Press release

TZR: A Custom Sheet Metal Fabrication Company Delivering Quality and Precision in Every Project

Discover high-quality custom sheet metal fabrication solutions with TZR Sheet Metal Co., Ltd. Serving industries like medical, automotive, 3D printing, and renewable energy globally. Expert team, advanced equipment, and rapid prototyping for guaranteed precision and quick turnaround times.Recommendation: * * * * *

To B or C: B2B

Main Markets: Global -Medical Devices, Automotive, 3D Printing, New Energy.

TZR: A Trusted Custom Sheet Metal Fabrication Company

Since its founding in 2013, TZR Sheetmetal Co., Ltd. has become a trusted leader in custom sheet metal fabrication, specializing in high-quality manufacturing of carbon steel, stainless steel, aluminum, copper, brass and extruded metal products. With more than 20 years of industry experience, the company has developed a solid reputation for delivering precision-driven metal components that meet stringent standards across various sectors.

TZR provides customized sheet metal fabrication solutions for industries such as automotive, medical, 3D printing and renewable energy, ensuring each project meets both functional and quality requirements. The company offers end-to-end manufacturing capabilities-from design engineering and prototyping to surface finishing and final assembly-all under one roof, streamlining the entire production process. The company holds ISO TUV ROHS engineering certifications, underscoring its commitment to delivering high-quality products that comply with international standards.

TZR's key strength lies in its highly skilled workforce, which enables the company to undertake a wide range of sheet metal custom fabrication projects with high precision and efficiency. This deep expertise, coupled with the company's unwavering commitment to quality, makes TZR a preferred choice for clients seeking reliable sheet metal solutions for their demanding needs.

Experienced Team Delivering Consistent Results

One of TZR's key strengths lies in its highly experienced team, which ensures that every project is completed to the highest standards of precision and quality.

Founder's Expertise: TZR was founded by Gary, who brings 24 years of experience in sheet metal production, having 14 years of working experience at Foxconn. This experience instills a commitment to the same high standards seen in major global companies, ensuring superior quality.

Expertise Across All Project Scales: TZR's team, including designers, engineers, technicians, and craftsmen, collectively brings over 10 years of experience in sheet metal fabrication. They are well-equipped to handle projects of varying complexity and scale, ensuring precision at every stage.

Global Reach and Client Success: Over the past decade, TZR has successfully served nearly 500 clients across 30 countries. The team's technical know-how ensures that all products, whether simple components or complex assemblies, meet rigorous standards.

This experienced team is the backbone of TZR's ability to deliver exceptional quality and reliable results.

Expertise in Custom Sheet Metal Design for Optimal Functionality

At TZR, sheet metal design is focused on more than just function-it's about optimizing every aspect of the part for performance, manufacturability, and long-term cost efficiency.

Professional Design Support: TZR's in-house design team includes two dedicated engineers who support clients from the earliest stages of development. With extensive experience, the team can transform anything from hand-drawn sketches into fully manufacturable components.

Design for Manufacturing (DFM) Excellence: Every project undergoes a thorough design review led by senior DFM specialists, some of them has over 30 years of industry experience. This process ensures every drawing is evaluated for production feasibility and performance. TZR's DFM analysis helps identify opportunities to reduce material usage, streamline assembly, and improve structural integrity.

Handling Complex Specifications Designs: TZR specializes in fabricating multi-plane, precision-bent parts and intricate geometries that demand tight tolerances. Through collaborative design processes, we ensure that each component is tailored to meet functional requirements while maintaining manufacturability.

Enhancing Performance and Appearance: We also offer 12 types of finishing options, including anodizing, powder coating, and polishing, integrated seamlessly during the design phase to optimize both performance and appearance.

This commitment to collaborative, engineering-led design results in components that are ready for scalable, high-precision production with reduced iteration cycles and improved performance.

State-of-the-Art Equipment for Efficiency

Efficiency and precision are at the core of TZR's manufacturing philosophy. To meet the demands of complex and high-volume production, TZR continuously upgrades its equipment and processes, ensuring every project meets industry-leading standards in speed, accuracy, and quality.

Advanced Machinery Line-Up: The facility is equipped with 3 times 6000W laser cutting machines, 1 times 12000W high-power laser cutter, and 9 bending machines supported by 2 robotic bending arms. These machines handle a wide range of materials-including steel, stainless steel, aluminum, copper, and brass-with high cutting precision and minimal deviation.

Integrated Automation Systems: Automated equipment such as 4 laser welding machines, 5 riveting machines, and 2 automatic deburring machines streamlines production while minimizing manual intervention. This leads to greater consistency and faster output.

This comprehensive setup-spread across an 11,000 m production floor and an 8,200 m coating area-enables TZR to deliver faster turnaround times, maintain quality across all production stages, and accommodate projects of varying complexity with ease.

Unmatched Precision and Quality Manufacturing

TZR stands out in precision manufacturing, thanks to its advanced equipment, skilled technicians, and strict quality control measures. Every product undergoes multiple stages of inspection, including first article inspection, in-process checks, and a 100% final inspection before packaging. This ensures consistent quality across all products.

