Press release

Defoamer Surfactant Manufacturing Cost Analysis and Setup Requirements in 2025

Introduction:A defoamer surfactant is a chemical additive used to eliminate or prevent foam formation in industrial processes. It works by reducing the surface tension of liquids, causing trapped air to escape and foam to collapse. These surfactants are widely used in industries such as paints and coatings, pulp and paper, food processing, wastewater treatment, and oil and gas, where excessive foam can hinder production efficiency and product quality.

Setting up a defoamer surfactant manufacturing plant involves securing a suitable location, acquiring raw materials (like silicones or non-silicone compounds), installing blending and reaction equipment, and complying with environmental and safety regulations.

IMARC Group's report, titled "Defoamer Surfactant Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a Defoamer surfactant manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/defoamer-surfactant-manufacturing-plant-project-report/requestsample

Defoamer surfactant Industry outlook 2025

The defoamer surfactant industry is poised for steady growth in 2025, driven by rising demand across sectors like wastewater treatment, paints & coatings, pulp & paper, and food processing. Valued at over USD 1.5 billion, the market is expected to grow at a CAGR of 4-5% through 2030. Increasing focus on eco-friendly, low-VOC, and bio-based formulations-spurred by environmental regulations-is reshaping product innovation. Regions like Asia-Pacific, especially India and China, are witnessing rapid industrial growth, fueling market expansion. Leading players such as BASF, Dow, and Evonik are investing in advanced, specialty defoamers, including silicone-based and food-grade variants. Overall, strong industrial demand, sustainability trends, and innovation in surfactant chemistry make 2025 an ideal time to invest in the defoamer surfactant space.

Key Cost Components of Setting Up a Defoamer surfactant Plant

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Defoamer surfactant Plant

• Land and Infrastructure: Costs for purchasing or leasing land, constructing production facilities, storage units, administrative buildings, and utility setups.

• Machinery and Equipment: Includes mixing tanks, reactors, emulsifiers, packaging lines, and quality control instruments. High-grade stainless-steel systems are often required.

• Raw Materials: Major inputs include silicone oils, polyethers, fatty alcohols, emulsifiers, and carriers. Costs vary by formulation type (silicone vs. non-silicone).

• Labor: Skilled and unskilled workforce expenses, including plant operators, chemists, engineers, and administrative staff.

• Utilities: Electricity, water, gas, and wastewater treatment costs essential for continuous plant operations.

• Regulatory Compliance: Fees for environmental clearances, health & safety certifications, and quality standards (e.g., ISO, REACH).

• Research & Development: For custom formulations, performance optimization, and compliance with industry trends (e.g., biodegradable or food-grade variants).

• Logistics and Distribution: Warehousing, packaging, and transportation infrastructure for finished products.

Economic Trends Influencing Defoamer surfactant Plant Setup Costs 2025

• Raw Material Price Volatility: Fluctuations in prices of key inputs like silicone oils, fatty alcohols, and polyethers-due to geopolitical tensions and supply chain disruptions-are raising initial procurement and inventory costs.

• Energy Inflation: Elevated electricity and natural gas prices, particularly in energy-intensive regions, are increasing utility costs for manufacturing operations.

• Green Compliance Costs: Stricter environmental regulations and a shift toward bio-based and low-VOC formulations demand investment in advanced R&D, cleaner technologies, and emissions-control systems.

• Labor Market Shifts: Skilled labor shortages and rising wages in chemical processing sectors, especially in Asia and North America, are pushing up personnel costs.

• Capital Equipment Inflation: Global inflation has led to higher prices for plant machinery, including reactors and quality control systems, due to increased steel and microchip costs.

• Logistics and Tariff Pressures: Cross-border tariff changes and higher shipping rates impact both material sourcing and distribution planning.

Speak to an Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=8988&flag=C

Challenges and Considerations for Investors

• Regulatory Compliance: Meeting strict environmental and safety standards (e.g., REACH, EPA) can increase setup and operational costs.

• Raw Material Volatility: Price fluctuations in silicone oils, polyethers, and fatty alcohols can impact profit margins and sourcing stability.

• High Capital and Operating Costs: Global inflation has raised expenses for plant equipment, utilities, and construction.

• Skilled Labor Demand: Recruiting experienced chemists, engineers, and plant operators is critical but increasingly difficult.

• Intense Market Competition: Established players dominate the global market, making product differentiation essential for new entrants.

• Logistics and Tariff Risks: Shipping delays, cross-border trade barriers, and increased transport costs can affect supply chains.

• Sustainability and Innovation Opportunity: Investing in bio-based, low-VOC, and environmentally friendly formulations aligns with market and regulatory trends.

• Digital Manufacturing and Automation: Adopting smart technologies enhances production efficiency, quality, and scalability.

• Strategic Plant Location: Setting up near industrial hubs or ports reduces logistics costs and improves client accessibility.

• Sector Diversification: Targeting multiple industriessuch as paints, pulp & paper, and food processinghelps reduce dependency on a single market.

