Press release

Global Metal Casting Market: Overview, Key Drivers, Competitive Landscape, Segmentation, and Regional Analysis (2023-2033)

According to a research report published by Spherical Insights & Consulting, The Global Metal Casting Market Size to grow from USD 151.9 billion in 2023 to USD 213.8 billion by 2033, at a Compound Annual Growth Rate (CAGR) of 3.48% during the Forecast period.The Metal Casting global market research studies offer an in-depth analysis of current industry trends, development models, and methodology. Production processes, development platforms, and the actual product models are some of the variables that have a direct impact on the market. The aforementioned characteristics can drastically vary in response to even minor changes in the product profile. The study provides a thorough explanation of each of these elements of Advanced Materials.

Request To Download Free Sample copy of the report: https://www.sphericalinsights.com/request-sample/8923

Market Overview

The market for metal casting is expanding steadily due to increased demand from sectors such industrial machinery, automotive, aerospace, and construction. Melted metal is poured into a mold to form intricate forms in a technique known as metal casting, which is popular because it is economical and effective for large-scale manufacturing. The market is expanding as a result of the growing trend toward lightweight and high-performance materials, especially in the automobile industry for fuel economy and pollution reduction.

Furthermore, improvements in casting technology, like as automation and 3D printing, are improving accuracy and lowering manufacturing costs. However, obstacles including expensive initial investment costs and environmental concerns could limit progress. Due to increased infrastructure investments and increasing industrialization, the Asia-Pacific region-led by China and India-dominates the market.

The global market is Metal Casting growth due to:

• Demand from Industrial and Automotive Sectors: Increased production of cars, aircraft, and construction equipment requires cast components that are durable, lightweight, and precise.

• Shift Toward Lightweight Materials: Especially in the automotive and aerospace sectors, where efficiency and emission reduction are key priorities.

• Technological Advancements:

• Automation and Robotics are enhancing production speed and reducing labor costs.

• 3D Printing (Additive Manufacturing) is revolutionizing mold design and prototyping, leading to better accuracy and reduced material waste.

• Rapid Industrialization and Urbanization in emerging markets, particularly in Asia-Pacific, led by China and India, is boosting infrastructure projects and manufacturing demand.

Buy Now this report: https://www.sphericalinsights.com/checkout/8923

Leading players of Metal Casting Market including:

• POSCO

• Dynacast

• Arconic

• Ryobi Limited

• Endurance Technologies Limited

• Alcast Technologies

• UNI Abex

• MES, Inc.

• CALMET

• Hitachi, Ltd.

Market Challenges

1. Stringent Environmental Regulations

Metal casting is inherently energy-intensive and emission-heavy, especially when using fossil fuels and older furnace technologies.

• Compliance often requires costly upgrades to filtration systems, waste management, and emissions monitoring.

• Foundries that fail to modernize may face penalties, plant closures, or brand damage.

2. Volatility in Raw Material Prices

The prices of key inputs-such as iron ore,

steel, aluminum, coke, and copper-are highly cyclical and vulnerable to geopolitical tensions, trade restrictions, and demand-supply shocks.

• This unpredictability strains profit margins and impacts planning for manufacturers.

• Smaller foundries especially struggle with hedging and bulk procurement, leading to cost disadvantages.

3. High Energy Consumption & Operating Costs

Energy accounts for a major share of production costs, particularly in melting and molding processes.

• With rising global electricity and fuel costs, operating expenses continue to rise.

• Energy inefficiencies in older plants hinder competitiveness.

4. Skilled Labor Shortage

The casting industry faces a global shortfall of trained metallurgists, CNC operators, mold designers, and foundry engineers.

• The physically demanding and hazardous nature of casting work deters younger workers.

• Talent gaps limit capacity expansion, innovation, and quality control in many regions.

5. Capital-Intensive Modernization Requirements

Adoption of automated casting systems, robotics, real-time quality inspection, and 3D printing requires significant investment.

• Many SMEs (Small and Medium Enterprises) cannot afford the transition, creating a competitive divide between large and small players.

• Without modernization, production inefficiencies and defect rates remain high.

6. Waste Management and Recycling Complexity

Foundries generate significant solid and hazardous waste, including used sand, slag, and chemical residues.

• Managing and recycling these materials compliantly is costly and often underregulated in developing economies.

• The pressure to reduce waste intensity and increase circularity is growing across industries.

Research Objectives

• To Analyze Current Market Trends and Growth Drivers

Identify the key factors fueling the growth of the metal casting industry, including demand across automotive, aerospace, construction, and heavy machinery sectors.

Evaluate the impact of material preferences (e.g., aluminum, cast iron) and lightweighting trends.