Precision Tolerances: TZR adheres to strict GB standards. For flat parts, tolerances are as tight as plus-minus 0.010 inches, while multi-plane bent components are held to plus-minus 0.030 inches. Bending angle accuracy is maintained at plus-minus 1 degrees .

Flatness Control: The company ensures flatness within 0.2 mm, reducing alignment issues and the need for rework during assembly.

Material Handling: TZR accommodates sheet sizes up to 10 ft times 20 ft (3.05 m times 6.10 m) and thicknesses from 0.024" to 0.250", providing flexibility for various project sizes.

High Acceptance Rate: With a product acceptance rate above 98%, TZR delivers defect-free products that meet both industry standards and client specifications.

This commitment to precision and quality ensures that TZR consistently meets or exceeds customer expectations, making them a reliable partner in custom sheet metal manufacturing.

Fast Prototyping and Quick Turnaround Times

TZR's ability to rapidly produce prototypes and deliver quick turnaround times sets it apart from many of its competitors.

Responsive Support: Technical inquiries receive expert responses within 12 hours, and quotations are typically provided in under 2 hours.

Rapid Test Sampling: Test samples can be delivered within 24-48 hours, providing a quick and reliable way to evaluate form, fit, and function before scaling to mass production.

Flexible Lead Times: Standard samples delivered in 7-10 days. For larger production volumes, typical delivery time ranges from 7 to 20 days, depending on product complexity.

Optimized Workflow: Lean manufacturing processes and efficient supply chain coordination ensure stable quality and timely delivery, even for urgent or complex orders.

By combining rapid response with robust quality control, TZR helps reduce development cycles and ensures that projects move from prototype to production smoothly and efficiently.

Contact TZR for Your Custom Sheet Metal Fabrication Needs

For businesses seeking high-quality, precision-driven custom sheet metal fabrication services, TZR offers the expertise and capabilities to meet any requirement. Whether you're looking for custom parts for automotive, medical, 3D printing, or renewable energy applications, TZR has the experience, equipment, and design capabilities to deliver outstanding results. As an OEM sheet metal fabrication provider, TZR is ready to partner on your next project.

TZR's customer-centric approach, from initial design consultation to final delivery, ensures that each project is handled with care and professionalism. The team's deep knowledge of various industries allows them to deliver solutions that are not only functional but also cost-effective.

If you're ready to take your custom sheet metal project to the next level, contact TZR today to discuss your requirements and get a free quote. TZR's quick response times and commitment to excellence ensure that every project will be completed to your satisfaction.

For more information, please visit https://www.tzrmetal.com/ or contact + 8615817333574 / sales@goodsheetmetal.com

Media Contact

* Company Name: TZR Sheet Metal Co., Ltd.

* Email: sales@goodsheetmetal.com

* Phone: + 8615817333574

* Website: http://www.tzrmetal.com

Media Contact

Company Name: TZR Sheet Metal Co., Ltd

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=tzr-a-custom-sheet-metal-fabrication-company-delivering-quality-and-precision-in-every-project]

Address:No. 1, Hongling Road, Shenxiang Village, Qishi Town

City: Dongguan

State: Guangdong

Country: China

Website: http://www.tzrmetal.com

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release TZR: A Custom Sheet Metal Fabrication Company Delivering Quality and Precision in Every Project here