Buy Now: https://www.imarcgroup.com/checkout?id=8988&method=1911

Conclusion

In conclusion, while setting up a defoamer surfactant manufacturing plant in 2025 presents certain challenges-such as rising input costs, regulatory complexity, and market competition-it also offers compelling opportunities. Investors who prioritize sustainability, technological innovation, and strategic location planning can gain a strong foothold in a growing industry. By addressing operational risks and aligning with evolving industry demands, such as eco-friendly formulations and diversified end-use markets, businesses can position themselves for long-term profitability and resilience in the global chemical landscape.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Defoamer Surfactant Manufacturing Cost Analysis and Setup Requirements in 2025 here

News-ID: 4085377 • Views: …

More Releases from IMARC Group

Acetone Price Trend Rises in Q1 2026 on Steady Industrial Demand

The global Acetone Prices continues to reflect dynamic shifts influenced by feedstock costs, downstream demand, and regional supply adjustments. The latest Acetone price index indicates moderate volatility across major producing regions in 2025, with early 2026 trends pointing toward cautious stabilization. Businesses tracking the Acetone price trend analysis & Acetone price forecast are closely monitoring crude-linked raw material movements and industrial demand recovery.

Acetone Current Price Movements:

Recent Acetone Prices have displayed…

India Diamond Market: Size, Share, Trends, Key Players, Opportunity Analysis & F …

The latest report by IMARC Group, 'India Diamond Market Size, Share, Trends and Forecast by Product, Application, and Region, 2026-2034', provides a comprehensive industry analysis. It delivers deep insights into the Indian diamond ecosystem, highlighting growth drivers, competitive landscapes, and emerging segment trends for the 2026-2034 forecast period.

What is the India Diamond Market Size, Share, Trends, and Growth Forecast (2026-2034)?

According to the latest analysis by IMARC Group, the India diamond…

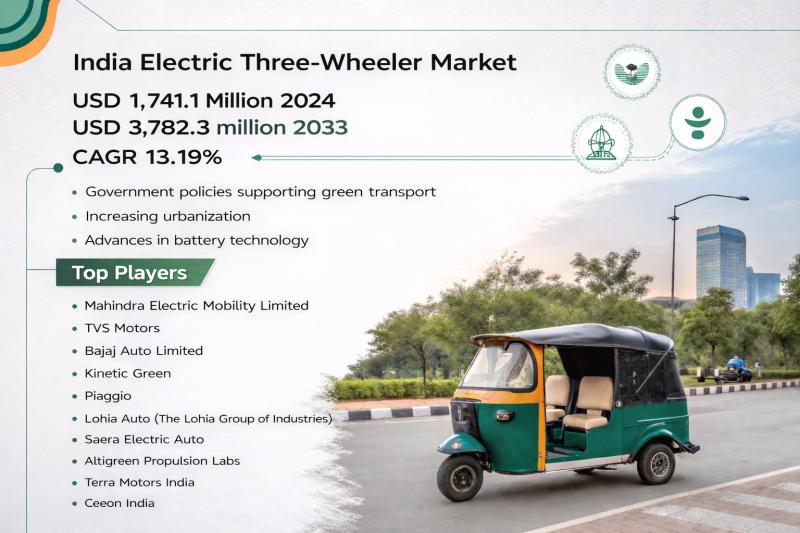

India Electric Three-wheeler Market Overview, Trends, Growth Drivers, Top Player …

India Electric Three-wheeler Market: Overview

According to IMARC Group's report titled "India Electric Three-Wheeler Market Size, Share, Trends and Forecast by Vehicle Type, Battery Type, Drive Type, Motor Type, Power Output, Voltage Capacity, and Region, 2025-2033" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

The India electric three-wheeler market size was valued at USD 1,174.1 Million in 2024. The market is projected to…

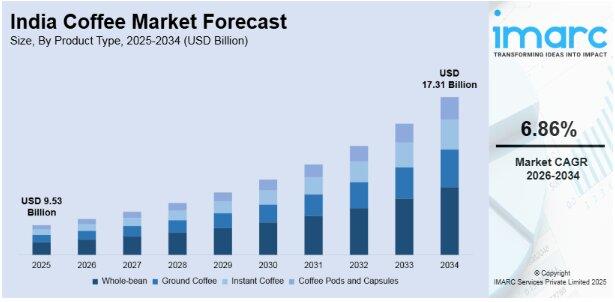

India Coffee Market Size, Share, Trends, Industry Analysis, Growth, Opportunity …

The latest report by IMARC Group, 'India Coffee Market Size, Share, Trends and Forecast by Product Type, Distribution Channel, and Region, 2026-2034', provides a comprehensive industry analysis. It delivers deep insights into the ecosystem, highlighting growth drivers, competitive landscapes, and emerging segment trends for the 2026-2034 forecast period.

What is the India Coffee Market Size, Share, Trends, and Growth Forecast (2026-2034)?

According to the latest analysis by IMARC Group, the coffee market…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…