Press release

Rotary Hopper Market to Reach USD 1.27 Billion by 2035: Driven by Automation Leaders Siemens, GEA, FLSmidth & Hosokawa

The global rotary hopper market is on a robust growth trajectory, projected to reach an impressive USD 1.27 billion by 2035, up from USD 817.1 million in 2025. This significant expansion, at a Compound Annual Growth Rate (CAGR) of 4.7% over the forecast period, underscores the increasing global demand for efficient and automated material handling solutions. The industry's consistent upward trend, particularly evident in 2024, was largely fueled by the surging adoption of automation across manufacturing sectors, coupled with the critical need for precision in material handling within food processing, pharmaceutical, and packaging industries.Browse full Report Here: https://www.futuremarketinsights.com/reports/rotary-hopper-market

Innovation and Strategic Imperatives Propel Growth

The integration of IoT and AI-based monitoring systems has been a pivotal driver, empowering manufacturers to significantly enhance throughput and minimize costly downtime. Furthermore, escalating labor expenses and stringent regulatory mandates have compelled businesses to invest in sophisticated, sanitary rotary hopper solutions, especially in the highly regulated pharmaceutical and food & beverage sectors.

Looking ahead, the market will prioritize customizable and energy-efficient hoppers featuring advanced automation capabilities. Emerging industrial hubs, particularly in the Asia-Pacific region, are expected to be key demand drivers. A growing emphasis on sustainability will also steer manufacturers towards eco-friendly and recyclable product designs, shaping long-term industry patterns.

Competitive analysis reveals that companies embracing intelligent, energy-efficient, and sanitary material-handling equipment will gain a distinct advantage. Conversely, those relying on outdated technologies risk being outpaced in this evolving landscape.

Navigating the Competitive Landscape: Risks and Opportunities

Stakeholders in the rotary hopper market face a dynamic environment characterized by both significant opportunities and inherent risks.

Strategic Imperatives for Success

Accelerate Automation & Smart Technology Integration: Investing in AI-driven monitoring, IoT-enabled tracking, and predictive maintenance is paramount for operational efficiency and reduced downtime. Companies that lead in smart rotary hopper adoption will secure a competitive edge in precision material handling.

Align with Sustainability & Regulatory Trends: Developing eco-friendly, energy-efficient, and compliant solutions is crucial to meet evolving industry regulations, particularly in the food, pharma, and packaging sectors. Prioritizing sustainability will attract environmentally conscious clients and ensure long-term market positioning.

Expand Through Emerging Markets & Strategic Partnerships: Strengthening distribution networks in high-growth regions like Asia-Pacific and forging alliances with OEMs and automation providers will be vital. Mergers, acquisitions, or joint ventures with key players can accelerate market penetration and technological advancement.

Key Risks to Monitor

Supply Chain Disruptions: Fluctuations in raw material availability and global logistics constraints pose a medium probability but high impact risk, potentially leading to cost increases and production delays.

Regulatory Compliance Challenges: Stricter environmental and safety regulations carry a high probability of requiring costly modifications to existing products and processes, with a medium-high impact.

Technological Disruption & Competition: The rapid advancements in automation and smart systems present a medium-high probability and high impact risk, as traditional rotary hoppers could become obsolete, particularly affecting legacy players.

Stakeholder Priorities and Regional Divergence

A recent survey conducted in Q4 2024 with 500 rotary hopper market stakeholders across the USA, Western Europe, China, and India revealed fascinating insights into industry priorities and regional variances.

Key Priorities Globally:

Automation & Efficiency: 79% of stakeholders cited automation and throughput optimization as critical.

Regulatory Compliance: 84% emphasized the need to meet stringent industry regulations.

Durability & Maintenance: 71% prioritized high-durability materials to reduce lifecycle costs.

Regional Adoption of Advanced Technologies:

The USA leads with 58% of stakeholders utilizing AI-powered rotary hoppers.

Western Europe shows a strong preference (53%) for automated material flow control systems due to strict environmental laws.

China has seen 41% adoption of robotic-assisted loading/unloading systems, driven by high-volume manufacturing.

India lags, with 29% still relying on manual or semi-automated systems, citing cost barriers.

ROI Perception on Automation: 73% of stakeholders in the USA and Europe believe smart rotary hoppers justify higher upfront costs through long-term savings, while 46% in China and India remain cautious regarding ROI for high-tech solutions.