• To Estimate the Market Size and Forecast Future Growth (2023-2033)

Quantify the global and regional market value in USD and project compound annual growth rates (CAGR).

Segment the market by material type, casting process, application, and geography.

• To Examine Key Market Challenges and Restraints

Investigate the effects of environmental regulations, energy consumption, raw material volatility, and labor shortages on industry performance.

Assess barriers to technology adoption and modernization, especially among SMEs.

• To Analyze Regional Market Dynamics

Explore country-level opportunities and risks, with a focus on Asia-Pacific, North America, and Europe.

Understand regional differences in production capacity, end-user industries, and regulatoryenvironments.

• To Assess Technological Advancements and Innovations

Study the integration of automation, Industry 4.0, AI, and 3D printing into casting processes.

Evaluate how innovation is influencing quality control, cost-efficiency, and sustainability.

• To Profile Key Players and Competitive Landscape

Identify leading manufacturers and suppliers, their market share, strategic moves, and R&D investments.

Analyze mergers, acquisitions, and partnerships shaping the global foundry market.

Recent Market Developments

• In July 2023, the American Foundry Society (AFS) announced the launch of the AM for Metal Casting program, designed to enhance the adoption of additive manufacturing in metal casting. This initiative targets metal casters seeking to improve their products and processes through advanced additive manufacturing technologies.

Access Full Report: https://www.sphericalinsights.com/reports/metal-casting-market

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Metal Casting Market, Material Type Analysis

• Cast Iron

• Aluminum

• Stainless Steel

• Zinc

• Magnesium

Metal Casting Market, Process Analysis

• Sand Casting

• Die Casting

• Shell Mold Casting

• Gravity Casting

• Vacuum Casting

Metal Casting Market, End Use Analysis

• Automotive & Transportation

• Building & Construction

• Mining

• Equipment & Machine

• Consumer Goods

Regional Segment Analysis of the Metal Casting Market

• North America (U.S., Canada, Mexico)

• Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

• Asia-Pacific (China, Japan, India, Rest of APAC)

• South America (Brazil and the Rest of South America)

• The Middle East and Africa (UAE, South Africa, Rest of MEA)

What's covered in the report?

1. Overview of the Inspection Metal Castingmarket.

2. The current and forecasted regional (North America, Europe, Asia-Pacific, Latin America, the Middle East and Africa) market size data for the Inspection Metal Castingmarket, based on segment.

3. Inspection Metal CastingMarket trends.

4. Inspection Metal CastingMarket drivers.

5. Analysis of major company profiles.

FIVE FORCES ANALYSIS

1. Competitive Rivalry - HIGH

• Numerous global and regional players: Thousands of foundries worldwide, ranging from small job shops to large integrated manufacturers.

• Low product differentiation: Many casting products (e.g., engine blocks, housings) are commoditized, increasing price competition.

2. Threat of New Entrants - MODERATE to LOW

• High capital investment: Setting up a foundry involves major upfront costs-furnaces, molds, machining tools, emissions control systems.

• Technical complexity: Expertise in metallurgy, quality control, and design is essential.

3. Bargaining Power of Suppliers - MODERATE

• Key materials:

metal, alloys, sand, resins, fuel, and refractory materials.

• Limited suppliers for specialty alloys: In high-spec segments (aerospace, defense), fewer suppliers have quality certifications.

4. Bargaining Power of Buyers - HIGH

• Large industrial buyers: Automotive, aerospace, energy, and machinery OEMs have significant negotiating power.

• Price sensitivity: Buyers often choose suppliers based on cost, lead time, and capacity rather than brand.

• Switching is relatively easy: Many cast parts are replaceable with minimal retooling.

5. Threat of Substitutes - MODERATE

• Forging and machining: In some applications, forged or machined components may replace cast parts for strength or precision.

• Additive manufacturing (3D printing): Emerging in prototyping and lightweight aerospace components but still costlier for mass production.

PESTLE ANALYSIS

Political Factors

• Trade policies & tariffs: Import/export duties on metals (e.g., aluminum, steel) affect cost structures, especially amid US-China/EU trade frictions.

• Government support for manufacturing: Initiatives like "Make in India" and China's "Industrial Upgrading" boost foundry infrastructure and investment.

• Defense and infrastructure spending: Increased funding in defense and public infrastructure indirectly boosts demand for metal castings.

• Political stability in emerging markets: Foundries in countries like India, Vietnam, and Mexico benefit from lower costs-but are exposed to political risks.

Economic Factors

• Global economic cycles: The industry is tightly linked to GDP, construction, and manufacturing trends. Recessions cut demand sharply.

