Press release

Polymer Foam Market to Reach USD 144.4 Bn by 2031, Driven by Industrial Demand

The global polymer foam market was valued at USD 94.6 billion in 2021 and is projected to reach USD 144.4 billion by the end of 2031, growing at a CAGR of 4.2% from 2022 to 2031. This growth is driven by rising demand across automotive, packaging, and construction industries due to polymer foam's lightweight, insulating, and durable properties.Polymer foam is a dispersion of gas in a polymer matrix. It is made of minimum two phases: solid phase and gaseous phase. Polymer foams offer lightness of weight and high strength-to-weight properties. Advantages of using polymer foams include superior thermal & acoustic insulation and energy absorptivity. These benefits make polymer foams a perfect choice of material for insulation of buildings and infrastructure. Thus, increase in number of construction projects and rise in reconstruction activities are expected to fuel the polymer foam market.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=5651

Market Segmentation

The polymer foam market can be segmented based on various factors:

By Type (Product/Resin Type):

Polyurethane (PU) Foam: This segment held the largest share in 2021 (28.4%) due to its versatility, high impact resistance, and excellent load-bearing capacity, particularly in construction and automotive applications.

Polystyrene (PS) Foam: Known for its lightweight, stiffness, and excellent thermal insulation, especially in packaging.

Polyvinyl Chloride (PVC) Foam

Polyolefin (PO) Foam: Including Polyethylene (PE) and Polypropylene (PP) foams, recognized for their flexibility, thermal insulation, and impact resistance, with polyethylene accounting for the largest share within this segment (47.52% in 2021).

Phenolic Foam

Melamine Foam

Others

By Service Type: (While specific data on "service type" segmentation such as molded, extruded, and expanded foam wasn't explicitly detailed with market shares in the provided data, these represent different manufacturing processes for polymer foams.)

Molded Foam

Extruded Foam

Expanded Foam

By Sourcing Type: (Specific market share data for "sourcing type" was not provided.)

Virgin

Recycled

By Application:

Building & Construction: Expected to be the dominant end-user, accounting for over 25% share in 2021. Polymer foams are extensively used for insulation, roofing, sealants, soundproofing, and lightweight construction materials.

Packaging: Driven by the need for protective, lightweight, and insulating solutions, especially in the food and beverage sector and e-commerce.

Furniture & Bedding: For cushioning, comfort, and durability in mattresses, seating, and other furniture items.

Automotive: Utilized for lightweight components to improve fuel economy, enhance safety (e.g., in seating, dashboards, and bumpers), and for insulation.

Footwear

Rail

Wind

Marine

Others (including electronics, sports, and recreational goods).

By Industry Vertical: (This overlaps significantly with the "By Application" segment, as industries like building & construction, automotive, and packaging are major consumers of polymer foams.)

By Region:

Asia Pacific: Anticipated to be a lucrative region, driven by rapid industrialization, urbanization, increasing per capita income, and burgeoning demand for automotive and housing facilities, particularly in China and India.

This region contributed 55.5% market share in 2021 for polyolefin foam.

North America: Characterized by the presence of key manufacturers and high demand from the automotive, construction, and packaging industries.

Europe: Similar to North America, with a focus on technological innovation and sustainability.

Latin America

Middle East & Africa

Regional Analysis

Asia Pacific is poised to remain a leading region in the polymer foam market due to robust economic growth, rising disposable incomes, and significant investments in infrastructure and manufacturing across countries like China, India, and Southeast Asian nations. The region's emphasis on urbanization and industrialization directly fuels the demand for polymer foams in construction, automotive, and packaging sectors. North America and Europe also hold substantial market shares, driven by established industries and increasing adoption of advanced foam technologies. Emerging applications in the healthcare sector are also contributing to market growth in these regions.