Material Preferences: Steel remains globally favored (66%), while Aluminum is preferred in Europe (42%) for lightweight, sustainable designs. Hybrid Steel-Aluminum (39%) offers a cost balance in Asia.

Market Dynamics by Region

United States and United Kingdom: Automation and Sustainability Drive Growth (CAGR ~5.2%)

Both the United States and the United Kingdom are set to experience a robust CAGR of approximately 5.2% from 2025 to 2035. In the U.S., increasing industrial automation, stringent OSHA and FDA standards, and the rising adoption of IoT-enabled hoppers for predictive maintenance are key drivers. Similarly, the UK's growth is fueled by automation investments, sustainability regulations aligning with the Net Zero Strategy, and strict FSA and CE marking specifications, particularly in the food and beverage sectors. Both regions face challenges from supply chain disruptions and labor shortages, but significant growth prospects lie in federal incentives for green manufacturing and investments in AI-based solutions.

France (CAGR 4.6%) and Germany (CAGR 4.9%): EU Regulations and Industry 4.0 Lead the Way

France and Germany demonstrate steady growth, driven by stringent EU regulations on sustainability and a strong focus on industrial automation. France's market is propelled by the EcoDesign Directive and key end-users in food and pharma adhering to ANSES regulations. Germany, a leader in Industry 4.0, benefits from strict CE and TÜV certifications, with strong demand from logistics, automotive, and pharmaceutical industries. Both nations prioritize sustainability, with Germany's Energiewende policy influencing carbon footprint reduction.

Italy (CAGR 4.4%) and Japan (CAGR 4.1%): Niche Applications and Efficiency Focus

Italy's rotary hopper market is driven by investments in packaging, food processing, and pharmaceuticals, with EU Machinery Directive and CE Marking regulations encouraging modernization. Japan sees growth stemming from an aging workforce, driving demand for compact, precision automation solutions. Both countries focus on niche applications and efficiency, with Japan emphasizing space-saving, multi-functional automation.

South Korea (CAGR 5.2%) and China (CAGR 5.5%): Rapid Automation and Industrial Expansion

South Korea and China are poised for significant growth, with CAGRs of approximately 5.2% and 5.5% respectively. South Korea's "Manufacturing Renaissance Vision 2030" and robust manufacturing base are driving the adoption of smart factory automation. China's "Made in China 2025" plan and rapid industrial expansion fuel high demand for automated material handling solutions. Both nations are investing heavily in AI-based automation and local R&D to enhance global competitiveness.

Australia & New Zealand (CAGR 4.8%): Resource-Driven and Sustainability-Conscious

The Australia and New Zealand rotary hopper industry is driven by resource-intensive sectors like mining, agriculture, and food processing. Strict safety and hygiene regulations from Safe Work Australia and FSANZ mandate automation. While facing high logistics costs, investments in mining automation and agritech are defining growth.

Segmentation Insights: Tailored Solutions for Diverse Needs

The market's segmentation by material type, capacity, and application reveals a drive towards specialized and efficient solutions. Grains, seeds, and animal feed will continue to drive demand, with an increasing focus on contamination-proof, dust-controlled, and aerated systems. The growing bakery and processed food industries will propel the need for hoppers with precise flow control and stainless steel or polymer-coated designs for hygiene.

Regarding capacity, small-capacity hoppers are gaining traction with localized production, while mid-capacity hoppers remain crucial for mid-sized manufacturers. Large-capacity hoppers will dominate bulk material handling in food processing, agriculture, and mining, requiring sophisticated automation and sensor-based systems.

Diverse applications, from animal feed production and food processing to grain trade operations and biofuel manufacturing, highlight the versatility of rotary hoppers. Emerging needs in mining, pharma, and agri-supply chains will further drive demand for purpose-built, highly specialized hoppers, including heavy-duty designs for ore handling and ultra-hygienic systems for pharmaceuticals.

Request a Sample Report Here: https://www.futuremarketinsights.com/reports/sample/rep-gb-17610

Competitive Landscape: Innovation and Collaboration Define the Future

The rotary hopper market remains competitive, with established players and emerging companies vying for market share through aggressive pricing, new product offerings, strategic alliances, and geographic expansions. Recent examples include MJE Livestock Equipment's partnership with Pearson Livestock Equipment for innovative squeeze chutes and Cattler Corporation's tripling of sales and integration with Micromachine, showcasing the industry's commitment to innovation and collaborative strategies. Leading companies like Schenck Process, Thyssenkrupp Industrial Solutions, and Coperion continue to offer advanced rotary hopper systems, emphasizing a future where automation, material technology, and regional adaptation will be paramount for sustained success.