• Energy & raw material costs: Volatility in energy prices, iron ore, and aluminum strongly impacts production costs.

• Labor costs and inflation: High wage inflation in developed markets pushes casting work offshore to Asia, Latin America, and Eastern Europe.

Social Factors

• Aging workforce in foundries: Many skilled workers are retiring without adequate replacements. The industry struggles to attract younger talent.

• Rising demand for green products: Consumer and corporate focus on sustainability drives interest in recyclable, low-emission cast materials.

• Urbanization and industrialization: Especially in Asia and Africa, spurs demand for castings in transport, construction, and energy.

• Customization demand: Clients increasingly request tailored cast solutions for performance, branding, or environmental compliance.

Technological Factors

• Automation & Industry 4.0: Smart foundries leverage sensors, robotics, and AI for real-time control and defect reduction.

• 3D printing (additive manufacturing): Used in prototyping and small-lot complex casting, with growing future potential.

• Advanced materials: Use of high-performance alloys, composites, and coatings in aerospace, EVs, and defense is growing.

• Simulation software: Enhances mold design, flow control, and yield optimization.

Environmental Factors

• High emissions footprint: Melting, molding, and finishing processes emit CO2, particulates, and hazardous waste.

• Strict environmental regulations: In the EU, US, and parts of Asia, foundries must comply with air, water, and waste standards.

• Circular economy pressure: Clients demand closed-loop systems with recycling of metal and sand.

• Green energy use: Shift toward solar, gas, and electric induction furnaces to reduce environmental impact.

Legal Factors

• Occupational health & safety: Foundries must adhere to strict workplace safety laws, particularly in developed countries.

• Intellectual property (IP): As casting designs become more complex (e.g., in aerospace), protection of mold and product designs becomes vital.

• Product liability laws: Defective parts-especially in automotive or aviation-can lead to lawsuits and recalls.

• Trade agreements & anti-dumping laws: Legal barriers can be used to protect domestic casting industries from cheap imports.

Table of Content (TOC)

• Introduction

1. Objectives of the Study

2. Market Definition

3. Research Scope

• Research Methodology and Assumptions

• Executive Summary

• Premium Insights

1. Porter's Five Forces Analysis

2. Value Chain Analysis

3. Top Investment Pockets

1. Market Attractiveness Analysis By Product Type

2. Market Attractiveness Analysis By Type

3. Market Attractiveness Analysis By Segment Type

4. Market Attractiveness Analysis By Region

4. Industry Trends

• Market Dynamics

1. Market Evaluation

2. Drivers

1. Increasing development in sector

3. Restraints

4. Opportunities

5. Challenges

• Global Metal Casting Market Analysis and Projection, By Product Type

• Global Metal Casting Market Analysis and Projection, By Type

• Global Metal Casting Market Analysis and Projection, By Segment Type

• Global Metal Casting Market Analysis and Projection, By Regional Analysis

1. Segment Overview

2. North America

1. U.S.

2. Canada

3. Mexico

3. Europe

1. Germany

2. France

3. U.K.

4. Italy

5. Spain

4. Asia-Pacific

1. Japan

2. China

3. India

5. South America

1. Brazil

6. Middle East and Africa

1. UAE

2. South Africa

• Global Metal Casting Market-Competitive Landscape

1. Overview

2. Market Share of Key Players in the Global Metal Casting Market

1. Global Company Market Share

2. North America Company Market Share

3. Europe Company Market Share

4. APAC Company Market Share

3. Competitive Situations and Trends

1. Coverage Launches and Developments

2. Partnerships, Collaborations, and Agreements

3. Mergers & Acquisitions

4. Expansions

• Company Profiles

1. Company1

1. Business Overview

2. Company Snapshot

3. Company Market Share Analysis

4. Company Coverage Portfolio

5. Recent Developments

6. SWOT Analysis

2. Company2

1. Business Overview

2. Company Snapshot

3. Company Market Share Analysis

4. Company Coverage Portfolio

5. Recent Developments

6. SWOT Analysis

3. Company3

1. Business Overview

2. Company Snapshot

3. Company Market Share Analysis

4. Company Coverage Portfolio

5. Recent Developments

6. SWOT Analysis

Industry Related Reports

Global Grouting Material Market Size

https://www.sphericalinsights.com/reports/grouting-material-market

Global Advanced Materials for Water Treatment Market Size

https://www.sphericalinsights.com/reports/advanced-materials-for-water-treatment-market

Global Advanced Materials for Semiconductor Market Size

https://www.sphericalinsights.com/reports/advanced-materials-for-semiconductor-market