Market Drivers and Challenges

Market Drivers:

Growing Demand from End-Use Industries: The rapid expansion of the building and construction, automotive, packaging, and furniture & bedding industries globally is a primary driver. Polymer foams offer essential properties like thermal insulation, sound dampening, lightweighting, and cushioning that are highly valued in these sectors.

Increasing Focus on Energy Efficiency and Lightweighting: Stringent regulations regarding energy savings in buildings and the automotive industry's continuous efforts to reduce vehicle weight to improve fuel efficiency are boosting the demand for high-performance polymer foams.

Urbanization and Infrastructure Development: Rapid urbanization, particularly in emerging economies, leads to increased construction activities, further driving the demand for polymer foams in insulation, roofing, and other building components.

Rise in Disposable Income: Improved living standards and increased disposable income, especially in developing countries, are augmenting the demand for consumer goods, including automobiles, housing facilities, and high-quality furniture, all of which utilize polymer foams.

Technological Advancements: Continuous innovation in foam technology is leading to the development of new and improved foam formulations with enhanced properties, expanding their application scope.

Market Challenges:

Volatility in Raw Material Prices: The key raw materials for polymer foams, such as crude oil and its derivatives, are subject to significant price fluctuations due to geopolitical and economic factors. This directly impacts manufacturing costs and profitability for foam producers.

Environmental Concerns and Regulations: Growing environmental concerns associated with the disposal of foam waste and stringent regulations regarding the use of certain foam types or blowing agents can hinder market growth.

Competition from Alternate Materials: Polymer foams face competition from other lightweight and insulation materials, including natural fibers and composite materials, in specific applications.

Complex Production Processes: The intricate manufacturing processes of polymer foams, requiring precise control over temperature and other parameters to achieve desired cell structures, can be a challenge.

Market Trends

Adoption of Bio-based and Recyclable Polymer Foams: Increasing eco-consciousness among consumers and manufacturers is driving the demand for sustainable solutions, leading to the development and adoption of bio-based polyols and foams from recycled materials.

Integration of Nanotechnology: Research and development efforts are focusing on integrating nanotechnology to enhance the properties of polymer foams, such as improved strength, insulation, and fire retardancy.

Shift Towards Sustainable Packaging Solutions: The packaging industry is increasingly seeking eco-friendly and lightweight foam solutions to reduce environmental impact.

Customization and Multi-functionality: Advances in extrusion and molding processes are enabling greater customization of high-density polymer foams to meet specific industry requirements, leading to their increased use in various applications.

Growth in Electric Mobility: The rising adoption of electric vehicles is expected to escalate the demand for new-age polymer foam materials for insulation and noise abatement.

Future Outlook

The future of the polymer foam market appears promising, driven by continued innovation and the increasing demand for lightweight, energy-efficient, and environmentally friendly solutions across diverse industries. The ongoing research into bio-based and recycled foams, coupled with technological advancements, will likely unlock new application areas and materials. The market is expected to witness steady growth, fueled by sustained demand from the construction, automotive, and packaging sectors, along with emerging opportunities in healthcare and energy storage.

Key Market Study Points

Key areas for market study include:

In-depth analysis of market dynamics, encompassing drivers, restraints, opportunities, and challenges.

Evaluation of prevailing market trends and their potential impact on the polymer foam industry.

Assessment of key market players, their strategic initiatives, and the competitive landscape.

Examination of regional market dynamics and growth prospects across various geographies.

Opportunities within various segments based on type, application, and end-use.

Competitive Landscape

The global polymer foam market is characterized by a robust competitive landscape with several key players. Companies are actively focusing on product innovation, strategic partnerships, mergers and acquisitions, and geographical expansion to strengthen their market presence and gain a competitive edge.

Key Players include (but are not limited to):

BASF SE

Covestro AG

Dow Chemical Company

Recticel NV/SA

Armacell International S.A.

