other thermoplastics like ABS and polycarbonate, which may be more cost-effective or offer specific performance advantages for certain applications.

• Environmental Regulations: Stricter environmental rules and a push for sustainable materials may force manufacturers to invest in eco-friendly practices, increasing costs.

• End-User Demand Fluctuations: Demand for ASA is heavily tied to the automotive and construction industries, which can be sensitive to economic downturns and market shifts.

Conclusion

This report aims to serve as a practical guide for entrepreneurs, investors, and industrial planners exploring opportunities in acrylonitrile styrene acrylate production. By understanding the cost structure, market dynamics, and operational challenges, stakeholders can make informed decisions and devise sustainable strategies for entry and expansion in the sector.

About Us: IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Acrylonitrile Styrene Acrylate Production Cost Analysis 2025: Industry Challenges, Competitive Landscape here

News-ID: 4136969 • Views: …

More Releases from IMARC Services Private Limited

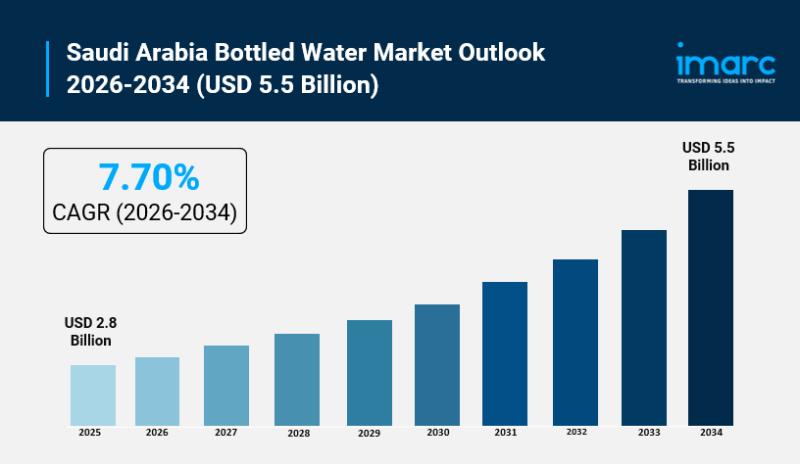

Saudi Arabia Bottled Water Market Set to Surge USD 5.5 Billion by 2034, Rising a …

Saudi Arabia Bottled Water Market Overview

Market Size in 2025: USD 2.8 Billion

Market Forecast in 2034: USD 5.5 Billion

Market Growth Rate 2026-2034: 7.70%

According to IMARC Group's latest research publication, "Saudi Arabia Bottled Water Market Size, Share, Trends and Forecast by Type, Distribution Channel, Packaging Size, and Region, 2026-2034", the Saudi Arabia bottled water market size was valued at USD 2.8 Billion in 2025. Looking forward, IMARC Group estimates the market to…

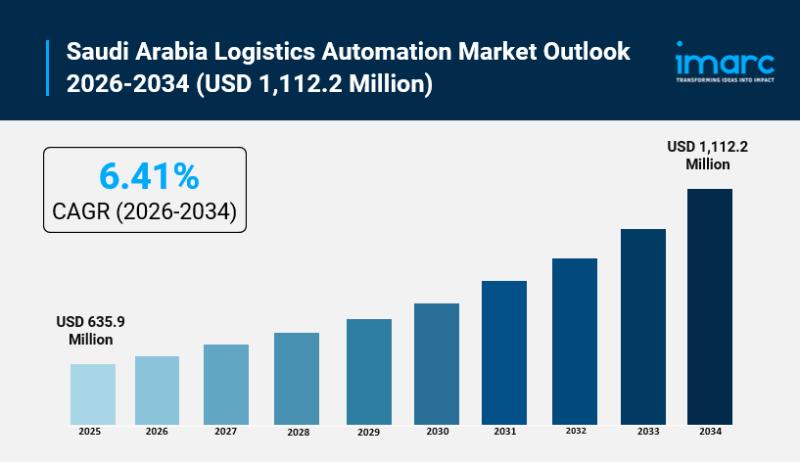

Saudi Arabia Logistics Automation Market Size to Worth USD 1,112.2 Million by 20 …

Saudi Arabia Logistics Automation Market Overview

Market Size in 2025: USD 635.9 Million

Market Forecast in 2034: USD 1,112.2 Million

Market Growth Rate 2026-2034: 6.41%

According to IMARC Group's latest research publication, "Saudi Arabia Logistics Automation Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", the Saudi Arabia logistics automation market size reached USD 635.9 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 1,112.2 Million by 2034, exhibiting…

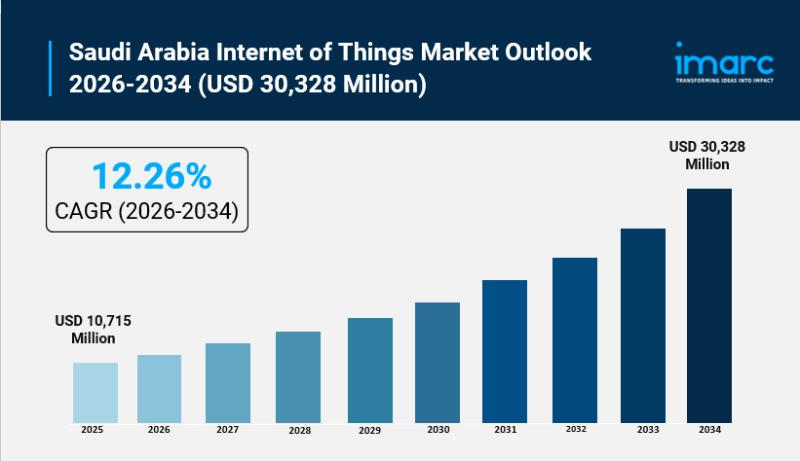

Saudi Arabia Internet of Things Market Set to Reach USD 30,328 Million by 2034 A …

Saudi Arabia Internet of Things Market Overview

Market Size in 2025: USD 10,715 Million

Market Forecast in 2034: USD 30,328 Million

Market Growth Rate 2026-2034: 12.26%

According to IMARC Group's latest research publication, "Saudi Arabia Internet of Things Market Size, Share, Trends and Forecast by Component, Application, Vertical, and Region, 2026-2034", The Saudi Arabia internet of things market size was valued at USD 10,715 Million in 2025 and is projected to reach USD 30,328…

Saudi Arabia Duty-Free and Travel Retail Market Projected to Reach USD 726.1 Mil …

Saudi Arabia Duty-Free and Travel Retail Market Overview

Market Size in 2025: USD 417.7 Million

Market Forecast in 2034: USD 726.1 Million

Market Growth Rate 2026-2034: 6.34%

According to IMARC Group's latest research publication, "Saudi Arabia Duty-Free and Travel Retail Market Size, Share, Trends and Forecast by Product Type, Distribution Channel, and Region, 2026-2034", the Saudi Arabia duty-free and travel retail market size reached USD 417.7 Million in 2025. Looking forward, IMARC Group expects…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…