Press release

Lightweight Plastics in the Automotive Industry: Tackling Challenges to Elevate Performance and Efficiency

In the ever-evolving automotive sector, lightweight plastics have become a game-changer. By offering a high strength-to-weight ratio, design flexibility, and cost-effectiveness, lightweight plastics are essential in addressing the industry's pressing demands for fuel efficiency, emissions reduction, and sustainability. However, while these materials present numerous benefits, they also come with specific challenges. In this article, we'll explore common pain points in the use of lightweight plastics in the automotive industry and offer practical solutions that can enhance performance and reduce production costs.What Are Lightweight Plastics?

Lightweight plastics are low-density polymers, such as polyethylene (PE), polypropylene (PP), polystyrene (PS), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and polybutylene terephthalate (PBT), with density ranges from 0.8-1.5 g/cm. Unlike metals (e.g., steel: ~7.8 g/cm), these plastics reduce weight without sacrificing essential mechanical or thermal properties. Advanced options like foamed plastics (e.g., expanded polystyrene, EPS) and thermoplastic composites further lower density while maintaining structural integrity, making them ideal for automotive use.

Applications of Lightweight Plastics in the Automotive Industry

Lightweight plastics are integral to modern automotive design, enabling manufacturers to meet performance, efficiency, and sustainability goals. Key applications include:

1. Automotive Interior Components:

Materials: PP, ABS, PC.

Applications: Dashboards, door panels, seat components.

Benefits: Lightweight, durable, and customizable for aesthetics and comfort.

2. Automotive Exterior Parts:

Materials: PP, PBT, PC/PBT blends.

Applications: Bumpers, grilles, mirror housings.

Benefits: Impact resistance, weatherability, and reduced vehicle weight.

3. Under-the-Hood Components:

Materials: PBT, polyamide (nylon), PEEK.

Applications: Engine covers, air intake manifolds, and connectors.

Benefits: Heat resistance, chemical stability, and dimensional accuracy.

4. Structural Components:

Materials: Glass or carbon fiber-reinforced PP or PA.

Applications: Chassis reinforcements, battery trays for electric vehicles (EVs).

Benefits: High strength-to-weight ratio, corrosion resistance.

5. Insulation and Cushioning:

Materials: PU foams, EPS.

Applications: Seat cushions, sound insulation panels.

Benefits: Ultra-light, excellent energy absorption.

In electric vehicles, lightweight plastics are particularly crucial, as they offset the weight of heavy battery packs, extending driving range. For example, PP-based battery housings and PC glazing reduce weight while maintaining safety standards.

Common Challenges and Solutions for Lightweight Plastics in Automotive Use

Despite their advantages, such as fuel efficiency, emissions reduction, design flexibility, cost-effectiveness, and recyclability, lightweight plastics face challenges in automotive applications. Below are common issues and practical solutions.

Challenge 1: Scratch and Wear Susceptibility in Automotive Plastics

Issue: Surfaces of lightweight plastics such as Polypropylene (PP) and Acrylonitrile Butadiene Styrene (ABS), commonly used in automotive components like dashboards and door panels, are susceptible to scratches and scuffs over time. These surface imperfections not only affect the aesthetic appeal but can also reduce the long-term durability of the parts, requiring additional maintenance and repairs.

Solutions:

To address this challenge, incorporating additives like silicone-based plastic additives or PTFE into the plastic formulation can significantly improve surface durability. By adding 0.5-2% of these additives, the surface friction is reduced, making the material less prone to scratches and scuffs.

Given the multitude of silicone additive manufacturers available, what criteria should you use to select the ideal business partner?

At Chengdu Silike Technology Co., Ltd., we specialize insilicone-based plastic additives designed to enhance the properties of Thermoplastics and Engineering plastics used in automotive applications. With over 20 years of experience in the integration of silicone and polymers, SILIKE is recognized as a leading innovator and trusted partner for high-performance processing additive and modifier solutions.

Our silicone-based plastic additives products are specifically formulated to help polymer manufacturers:

1) Improve extrusion rates and achieve consistent mold filling.

2) Enhance surface quality and lubricity, contributing to better mold release during production.

3) Lower power consumption and reduce energy costs without requiring modifications to existing processing equipment.

4) Our silicone additives are highly compatible with a wide range of thermoplastics and engineering plastics, including:

Polypropylene (PP), Polyethylene (HDPE, LLDPE/LDPE), Polyvinyl Chloride (PVC), Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS), Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS), Polystyrene (PS/HIPS), Polyethylene Terephthalate (PET), Polybutylene Terephthalate (PBT), Polymethyl Methacrylate (PMMA), Nylon (Polyamides, PA), Ethylene Vinyl Acetate(EVA), Thermoplastic Polyurethane (TPU), Thermoplastic Elastomers (TPE), and more.

These siloxane additives also help drive efforts toward a circular economy, supporting manufacturers in producing sustainable, high-quality components that meet environmental standards.