Sealed Air Corporation

Saint-Gobain

Huntsman

Zotefoams

DuPont

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=5651<ype=S

Recent Developments

September 2022: Covestro began offering polyether polyols using bio-circular feedstock together with renewable toluene diisocyanate (TDI) and climate-neutral methylene diphenyl diisocyanate (MDI), signifying a move towards more sustainable offerings.

January 2023: Firestable Insulation Company launched new open and closed cell spray foam products, StablebaseTM 2.0 Max R (HFO blown, closed-cell) and StablebaseTM 0.5 Max Yield (open-cell) spray polyurethane foam (SPF), indicating continuous product development in the insulation sector.

Ongoing Initiatives: Many companies are investing in R&D to produce foams from renewable biomass sources and exploring ways to utilize recycled polymers to manufacture new foams, aligning with the growing demand for eco-friendly solutions.

Explore Latest Research Reports by Transparency Market Research:

Rubber Processing Chemicals Market - https://www.transparencymarketresearch.com/rubber-processing-chemicals-market.html

Ion Exchange Membrane Market - https://www.transparencymarketresearch.com/ion-exchange-membrane-market.html

Sodium Silicate Market - https://www.transparencymarketresearch.com/global-sodium-silicate-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Want to know more? Get in touch now. -https://www.transparencymarketresearch.com/contact-us.html

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polymer Foam Market to Reach USD 144.4 Bn by 2031, Driven by Industrial Demand here

News-ID: 4078455 • Views: …

More Releases from transparencymarketresearch

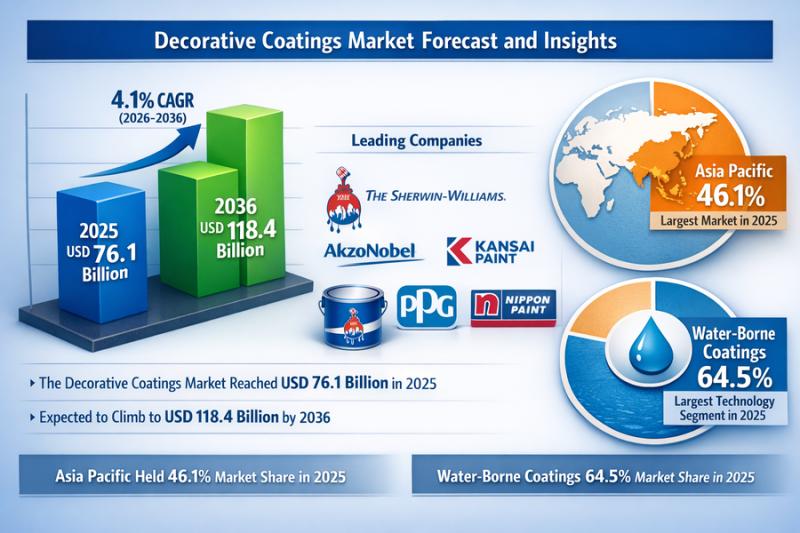

Decorative Coatings Market to Reach USD 118.4 Billion by 2036 at 4.1% CAGR

The decorative coatings market was valued at USD 76.1 billion in 2025 and is projected to reach USD 118.4 billion by 2036. The industry is expected to grow at a steady CAGR of 4.1% during the forecast period from 2026 to 2036, driven by rising construction activities, increasing demand for aesthetic building solutions, and ongoing product innovations.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1450

Market Overview

Decorative coatings are applied…

Europe and Asia Pacific Commercial Fuel Cards Market to Reach USD 1,042.2 Billio …

The Europe and Asia Pacific commercial fuel cards market was valued at USD 534.2 billion in 2025 and is projected to reach USD 1,042.2 billion by 2036, growing at a CAGR of 6.2% from 2026 to 2036. Market growth is driven by rising cross-border transportation demand across Europe and the rapid expansion of fuel retail networks in the Asia Pacific region.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85701

Market…

Air Fryer Market to Reach USD 2,343.9 Mn by 2036 Driven by Health-Focused Cookin …