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Follow Us: LinkedIn | Facebook | Twitter

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Metal Casting Market: Overview, Key Drivers, Competitive Landscape, Segmentation, and Regional Analysis (2023-2033) here

News-ID: 4105514 • Views: …

More Releases from Spherical Insights LLP

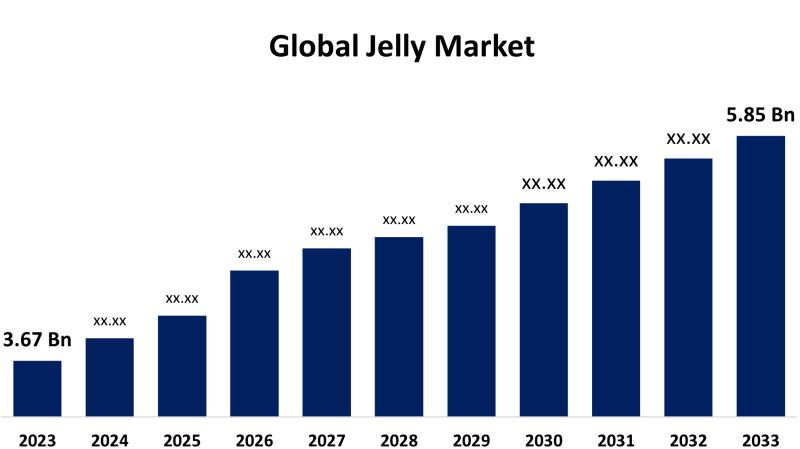

Global Jelly Market Size, Share, Forecasts 2023 - 2033 | Top key players: Bonne …

According to a research report published by Spherical Insights & Consulting, the Global Jelly Market is Expected to Grow from USD 3.67 Billion in 2023 to USD 5.85 Billion by 2033, at a CAGR of 4.77% during the forecast period 2023-2033.

Request To Download Free Sample copy of the report: https://www.sphericalinsights.com/request-sample/8511

The jelly industry comprises the international sector dealing with the manufacture, distribution, and sale of jelly products. Such products cover…

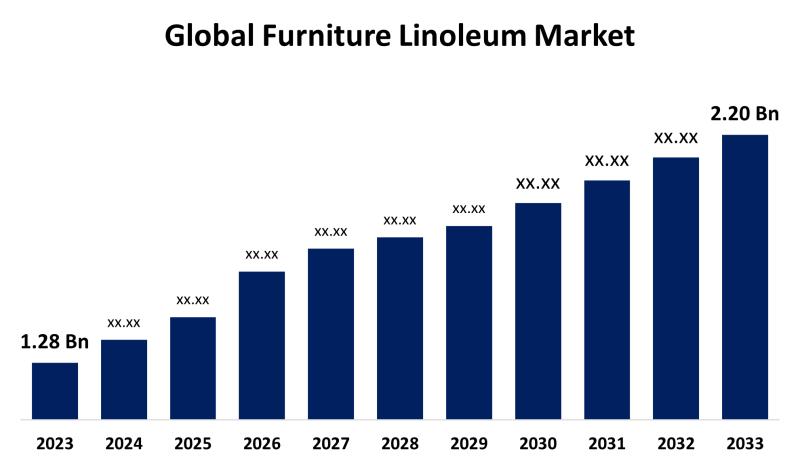

Global Furniture Linoleum Market Size, Share, Forecasts 2023 - 2033 | Top key pl …

According to a research report published by Spherical Insights & Consulting, the Global Furniture Linoleum Market Size is Estimated to Grow from USD 1.28 billion in 2023 to USD 2.20 billion by 2033, Growing at a CAGR of 5.57% during the forecast period 2023-2033.

Request To Download Free Sample copy of the report: https://www.sphericalinsights.com/request-sample/8455

The industry engaged in the manufacture, marketing, and distribution of linoleum products, especially made for furniture…

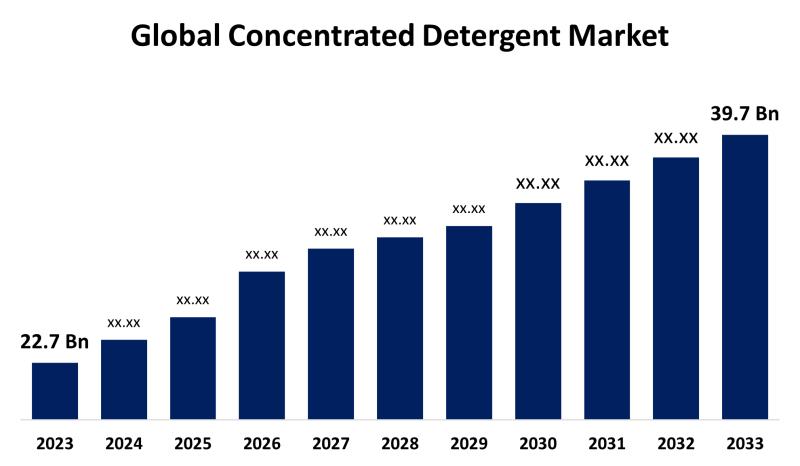

Global Concentrated Detergent Market Size, Share, Forecasts 2023 - 2033 | Top ke …