Related Reports:

Centrifugal Pump Industry Analysis in Africa- https://www.futuremarketinsights.com/reports/centrifugal-pump-industry-analysis-in-africa

Bioliquid Heat and Power Generation Market- https://www.futuremarketinsights.com/reports/bioliquid-heat-and-power-generation-market

Critical Power and Cooling Market- https://www.futuremarketinsights.com/reports/critical-power-and-cooling-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Rotary Hopper Market to Reach USD 1.27 Billion by 2035: Driven by Automation Leaders Siemens, GEA, FLSmidth & Hosokawa here

News-ID: 4123355 • Views: …

More Releases from Future Market Insights

Global Digital Phase Shifters Market to Reach USD 2.9 Billion by 2035 as 5G, Sat …

The global digital phase shifters market is poised for substantial expansion, projected to grow from USD 847.0 million in 2025 to approximately USD 2.9 billion by 2035, registering a robust compound annual growth rate (CAGR) of 13.1%. This accelerated growth trajectory reflects the rapid proliferation of active phased-array antenna systems across next-generation telecommunications, satellite communications, defense radar, and automotive safety applications.

As wireless infrastructure evolves toward higher frequencies and greater signal…

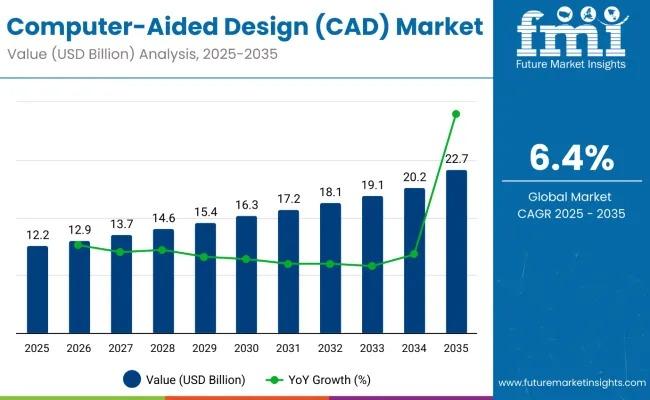

Global Computer-Aided Design Market to Reach USD 22.7 Billion by 2035 as AI-Driv …

The global computer-aided design (CAD) market is poised for steady expansion, with total industry value projected to grow from USD 12.2 billion in 2025 to USD 22.7 billion by 2035, reflecting a compound annual growth rate (CAGR) of 6.4% over the forecast period. This growth is driven by accelerating adoption of digital engineering technologies across key industries including automotive, aerospace, construction, healthcare, electronics, and advanced manufacturing. CAD software has become…

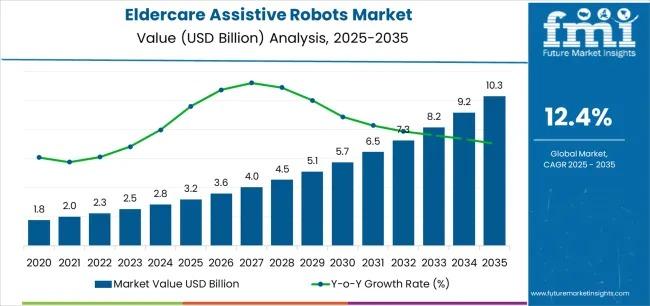

Global Eldercare Assistive Robots Market to Reach USD 10.2 Billion by 2035 as AI …

The global eldercare assistive robots market is entering a decisive expansion phase, projected to grow from USD 3.2 billion in 2025 to USD 10.2 billion by 2035, representing an absolute value increase of USD 7.0 billion and a total expansion of 218.8%. This sustained momentum reflects a robust compound annual growth rate (CAGR) of 12.4%, driven by accelerating demographic shifts, intensifying caregiver shortages, and rapid advancements in artificial intelligence, mobility…