The global air fryer market was valued at USD 1,103.4 Mn in 2025 and is projected to reach USD 2,343.9 Mn by 2036, expanding at a CAGR of 7.8% from 2026 to 2036. Market growth is primarily driven by rising health consciousness and increasing demand for low-oil cooking appliances among consumers. Busy urban lifestyles, compact kitchen trends, and the growing preference for convenient home-cooking solutions are further supporting adoption. Additionally,…

Global Yeast Market to Reach US$ 16.9 Bn by 2036 Driven by Bakery and Beverage D …

The global yeast market was valued at USD 9.7 Bn in 2025 and is projected to reach USD 16.9 Bn by 2036, expanding at a CAGR of 5.1% from 2026 to 2036. Market growth is primarily driven by increasing demand from the bakery and food processing industries, along with the steady expansion of alcoholic and non-alcoholic beverage production. Rising consumption of convenience foods and fermented products continues to support sustained…

More Releases for Foam

Foam Concentrate Market: High-growth Regions to Expand Geographic Footprint | Ch …

"This research study presents a comprehensive compilation of insightful findings concerning key aspects of the global Foam Concentrate industry, impacting its growth trajectory over the forecast period from 2023 to 2029. The report sheds light on the evolving sales trends of various tech products across different regions and countries, highlighting both growth and decline. A detailed regional analysis is a crucial part of this Foam Concentrate report, offering a meticulous…

Packaging Foams Market Report with Forecast 2020-2025 | Top Key Players: BASF, A …

Global Packaging Foams market would thus note a steady growth over the forecast period of 2020 - 2025. The robust CAGR (Compound Annual Rate Growth) will chart an upward growth curve and create lucrative growth opportunities in the global Packaging Foams market. In, turn, this will lead to improvement in market worth.

Request a PDF sample of this report: https://www.adroitmarketresearch.com/contacts/request-sample/1415

Global Packaging Foams Market: Notable Development

Global Packaging Foams market is set to…

Technical Foam Services Develops Innovative New Scaffold Foam

Northamptonshire, United Kingdom (8th February, 2013) - Technical Foam Services Ltd, a leading independent engineer-based manufacturer and foam producer, announces the creation of a new scaffold foam.

Technical Foam Services Ltd and their strategic construction partner have been working in unison to develop the Closed Cell PE Scaffold Foam, which uses high density polyethylene foam to offer protection against work equipment damage to decorated surfaces. The scaffold foam also uses a…

Technical Foam Services Creates Foam Inserts for Rak Ceramics

Northamptonshire, United Kingdom (18th February, 2013) - Technical Foam Services Ltd, a leading independent engineering-based manufacturer and foam producer, earlier this month secured a contract with leading ceramic tile design and manufacturer Rak Ceramics.

Rak Ceramics specialises in offering a range of high-quality ceramic tiles, distributing their products to DIY retailers and kitchen designers nationwide.

Sales representatives from the company were becoming increasingly concerned with the loss and damage of these tiles…

Technical Foam Services Manufactures Cancer Prevention Foam

Northamptonshire, United Kingdom (17 June, 2011) - Technical Foam Services, a leading independent engineering-based manufacturer and foam producer, is proud to have been part of an exciting new development in the world of cancer prevention.

A far cheaper and more patient-friendly method has been developed by the UK Medical Research Council, which involves the use of a reticulated foam sponge encapsulated within a pill. Once the pill is swallowed, it dissolves…

Technical Foam Services Expand Range of Foam Insert Fabrics

Northamptonshire, United Kingdom (19th May, 2011) – Technical Foam Services, a leading independent engineering-biased manufacturer and foam producer, has expanded their range of fabrics to be used with foam inserts.

Technical Foam Services have long been recognised as the UK’s leading supplier of foam inserts, producing them for a wide variety of applications, such as large suitcase inserts suitable for holding ceramics and glassware through to small inserts used…