According to a research report published by Spherical Insights & Consulting, the Global Concentrated Detergent Market Size Expected to Grow from USD 22.7 Billion in 2023 to USD 39.7 Billion by 2033, at a CAGR of 5.75% during the forecast period 2023-2033.

Request To Download Free Sample copy of the report: https://www.sphericalinsights.com/request-sample/8439

The division of the detergent industry that produces and markets highly concentrated…

Global Wireless Home Weather Station Market Size, Share, Forecast 2023 - 2033 | …

According to a research report published by Spherical Insights & Consulting, the Global Wireless Home Weather Station Market Size is Expected to Grow from USD 249 Million in 2023 to USD 508 Million by 2033, at a CAGR of 7.39% during the forecast period 2023-2033.

Request To Download Free Sample copy of the report @ -

https://www.sphericalinsights.com/request-sample/7694

A system that measures and sends environmental data from outside to within, including temperature,…

More Releases for Cast

Cast Iron & Cast Iron Castings Market Is Going to Boom |• Erdos Group • Neen …

Worldwide Market Reports has released a new in-depth research study on the "Cast Iron & Cast Iron Castings Market," highlighting strong growth potential in the coming years. The report delivers a structured and data-driven analysis of the market landscape, combining robust research methodology, market sizing, validated data modeling, and insights sourced from reliable primary and secondary channels.

The study thoroughly examines key market aspects, including growth drivers, restraints, challenges, emerging opportunities,…

Cast Iron vs Cast Steel: Which Manifold Enhances Performance?

Image: https://statics.mylandingpages.co/static/aaanxdmf26c522mp/image/b70503509e2c4604aa87f3862c47fe21.webp

Manifolds play a crucial role in engine performance. These components channel exhaust gases away from the engine, impacting efficiency and power output. A cast iron exhaust manifold [https://www.werkwell.com/exhaust-manifold/] offers durability and heat retention, making it a popular choice. However, advancements in material technology have introduced alternatives like cast steel [https://www.iron-foundry.com/cast-iron-exhaust-manifold-vs-cast-steel-manifolds.html], which provide enhanced strength and corrosion resistance.

Importance in Engine Performance

Impact on Efficiency

Manifolds significantly influence engine efficiency. Properly designed manifolds…

Cast Elastomer Market is Driven by Growing Demand for Cast Elastomers in the Aut …

A cast elastomer is a type of elastomeric material that is cast or molded into the desired shape. It is a versatile material that can be used for a variety of applications, including seals, gaskets, and vibration-damping materials. The cast elastomer has good mechanical properties and can withstand a wide range of temperatures and chemicals. It is also resistant to abrasion and tearing.

Get a Sample Report- https://www.globalinsightservices.com/request-sample/GIS20867

Key Trends

There are a…

Cast Resin Current Transformers Market Report 2018: Segmentation by Type (Indoor …

Global Cast Resin Current Transformers market research report provides company profile for CHINT, Stemar Electrical Products, Gemini Instratech Ltd., Elba d.o.o., Kaldera Company, ABB, Siemens, Schneider Electric, Toshiba, Fuji Electric and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the…

CONNOR FOX CAST IN SHOUTING SECRETS

Los Angeles, CA (April 28, 2010)- Award-winning actor Connor Fox, has officially signed on to play the role of Brody in the Korinna Sehringer film “Shouting Secrets” which started shooting in Arizona on April 26th. Fox will join Twilight Saga actors Gil Birmingham and Chaske Spencer as well actress, Q'orianka Kilcher (“The New World”), in this film about a successful young writer in Los Angeles who is called back…

Hexis launches carbon cast film

Hexis has launched a new cast vinyl with a carbon fibre look destined for wrapping applications. The company is promoting the new line with a dedicated mini-site: ilovehx.com.

Part of the HX30000 Series, the “Carbon Cast” is a multi-layered 135µm cast vinyl film with a carbon fibre embossed pattern. It carries the proven solvent-based adhesive and a structured PE liner with Hex’Press technology that allows convenient air egress during application. With…