SILIKE Silicone Wax SILIMER 5235: A Novel Approach to Surface Enhancement for Improved Scratch Resistance

Image: https://www.siliketech.com/uploads/Improve-Scratch-Resistance-Processing-Efficiency-with-SILIKE-Silicone-Wax-SILIMER-52351.png

Beyond standard silicone-based plastic additives, SILIMER 5235, an alkyl-modified silicone wax, stands out. Specifically designed for super-light plastic products such as PC, PBT, PET, and PC/ABS, SILIMER 5235 offers exceptional scratch and wear resistance. By enhancing surface lubricity and improving mold release during processing, it helps to maintain the texture and lightness of the product surface over time.

One of the key advantages of silicone wax SILIMER 5235 is its excellent compatibility with various matrix resins, ensuring there is no precipitation or impact on surface treatments. This makes it ideal for automotive interior parts where both aesthetic quality and long-term durability are essential.

Challenge 2: Surface Defects During Processing

Issue: Injection-molded parts (e.g., PBT bumpers) may exhibit splay, flow lines, or sink marks.

Solutions:

Dry pellets thoroughly (e.g., 120 degrees C for 2-4 hours for PBT) to prevent moisture-related splay.

Optimize injection speed and packing pressure to eliminate flow lines and sink marks.

Use polished or textured molds with proper venting to reduce burn marks.

Challenge 3: Limited Heat Resistance

Issue: PP or PE may deform under high temperatures in under-the-hood applications.

Solutions:

Use heat-resistant plastics like PBT (melting point: ~220 degrees C) or PEEK for high-temperature environments.

Incorporate glass fibers to enhance thermal stability.

Apply thermal barrier coatings for added protection.

Challenge 3: Mechanical Strength Limitations

Issue: Lightweight plastics may lack the stiffness or impact resistance of metals in structural parts.

Solutions:

Reinforce with glass or carbon fibers (10-30%) to boost strength.

Use thermoplastic composites for load-bearing components.

Design parts with ribbing or hollow sections to improve stiffness without adding weight.

Looking to improve the scratch resistance of your Lightweight Plastics in automotive components?

Connect with SILIKE to explore more about their lightweight plastic solutions in the automotive industry, including plastic additives, anti-scratch agents, and mar resistance modifier solutions.

Tel: +86-28-83625089, Email: amy.wang@silike.cn, Website: www.siliketech.com

Media Contact

Company Name: Chengdu Silike Technology Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=lightweight-plastics-in-the-automotive-industry-tackling-challenges-to-elevate-performance-and-efficiency]

Country: China

Website: https://www.siliketech.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Lightweight Plastics in the Automotive Industry: Tackling Challenges to Elevate Performance and Efficiency here

News-ID: 4094680 • Views: …

More Releases from ABNewswire

Living Forever - AI Selected for Startup Grind Global Conference 2026 - Named Am …

AI-powered platform preserving living people's personalities, voices, and stories earns exhibition and pitch slot at premier Silicon Valley startup event

ATLANTA, GA - February 26, 2026 - Living Forever - AI [https://livingforeverai.com], an Atlanta-based startup building fully interactive video AI digital twins that preserve the personalities, voices, and life stories of living people for future generations, today announced its acceptance into the Startup Grind Global Conference 2026. The company was selected…

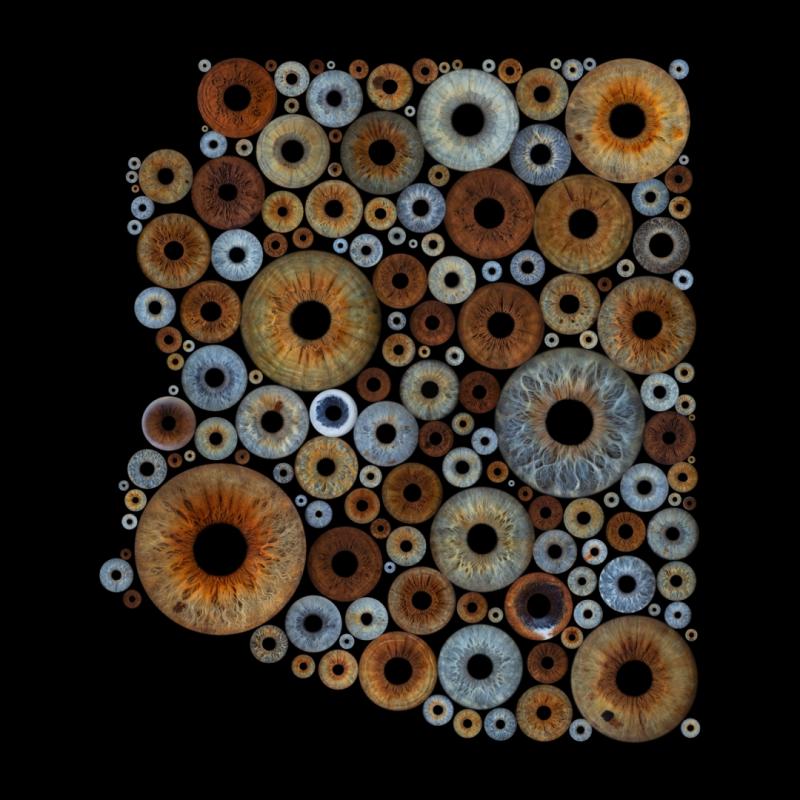

Mesa Studio Blends Iris Photography with the Art of Becoming Through the Iris Wi …

Sol Iris Photography founder Saskia Soliz draws on a background in autism support and personal growth to create a creative experience rooted in self-discovery.

