Press release

On a mission: producing safe food

Fresh meat for consumers: Gases supplied by Messer ensure the hygienic and quality-preserving production of meat products.

on air: Mr Kolar, you set very high quality standards in the manufacture of meat products. How does the application of gases assist you in this objective?

Igor Kolar: We use gases at various stages in our production process. Our fresh sausage meat is packed in an inert-gas atmosphere. This means that we carefully regulate the composition of the atmosphere in the packaging to avoid undesirable influences, such as bacterial infection or mould. This necessitates the application of a precisely-defined mixture of nitrogen and oxygen. In the production of our Ćevapčići meatballs, which are made from mince, we use liquid carbon dioxide for cooling the meat in the mixer. The carbon dioxide is fed directly into the mixer which rapidly lowers the temperature and protects the product from the heat generated during mixing, thus keeping it fresh. As no cooling water is required, the mince retains a low water content.

on air: What criteria do you use to select your preferred suppliers, and why did you opt for Messer?

Igor Kolar: In order to remain competitive and successful on the European market we focus carefully not only on maintaining product quality, but also on nurturing a partnership with our suppliers. We select suppliers commanding extensive experience in implementing new technologies on the European market. We build up successful partnerships based on the principle of mutual benefit. Only by optimising the manufacturing process can we acquire the flexibility to offer our customers new types of products. Last summer, for example, we launched “Ćevapčići kebabs” onto the market – which will mean a lot less sticky fingers at the next family barbecue!

on air: Mr Lukač, as a supplier, how would you describe the nature of your cooperation with Panvita?

Danilo Lukač: As a supplier of gases we know exactly how the properties of our products can influence and protect the fine quality of foodstuffs. However, each and every technical advancement in the production process must be coordinated with our colleagues at Panvita. We engage in regular discussion over the various technical issues, inspect the production halls and have become closely acquainted with the manufacturing processes. Although a new development may require only minimal technical effort, it can have a huge impact – and this requires excellent cooperation.

on air: Mr Kolar, what importance do you attach to quality control on the part of the suppliers?

Igor Kolar: Of course, certification assumes a crucial role in the production of foodstuffs, particularly in the meat-processing industry. The gases supplied to us by Messer are certified according to HACCP – as are our raw materials. HACCP stands for “Hazard Analysis and Critical Control Point”, which, in practice, means that product traceability must be guaranteed at all times across the entire production and supply chain. We are delighted to be able to provide our customers with this safety guarantee. As one of only a handful of companies in Slovenia, we are also certified under the international foodstuffs standards. However, the most important factor for us is the award from the Ministry for Agriculture, Forestry and Foodstuffs in recognition of the quality of our fresh meat products. We are proud of this.

16,000 tonnes of fresh meat annually

The brand name Skupina Panvita encompasses the three interrelated sectors of agriculture, meat and meat products, as well as energy. The production of meat under the company name Panvita MIR has its roots in the town of Gornja Radgona, near Maribor. Founded in 1922, the small company has grown into one of Slovenia’s leading meat processors.

Panvita MIR is the only meat processing enterprise in Slovenia certified to process both white and red meat, which is supplied by the company’s own pigbreeding plant and poultry farms. Each year Panvita MIR brings 16,000 tonnes of fresh meat and other meat products onto the market. The company cooperates with all the leading food-store chains in Slovenia and a number of major retailers across the former Yugoslavia and the European Union. 15 per cent of the entire production output is sold abroad. In line with its corporate mission statement, the company is committed to the environmentally friendly production of foodstuffs.

Messer Group GmbH

Vice President

Corporate Communications

Diana Buss

Gahlingspfad 31

47803 Krefeld

Phone: +49 (0) 2151 7811-251

Fax: +49 (0) 2151 7811-598

Email: diana.buss@messergroup.com

www.messergroup.com

Messer is a leading industrial gas enterprise with more than 60 companies operating in over 30 countries in Europe and Asia as well as in Peru, including non-consolidated companies. The international activities are headed from Frankfurt/Main, while the central technical functions of Logistics, Engineering and Production as well as Applied Technology are controlled from Krefeld. The Messer Group had more than 4,400 employees in 2007. From acetylene to xenon, the Messer Group has one of the most diverse product portfolios on the market – it produces industrial gases such as oxygen, nitrogen, argon, carbon dioxide, hydrogen, helium, shielding gases for welding, specialty gases, medical gases and many different gas mixtures.

