Press release

Chemical Mechanical Polishing - Specifications and Industry Applications

The chemical-mechanical polishing (CMP) is often involved with producing smooth surfaces by chemical reaction, especially works in the industry of semiconductor manufacturing. Lonnmeter [https://www.lonnmeter.com/], a trusted innovator with over 20 years of expertise in inline concentration measurement, offers state-of-the-art non-nuclear density meters [https://www.lonnmeter.com/density-meters/] and viscosity sensors to address the challenges of slurry management.Image: https://www.lonnmeter.com/uploads/CMP1.png

The Importance of Slurry Quality and Lonnmeter's Expertise

The chemical mechanical polishing slurry is the backbone of the CMP process, determining the uniformity and quality of surfaces. Inconsistent slurry density or viscosity can lead to defects like micro-scratches, uneven material removal, or pad clogging, compromising wafer quality and increasing production costs. Lonnmeter, a global leader in industrial measurement solutions, specializes in inline slurry measurement to ensure optimal slurry performance. With a proven track record of delivering reliable, high-precision sensors, Lonnmeter has partnered with leading semiconductor manufacturers to enhance process control and efficiency. Their non-nuclear slurry density meters and viscosity sensors provide real-time data, enabling precise adjustments to maintain slurry consistency and meet the stringent demands of modern semiconductor manufacturing.

Over two decades of experience in inline concentration measurement, trusted by top semiconductor firms. Lonnmeter's sensors are designed for seamless integration and zero maintenance, reducing operational costs.Tailored solutions to meet specific process needs, ensuring high wafer yields and compliance.

The Role of Chemical Mechanical Polishing in Semiconductor Manufacturing

Chemical mechanical polishing (CMP), also referred to as chemical-mechanical planarization, is a cornerstone of semiconductor manufacturing, enabling the creation of flat, defect-free surfaces for advanced chip production. By combining chemical etching with mechanical abrasion, the CMP process ensures the precision required for multi-layered integrated circuits at nodes below 10nm. The chemical mechanical polishing slurry, composed of water, chemical reagents, and abrasive particles, interacts with the polishing pad and wafer to remove material uniformly. As semiconductor designs evolve, the CMP process faces increasing complexity, requiring tight control over slurry properties to prevent defects and achieve the smooth, polished wafers demanded by Semiconductor Foundries and Materials Suppliers.

The process is essential for producing 5nm and 3nm chips with minimal defects, which ensures flat surfaces for accurate deposition of subsequent layers. Even minor slurry inconsistencies can lead to costly rework or yield loss.

Image: https://www.lonnmeter.com/uploads/CMP-schematic.jpg

Challenges in Monitoring Slurry Properties

Maintaining consistent slurry density and viscosity in the chemical mechanical polishing process is fraught with challenges. Slurry properties can vary due to factors such as transport, dilution with water or hydrogen peroxide, inadequate mixing, or chemical degradation. For instance, particle settling in slurry totes can cause higher density at the bottom, leading to non-uniform polishing. Traditional monitoring methods like pH, oxidation-reduction potential (ORP), or conductivity are often inadequate, as they fail to detect subtle changes in slurry composition. These limitations can result in defects, reduced removal rates, and increased consumable costs, posing significant risks for semiconductor equipment manufacturers and CMP services providers. Compositional changes during handling and dispensing affect performance. Sub-10nm nodes require tighter control over slurry purity and blend accuracy. pH and ORP show minimal variation, while conductivity varies with slurry aging. Inconsistent slurry properties can increase defect rates by up to 20%, per industry studies.

Lonnmeter's Inline Sensors for Real-Time Monitoring

Lonnmeter addresses these challenges with its advanced non-nuclear slurry density meters and viscosity sensors [https://www.lonnmeter.com/viscometers/], including viscosity meter inline for in-line viscosity measurements and the ultrasonic density meter for simultaneous slurry density and viscosity monitoring. These sensors are designed for seamless integration into CMP processes, featuring industry-standard connections. Lonnmeter's solutions offer long-term reliability and low maintenance for its robust construction. Real-time data enables operators to fine-tune slurry blends, prevent defects, and optimize polishing performance, making these tools indispensable for Analysis and Testing Equipment Suppliers and CMP Consumables Suppliers.

