Press release

Manganese Nitrate Production Cost Analysis 2025: Equipment, Raw Materials, and Investment Overview

Introduction:Manganese(II) nitrate, with the chemical formula Mn(NO3)2, is an inorganic salt that typically exists as a white crystalline solid. It is highly soluble in water and is most commonly found as a hydrate, such as the tetrahydrate, Mn(NO3)2⋅4H2O. This compound is an important precursor for producing manganese oxides, which are used in various industrial applications. Manganese nitrate is also utilized in agriculture as a fertilizer to supply manganese and nitrogen to plants, in the textile industry, and as a coloring agent for ceramics and porcelain.

Setting up a manganese nitrate production plant requires careful planning and a significant capital investment. The core process involves reacting manganese carbonate or a manganese oxide with nitric acid to produce manganese nitrate. Key requirements include a reliable source of raw materials (manganese ore, nitric acid), specialized equipment like reactors and filtration systems, and a site with a suitable infrastructure for utilities and waste management. A feasibility study is essential to assess market demand, raw material costs, and regulatory compliance. The total cost can vary widely based on the scale of the operation, from a small-scale facility to a large, industrial-level plant.

IMARC Group's report, titled "Manganese Nitrate Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a manganese nitrate production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/manganese-nitrate-manufacturing-plant-project-report/requestsample

Manganese Nitrate Industry Outlook 2025

The manganese nitrate industry in 2025 is poised for growth, driven by its diverse applications. It is a key precursor for manganese dioxide, a crucial component in the cathodes of lithium-ion batteries, essential for electric vehicles and energy storage. Additionally, manganese nitrate serves as a colorant in ceramics and glass, a catalyst in chemical processes, and a vital micronutrient in fertilizers, addressing crop deficiencies and improving agricultural yields. The push for cleaner energy and sustainable practices will continue to fuel demand for this versatile chemical.

Key Insights for Manganese Nitrate Production Plant Setup

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements, and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=19053&flag=C

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Buy Now: https://www.imarcgroup.com/checkout?id=19053&method=1911

Key Cost Components of Setting Up a Manganese Nitrate Plant

• Raw Materials: The largest operational expense, encompassing manganese carbonate, nitric acid, and other chemicals. Costs are subject to market volatility.

• Plant and Machinery: Capital expenditure for reactors, crystallizers, filtration systems, and other specialized processing equipment. This is a major upfront cost.

• Infrastructure: Costs for land acquisition, civil construction of the facility, and utility connections (water, power, gas).

• Labor and Staffing: Ongoing operational costs for skilled and unskilled labor, including engineers, technicians, and operators.

• Utilities and Energy: Expenses for electricity, water, and fuel required for the chemical processes and plant operations.

• Regulatory and Environmental Compliance: Costs for obtaining licenses, permits, and implementing waste treatment and pollution control systems to meet environmental standards.

Economic Trends Influencing Manganese Nitrate Plant Setup Costs 2025

• Raw Material Costs: Volatility in global manganese ore and nitric acid prices directly impacts production expenses. Supply chain disruptions and mining-related issues can lead to significant cost fluctuations.

• Energy Prices: High electricity and fuel costs are a major factor, as the manufacturing process is energy-intensive. Increasing energy prices raise operational expenditure.

• Financing and Interest Rates: Rising global interest rates make borrowing for plant construction more expensive, affecting the initial capital investment and return on investment timeline.

• Environmental Regulations: Stricter environmental and sustainability regulations necessitate investment in expensive pollution control systems, waste management, and permits, increasing setup costs.

Challenges and Considerations for Investors

• Market Volatility: Price fluctuations are a key risk due to its use in various industries like steel and batteries, which have their own market cycles.

• Supply Chain Risks: Manganese mining is concentrated in a few countries, creating geopolitical and logistical vulnerabilities.

• Environmental & Regulatory Concerns: Manganese mining and nitrate production face increasing scrutiny over environmental impact and health risks, leading to potential regulatory changes.

• Competition: The market for manganese nitrate faces competition from substitute materials and other forms of manganese.

• Limited Demand in Niche Markets: While demand is growing in sectors like EV batteries, the majority of manganese still goes to steel production.

Conclusion

This report aims to serve as a practical guide for entrepreneurs, investors, and industrial planners exploring opportunities in manganese nitrate production. By understanding the cost structure, market dynamics, and operational challenges, stakeholders can make informed decisions and devise sustainable strategies for entry and expansion in the sector.

About Us: IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Manganese Nitrate Production Cost Analysis 2025: Equipment, Raw Materials, and Investment Overview here

News-ID: 4135311 • Views: …

More Releases from IMARC Services Private Limited

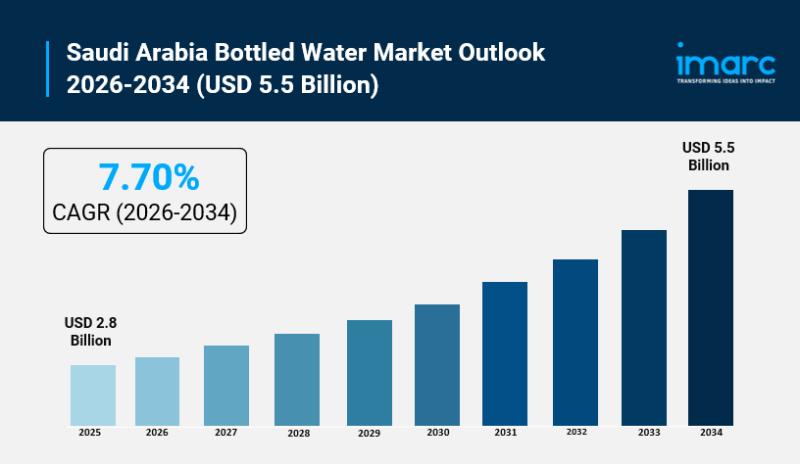

Saudi Arabia Bottled Water Market Set to Surge USD 5.5 Billion by 2034, Rising a …