News-ID: 4123444 • Views: …

More Releases from ABNewswire

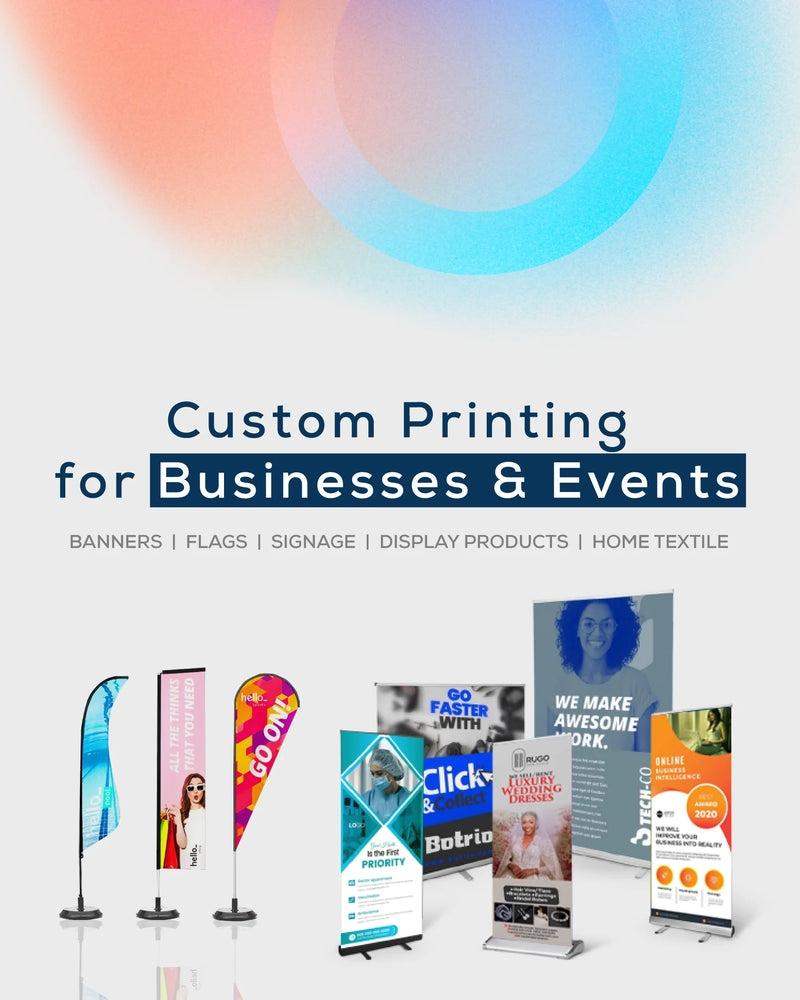

Digital Printing Service Support in Nazareth, PA Expanded by Sign Textile to Cov …

Sign Textile, a full-service digital printing company based in Nazareth, PA, has expanded its production and fulfillment support to businesses across Allentown, Philadelphia, Trenton, and Princeton. The company now offers direct access to custom outdoor signs, banner printing, vehicle wrap services, large format printing, and custom textile products across the broader Pennsylvania and New Jersey region. Orders are available online at signtextile.com.

Digital Printing Service in Nazareth, PA

Digital printing service [https://www.google.com/maps/place/Sign+Textile/@40.7385309,-75.3075722,794m/data=!3m2!1e3!4b1!4m6!3m5!1s0x89c4698e5e06db87:0xec2c645ea7b860f8!8m2!3d40.7385309!4d-75.3075722!16s%2Fg%2F11zk5427c5?hl=en-GB&entry=ttu&g_ep=EgoyMDI2MDIyMy4wIKXMDSoASAFQAw%3D%3D#:~:text=digital%20printing%20service]…

CoreAge Rx Raises the Bar on Medication Delivery With Free 2-Day Shipping, Tempe …

As GLP-1 demand continues to grow across the United States, CoreAge Rx delivers compounded Semaglutide and Tirzepatide directly to patients' doors with speed, discretion, and pharmaceutical-grade handling at no extra cost.

Image: https://www.abnewswire.com/upload/2026/02/97f63fd2a72edd923f925e1750cfbd14.jpg

CoreAge Rx, a LegitScript-certified telehealth weight management provider based in Wichita Falls, Texas, has built a medication delivery model that independent reviewers and patients consistently describe as one of the strongest in the GLP-1 telehealth space. Free 2-day shipping…

CoreAge Rx Builds Its GLP-1 Program Around Patient Support That Goes Beyond the …

With 24/7 access, rapid response times, dedicated care coordinators, and physician continuity throughout treatment, CoreAge Rx has set a new standard for what patient support looks like in telehealth weight management.

Image: https://www.abnewswire.com/upload/2026/02/79b953c7d7b86bdc830623292680666e.jpg

CoreAge Rx, a LegitScript-certified telehealth weight management provider based in Wichita Falls, Texas, has built a patient support model that independent reviewers consistently identify as one of the most comprehensive in the GLP-1 telehealth space. From 24/7 access across…

Healthy for Wellness Has Given an In-Depth Analysis of Why CoreAge Rx Is Better …

Image: https://www.abnewswire.com/upload/2026/02/850d8bbc779e7d12fe40cc6941e07be3.jpg

Healthy for Wellness has published an in-depth analysis [https://healthyforwellness.com/healthy-for-wellness-has-given-an-in-depth-analysis-of-why-coreage-rx-is-better-than-its-competitors/]examining why CoreAge Rx stands out within the growing GLP-1 prescription weight management space. The review evaluates the company's physician-supervised structure, telehealth-based accessibility, compounded GLP-1 medication program, and patient-centered model in comparison to other providers operating in the same category.

CoreAge Rx [https://www.coreagerx.com/] operates as a prescription-based telehealth program that provides compounded GLP-1 medications for eligible adults seeking medically supervised weight management…

More Releases for TZR

Leading Precision Sheet Metal Fabricator: How TZR Powers Custom High-Quality Sol …

Discover TZR's high-precision sheet metal fabrication services for medical, automotive, 3D printing, and new energy industries. From design to finishing, TZR delivers quality, speed, and reliability worldwide.

Recommendation: * * * * *

To B or C: B2B

Main Markets: Global -Medical Devices, Automotive, 3D Printing, New Energy.

TZR: Trusted Precision Sheet Metal Fabricator

As a recognized player in the global precision sheet metal market, TZR has built a reputation for delivering high-quality, custom precision…

Full throttle through life: Training at SIP Scootershop

At just 20 years old, Elvis Jueterbock has successfully completed his training as a technical product designer at SIP Scootershop - and with a very special background, a good dose of self-drive and a passion for Vespas that goes far beyond the job.

From student to designer

Immediately after graduating from Ignaz-Kögler-Gymnasium in Landsberg, Elvis went straight to SIP Scootershop. He had already done a vacation job in the call center -…