Benefits of Continuous Monitoring for CMP Optimization

Continuous monitoring with Lonnmeter's inline sensors transforms the chemical mechanical polishing process by delivering actionable insights and significant cost savings. Real-time slurry density measurement and viscosity monitoring reduce defects like scratches or over-polishing by up to 20%, according to industry benchmarks. Integration with PLC system enables automated dosing and process control, ensuring slurry properties stay within optimal ranges. This leads to a 15-25% reduction in consumable costs, minimized downtime, and improved wafer uniformity. For Semiconductor Foundries and CMP Services Providers, these benefits translate to enhanced productivity, higher profit margins, and compliance with standards like ISO 6976.

Common Questions About Slurry Monitoring in CMPWhy is slurry density measurement essential for CMP?

Slurry density measurement ensures uniform particle distribution and blend consistency, preventing defects and optimizing removal rates in the chemical mechanical polishing process. It supports high-quality wafer production and compliance with industry standards.

How does viscosity monitoring enhance CMP efficiency?

Viscosity monitoring maintains consistent slurry flow, preventing issues like pad clogging or uneven polishing. Lonnmeter's inline sensors provide real-time data to optimize the CMP process and improve wafer yields.

What makes Lonnmeter's non-nuclear slurry density meters unique?

Lonnmeter's non-nuclear slurry density meters offer simultaneous density and viscosity measurements with high accuracy and zero maintenance. Their robust design ensures reliability in demanding CMP process environments.

Real-time slurry density measurement and viscosity monitoring are critical for optimizing the chemical mechanical polishing process in semiconductor manufacturing. Lonnmeter's non-nuclear slurry density meters and viscosity sensors provide Semiconductor Equipment Manufacturers, CMP Consumables Suppliers, and Semiconductor Foundries with the tools to overcome slurry management challenges, reduce defects, and lower costs. By delivering precise, real-time data, these solutions enhance process efficiency, ensure compliance, and drive profitability in the competitive CMP market. Visit Lonnmeter's website [https://www.lonnmeter.com/density-meters/] or contact their team today to discover how Lonnmeter can transform your chemical mechanical polishing operations.

Media Contact

Company Name: SHENZHEN LONNMETER GROUP

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=chemical-mechanical-polishing]

Country: China

Website: https://www.lonnmeter.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Chemical Mechanical Polishing - Specifications and Industry Applications here

News-ID: 4121092 • Views: …

More Releases from ABNewswire

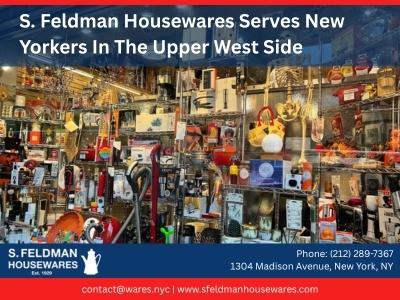

S. Feldman Housewares Serves New Yorkers In The Upper West Side With Kitchen Sup …

For 96 years, S. Feldman Housewares has been a trusted resource for Manhattan families seeking quality kitchen supplies, home goods, and hardware. Located at 1304 Madison Avenue, this fourth-generation, family-owned store serves customers throughout the city, including Upper West Side residents who appreciate shopping at a trusted hardware store Upper West Side families have relied on for nearly a century.

New York, NY - February 23, 2026 - S. Feldman Housewares…

Country Creek Animal Hospital Broadens Veterinarian Offerings Across Allen, TX, …

Country Creek Animal Hospital remains committed to providing dependable, locally focused care for pets and their owners throughout Allen and Plano. Through steady service growth and a focus on accessibility, Country Creek Animal Hospital continues to support community trust, reliable care standards, and meaningful relationships with the families it serves.