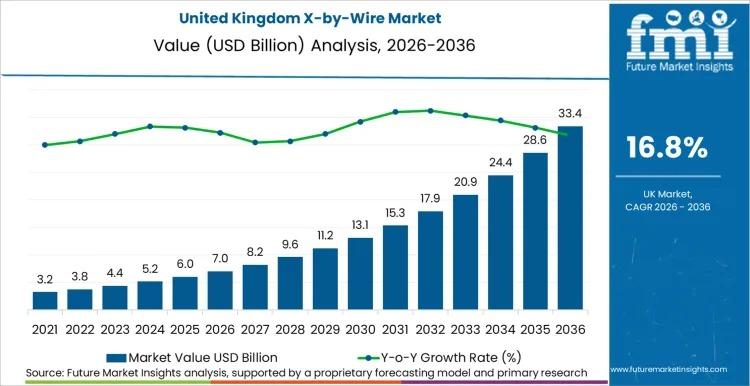

UK X-by-Wire Industry Set for Accelerated Expansion, Projected to Reach USD 33.4 …

The United Kingdom's X-by-Wire industry is poised for substantial expansion, with the market forecasted to grow from USD 7.0 billion in 2026 to USD 33.4 billion by 2036, registering a strong compound annual growth rate (CAGR) of 16.8%. This sustained growth trajectory reflects the automotive sector's transition toward software-defined vehicle architectures, electrified platforms, and precision electronic control systems that are rapidly replacing traditional mechanical linkages.

X-by-Wire technologies-encompassing throttle-by-wire, brake-by-wire, steer-by-wire, and…

More Releases for CAGR

[CAGR of 6.7%] Nanocoatings Market Size, Industry Share, CAGR, Regional Forecast …

The global Nanocoatings Market generated $10.7 billion in 2020, and is projected to reach $20.1 billion by 2030, growing at a CAGR of 6.7% from 2021 to 2030. The report provides an in-depth analysis of the top investment pockets, top winning strategies, drivers & opportunities, market size & estimations, competitive scenario, and wavering market trends.

Download sample PDF @ https://www.alliedmarketresearch.com/request-sample/2064

According to the report published by Allied Market Research,…

[CAGR of 5.3%] Pigments Market Size, Industry Share, CAGR, Regional Forecast, 20 …

A recent report by Allied Market Research provides a detailed analysis of the pigments market, highlighting its robust growth. The industry was valued at $27.2 billion in 2022 and is projected to surge to $45.4 billion by 2032, exhibiting an impressive CAGR of 5.3% from 2023 to 2032.

This research report identifies the growth drivers behind the market's expansion and delves into the market dynamics using advanced analytical frameworks…

Enzymes Market Expansion CAGR of 4.9% CAGR Anticipated 2025-2034

The Enzymes Market report is an in-depth examination of the global Enzymes Market's general consumption structure, development trends, sales techniques, and top nations' sales. The research looks at well-known providers in the global Enzymes Market industry, as well as market segmentation, competition, and the macroeconomic climate. A complete Enzymes Market analysis takes into account a number of aspects, including a country's population and business cycles, as well as market-specific microeconomic…

Waterproofing Membranes Market is Projected Grow at CAGR of 8% CAGR by 2033

The waterproofing membranes market is anticipated to witness a Compound Annual Growth Rate (CAGR) of 8.0% over the forecast period. By 2023, the estimated market value for waterproofing membranes is substantial, reaching US$ 31.5 billion.

These waterproofing materials comprise thin, impermeable membranes designed to collaborate with asphalt, providing a protective shield for the structural integrity of buildings. The asphalt component in these membranes acts as a safeguard, preserving the underlying membrane…

Electric Bed Market CAGR, Size, Share Grow USD 2,063 Million by 2030 CAGR 13.70%

Global electric bed market size is expected to be worth roughly USD 2,063 million by 2030, growing at a CAGR of more than 13.7% during the projected timeframe of 2022-2030, according to Ameco Research

A significant portion of the population over the age of 60, who often have reduced immunity levels and are more susceptible to neurological disorders, cardiac issues, tumors, and spinal cord compression, is anticipated to have a substantial…

Pediatric Radiology Market Size will Grow at CAGR 7.7% CAGR during 2017-2026

Pediatric Radiology Market:Overview

The pediatric radiology market is likely to register robust growth in the near future. Chronic illnesses among children including neurological disorders such as ADHD are on the rise. According to the US labor bureau, the demand for pediatrician is expected to grow by 24% on average by 2020. This is the highest average growth among all professionals in the United States.

Despite challenges such as training for new…