The Messer Group has state-of-the-art research and competence centers in which it develops applied technologies for the use of gases in almost every sector of industry, in food technology and environmental technology, medicine as well as research and science.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release On a mission: producing safe food here

News-ID: 41086 • Views: …

More Releases from Messer Group GmbH

Messer consolidates its position in China

Three new air separation units opened in western China

In March, the largest privately managed industrial gases specialist, Messer, put three new air separation units into operation in the western Chinese province of Sichuan. The total investment comes to approximately 80 million euros. Two of the three new facilities will each produce around 30,000 normal cubic metres of air gases such as argon, oxygen and nitrogen per hour, and will…

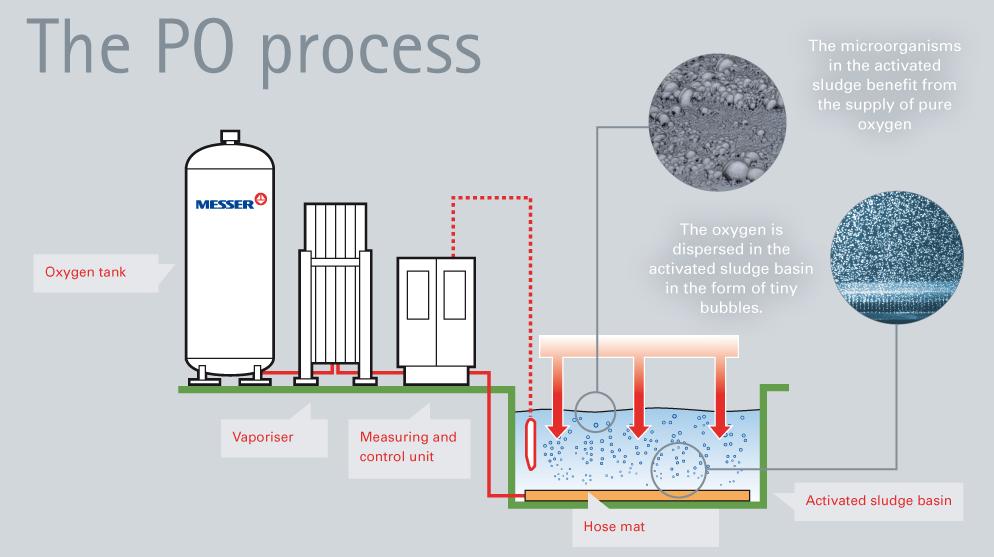

Pure air thanks to pure oxygen

Messer, the largest privately run industrial gases specialist, is supplying Südzucker AG in Ochsenfurt, Germany, with pure oxygen in order to eliminate oxygen deficiency in settling ponds – and to prevent recurrences in the future. Oxygen injection here supports the natural purification processes.

The large quantities of water which Südzucker uses to wash beets are treated in a wastewater treatment plant. The wastewater is stored temporarily in settling ponds. Aerobic bacteria…

Blechexpo 2011 in Stuttgart – Industrial gases specialist Messer showcases its …

Messer will be showcasing its diverse product portfolio of welding and cutting gases at Blechexpo in Stuttgart from 6 to 9 June 2011. At Stand 7309 in Hall 7, the largest privately run industrial gases specialist will be provid-ing information on its range of shielding gases for welding, giving both lower-volume users and bulk customers valuable insight into these product lines.

Insight into the Messer World

The 270 m2 Messer World stand…

Messer consolidates market position in Austria

On 2 May 2011, Messer Austria acquired the gas business of Sapio Gase GmbH.

Messer Austria, the Austrian subsidiary of Messer, the largest privately run specialist for industrial gases, intends to consolidate its market position in Upper Austria through its purchase of the gas business of Sapio Gase GmbH. The transaction was completed on 2 May 2011. Sapio Gase, a subsidiary of SAPIO, an Italian company, has a strong presence in…