Introduction: Expanding Veterinarian Care in Allen, TX

Country Creek Animal Hospital continues to strengthen its role as a dependable veterinarian [https://www.countrycreekvets.com/#:~:text=The%20best-,veterinarian,-in%20Allen%2C%20TX] provider…

Country Creek Animal Hospital Strengthens Veterinarian Support in Allen, TX, Ext …

Country Creek Animal Hospital continues to support pet owners across Allen and Frisco by focusing on dependable care, consistent service coverage, and community-centered values. Through thoughtful growth and operational improvements, Country Creek Animal Hospital remains dedicated to providing reliable veterinary support that meets local needs while maintaining the trust of the families it serves.

Introduction: Expanding Vet Clinic Support in Allen, TX

Country Creek Animal Hospital continues to reinforce its role as…

Kids Dentist in Las Vegas and Centennial Offers Pain-Free, Needle-Free Laser Den …

Desert Kids Dental, led by pediatric dentist Dr. Sandra Thompson, is redefining the dental experience for children in Centennial and Las Vegas by offering advanced Solea Registered Laser dentistry, a modern technology designed to deliver truly pain-free and needle-free dental care. As a trusted Kids Dentist serving local families, Desert Kids Dental continues to focus on comfort, efficiency, and positive experiences for children of all ages.

For many children and parents…

More Releases for CMP

CMP Materials for Semiconductor Market Share Driven by CMP Slurry and Widespread …

CMP Materials for Semiconductor Market Size

The global market for CMP Materials for Semiconductor was valued at US$ 3701 million in the year 2024 and is projected to reach a revised size of US$ 5657 million by 2031, growing at a CAGR of 6.3% during the forecast period.

View sample report

https://reports.valuates.com/request/sample/QYRE-Auto-14V14904/Global_CMP_Materials_for_Semiconductor_Market_Research_Report_2023

The CMP (Chemical Mechanical Planarization) Materials for Semiconductor market is witnessing consistent growth as global chip manufacturers pursue higher precision and yield…

Global CMP Pads Conditioning Disk Market Size by Application, Type, and Geograph …

According to Market Research Intellect, the global CMP Pads Conditioning Disk market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

Due to rising demand in the semiconductor production industry, the market for CMP (Chemical Mechanical Planarization)…

Colloidal Silica For CMP Slurry Market

Colloidal Silica For CMP Slurry Market analysis report has recently added which helps to make informed business decisions. This research report further identifies the market segmentation along with their sub-types. The Global Colloidal Silica For CMP Slurry Market is expected to reach at a huge CAGR during the forecast period. Various factors are responsible for the market's growth, which are studied in detail in this research report.

The report envelops a…

SiC CMP Slurry Market 2022 | Detailed Report

This report offers a detailed view about the challenging landscape of the international market. The exact and innovative information gave through this report helps organizations with getting mindful of the kinds of consumers, buyer's demand and preferences, their perspective, their purchasing aims, their reaction to a specific item, and their different tastes about the certain item already prevailing in the SiC CMP Slurry market. It includes a point-by-point illustration of…

CMP Slurry Filters Market Competitive Insights with Global Outlook 2021-2027|Pal …

Los Angeles United States: The global CMP Slurry Filters market is researched with great precision and in a comprehensive manner to help you identify hidden opportunities and become informed about unpredictable challenges in the industry. The authors of the report have brought to light crucial growth factors, restraints, and trends of the global CMP Slurry Filters market. The research study offers complete analysis of critical aspects of the global CMP Slurry…

CMP Slurry Market Forecast to 2026- Analysis of CMP Slurry Industry by Manufactu …

CMP Slurry market report provides key insights about industry including market drivers, restraints, opportunities, new product launches or approval, market trends, regional outlook, and competitive strategy adopted by key players. CMP Slurry market report explains potential revenue opportunities across different segments, sub segments and explains attractive investment proposition matrices for the market.

Chemical mechanical polishing (CMP) is a process of smoothing surfaces with the combination of chemical and mechanical forces. It…