MESA, AZ - February 26, 2026 - Sol Iris Photography, a Mesa-based studio specializing in high-resolution iris photography, is quietly building something beyond photography. Through the Iris Wisdom Project, clients are invited to share a brief piece of wisdom alongside their iris portrait - a thought, truth,…

Power Couple Combines Army Structure and Insurance Expertise to Launch Family-Ow …

Red Rover Roofing, a family-owned roofing company in Williamson County, Tennessee, brings Xactimate-certified insurance claim expertise and CertainTeed Master Shingle Applicator credentials to Middle Tennessee homeowners navigating storm damage roof replacement and insurance disputes across Franklin, Brentwood, Spring Hill, Nashville, and Murfreesboro.

SPRING HILL, TN - February 26, 2026 - When retired U.S. Army Captain Courtney Hostetler came home from deployment in Kuwait, she and her husband Alex knew they wanted…

Primary Biliary Cholangitis Market: Rapid Increment Driven by Innovation by 2034 …

The Key Primary Biliary Cholangitis Companies in the market include - CymaBay Therapeutics, Inc., Zydus Therapeutics Inc., Gannex Pharma Co., Ltd., Nanjing Chia-tai Tianqing Pharma, Intercept Pharmaceuticals, Enanta Pharmaceuticals, COUR Pharmaceutical, Novartis, Merck, Mirum Pharmaceuticals, Inc., Genfit, CymaBay Therapeutics, Inc., Calliditas Therapeutics, HighTide Biopharma Pty Ltd, Albireo, Curome Biosciences, Biotie Therapies Corp., and others.

DelveInsight's "Primary Biliary Cholangitis Market Insights, Epidemiology, and Market Forecast-2034 report offers an in-depth understanding of the…

More Releases for Lightweight

Headlamp for Kayaking: Waterproof & Lightweight

Image: https://statics.mylandingpages.co/static/aaanxdmf26c522mpaaaaz2wwe7ppkact/image/653b91aff764455da556fe386523434a.webp

A specialized Kayaking Headlamp plays a critical role in ensuring safety and aiding navigation. Kayaks sit low on the water, making them inherently difficult for other vessels to spot, especially during low-light conditions or dense fog. This significantly increases the risk of collisions and kayakers getting lost. Therefore, a headlamp's waterproof and lightweight design becomes non-negotiable. The right headlamp enhances night paddling, providing essential visibility to avoid hazards and…

Lightweight Packaging Market Size & Innovations

The Lightweight Packaging Market is witnessing rapid expansion, fueled by global sustainability efforts, growth in e-commerce, and advancements in material science. Lightweight packaging reduces material use, waste, and transportation emissions, making it a key player in sustainable packaging.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5408

Key Materials:

• EPP and EPS: Ultra-light materials (98% air), offering thermal insulation and shock absorption.

• PET: Recyclable, durable, and widely used for food and beverage packaging

Key Trends and Findings

1. Eco-friendly Innovations:

o Reducing packaging size…

Electric Vehicle Lightweight Materials Market Report 2024 - Electric Vehicle Lig …

"The Business Research Company recently released a comprehensive report on the Global Electric Vehicle Lightweight Materials Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, The electric vehicle…

RUDERER - Bonding of lightweight carbon components

From zero to one hundred in 3.21 seconds: The new BMW S 1000 RR makes the hearts of enthusiastic motorcyclists beat faster. The 210 hp superbike is the result of ultra-modern production technologies. Ultra-light composite materials ensure driving dynamics, flexibility and stability. Various manufacturers rely on the ultra-modern industrial adhesives from RUDERER KLEBETECHNIK GmbH to bond a wide variety of lightweight components together quickly, reliably and visually flawlessly. The structural…

Autoclaved Lightweight Concrete (ALC) Blockss as Currency: Exploring the Global …

Los Angeles, United States - In this comprehensive research study, we delve into the intricate details of the global Autoclaved Lightweight Concrete (ALC) Blocks market, providing a thorough analysis of its critical aspects. The report illuminates the anticipated growth of the global Autoclaved Lightweight Concrete (ALC) Blocks market during the forecast period, supported by SWOT analysis and Porter's Five Forces analysis. This illumination includes an in-depth exploration of the market's…

Lightweight Materials in Transportation Market

"Lightweight Materials in Transportation Market" In this report, thorough SWOT analysis & investment analysis is provided which forecasts imminent opportunities for the Lightweight Materials in Transportation Market players shared by Infinitybusinessinsights.com. This report will help the viewer in Better Decision Making.

In 2022, there was a $115.4 billion global market for lightweight materials used in transportation. This market is anticipated to develop at a compound annual growth rate (CAGR) of 12.6%…