Saudi Arabia Bottled Water Market Overview

Market Size in 2025: USD 2.8 Billion

Market Forecast in 2034: USD 5.5 Billion

Market Growth Rate 2026-2034: 7.70%

According to IMARC Group's latest research publication, "Saudi Arabia Bottled Water Market Size, Share, Trends and Forecast by Type, Distribution Channel, Packaging Size, and Region, 2026-2034", the Saudi Arabia bottled water market size was valued at USD 2.8 Billion in 2025. Looking forward, IMARC Group estimates the market to…

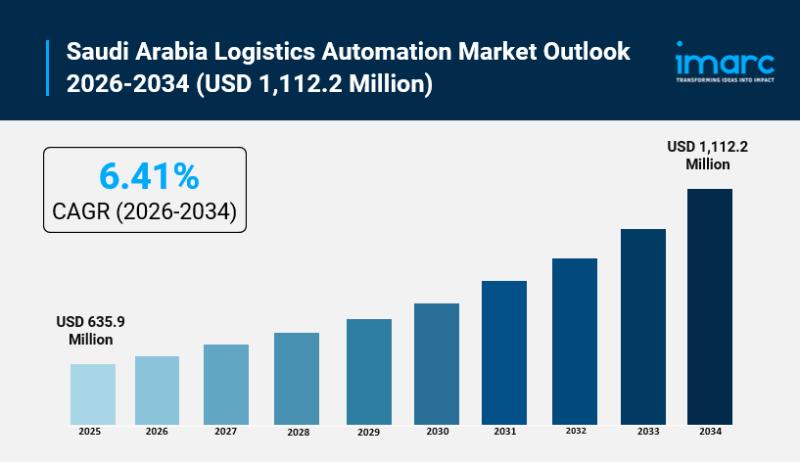

Saudi Arabia Logistics Automation Market Size to Worth USD 1,112.2 Million by 20 …

Saudi Arabia Logistics Automation Market Overview

Market Size in 2025: USD 635.9 Million

Market Forecast in 2034: USD 1,112.2 Million

Market Growth Rate 2026-2034: 6.41%

According to IMARC Group's latest research publication, "Saudi Arabia Logistics Automation Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", the Saudi Arabia logistics automation market size reached USD 635.9 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 1,112.2 Million by 2034, exhibiting…

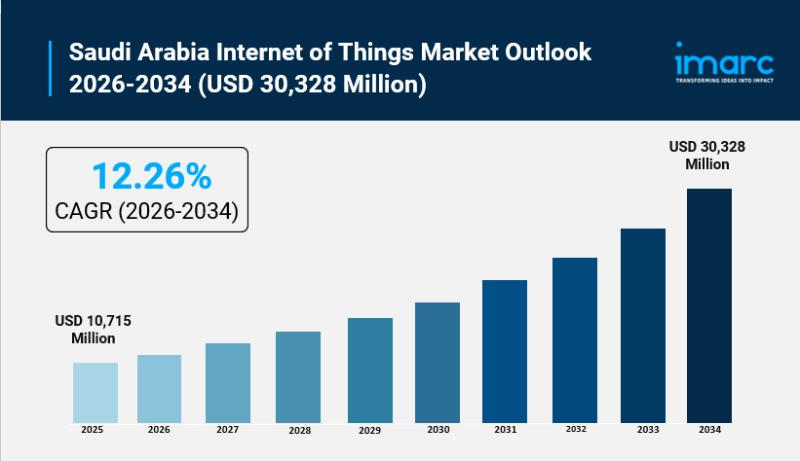

Saudi Arabia Internet of Things Market Set to Reach USD 30,328 Million by 2034 A …

Saudi Arabia Internet of Things Market Overview

Market Size in 2025: USD 10,715 Million

Market Forecast in 2034: USD 30,328 Million

Market Growth Rate 2026-2034: 12.26%

According to IMARC Group's latest research publication, "Saudi Arabia Internet of Things Market Size, Share, Trends and Forecast by Component, Application, Vertical, and Region, 2026-2034", The Saudi Arabia internet of things market size was valued at USD 10,715 Million in 2025 and is projected to reach USD 30,328…

Saudi Arabia Duty-Free and Travel Retail Market Projected to Reach USD 726.1 Mil …

Saudi Arabia Duty-Free and Travel Retail Market Overview

Market Size in 2025: USD 417.7 Million

Market Forecast in 2034: USD 726.1 Million

Market Growth Rate 2026-2034: 6.34%

According to IMARC Group's latest research publication, "Saudi Arabia Duty-Free and Travel Retail Market Size, Share, Trends and Forecast by Product Type, Distribution Channel, and Region, 2026-2034", the Saudi Arabia duty-free and travel retail market size reached USD 417.7 Million in 2025. Looking forward, IMARC Group expects…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…